3 Sets of 5 Ton Explosion-Proof Crane Kits to Pakistan Good Price

5 ton overhead crane kit for sale. 3 sets of 5-ton explosion-proof crane kits to Pakistan, for efficient lifting in hazardous chemical environments.

Category: 5 Ton Overhead Crane

Your Trusted Overhead Crane Kit Manufacturer & Supplier

3 Sets of 5 Ton Explosion-Proof Crane Kits to Pakistan

A Safe and Economical Material Handling Crane Solution for Hazardous Environments

5 Ton Explosion Proof Cane Kit Project Background in Pakistan

This project started with a client in Pakistan working in the chemical storage and processing industry. Their facility handles flammable gases and liquids, so safety is a major concern.

They were expanding their operations and needed three sets of overhead cranes to handle materials in different workshop areas. Each area had a slightly different layout, but they all required reliable lifting equipment that could safely operate in hazardous zones.

Why They Chose Explosion-Proof Crane Kits

The environment they work in is high-risk. Any spark or open electrical system could be dangerous. That's why they needed cranes with explosion-proof protection.

But they also faced another problem — shipping costs. Importing fully assembled cranes would be expensive and hard to manage at the port. So, they started looking for a better solution.

Here's what they needed:

- Safe cranes for flammable and explosive environments

- A way to avoid the high cost of oversized freight

- Flexibility to install the cranes using their own team

- Custom sizes to fit different span widths across their workshops

That's where our explosion-proof crane kits came in.

Why We're Sharing This Case

We want to show how crane kits helped this client:

- Stay safe in a high-risk environment

- Save time and money on shipping and installation

- Customize the cranes to their local workshop sizes

- Use their own team for on-site assembly with our guidance

If you're facing similar challenges — tight budgets, special safety requirements, or limited access to imported machinery — this case might give you a few useful ideas.

Client Profile and Project Background

Industry Overview: Chemical Storage and Handling

The client is a mid-sized industrial operator based in southern Pakistan, specializing in chemical storage, repackaging, and internal transfer operations. Their plant handles various flammable liquids and industrial gases used in downstream manufacturing. Due to the nature of their materials, their entire working zone is classified as a hazardous area, requiring all electrical and mechanical systems to follow explosion-proof safety standards.

The expansion project involved upgrading internal material handling across three different workshop zones. The client needed reliable lifting solutions that could meet both their daily operational demands and their strict safety requirements.

Site Layout and Lifting Needs

The workshops were already built, with different building spans and structural heights. The client needed a crane solution that could be adapted to the existing layout without major structural changes.

Here were the key lifting requirements:

- Capacity: 5 tons per crane

- Quantity: 3 sets of overhead cranes

- Spans: 8.4 meters, 7 meters, and 5.4 meters, customized for each workshop

- Lifting height: 8 meters in all zones

- Duty class: High-frequency use (H8M), suitable for regular loading and unloading

- Power: 400V, 50Hz, 3-phase, compatible with the plant's power grid

The working environment involved constant movement of metal drums and bulk containers. These loads needed to be handled safely and consistently, without risking sparks, electrical shorts, or mechanical failure under pressure.

Why Explosion-Proof Cranes Were Essential

Explosion-proof equipment wasn't just a recommendation—it was non-negotiable. Any spark or exposed component could cause a serious accident in such a volatile atmosphere. That meant the crane systems needed:

- Explosion-proof wire rope hoists, sealed and rated for hazardous environments

- Explosion-proof control panels and travel motors

- Fully enclosed wiring and electrical safety features

- Corrosion-resistant parts to handle chemical exposure

- Long-term reliability in a heavy-duty production setting

In addition to protecting workers and assets, having compliant explosion-proof equipment also helped the client meet insurance and government safety regulations.

Challenges with Traditional Crane Procurement in Pakistan

The client originally considered ordering fully assembled cranes from international suppliers. But that plan quickly ran into practical and financial barriers:

- Shipping size and weight: Fully assembled cranes require special freight, which is expensive and harder to clear through customs.

- Import delays: Pakistan's port processes can be slow, especially for oversized cargo that needs inspection.

- Installation complexity: Lifting a complete crane into place would need heavy mobile cranes and trained riggers, which aren't always available in remote regions.

- Lack of after-sales support: Once delivered, overseas suppliers often can't provide on-site assistance for setup or troubleshooting.

These problems created too much risk and delay. The client needed a more flexible and affordable solution that still met all safety requirements—and that's when they turned to modular explosion-proof crane kits from us.

Crane Kit Specifications Provided

Overview of the Supplied Equipment

For this project, we provided three sets of 5-ton explosion-proof overhead crane kits. Each kit was fully customized to match the exact layout and working conditions at the client's site.

These crane kits were designed for indoor use in hazardous environments, offering both safety and efficiency for high-frequency operations.

Key Specs:

- Capacity: 5 tons per set

- Quantity: 3 complete crane kits

- Lifting height: 8 meters (standard across all three sets)

Span sizes:

- 1st crane: 8.4 meters

- 2nd crane: 7 meters

- 3rd crane: 5.4 meters

The span lengths were carefully adjusted to fit the beam spacing and workshop width of each zone, without needing structural modification. All technical specs followed explosion-proof design guidelines.

| Specification | 5T-8.4M H8M | 5T-7M H8M | 5T-5.4M H8M |

|---|---|---|---|

| Crane Capacity | 5 tons | 5 tons | 5 tons |

| Span | 8.4 meters | 7 meters | 5.4 meters |

| Height of Lift | 8 meters | 8 meters | 8 meters |

| Power Supply | 400V, 50Hz, 3-Phase | 400V, 50Hz, 3-Phase | 400V, 50Hz, 3-Phase |

| Explosion-Proof Design | Yes | Yes | Yes |

Key Parts and Components in the 5 Ton Explosion-Proof Crane Kit (Without Main Girder)

The kits were designed for on-site assembly, meaning the client could fabricate the main girder locally and install the crane system with their own team, guided by our drawings and documentation.

Each kit included:

- Explosion-proof wire rope hoist:

Heavy-duty and sealed for use in flammable environments. Designed for smooth, stable lifting with safety limits and overload protection. - End carriages with travel drives:

Pre-assembled and tested. Built to support horizontal crane movement with explosion-proof motors and gearboxes. - Explosion-proof control system:

Including electrical panels, wiring layout, and pendant controls. All electrical parts were certified and fully enclosed to prevent sparks or ignition. - Installation accessories:

Bolts, brackets, fasteners, and detailed fabrication and wiring drawings for local assembly and commissioning.

Everything was packaged for safe shipment, and labeled for easy identification during installation.

5 Ton Explosion-Proof Crane Kit – No Main Girder Included

This crane kit includes all the essential components needed to assemble an explosion-proof overhead crane on-site, except the main girder, which can be locally fabricated based on the supplied drawings.

A. Lifting System

Explosion-Proof Electric Hoist (5 Ton)

- Designed for hazardous environments

- Integrated lifting and cross-travel trolley

- Standard lifting height: 8 meters

- Flameproof motor and electrical components

- Spark-resistant design for safe lifting

B. Crane Travel System

End Carriages (Pair)

- Pre-assembled structure

- Explosion-proof motors for long travel

- Equipped with wheels, buffers, and limit stops

- Ready to be connected to your locally made main girder

C. Electrical Control System

Explosion-Proof Control Panel

- Enclosed flameproof control box

- Includes overload protection and thermal relay

- Properly labeled terminals for easy wiring

- Suited for 400V, 50Hz, 3-phase systems

Pendent Crane Control (Explosion-Proof)

- Forward, reverse, up, down, emergency stop functions

- Wired pendant or optional wireless remote

- Safe and easy operation in explosive environments

D. Power Supply System

Festoon Cable and Track Set

- Explosion-proof flat cable system

- Includes cable trolleys and C-rails

- Organized layout for power delivery to hoist and trolley

E. Documentation and Support

- Technical drawings for main girder fabrication

- Electrical schematics

- Installation guide with step-by-step instructions

F. Installation Accessories

- Assembly bolts and fasteners

- Mounting brackets

- Pre-configured to simplify on-site assembly

Customization and Engineering Support

Tailored to the Client's Workshop Layout

No two buildings were exactly the same, so we adapted each crane kit to match the dimensions and limitations of the client's facility. The span lengths—8.4 meters, 7 meters, and 5.4 meters—were calculated based on their actual beam-to-beam widths.

Each set was customized with:

- Matching wheelbases for their runway structure

- Lifting height fixed at 8 meters to clear pipes and storage racks

- End carriage spacing and connection points adjusted to avoid structural interference

These adjustments helped avoid costly rework or structural modifications on-site.

Local Voltage and Power Compatibility

Power supply at the client's site runs on 400V, 50Hz, 3-phase, which is standard in Pakistan. We matched all motors, control panels, and hoists to this specification to ensure smooth operation without additional converters or transformers.

- Explosion-proof motors and control gear were factory-wired for this voltage

- We also ensured correct plug types and fuse ratings for local conditions

This made electrical hookup easier for the client's installation team.

Surface Treatment for Harsh Environments

The cranes were going into a chemical-heavy atmosphere, so we applied extra protection to extend their working life. Every metal surface had an anti-corrosion finish, designed to resist the effects of acidic fumes, chemical spills, and high humidity.

This included:

- Painted end carriages and hoist frames with corrosion-resistant coatings

- Sealed control boxes to prevent chemical ingress

- Optional galvanized fasteners and exposed hardware upon request

These steps reduce long-term maintenance and help the cranes stay safe and functional in tough conditions.

Documentation and Installation Support

To help with both import and installation, we provided a complete English-language documentation package. Everything was clear, organized, and tailored to the buyer's needs.

The support documents included:

- Installation drawings for mechanical assembly

- Electrical wiring diagrams and safety schematics

- Foundation and rail layout instructions

- Operation and maintenance manuals

- Packing list and parts inventory for customs clearance

This helped the client get the crane kits cleared quickly at the port and allowed their in-house team to assemble and install the cranes smoothly.

Shipping and Delivery Efficiency

Compact and Secure Packing for Export

All three crane kits were packed for international sea freight. Each component was securely placed in wooden crates and steel-framed pallets to prevent damage during transport. The packaging was compact—designed specifically for container loading to make the most of space and reduce shipping costs.

- Wire rope hoists were boxed with internal bracing

- End carriages and panels were stacked and wrapped

- Fasteners and small parts were packed in clearly labeled boxes

- Drawings and manuals were included in waterproof document sleeves

This careful packing method kept the equipment safe, organized, and easy to unload.

Reduced Freight Costs with Crane Kits

Because the kits were shipped without the main girders, they avoided oversized cargo fees. The main steel beams could be fabricated locally, which made a huge difference in total logistics cost.

- Lower volume and weight = lower freight charges

- No need for special transport vehicles or lifting equipment at the port

- Avoided costs for crane disassembly or bulky packaging

For the client, this meant saving thousands in shipping fees while still receiving a full crane system.

On-Time Dispatch and Support Throughout Delivery

We worked closely with our logistics partner to ensure smooth and timely dispatch. The entire shipment was sent from our factory within the agreed lead time and delivered to Karachi Port on schedule.

Our team provided:

- Real-time updates on packing and shipment status

- Bill of lading and clearance documents shared in advance

- Tracking info for container movement

- Coordination with freight forwarders familiar with Pakistan's customs procedures

Working Closely with the Client's Receiving Team

We stayed in contact with the client throughout the delivery process. Their customs agent received all required paperwork in advance, which helped avoid any port delays.

After customs clearance:

- The kits were transported to the job site by local trucks

- The client's in-house team checked parts against the packing list

- Our team remained available to assist remotely during unpacking and inspection

This coordination helped the client stay on schedule and prepare for installation without stress.

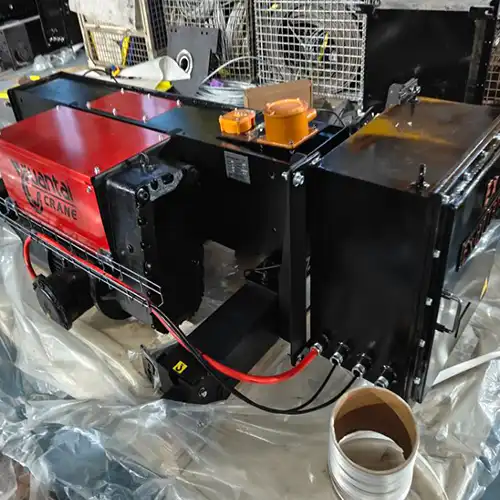

5 ton top running single girder overheaad crane kit for sale pakistan

5 ton overhead crane kit packed for delivery to port for pakistan

Installation and On-Site Assembly

Local Assembly by Client's In-House Team

The client's in-house technical team took the lead on assembling the crane kits at the site. With our detailed installation manuals and assembly drawings, they were able to put together the equipment without the need for external contractors. This approach saved time and further reduced costs.

Key points:

- Local fabrication of main girders saved on assembly time

- The end carriages and hoists were mounted and wired as per the instructions

- On-site modifications were minimal, allowing for a quick and smooth assembly process

The client's technicians were familiar with overhead crane assembly, which made the process much easier.

Remote Support and Video Instructions from Yuantai

To ensure the client's team was fully supported during assembly, our Yuantai team provided remote assistance throughout the process. We sent video tutorials demonstrating critical assembly steps, from the hoist installation to electrical connections.

Additional support included:

- Live troubleshooting calls if the client encountered any challenges

- Email follow-ups to ensure no details were missed

- Video guides for complex steps, such as wiring the control panels

This combination of remote assistance and clear documentation helped resolve any concerns quickly and efficiently.

Assembly Time and Final Inspection

The cranes were fully assembled in approximately 2 to 3 weeks, which was ahead of the client's initial timeline. After assembly, we conducted a final inspection via video call to ensure everything was installed correctly, and all components were operating as intended.

The final checks included:

- Testing all electrical components for proper function

- Ensuring hoists and motors operated smoothly

- Verifying end carriage movement and alignment

- Inspecting safety features like overload protection and emergency stops

Once everything passed inspection, the cranes were ready for full operational use.

Compliance with Safety Standards in Hazardous Zones

The explosion-proof features of the cranes were thoroughly checked to ensure they met the local safety standards for hazardous zone environments. The cranes complied with the relevant IECEx and ATEX certifications, ensuring safe operation even in the plant's most dangerous zones.

This safety compliance helped the client meet both local regulations and international safety standards, minimizing the risk of accidents.

Results and Feedback

Enhanced Lifting Efficiency and Site Safety

After the cranes were put into operation, the client saw immediate improvements in lifting efficiency. The cranes allowed for faster and safer material handling in their chemical storage and transfer areas, directly boosting production rates.

Key outcomes:

- Faster loading and unloading of chemical drums and gas cylinders

- Improved overall site safety with explosion-proof systems

- Less manual handling, reducing the risk of injuries

These improvements had a significant positive impact on the daily operations.

Significant Cost Savings in Freight and Installation

By opting for crane kits, the client saved a considerable amount in shipping costs compared to the alternative of purchasing fully assembled cranes. The modular kits meant they avoided oversized freight fees and special handling charges at the port.

Additionally, the local assembly reduced the need for expensive installation services, and the client was able to leverage their own technical team.

Positive Client Feedback on Quality, Support, and After-Sales Service

The client expressed high satisfaction with both the crane kits and our service:

- They praised the quality and durability of the cranes, even in a harsh, chemical-rich environment.

- The remote support and installation assistance provided by Yuantai's team were particularly valued.

- The after-sales service helped maintain smooth operations and provided peace of mind for any future needs.

Overall, the project was a success, and the client has expressed interest in future crane purchases as their operations grow.

Conclusion

Success in Meeting Hazardous Lifting Needs

This project was a complete success in addressing the client's need for reliable, explosion-proof lifting equipment in a hazardous environment. The 5-ton explosion-proof crane kits were perfectly tailored to meet the specific demands of their chemical handling operations. With our kits, the client was able to safely handle materials, improve operational efficiency, and ensure compliance with local safety standards.

Crane Kits: A Smart, Cost-Effective Solution for Industrial Buyers

The case of this client demonstrates how crane kits can be a smart, cost-effective alternative to fully assembled cranes. By opting for crane kits, the client saved significantly on shipping and installation costs, while still receiving a high-quality, customized crane solution. For industrial buyers looking to reduce upfront costs without compromising on quality, crane kits offer a practical and efficient choice.

Invitation for Similar Buyers in Pakistan and Nearby Regions

If you're facing similar challenges—whether it's high shipping costs, hazardous lifting requirements, or tight budgets—our crane kits could be the ideal solution for your needs. We invite buyers in Pakistan and neighboring regions to inquire about our explosion-proof crane kits, tailored to suit your specific industry and application.

Our team is ready to assist you with any questions and provide a customized solution that fits your needs and budget.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch