Anti-collision System to Ensure Bridge Crane Safety & Lower Maintain Costs

Crane anti-collision system to ensure overhead crane operation safety & lower maintain costs. How to keep your electric travelling crane from collision? Check now.

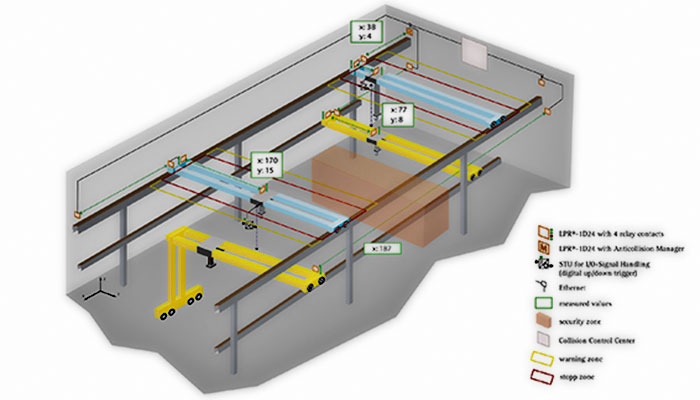

Crane anti-collision systems are electronic devices. The goal of these devices is to reduce the likelihood of accidents. It also protects the bridge crane, the facility, and the people. Its primary application is in overhead material handling. If you have multiple overhead cranes on a single runway, this is one of the most important systems. It also has to be used even if only a single crane is operated. They are designed to avoid all types of material handling crane collisions. It will prevent all types of collisions, whether crane-to-crane or crane-to-end. It improves the operator's overall safety. As a result, it will reduce the need for system maintenance and lower your cost.

Requirements and standards of the anti-collision system

The primary purpose of their design is to prevent overhead crane and other equipment collisions. There are no such requirements for general-purpose cranes. However, according to CMAA, the purchaser or owner must specify the collision avoidance criteria. The design of the end-of-travel collision avoidance must prevent the overhead cranes from colliding unintentionally. It must also ensure that the trolley does not have mechanical end stops or other tools. Furthermore, the system must either stop or slow down prior to the collision.

Importance of crane anti collision system

You'll see that it's one of the top requirements for companies right now. It is an important safety system that will improve the material handling safety in your workstations and workshops . This anti-collision crane system will intervene whenever there is a risk of an accident due to collisions. Furthermore, they are an excellent tool for preventing human errors. As a result, you won't have to worry about bridge crane maintenance costs, and your workplace will be safer.

What are the features of an overhead crane anti-collision system?

There are many characteristics in this anti-collosion system. We would explain those features to you so you could choose properly. The features include:

- A Forward-collision warning: An auditory or visual warning will be given to the driver if a collision is imminent with another vehicle.

- Blind-spot warning: There's a chance the load is in the operator's blind spot. This anti-collision system will alert the operator throughout that time.

- Lane departure warning: There may be a lane on the runway, so be aware of it. The crane is ready to cross a lane, and this system will alert the operator. As a result, it increases both the operator's and the working environment's safety.

- Parking assist: Parking the material handling crane is an essential part. Therefore, it will be advantageous for the operator if the sensors and cameras provide assistance. The pace can be adjusted by the operator to suit their preferences.

- Automatic emergency braking: The system will apply the brakes to the overhead cranes based on the sensors' response. As a result, it is crucial in avoiding collisions or reducing their impact.

- Electronic stability control: The bridge crane could occasionally become unbalanced. These brakes are going to be useful in certain circumstances.

- Adaptive speed control: Adaptive speed control is an important preventive feature. According to the needs, it regulates the crane's speed. As a result, the operator will keep the overhead cranes safely apart from the other lifting equipment.

You have three optional anti-collision system to ensure your overhead crane safety. The best feature of this type is that it is compatible with all types of cranes. It is available with variable frequency, contractor controls, or soft starters. You will also be given several configuration options, from which you must select the one that best fits your application. You must also decide whether you want an indoor or outdoor system. One of the most exciting aspects of this type is that it is fail-safe. The crane will come to an immediate stop if the sensor stops functioning. As a result, the accident will be limited.

Significance of the sensor technology

It is critical to understand sensor technology. It will improve your understanding of the system. The modulated visible LED light signal is the best and most recent technology that they use. Some of the systems also include infrared light signals. Light signals are transmitted at a reflective surface, and the signal from the target is received by a receiver. Following that, the system will examine the data and take appropriate action. It could be slowing down or stopping the crane. There will also be self-monitoring optical lasers that will pinpoint the crane's location. If you work in an automated environment, you should be aware that laser-based positioning systems are the most precise and valuable.

You need to be aware of the collision avoidance system if your job requires you to operate an overhead crane. The most important part is that it will add another layer of safety to your workplace.

Proper stopping distance of to reduce collision

You must determine the stopping distance of a bridge crane in order to understand the OSHA rules. Otherwise, there's a chance that the overhead crane will go too far when you let off of the remote's button. As a result, one of the crucial things to remember is that you must adhere to ASME B30 and OSHA (Occupational Safety and Health Administration) regulations. Thus, we shall discuss stopping distance in this section along with its calculation. You will learn a lot from the conversation if you work with bridge cranes. Among the rules you must follow are the following:

- According to OSHA 1910.179(f)(4)(vii), trolleys and bridges should both have sizable brakes. To be more specific, the brake should be capable of stopping the bridge or trolley at a distance of at least 10% of its maximum speed. The speed should be measured in feet per second. When the trolley or bridge is fully loaded, the brakes should achieve this stopping distance.

- According to ASME B30.2-1.12.3 (a)(1), the brakes must have a high torque. It must stop the bridge or trolley after traveling 10% of the rated load speed. However, you must ensure that the bridge or trolley is capable of carrying the rated load. You should be aware that the 'rated load speed' of an electric travelling crane is the speed determined by the manufacturer. You can find the speed of an electric travelling crane in the manual's specifications section. However, if you are unable to find the speed, there are procedures for calculating it. We will present you with two processes, and you must select one based on your preferences and requirements.

Determine the 10% of a minute is the best option for you. If you look at the standard, you'll notice that it says "10% of full load speed in meter per minute." So, 10% of a minute equals 6 seconds. As a result, when the trolley or bridge is traveling at full speed and load, it should take 6 seconds to stop once the off or neutral position is pressed. The trolley or bridge will drift in less than 6 seconds if the load is less than the rated load.

There is another method for calculating stopping distance. You must determine 10% of the distance, with feet as the unit. The first step is to load your travelling crane and allow it to traverse at full speed for one minute. Take note of how far the electric travelling crane has traveled. In most cases, trolleys will exit the room in less than a minute. As a result, you must take 10% of that distance as the maximum 'drift' distance you must allow.

In other words, once you turn off the electric crane, it should not drift more than the drift distance. It is one of the most common approaches taken by most people, but it is a time-consuming process. It will take a long time to calculate using this method.

The factors that impact the stopping distance

We are aware that the most important factor affecting stopping distance is speed. Additional than that, a few other factors can affect stopping distance. Understanding these elements will improve the accuracy of the stopping distance calculation. When it comes to safety, such elements are also quite important. Taking those things into account will improve the facility's overall security. The factors are listed below.

- Absence of scanning techniques.

- Distracted operation of the cranes.

- Poor knowledge on the areas that comes with high risk.

- Improper condition of the brake pads.

- Condition of the operators.

- Poor traction.

- Limited visibility.

- Type of the braking system that you are using.

Important components of the stopping distance

You must also take into account a few other significant elements when determining the stopping distance in addition to those mentioned above. These key elements are:

- Perception distance: This refers to visual perception. Every person has a different perspective. The perception of a person is crucially influenced by experience as well. For instance, the operator's visual perception will be almost accurate provided they have the necessary experience.

- Braking distance: The goal of braking is to reduce the crane's speed. Therefore, the braking distance is the distance from the moment the brake is applied till the moment the vehicle stops.

- Reaction distance: Reaction distance is another important factor that affects stopping distance. It is affected by environmental factors. By measuring the distance between the operator's positions while using the brake in response to external stimuli and when the crane stops, you can calculate the reaction distance.

Therefore, this is how you should determine a bridge crane's stopping distance. Examine the elements that affect the crane's stopping distance as well. It will assist you in creating a secure workplace. If you take those factors into consideration, your employees and your facility will be safe.

The above anti-collision systems, devices and measures will help you to prevent your overhead crane from collision to ensure your workplace safety and personnel safety. If you want to know more on crane anti-collision system or about crane safety, please feel free to contact us. Better overhead crane, higer crane safety.