Electric Overhead Cranes Guide: Types, Safety, Power Supply & Design

Guide to electric overhead crane: types, safety, power supply & customization, all types of electric bridge cranes, single girder & double girder design.

Comprehensive Guide to Electric Overhead Cranes: Types, Safety, Power Supply, and Customization

Electric overhead cranes are versatile material handling equipment used in various industries to lift, move, and position heavy loads. This comprehensive guide focuses on different types of electric overhead cranes, safety considerations, power supply requirements, and the benefits of customization. Understanding these details will help businesses make informed decisions when selecting the most suitable electric overhead crane for their specific needs.

A. Single Girder Electric Overhead Crane:

- Description and Working Principle: Single girder electric overhead crane consists of a single main girder supporting the hoist and trolley. The hoist is mounted on the bottom flange of the girder, and the trolley travels along the length of the girder. The bridge, which supports the girder and moves on rails, spans the width of the work area.

- Applications: Single girder electric overhead cranes are ideal for light to moderate lifting tasks in workshops, warehouses, and smaller industrial facilities. They are commonly used for maintenance, assembly, and material handling operations.

B. Double Girder Electric Overhead Crane:

- Description and Working Principle: Double girder electric overhead crane has two main girders supporting the hoist and trolley. The hoist and trolley travel between the girders, which are connected to the bridge that moves on rails.

- Applications: Double girder electric overhead cranes are suitable for heavy-duty lifting in industrial settings. They are commonly used in steel mills, foundries, and construction sites for handling large and heavy loads.

C. Under Running Electric Overhead Crane:

- Description and Working Principle: Under running electric overhead crane's bridge runs on the lower flange of the runway beam. The hoist and trolley move beneath the runway beam.

- Applications: Under running electric overhead cranes are ideal for facilities with limited headroom, as they require less vertical space. They are commonly used in workshops and manufacturing facilities.

Capacity of electric overhead cranes

The capacity of electric overhead cranes can vary widely depending on their type, design, and intended application. Electric overhead cranes are available in a range of capacities to meet diverse material handling needs in different industries. Here are the typical capacity ranges for different types of electric overhead cranes:

Single Girder Electric Overhead Crane:

- Light-duty: Up to 10 tons

- Medium-duty: 10 to 20 tons

- Heavy-duty: 20 to 50 tons

Double Girder Electric Overhead Crane:

- Medium-duty: 10 to 20 tons

- Heavy-duty: 20 to 500 tons (or even higher for special applications)

Under Running Electric Overhead Crane:

- Light to medium-duty: Up to 10 tons

It's essential to note that these are general capacity ranges, and there may be variations based on specific manufacturers and customizations. When selecting an electric overhead crane, it's crucial to consider the actual lifting requirements of the application, including the weight of the heaviest loads to be handled and any potential future capacity needs.

Additionally, electric overhead cranes can be designed with different span lengths and lifting heights to accommodate various material handling scenarios. Properly sizing the crane capacity is critical to ensure safe and efficient operations while avoiding overloading the crane's components and electrical systems. Consulting with a reputable crane supplier or an experienced engineer can help determine the most appropriate capacity for a specific application.

Applications of light duty and heavy duty electric overhead cranes

The applications of electric overhead cranes vary depending on their capacity and design. Different industries and material handling needs require specific types of electric overhead cranes. Here are the typical applications of electric overhead cranes based on their capacity:

Light-Duty Electric Overhead Cranes (Up to 10 tons):

- Small Workshops: Light-duty overhead cranes are commonly used in small workshops for tasks such as assembly, maintenance, and general material handling of lighter loads.

- Warehouses: They are suitable for small-scale warehouses where the loads are relatively light and require efficient movement within a limited space.

- Retail Stores: Electric overhead cranes in this capacity range can assist with stocking shelves and handling inventory in retail stores.

Medium-Duty Electric Overhead Cranes (10 to 20 tons):

- Manufacturing Plants: Medium-duty overhead cranes are widely used in manufacturing facilities for various material handling tasks, including moving raw materials, parts, and finished products.

- Fabrication Shops: These cranes are suitable for lifting and positioning heavy fabrication materials during welding and other processes.

- Automotive Industry: Medium-duty overhead cranes are utilized in vehicle assembly lines for transporting car bodies and components.

Heavy-Duty Electric Overhead Cranes (20 tons and above):

- Steel Mills and Foundries: Heavy-duty overhead cranes are crucial in steel mills and foundries for handling large and heavy steel coils, ingots, and other materials.

- Construction Sites: Heavy-duty overhead cranes are employed in construction projects for lifting and moving heavy construction materials and equipment.

- Ports and Shipyards: They are used for loading and unloading heavy containers and cargo in port and shipyard operations.

- Mining Industry: Heavy-duty overhead cranes are utilized in the mining industry for transporting heavy materials and equipment underground and at surface operations.

It's important to note that these applications are not exhaustive, and the suitability of an electric overhead crane depends on specific requirements of each industry and facility. In some cases, customizations and modifications may be necessary to ensure the crane meets the precise needs of the application. Consulting with crane manufacturers or experts in material handling can help determine the most appropriate electric overhead crane for a particular industry or application.

General use and hazardous use electric overhead cranes

General Use Electric Overhead Crane:

General use electric overhead cranes are designed for standard material handling applications in non-hazardous environments. They are commonly used in industries such as manufacturing, warehouses, construction, and automotive, where the lifting and moving of loads are performed under normal operating conditions. These cranes are built to meet industry standards and safety regulations and are suitable for handling various types of loads within their specified capacity range.

Typical Applications of General Use Electric Overhead Cranes:

- Material Handling in Manufacturing: General use electric overhead cranes are used in manufacturing plants for tasks like moving raw materials, finished products, and heavy components along the assembly line.

- Warehouses and Distribution Centers: These cranes are employed for efficiently handling and organizing goods in warehouses and distribution centers.

- 3. Construction Sites: General use electric overhead cranes help in lifting and transporting construction materials, equipment, and tools at construction sites.

- 4. Automotive Industry: These cranes are used in vehicle assembly lines to position car bodies and components during production.

Hazardous Use Electric Overhead Crane:

Hazardous use electric overhead cranes are specifically designed for environments with potentially explosive or hazardous atmospheres. These cranes are engineered to meet strict safety standards to prevent any ignition source that could cause explosions or fires. They are equipped with explosion-proof components and are constructed to minimize the risk of sparking or electrical discharge in hazardous areas.

Typical Applications of Hazardous Use Electric Overhead Cranes:

- Petrochemical Industry: Hazardous use electric overhead cranes are commonly used in refineries, chemical plants, and petrochemical facilities where flammable gases, vapors, or dust are present.

- Oil and Gas Industry: These cranes are utilized on offshore platforms and drilling rigs where there is a risk of exposure to flammable materials.

- 3. Chemical Manufacturing: Hazardous use electric overhead cranes are deployed in chemical manufacturing plants where the handling of volatile substances requires specialized equipment.

- 4. Pharmaceutical Industry: These cranes are used in pharmaceutical production facilities where certain processes involve hazardous materials.

It is crucial to select the appropriate type of electric overhead crane based on the specific operating environment and application requirements. Hazardous use electric overhead cranes must adhere to stringent safety standards to ensure safe and reliable operations in potentially dangerous settings. Consulting with experts in hazardous area classification and crane safety is essential when choosing and operating hazardous use electric overhead cranes.

Safety Considerations for Electric Overhead Cranes:

- A. Overload Protection: - Electric overhead cranes are equipped with overload protection devices that prevent the crane from lifting loads beyond its rated capacity. These systems ensure safe and efficient crane operations.

- B. Limit Switches and Sensors: - Limit switches and sensors are installed to control the crane's movements and prevent collisions with obstacles. They help maintain safe working conditions and prevent damage to the crane and its surroundings.

- C. Emergency Stop Mechanism: - An emergency stop button is a crucial safety feature that allows crane operators to quickly stop all crane movements in case of emergencies, preventing accidents and injuries.

- D. Crane Operator Training: - Proper training of crane operators is essential to ensure safe and efficient crane operations. Operators must be familiar with the crane's controls, safety procedures, and load handling techniques.

- E. Regular Inspections and Maintenance: - Regular inspections and maintenance are crucial for identifying potential issues and ensuring the safe functioning of electric overhead cranes. Routine maintenance helps prevent breakdowns and ensures optimal performance.

Power Supply Requirements for Electric Overhead Cranes:

- A. Voltage and Frequency Adaptability: - One of the key advantages of custom electric overhead cranes is the ability to adapt to different voltage and frequency requirements in various countries. These cranes can be designed to operate seamlessly with the local electrical grid.

- B. Power Capacity Optimization: - Custom electric overhead cranes can be precisely engineered to match the available power capacity, ensuring efficient and reliable operation without overloading the electrical supply.

- C. Dual or Multi-Voltage Capability: - For businesses with operations in multiple countries or regions, custom electric overhead cranes can be designed with dual or multi-voltage capabilities, allowing them to be used in different locations without modification.

General power supply of electric overhead cranes

The power supply for electric overhead cranes is typically sourced from the local electrical grid and varies based on the region and the specific requirements of the crane. The general used power supply for electric overhead cranes includes:

- Three-Phase Power: Most electric overhead cranes require a three-phase electrical power supply. Three-phase power provides a continuous and stable supply of electricity, which is essential for the smooth and efficient operation of the crane's electric motors and controls.

- Voltage: The voltage of the power supply can vary depending on the country and the electrical standards in the region. Common voltages for electric overhead cranes include 380V, 415V, 440V, or 460V for industrial applications. The voltage requirement is determined by the crane's motor ratings and the specific power system in use.

- 3. Frequency: The frequency of the power supply is also important, and it is typically either 50Hz or 60Hz, depending on the country. The crane's motor and control systems must be designed to operate at the specific frequency of the electrical supply.

- 4. Power Capacity: The power capacity of the electrical supply should match the requirements of the electric overhead crane. Properly sizing the power capacity ensures that the crane operates efficiently and avoids power fluctuations that could affect performance or cause damage to the equipment.

- 5. Power Distribution: The power distribution system should be designed to provide an uninterrupted supply of electricity to the crane. Adequate wiring, circuit breakers, and fuses are essential components of the power distribution system to ensure safe and reliable operation.

- 6. Transformer (Optional): In some cases, depending on the available power supply and the crane's voltage requirements, a transformer may be used to convert the voltage to the desired level for the crane's operation.

It's essential to follow the manufacturer's specifications and guidelines when connecting the electric overhead crane to the power supply. Proper installation and maintenance of the electrical components ensure the safe and efficient operation of the crane, extending its lifespan and minimizing downtime. Consulting with a qualified electrician or the crane manufacturer can help determine the appropriate power supply and electrical requirements for a specific electric overhead crane installation.

Electric power supplying system for electric overhead cranes

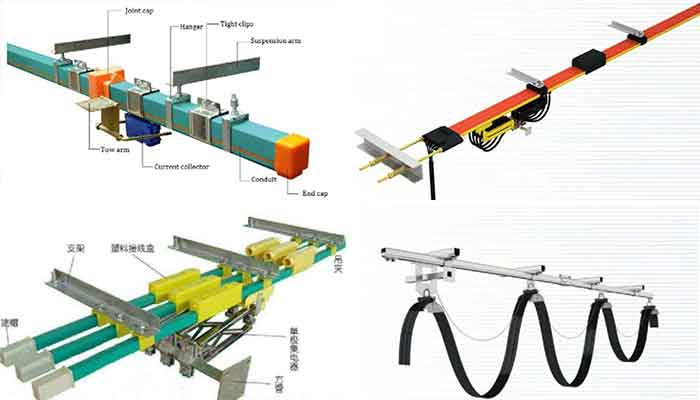

There are several types of power supplying lines commonly used for electric overhead cranes. Each type has its own features and applications. Here are some of the main types:

Festoon System:

- Features: Festoon systems consist of a trolley and a cable festooned between two supporting structures. The cable is looped and hangs down, providing power to the moving trolley via sliding collectors.

- Applications: Festoon systems are suitable for light to medium-duty electric overhead cranes. They are commonly used in indoor environments, such as warehouses, manufacturing plants, and assembly lines.

C-Track System:

- Features: The C-track system consists of a track-shaped rail with a conductor bar inside. The trolley moves along the track, and the conductor bar provides power to the trolley through spring-loaded brushes or collectors.

- Applications: C-track systems are versatile and used in various applications, including medium to heavy-duty electric overhead cranes in indoor environments like steel mills, foundries, and heavy manufacturing facilities.

I-Beam System:

- Features: The I-beam system utilizes an I-shaped beam as the power supply track. A conductor line runs inside the beam, and the trolley collects power through sliding contacts or collectors.

- Applications: I-beam systems are commonly used in heavy-duty electric overhead cranes for demanding applications, such as shipyards, ports, and large-scale material handling operations.

Cable Reel System:

- Features: The cable reel system employs a spooled cable that extends and retracts as the trolley moves along the crane runway. The cable is wound or unwound on a reel as the trolley travels.

- Applications: Cable reel systems are often used for long-travel electric overhead cranes in outdoor environments, such as container yards, where the crane requires extended mobility without the need for festoons or tracks.

Conductor Bar System:

- Features: The conductor bar system uses an enclosed conductor bar with insulated conductive rails. The trolley collects power through a sliding shoe or collector.

- Applications: Conductor bar systems are used in various applications, especially where dust, debris, or environmental factors could affect power supply. They are commonly used in outdoor environments, such as steel mills, foundries, and ports.

Busbar System:

- Features: Busbar systems consist of an enclosed conductive bar with multiple power taps. The trolley collects power through a sliding contact.

- Applications: Busbar systems are used in a wide range of applications, from light-duty to heavy-duty electric overhead cranes. They are suitable for both indoor and outdoor environments.

The choice of power supplying lines for electric overhead cranes depends on factors such as the crane's capacity, the working environment, mobility requirements, and budget constraints. Proper selection and maintenance of the power supplying lines are crucial to ensure efficient and safe operation of the electric overhead crane.

Custom Electric Overhead Cranes:

- A. Tailored to Specific Applications: - Custom electric overhead cranes can be designed and engineered to suit the unique requirements of different applications and industries. This includes factors such as load capacity, span, lifting height, and duty cycle.

- B. Increased Efficiency and Productivity: - By customizing the crane to precisely match the intended tasks and workflow, businesses can experience improved productivity and operational efficiency, reducing handling times and optimizing material flow.

- C. Space Optimization: - Custom electric overhead cranes can be configured to fit within the available space, ensuring that the crane system optimally utilizes the workspace and avoids interference with other equipment.

- D. Enhanced Safety Features: - Safety features can be customized to meet specific safety regulations and industry standards, ensuring a safer work environment and reducing the risk of accidents.

Industries and Applications:

- A. Manufacturing: - Custom electric overhead cranes are tailored for manufacturing processes, including assembly lines, material handling, and precision tasks.

- B. Warehousing and Logistics: - These cranes are optimized for warehouses and logistics centers, enhancing inventory management and efficient goods handling.

- C. Construction: - Custom electric overhead cranes can be designed for construction sites, enabling the movement of heavy construction materials and equipment.

Conclusion:

Electric overhead cranes are indispensable in various industries for their ability to handle heavy loads efficiently. By understanding the different types of electric overhead cranes, safety considerations, power supply requirements, and the benefits of customization, businesses can make informed decisions and enhance productivity while ensuring the safety of their operations. Regular maintenance, operator training, and adherence to safety guidelines are essential for maximizing the performance and longevity of electric overhead cranes. Custom electric overhead cranes offer tailored solutions that cater to specific application needs, ensuring increased efficiency, safety, and productivity. The ability to customize the power supply of these cranes to meet different voltage and frequency requirements in various countries further adds to their versatility. Businesses can benefit significantly by investing in custom electric overhead cranes, as they provide tailored solutions to optimize material handling operations, regardless of the industry or location.

Frequently asked questions and answers on electric overhead cranes

There are some frequently asked questions and their answers on electric overhead cranes:

What is an electric overhead crane, and how does it work?

- An electric overhead crane is a type of material handling equipment that operates on an overhead runway system. It is equipped with an electric hoist and trolley to lift, lower, and move heavy loads horizontally within its span. The crane's electric motor powers the lifting and horizontal movement of the hoist and trolley.

What are the main types of electric overhead cranes and their differences?

- The main types of electric overhead cranes include single girder overhead cranes and double girder overhead cranes.

- Single girder overhead cranes have one bridge girder supporting the hoist and trolley, suitable for lighter loads and shorter spans.

- Double girder overhead cranes have two bridge girders, offering higher lifting capacities and longer spans for heavy-duty applications.

What are the typical applications of electric overhead cranes?

- Electric overhead cranes are commonly used in various industries for material handling, such as warehouses, manufacturing plants, construction sites, and steel mills.

- They are used to lift and move heavy items like raw materials, finished products, machinery, and large components.

What are the advantages of using an electric overhead crane?

- Electric overhead cranes provide efficient and precise material handling, reducing manual labor and increasing productivity.

- They are ideal for moving heavy loads over large distances and can be customized to fit specific application requirements.

- Overhead cranes free up floor space, allowing for better utilization of the workspace.

Are electric overhead cranes safe to use?

- Yes, electric overhead cranes are designed with various safety features to ensure safe operations.

- Safety features may include overload protection, emergency stop buttons, limit switches, and safety brakes.

- Proper operator training and adherence to safety guidelines are essential for safe crane usage.

Can electric overhead cranes be customized to meet specific requirements?

- Yes, electric overhead cranes can be customized based on lifting capacity, span, lifting height, control options, and specific industry requirements.

- Customization allows the crane to be tailored to the specific needs of the application.

What maintenance and inspection practices are required for electric overhead cranes?

- Regular maintenance practices, including visual inspections, lubrication, and component checks, are essential to ensure the crane's smooth and safe operation.

- Crane owners should follow the manufacturer's recommended maintenance schedule and conduct periodic inspections.

What are the future trends in electric overhead crane technology?

- Future trends may include advancements in automation, integration with IoT and data analytics for predictive maintenance, and improvements in energy efficiency.

- Smarter control systems and improved safety features are also expected to be part of future electric overhead crane technology.

What are the typical capacity and lifting height of electric overhead cranes?

- Electric overhead cranes can have various lifting capacities, ranging from a few hundred kilograms to hundreds of tons, depending on the specific model.

- The lifting height can also vary, depending on the height of the facility and the crane's design.

These are some of the frequently asked questions and answers about electric overhead cranes. For specific inquiries or more information, it is advisable to consult with crane manufacturers or industry experts.