What Is Crane Coverage & Hook Coverage of Your Overhead Cranes?

What's the crane coverage of types of overhead cranes? How to measure your overhead crane hook coverage? How to maximize it? Check now !

Coverage, Reach & Travelling of Hoisting Cranes,Optimized For Your Industrial or Manufacturing Facility

The variety of lifting crane options available for industrial or manufacturing workshops and facilities will astound you from gantry cranes to overhead cranes to monorails to slewing jib cranes, etc. For your material handling needs, our overhead material handling specialists will support you in selecting the optimal hoisting solution and product combination.

Working coverage of overhead cranes

What is Hook Coverage?

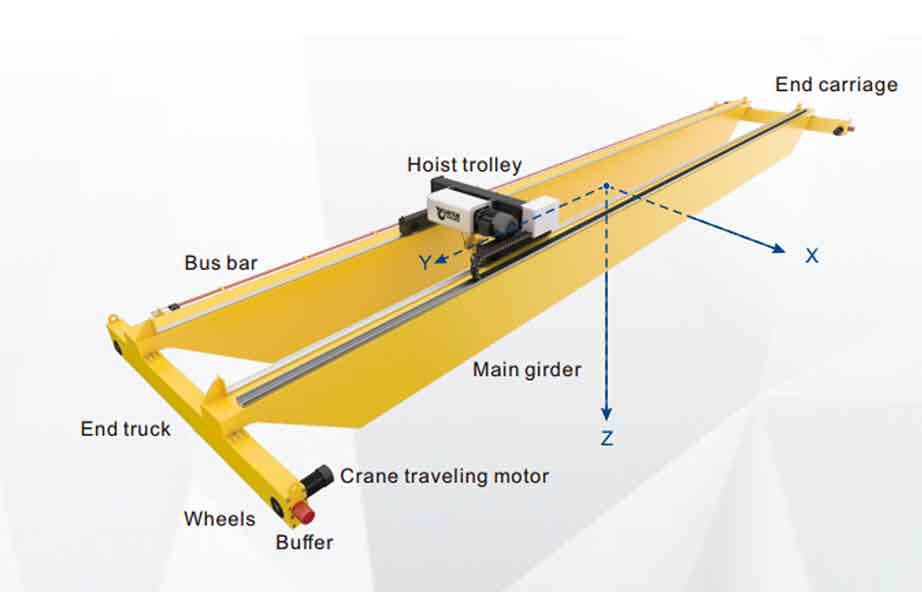

Hook coverage or working coverage usually refers to the area that your lifting crane's hook can reach. It covers all three hook travelling motions in x, y, and z three dimensions, from the coverage area of the floor to the coverage area of the hook's highest point. How close a crane's hook can move to the end of the bridge and runway affects hook coverage and crane working coverage.

- Long travelling, horizontal movement , forward & back word, along crane runway

- Cross travelling- horizontal movement ,left & right travelling along crane girder

- Hook vertical travelling - up & down, the lifting up & down

The greater your travelling crane's hook coverage, the greater the impact your electrical overhead crane can have on your facility's working area and operations. Good hook coverage and your crane working area not only maximizes your facility's efficiency and profitability, but it also prepares your facility and company for future increases in profitability and productivity. Greater hook coverage will give your company the flexibility to adapt to changing environments or increasing workload as operations expand or change.

Factor affect hook overages of overhead cranes

Crane Span , cross travelling length of crane hook

The measured distance between the runway beams from center to center is known as the crane span.

The span of the an overhead crane is one of the most important measurements you can provide during an overhead crane consultation. The span of an overhead crane is the width of the bay—or the measured center-to-center distance between the runway beams. It is crucial because it specifies how much steel material will be needed to construct the bridge girders and has a big impact on how much the overhead crane will cost.

Lifting height of bridge cranes , the vertical hook travelling patch

What is lift height, and how do I evaluate it?

First, we'll go over the fundamental concepts. Lift height of an overhead travelling crane is defined as the distance from the floor to the saddle of the hook when it is in its highest position. Lift height of hoist and cranes is an important measurement in any crane design because it ensures that there is enough room to lift or loads lifting and reposition. Miscalculation of this dimension can have disastrous consequences for material handling crane. The first step toward success is understanding what you're lifting, how it needs to be lifted or moved, and any limitations you may have so that the lift height can be optimized for the needs of today and tomorrow.

Run way length affects the overhead crane long travelling length

Consider the length of your runway and the number of building column supports available to support the bridge crane's deadweight and load.

The runway length is the total distance that the overhead travelling crane will travel through the facility. The layout of your current production area, the building's specifications, or a map of an area you want to be able to use for load movement and material handling can all be used to estimate this length roughly.

The calculated distance between the building supports that the runway beam will run on top of must also be ascertained. Place your laser flat against a building support beam to do this, then count down the distance from that support to the runway beam.

What is the hook coverage or crane envelope? Always ask your crane provider; this question is frequently overlooked. This is the genuine working range of the bridge crane, free from side pulling and risky lifting and lowering approaches.

An industrial crane's hook will normally cover 10 x 18 meters if its span in a warehouse is 11 meters wide and 19 meters down shop. This can be varied and enhanced by employing shorter end carriages and a different style of lifting hoist. The fact that electric chain hoists are smaller than wire rope hoists will also be helpful. And special designed crane girder, low headroom hoist, and special placement of hoist trolley are available to enlarge the lifting height and maximize the hook coverage. Based on the special application conditions and lifting requirements, the processed crane designs and custom crane designs are provided.

Crane span

What is the maximum width of an overhead crane?

- Suspension single girder overhead crane - 3m- 20m span (customized)

- Top running single girder overhead crane European style - 3m- 35m span (customized)

- Top running double girder overhead crane - 5m- 60m span (customized)

Crane lifting height

Which type of crane configurations provides the highest lifting height?

The lifting height is usually determized by the workshop height and the crane headroom. The lifting height of the different types of crane designs:

- 1. Underhung single girder crane: the hoist hangs on the lower parts of crane girder which is mounted on the ceiling or mounting structure.

- Underhung double girder crane: the hoist hangs between the bridge crane beam which will increase the lifting height.

- Top running double girder crane - the hoist hangs above bridge beams increases lift height.

Hook coverage determines the ability of a crane hook to reach various places. Crane hook coverage also depends on the hook's ability to approach runways and bridges. Optimizing hook coverage is the only way to achieve maximum crane efficiency and flexibility.

How to determine your overhead crane's hook coverage?

There are various methods for determining hook coverage.

- The side approach. You can determine the crane's useable lateral working span using this side approach, but keep in mind that this is often not a symmetrical measurement. The hoist trolley often has two sides, one long and one short. When installing an overhead crane, the short and long sides must be identified to make sure the side approach span is sufficient.

- The end approach. The centerline coverage of the hook's end approach enables end-to-end movement. It is often symmetrical, as opposed to the side approach. Depending on how long the runway is, the crane's overall span could be more than its actual operating span. A zero clearance end stop can offer around one foot of lateral or centerline coverage when additional hook coverage is needed.

It's critical to have a thorough understanding of the working space when establishing the required overhead crane hook coverage. The working span of the crane hook may be constrained by the work area's walls, objects, and floor-to-ceiling height. It is best to think about any adjustments and improvements before the overhead crane manufacturering. Once finished, working span optimization might be expensive and have an impact on daily output.

Crane size requirements for maximum coverage

To maximize hook coverage, accurate measurements are crucial.

- Runway beam size is one of many crucial metrics. Measure the width of the runway beam from the bottom to the top. This measurement can be used to estimate the system height.

- Runway rail length

- The crane's wheel size is influenced by the width of the runway rail. In order to maintain alignment and ensure maximum durability, the runway rail height and width are critical dimensions.

- ·Crane span. The distance between runways, or crane span, usually equals the bay's width. To buy adequate material to make the girders and produce correct drawings, precise measurements are essential.

- Runway length and the distance between each runway support.Measurements for the runway support and length are complementary. The supports must be strong enough to carry the crane's weight in relation to the runway's length.

To make sure there are no unintentional obstructions or clearance concerns, the building clearance and any AC ducts, heaters, fixtures, pipes, and electrical lines should be taken into account. Contact a specialist to get your work done efficiently and professionally.

Common mistakes: right-sizing an electric travelling crane

When it comes to hook coverage, failing to prepare far enough in advance is a common mistake. Although upgrading an existing crane to increase hook coverage is conceivable, it is not advised because it can be a time-consuming and costly expenditure. The replacement of significant components and occasionally the rearrangement of electronics required to modify an existing crane to increase hook coverage might cause operations to be delayed. Look ahead to prepare for changes in workflow or an increase in production when it comes to ensuring optimum hook coverage in your production area.

You must first have a thorough awareness of your building area, including barriers on the walls, ceiling, and floor, in order to design for optimal hook coverage. Your crane's hook coverage area will never be as large as its overall span or runway length. To minimize modification orders and increase the profitability of your manufacturing, explain the layout of your plant and make sure the crane builder is asking the correct questions.

Second, prepare your next project or product in advance for any growth or adjustments. Aim for the best hook coverage you can with your crane since you could need more coverage than you anticipate sooner than you had anticipated.

Which lifting equipment have the best hook coverage?

The profitability of your working space and how efficiently your crane uses each inch will be determined by the crane's separate components, even if the size of your overhead crane will ultimately have the most impact on hook coverage. Take into account these optimized eot crane parts and designs to achieve the highest lifting heights and hook-to-wall dimensions.

Double-girder hoist: For the best clearance, go for a double-girder hoist design. By allowing for even higher hook heights than single-girder cranes, double-girder designs maximize your vertical hook coverage. Larger capacities are covered by double-girder hoists; they can handle capacities of up to 80 tons. Your overhead dimensions are reduced by its small trolley design while the vertical hook coverage is increased.

Every component of our overhead crane packages, from the hoist selection to the bridge drives and girders, is made to function as a whole crane system in order to achieve the greatest possible operating span and floor coverage. Get in touch with us to order a crane that is specifically tailored to your needs for working space and hook coverage.

Working coverage's of jib cranes

The electric rotary jib cranes are the ideal lifting equipment for short-distance material handling and transferring. Electric slewing jib cranes have the ability to lift and move items or loads in semicircles or full circles around their supporting structures to provide targeted material handling in work cells, supplement a sizable overhead crane system, move materials from one work cell to another, and safely lift a line load up to the rated capacity.

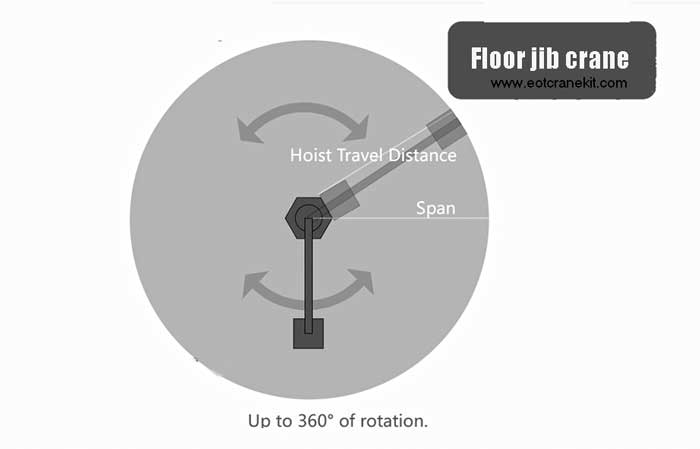

Jib Crane Span

The distance between the middle of the mast or wall bracket and the end of the crane's boom/ cantilever / arm. The total distance that materials will be lifted from the mast should equal this length (the crane span), plus the width of the trolley and hoist width.

Crane Jib Height

Make sure the underboom height, or the distance between the ground and the jib crane, is high enough to lift the objects you will be handling. Additionally, confirm that there is space above the slewing jib crane's stated height so it won't be in risk of colliding with your roof or support beams.

Working span of a jib crane

How much space do you require?

Determine your needs by dividing them by the length of the trolley, measured from the end of the beam (or distance from the vertical support column to the end of the beam).

Rotation of a Jib Crane

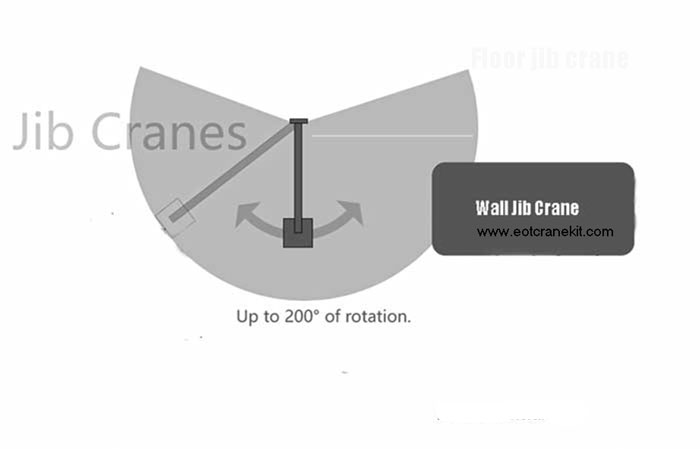

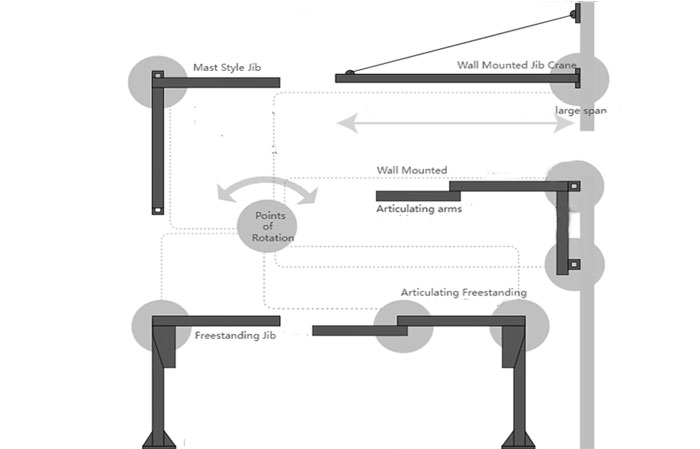

The space required for rotation will vary depending on the crane you choose. Wall mounted cranes can rotate roughly 200 degrees, but free standing and mast jib cranes require space for 360-degree rotation.

Hook coverages of wall jib crane

Hook coverage of floor jib crane

Hook coverages of articulating jib cranes

Hook coverage of workstation jib crane

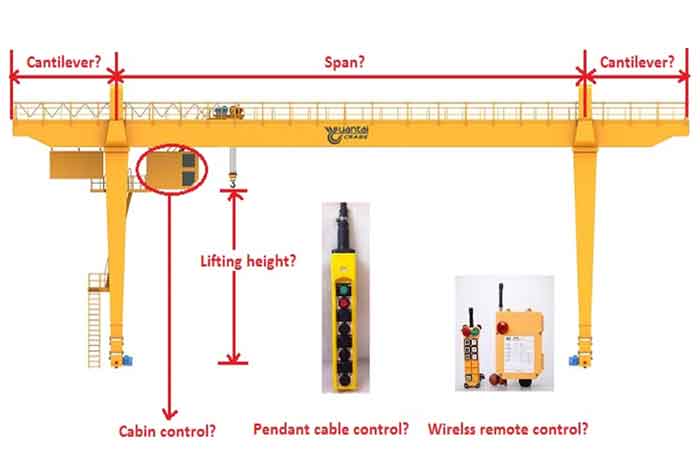

Working coverage's of gantry crane

Hooking coverages of gantry cranes

Gantry crane specifictions that affect its hooking coverages

Working coverage of workstation cranes & monorails

Workstation cranes hook coverage

Monorail crane hook coverage