How to Calculate the Weight of a Load of Overhead Crane?

Understanding the weight of the load you intend to raise and move is the first step in planning an overhead lift.

Before lifting a load, one of the first things you should do is determine the entire weight of the burden. This should be calculated during the early phases of a lift's planning, as everything else about the overhead lift will have to account for the load's weight, including:

- Equipment / type of crane being used for the lift

- Type of lifting slings, rigging hardware, and/or below-the-hook devices being used

- Type of sling hitch and sling angle

Every piece of lifting gear used in the lift, including the hook and everything else below, must be factored into the total weight of the load:

- Hook block

- Ropes

- Lifting beams

- Shackles, hoist rings, and other hardware

- Lifting slings

There are several ways for determining the weight of a load, which we shall go through in greater detail in this post.

Simple Methods to Determine the Weight of a Load

There are a variety of methods for determining the weight of a load that do not require any calculations or the use of specially-engineered load cells or dynamometers.

Check to see if the weight is marked on the load.

The manufacturer may have marked the load with the weight, or it may have been estimated and marked previously. Before choosing the right lifting and rigging equipment, look for any obvious signs of load weight.

Familiarity with the Load

If you're lifting and moving a load around your facility on a daily basis, such as a steel coil, a bundle of pipes, or logs, you'll already know how much it weighs. In many cases, your overhead crane was built with a duty cycle and capacity tailored to that repetitive lifting application, thus the weight of the load was taken into account when it was created.

Engineered Prints or Design Plans are useful resources.

The ultimate assembled weight may be shown via product printouts or technical drawings of the load.

Examine the Bill of Lading or other shipping documents.

The shipping documents you received should include some type of weight information if the load was shipped or delivered to your facility or job site.

Use a Commercial Scale

You might be able to utilize an industrial floor scale, which are frequently found in production areas or the shipping and receiving department of a facility, for smaller and lighter weights.

Consult the manufacturer's specifications or the data in the catalog.

- The weight of the load, if it is a product or piece of machinery, may be stated on:

- Paperwork provided by the manufacturer

- Information on the manufacturer or distributor's website

- Product specifications in a catalog or product brochure

Calculating the Weight of a Load

If no load weight information is provided, you will have to make some calculations to establish the weight of the load you will be lifting. We'll go over some basic calculations for calculating the weight of various sized loads made of various materials in this section.

Step 1: Determine the Volume of the Load

- Rectangle/Square: Volume = Length x Width x Height

- Hollow Cylinder: Volume = 3.14 x Length x Wall Thickness x (Diameter – Wall Thickness)

- Complex Shapes: Consider enclosing the entire thing in a rectangle and then calculating the volume of that rectangle. Alternatively, divide the object into two or more smaller rectangles and calculate the weight of each section separately before adding them up.

Step 2: Determine the Material You'll Be Lifting

The table below can be used for approximate weight values of common loads and materials:

Material | Pounds / Cubic Foot | Material | Pounds / Cubic Foot |

Aluminum | 165 | Iron Casting | 450 |

Asbestos | 153 | Lead | 708 |

Asphalt | 81 | Lumber (Fir) | 32 |

Brass | 524 | Lumber (Oak) | 62 |

Brick | 120 | Lumber (RR Ties) | 50 |

Bronze | 534 | Oil, Motor | 58 |

Coal | 56 | Paper | 58 |

Concrete | 150 | Portland Cement | 94 |

Crushed Rock | 95 | River Sand | 120 |

Diesel | 52 | Rubber | 94 |

Dry Earth (loose) | 75 | Steel | 480 |

Gasoline | 45 | Water | 63 |

Glass | 162 | Zinc | 437 |

Step 3: Determine the Weight of Object

To calculate the weight of an object or load, multiply the approximate pounds per cubic foot of the material by the calculated volume of the load.

Using Load Cells or Dynamometers to Determine Load Weight

Other gadgets that can be incorporated in the rigging to provide the operator with a read-out and determination of the load weight when it is lifted slightly off the ground can also be included. These load cells, sometimes known as dynamometers, are attached to the crane hook, slings, and hardware. The load is then coupled to the load cell, which estimates the load's weight by measuring the force applied to it with a strain gauge or hydraulic or pneumatic pressure within the device.

These gadgets can show the load's measured weight in a variety of ways. Some are mechanical and have an analog display with a needle and dial, similar to how many bathroom or medical scales work. Others can have digital displays built right into the apparatus, and some even use handheld digital devices or computer software to deliver the reading to a crane operator performing remote monitoring and diagnostics.

A loadshackle, which is simply a fully-rated lifting shackle with integrated electronics and microprocessors to determine the weight of a load once hoisted into the air, is another sort of load cell device. Data is also sent from these devices to a handheld device or a remote desktop.

Overload sensors are built into many load cells and dynamometers, alerting the crane operator, safety managers, or other specified individuals if the crane is overloaded. When a lift exceeds the crane's rated capacity, an overload occurs. According to OSHA and ASME B30 rules, overloading is banned because it can stress and damage crane equipment, putting adjacent employees in danger if the crane fails.

Always follow the manufacturer's instructions for scheduled maintenance and calibration when utilizing load cells or dynamometers to guarantee your instrument is in compliance and continues to deliver accurate results.

Summary

Understanding the weight of the load you intend to raise and move is the first step in planning an overhead lift. If you follow lifting and rigging best practices and create a lift plan before lifting any load into the air, everything else should fall into place.

The following are some of the rigging best practices:

- When calculating or estimating total load weight, always determine the weight of the load and account for any other things employed below-the-hook. Slings like as chan slings, wire rope slings, and synthetic slings are examples.

- Shackles, hooks, eye bolts, master links, and any other rigging hardware are all examples of rigging hardware.

- Lifting beams, magnets, c-hooks, vacuum lifters, and other devices used below the hook

- Determine the sling style (chain, wire rope, or synthetic) and hitch type you'll be employing (vertical, basket, or choker). Determine the sling angle. Based on the lift's rating and working load limit, select the appropriate hardware and slings (WLL).

- Prior to any overhead lift, inspect all rigging equipment. Any object that appears to be damaged, deformed, or irregular in appearance should be taken from service and inspected by a qualified person to decide if it can be repaired or disposed away.

- Lifting the weight a few inches off the ground to ensure that no swing develops and that the load is totally secure and the center of gravity has been accounted for will ensure proper rigging connection and method.

Additional environmental elements can increase resistance to the load's weight, which must be taken into account. Here are a few examples:

- A load being raised off of a muddy surface, or a load being dipped in and out of chemicals or other liquids, causes friction or resistance.

- A load being raised from a slanting surface

- Heavy winds/gusts of wind

Never lift a weight higher than necessary off the ground; identify potential impediments; and, if necessary, use a tagline to offer additional load control.

- We can provide a lifting and rigging consultancy to ensure that you're rigging, lifting, and moving a load through your facility according to best practices. We also provide classroom instruction for your personnel and supply a wide range of lifting and rigging equipment, such as:

- Overhead cranes

- Hoists and hoist parts

- Alloy chain, wire rope, and synthetic slings

- Rigging hardware

- Load cells and dynamometers

Please contact us today to speak with a Lifting Specialist if you need help putting together a lift plan, need rigging training for your personnel, or want to schedule a site evaluation of your rigging equipment and methods.

Hoist & Cranes for General Use

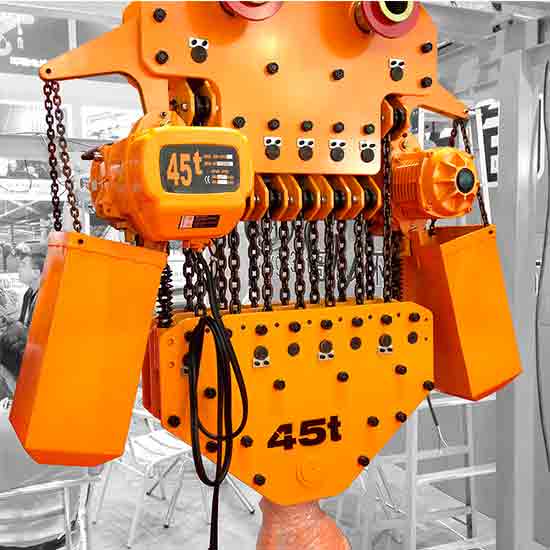

Electric chain hoists mounted on hook, lug, manual or electric hoist trolley for types of electric chain hoist cranes with capacity of 500kg, 5 ton, 10 ton, 32 ton.

Types of wire rope hoists designs for overhead hoist cranes- explosion-proof cable hoist, low profile wire hoist & single & double girder hoists for your hoist cranes.

Safe & fast air operated hoists. Air hoist & pneumatic hoist is a compressed air powered hoist & air operated hoists, various hoist designs,wide specification, good price.

European standard overhead hoist crane, Small overhead crane:European single girder overhead cranes, compact FEM hoist crane design, small & light overhead hoist crane.

1 ton -10 ton underhung bridge crane, light single girder overhead crane design, suspended on overhead roof, free floor space, economical underhung crane.

FEM/ DIN open winch bridge crane-European standard double girder overhead crane with open winch trolley, your heavy duty winch crane up to 320 ton.

Single girder hoist gantry cranes, FEM,DIN & ISO standards: Single beam gantry cranes, European style box girder, FEM hoists for 3 ton, 5 ton, 10 ton, & 16 ton load handling.

European style double girder hoist trolley gantry cranes: European type double girder gantry cranes with FEM standard wire rope hoists trolley with capacity of 5 ton up to 75 ton for sale.

Free standing jib crane-Pillar mounted jib crane is a free standing jib crane with pillar jib mounted on floor, for short & crowded lifting, capacity up to 16 ton.

Wall mounted jib crane & wall bracket jib crane with I beam & tie rod design for light duty handling with capacity up 2 ton. or less building structure changes.

Light crane kbk system-kbk light crane systems, flexible kbk crane & rigid kbk crane, modular crane design, cost-effective workstation crane solution, tailored light duty bridge crane.

Portable gantry crane & Economical mobile gantry-250 kg - 10 ton portable gantry cranes & mobile gantry cranes with adjustable / fixed gantry for small & light material handling.

As one of the best crane manufactuer and supplier in China, we offer crane sevices for turnkey crane projects ie.overhead, gantry & jib cranes and other travelling cranes from crane degin, manufactuering & installation, and crane parts supplying, etc.

Contact us to get tailored overhead crane design, free CAD overhead crane drawing, defined overhead crane specifications for your particular application with lower overhead crane costs & good overhead crane price. Send an overhead crane inquiry to your latest eot crane price now!