Overhead Clean Cranes and Hoists For Food and Beverage Industry

Food and beverage production involves a variety of manual tasks, from lifting and carrying raw materials to sealing or shipping completed goods. Risks to worker safety, process effectiveness, product quality, and sanitation can be significantly increased by the heavy lifting. To address the most fundamental of these issues, one can use custom cleanroom overhead cranes, hoists, and trolleys, which will improve safety and hygienic conditions throughout the entire manufacturing process.

Challenges of material handling in food and beverage industry

The food and beverage industry's need for heavy lifting can put worker safety, process effectiveness, product quality, and sanitation at serious danger.

They transport the barrels or bags of ingredients or material from their current location to the location where it is needed during the mixing and blending process for foods and beverages. Every day, a large number of containers, bags, barrels, reels, rolls, and other goods need to be lifted, moved, tipped, and positioned in various ways. Since these things come in a variety of shapes and weights, manual lifting tasks are both physically taxing and time-consuming.

The products made by the food and beverage sector require stretch film packaging and wrapping in addition to handling the various delicate or liquid materials that must be carried via warehouses and storage locations. This method involves handling reels quite a bit.

Custom cleanroom overhead cranes and hoists for food processing industry

A cleanroom crane, hoist, and lifting trolley enable a single employee to work with heavy products in almost any environment. Using a solution-oriented approach, the cleanroom crane equipment can be tailored to meet anything from specific aspects of a manufacturing facility to changing environmental challenges.

- Cleanroom cranes and hoists are customized for food processing indutry to ensure cleaness and sanity in food processing, storage and delivery.

- A lifting trolley appears to be simple, but it contains numerous variables that can be adjusted or modified to meet specific needs.

- Stainless steel lifting trolleys can withstand the harshest environments in the food and beverage industries.

- We took into account everything from ceiling height to doorway size and position.

- Customers can adjust the legs, and mast height or lift height may need to be adjusted to accommodate a specific workplace.

Cranes and hoists for handling reels in clean rooms

Our lifting hoists and cranes are most frequently used to hoist reels rather than actual food in the food business.

In food processing production, many types of reels need loading and theoverhead crane and hoist equipment are used to handle large reels of materials. These rolls are bulky, challenging to maneuver, and put a lot of physical strain on workers. Any employee can handle even the heaviest roll at any point in the process thanks tocustom hoist and crane used.

We make every effort to build specialized solutions based on special application conditions and lifting requirments.. Our team of application engineers, on the other hand, works to develop distinctive products that cater to the needs of our clients.

Why cleanroom cranes are essential to the food industry

Do you work in the food industry? Then you understand how crucial food safety is now more than ever. cranes in cleanrooms that are exceedingly sanitary and reduce the growth of bacteria. A controlled environment, also called a cleanroom, is created to reduce contamination during production. To reduce the amount of microorganisms, in other words (bacteria, viruses, yeasts, fungi, and parasites). You can see how crucial it is for the food sector that no raw materials or finished goods are polluted during production.

- Sanitary cranes - Here's where incredibly hygienic cranes come into play. They also reduce the growth of microbes because they were created for cleanrooms. Cranes for cleanrooms are built with practical and hygienic designs that are devoid of the cracks, fissures, and hollow spaces where germs typically grow.

- Many options - Each controlled environment is unique. There are also numerous lifting and hoisting solutions for the food industry. So, which design should you go for? Because your cleanroom equipment must also meet industry standards and requirements, we recommend a custom-made hygienic crane. Remember that these aren't applicable in all situations. Different requirements may apply depending on your location or the type of food you produce.

- Keep up to date - As a result, it is critical to monitor developments in the food industry. Much has changed and improved in recent years. Due to disease outbreaks, the entire food chain has been forced to improve its hygiene. With fantastic results! Furthermore, digitization is rapidly leaving its imprint on the food industry. Smart digital applications and other electrical components are being used to make the food system more transparent, sustainable, and safe.

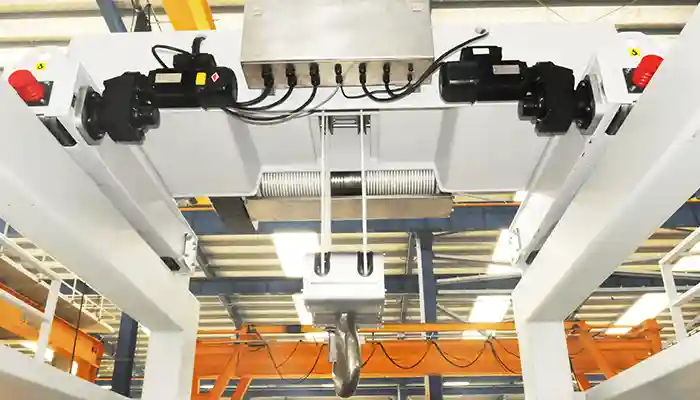

cleanroom overhead crane hoist diagram

1. Main body of cleanroom crane, 2. Anti-dust cover 3. Anti-dust hook

Portable alumnium gantry cranes are extremely versatile cranes that can be used in a wide range of cleanrooms.Alumnium Gantry cranes can be moved manually or electrically around a cleanroom due to their portable wheels design.

Jib cranes for clean rooms are constructed with stainless steel parts and a heavy nickel coating.

2 ton cleanroom jib crane for sale

Lifting capacity: 2 tons

Lifting height: 3.5 meters

Arm length: 5 meters

Application scenario: clean room of Pakistan machinery factory

3 key points for sanitary cleanroom cranes in the food industry

Do you work on the (re)design of a controlled environment for the food industry? And are you looking into the best options for sanitary cranes? Then you know there are numerous options. Here are three key points to consider when selecting the best solution.

But first, consider what hygienic means. Microorganisms such as bacteria, viruses, yeasts, fungi, and parasites are reduced by a hygienic crane. These organisms have the potential to contaminate or poison ingredients and end products. They can grow as a result of a variety of factors, including improper cleaning methods or neglected equipment maintenance. As a result, it is critical to consider the following points:

- Cleanliness- First, don't let your cleanroom machinery and equipment have any hollow spaces. Hollow spaces are extremely difficult to clean, allowing anything to grow in them. Install hygienic cranes in your cleanroom in a way that allows easy access to all parts of the crane to make cleaning much easier.

- Manufacturing lines -Extra care is required when a lifting and/or hoisting solution moves across and over food production lines. Because you don't want metal and plastic fragments from manufacturing equipment to end up in food. As a result, you should pay close attention to the material of your lifting and hoisting equipment. A proper surface treatment may be sufficient.

- Electrical power -The food industry is typically a very wet industry. Meanwhile, smart digital applications and other electrical components are being used to create a more transparent, sustainable, and safe food system. Consider how repetitive production tasks that were once completed by people are now handled by robots. However, water and electricity are not always the best combination. Make sure to properly seal off the equipment before using electrical components in your damp cleanroom environment to prevent a catastrophe.

In addition to the industry's standard challenges, rising demand for craft beer and other niche foods and beverages has resulted in a slew of new products. These impose new demands on productivity and efficiency, putting workers' well-being at risk. Do you face the same challenges that companies in the food and beverage industry do? With a clean hoist and crane, you can move your work product or object from one location to another without jeopardizing product or employee safety. Contact us to learn more about how we can help you optimize workflows, increase profits, and protect your employees' health.

How to get customized overhead crane and hoists for your use?

When dealing with a new customer, we begin by getting to know their needs, and what cleanroom crane and hoist solutions must achieve. How to get your custom hoist and cranes? The following questions can help you to get customized solution :

- Whatare the loads or object that needs to be lifted?

- Which dimensions or weights must be lifted?

- What needs to be done when the loads are lifted?

- What other difficulties do you encounter?

With tailored hoists and cranes designs, our products can fully meet the demands of the consumer, not the other way around. We frequently assist the customer in streamlining or optimizing their job to arrive at the most affordable and user-friendly solution.

More than half of the cleanroom cranes and hoists we offer are partially or completely customized. Initially, we analyze the condition, then we look at our standard range to determine how we might dimension a product to meet the specific requirements. Customizing a product in this manner requires striking the right balance; you don't want to under-dimension or over-dimension the product; the former may result in product failure, while the latter may make the product more difficult to use. No matter if a product is customized or even comes from our standard product line, our goal is to always set it up so that operators may use it as quickly and easily as possible while still getting the job done.