Small Wall Mounted JIb Crane Overview 1 Ton, 2 Ton, 3 Ton

Small Wall Mounted Jib Crane Overview 1 Ton, 2 Ton, 3 Ton - Wall jib crane specifications, installation, testing, safe operation guide, lubrication & maintenance . Check now.

Main content of small wall mounted jib cranes

- Introduction of wall mounted jib cranes

- The main wall jib crane specifications

- Installation precautions and assembly sequence

- The test run of wall mounted jib crane

- Safe operation of wall mounted crane

- Lubrication and maintenance of wall jib crane

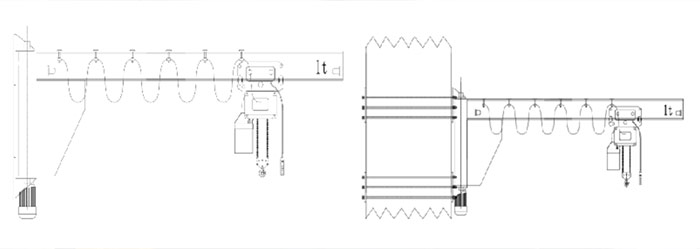

Description of wall mounted jib crane

The small wall mounted jib crane is a light work-strength crane. It is composed of a column, a rotary arm rotary drive device and a chain electric hoist. It has advantages of light weight, economic and durable, high mechanical efficiency, convenient installation, use and maintenance, and lower cost.

Column of wall jib crane

The column is made of round pipe, and the two ends are welded to the bottom plate and the rotating shaft, and the upper part is installed with the waist ring track. The bottom plate is installed and fixed by embedded parts to ensure the stability of the wall mounted crane. A through hole is opened on the rotating shaft to realize the hidden threading of the cable from the inside of the column. The waist loop track is used for wall mounted crane rotation, and the track can be equipped with a number of through holes for installing the physical rotation limit stop of the rubber pier, which can realize the 0-360° angle limit.

Wall mounted jib arm / cantilever

The cantilever adopts a special box beam composed of I-beam and square tube, which can be suitable for the installation and operation of electric chain hoist.

Rotating devices of wall mounted jib

The slewing device of the wall mounted crane uses a round tube as the shell, and a spherical roller bearing is installed inside, which can realize the free rotation of the cantilever. Due to the performance of the spherical roller bearing itself, even if the concentricity of the waist ring and the column is slightly deviated, it can Ensure the safe and normal use of the wall mounted crane.

Wall jib hoist

The wall mounted crane can be installed with a C-shaped track or wire rope on the cantilever to install the power supply cable of the electric chain hoist. The appearance is compact and beautiful, and the applicability is high.And also , electric wire rope hoist and manual hoist are available for your selection.

Application of light duty wall mounted jibs

This small wall mounted jib crane is mainly used for hoisting light duty material handling operations and cargo handling in assembly workshops, machining workshops, mold assembly, scientific research laboratories, maintenance workshops, small freight stations, warehouses, and auto repair shops etc.

Main Technical Parameters of wall mounted jib crane

| BX Types of Light Duty Wall Mounted Jib Crane | ||

| Working Class | A3,A4,A5 | |

| Capacity | t | 0.5ton, 1 ton, 2 ton, 3 ton |

| Effective Radius | m | 1~8 |

| Lifting Height | 3~100 | |

| Lifting Speed | m/min | 0.33~8,Single or Dual Speed |

| Trolley Travelling Speed | m/min | 2~30,Single or Dual Speed |

| Rotation Angle | ° | 0~360 |

| Power Supply | 380V 50HZ 3PHASE or Customized | |

| Temperature | ℃ | -20~60 |

| Protection Grade | IP44~65 | |

| The above are standard parameters for your reference, and customized wall jib cranes solutions and designs are provided according to your actual needs. | ||

Installation precautions and assembly sequence

When installing the jib crane, pay attention to the following points:

- After the crane is transported to the site, first check the parts and components according to the cargo list, and check whether the components are damaged or deformed during the transportation. If any, they must be repaired before they can be assembled and erected.

- Installation should be carried out by professionals.

- The installation ground must be solid and level.

Installation of wall bracket jib crane

- First install the hoist, hoist cable and rotating motor on the ground.

- Use a forklift or other lifting equipment to pick up the beam and install the beam to the specified height.

- Connect the cantilever to the back plate by means of bolts, adjust the level to ensure that the crossbeam is horizontal and tighten the bolts.

Crane test run

1、Preparation and inspection before commissioning

- Cut off all power, check the whole machine according to the drawing size and technical requirements: whether the fasteners are firm and whether the metal structure is deformed.

- Check whether the assembly and erection of the crane meet the requirements.

- Use a megameter to check the insulation resistance of all electrical systems and all electrical equipment.

- Cut off the circuit, check whether the control circuit is correct and whether the moving parts of all control equipment are flexible and reliable, and lubricate if necessary.

2. No-load test

The electric hoist should run smoothly when running left and right on the beam and lifting up and down. The swing arm beam should be flexible and stable when rotating, and should stop at any position without sliding by itself, and the outer end has a certain upward deflection.

3. Rated load test

Under the condition of rated load, the crane hook is at the extreme position of the farthest end of the column to lift the heavy object, and rotate (electric or manual), and test for 15 minutes. The descending value of the farthest cantilever should not exceed R/125mm.

4.It can be delivered to use only after passing all tests.Safe crane operation

- Crane operators should be familiar with the structural features and operation methods of this machine.

- When lifting objects for the first time in each shift to bring objects close to the rated load, the heavy objects should first be lifted to no more than 0.5 meters, and then braked when they descend close to the ground.

- Overload usage is prohibited.

- It is forbidden to lift items at an angle.

- It is forbidden for people to go up and down with the objects.

- It is not allowed to hang heavy objects in the air for a long time, when the crane is lifting heavy objects.

- It is forbidden to put tools, parts and other items on the beam to avoid falling and hurting people.

- In the event of a sudden power failure, turn all control handles to the zero position.

- When not working, step on the brake to prevent slippery.

- Wind work above level 6 is prohibited.

Prohibited applications conditions

The operator must read this manual carefully before using the wall mounted crane, and strictly follow the operation steps in this manual. Illegal operations will cause serious consequences.

In any of the following situations, lifting is strictly prohibited:

- The mass of the hoisted weight exceeds the allowable range of the machine;

- There are people under the hanging objects;

- People standing above hanging objects;

- Lifting buried objects

- Diagonal pull

- Slings and accessories are not tied tightly and do not meet safety requirements.

- Strong wind above level 6

- The rigging is not strong

Warning:

- Illegal operation will cause serious consequences;

- It is strictly prohibited for non-local operators to start

- After use, the power should be cut off in time

Lubrication and maintenance

- The service quality and life span of various cranes depend largely on frequent and correct lubrication. Therefore, the traveling mechanism and lifting mechanism of the crane should be regularly lubricated.

- Perform regular inspections on the remote control: check the integrity of the transmitter, check whether each action is normal, check whether the emergency stop is effective, etc.

- The remote control should be placed in a designated location, and someone is responsible, and should not be placed randomly.

- Replace the remote control battery in time to ensure normal operating signals.

- The protective devices on the crane are not allowed to be dismantled at will, and must be kept intact.

- It is not allowed to store or leave debris on the crane.

- The hook must be checked regularly.

- Regularly check the rim and tread surface, and replace the new wheel when the wear or crack of the rim reaches 30% of its thickness.

- The brake of the lifting mechanism should firmly support 1.25 times of the rated load (during lowering braking), and the brake of the operating mechanism should be adjusted to stop the operation of the mechanism in time without slipping.