Overhead travelling crane Camber Deformation and Restoration

The crane bridge frame and the operating system are the two main components of an overhead travelling crane, often known as a bridge crane. The main beams and end beams or end trucks make up the overhead travelling crane bridge frame, which is a rigid structure. overhead travelling cranes are classified as truss overhead travelling cranes, box type overhead travelling cranes, and tube type overhead travelling cranes based on the bridge frame structures. General carbon steel, such as Q 235 –B, and general low alloy steel, such as 16 Mn, can be used to construct the bridge frame.

Main girder of overhead bridge crane

One of the most significant crane sections is the main girder, which supports the trolley or hoist. Crane main girders are categorised as truss girders, box girders, single girders, and double girders, among other structures. Single girder, double girder, triple girder, box girder, truss grider, and other girder designs are available from Dongqi Crane. Please do not hesitate to contact us if you require crane girder design. Please contact us by WhatsApp/Wechat at +86 151 3871 1597, or leave a message below, and we will get back to you as soon as possible.

Overhead travelling crane girder camber

The main supporting portion of the lifting system and the weights is the overhead travelling crane girder, which requires great stiffness, strength, and stability to assure safety. Furthermore, crane girders are constructed with a specific camber to prevent trolley climbing and gliding, ensuring optimum crane utilization.

The crane girder camber allows the trolley to move up and down the main girder.

Overhead travelling crane girder camber deformation

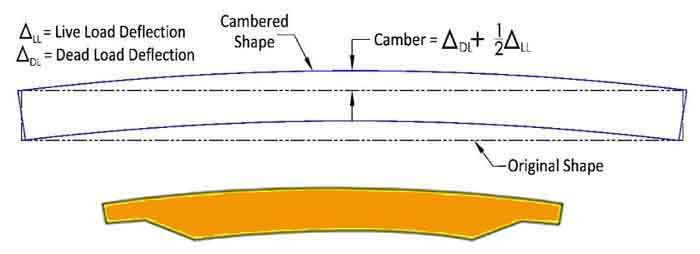

The girder will spring back to its original shape after unloading if the yield strength of crane girder steel is less than the yield strength. The girder camber of an overhead travelling crane is depicted in the diagram below:

However, the girder camber will be lost if the loads surpass the yield strength by more than 10%. When it is loaded with the rated capacity of the loads, it will deflect the normal incremental amount, and the stress will be at the normal level, except that the beginning point for the deflection increment will be at a lower elevation due to the lost camber. The girder camber will be lost each time the girder is loaded above its yield strength, resulting in permanent deformation, as seen in the diagram below:

Permanently distorted crane camber vs. normal crane camber deflection

In extreme cases, an overhead travelling crane girder may "kink" around the crane span's center.

Overhead travelling crane camber deformation causes

overhead travelling crane camber deformation occurs for a variety of reasons, most of which are related to crane design, production, transportation, installation, and use.

1) The design is irrational.

It is a crane's inherent difficulty that can be prevented by working with competent overhead travelling crane manufacturers.

Internal Residual Stress is the second type of stress.

The spot heat produced during crane girder production will cause metal shrinkage, and the internal residual tension produced will cause the overhead travelling crane girder to distort.

3) Camber creation of crane girders.

The loss of girder camber owing to the formation of the crane girder camber can be avoided thanks to technological advancements.

4) Overloading of the crane.

When an overhead travelling crane's weight exceeds its rated capacity, the girder will bend, potentially resulting in a crane accident.

5) overhead travelling crane malfunction.

Girder camber deformation can also be induced by improper overhead travelling crane operation, such as abruptly lifting loads without stressing the wire rope, abrupt braking, greatly braking, abruptly braking large loads vertically, and so on.

6) Deformation of the web plate

The crane girder's major supporting component is the web plate. Normally, web plate deformation has little effect on crane girder camber deformation; but, as the web plate deformation grows larger, the influence on the camber grows larger, eventually causing the camber to deform.

7) Extremely hot weather.

The temperature difference between the upper and lower plates of the crane girder will be caused by a large quantity of heat radiation, and the bottom plate will expand, resulting in camber loss.

8) Improper storage, shipping, lifting, and installation.

The girder of an overhead travelling crane is a long, thin metal section with a high internal Residual Stress that is susceptible to damage. As a result of incorrect storage, transportation, lifting, and installation, the overhead travelling crane camber will distort.

9) Inadequate upkeep.

Crane girder camber deformation occurs as a result of the heat created by cutting and welding on the crane girder during repair.

Influences of overhead travelling crane camber deformation

The camber distortion of an overhead travelling crane will have a negative impact on the entire crane and may result in crane accidents. In general, it will have the following effects on the overhead travelling crane:

1) To travel by trolley. The crane trolley will ascend and slide due to the severe deformation of the overhead travelling crane girder, which may result in crane accidents.

2) To move the traveling mechanism using crane. The transmission shaft will be damaged by the severe deformation of the crane girder camber, and the coupling tooth or coupling bolt may be broken, among other things.

3) To use a crane to lift a girder. The crane girder will bend as a result of the camber deformation, which will result in trolley track deformation and eventually gnawing track.

4) To protect a plate or a web plate from damage. The cover plate or web plate will be shattered as a result of camber distortion, increasing the likelihood of server crane accidents.

5) overhead travelling crane camber restoration. If the girder camber of an overhead travelling crane is distorted, it must be repaired. If you have enough money, you can replace the old piece of lifting equipment with a new set of overhead travelling cranes. The conventional Flame Correction Method and the Prestress Correction Method are two methods for restoring the distorted crane girder.

Method of Flame Correction

The flame correction method works by heating and cooling the three sides of the girder to reform the girder camber. Controlling the heating temperature and time is difficult, making the reformation of the girder camber even more difficult.

Prestress Correction Method

The crane girder camber can be restored by installing two prestressed tensioners on both sides of the flange-slabs of the overhead travelling crane girder and using the tensioners to provide tensioning pressures uniformly and concurrently. The following are some of the benefits of this strategy:

- There is no need to disassemble the repairing crane girder since it stays in place and takes up no space.

- Repairs take a short time, usually about 2-3 days.

- It not only recovers the overhead travelling crane girder's camber, but it also increases the girder's strength, stiffness, and bearing capacity. Repair costs are low.

When an overhead travelling crane's camber deforms, a crane restoration engineer is required, as well as advice, technique support, and services from the overhead travelling crane manufacturer. Free consultations are available.

Get custom girder crane design

We can provide you with various girder crane designs for your various material handling requirements as a professional crane designing, manufacturing, and installing team.