How Are Overhead Cranes Powered? Types of Overhead Crane Power Supply Systems

How are overhead cranes powered? Conductor bar, Festooning system, Cable reel or Seamless power line, which is right for you? Check various types of overhead crane power supply system and select the right overhead crane power system for your overhead crane system.

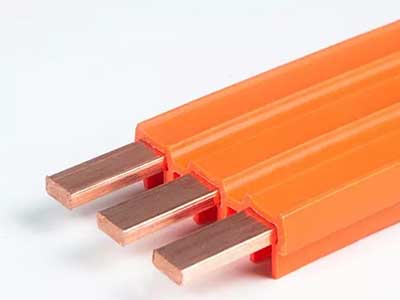

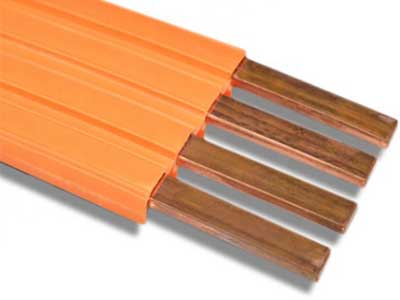

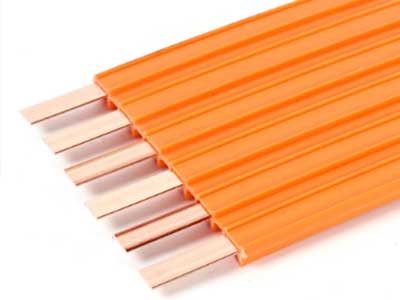

Single pole busbar

Single pole bus bar, also named single pole sliding wire or single pole conductor bar is a modern and advanced crane power supply system for overhead travelling cranes, fabricated in compliance with the latest regulations to ensure crane power supply safety, efficient and stable. The single pole busbars feed the power to your overhead travelling cranes through four lines which are available with copper crane conductor bar and aluminum crane conductor bar.

Single pole busbar can be adopted in indoor or outdoor applications and can be installed vertically or horizontally, on straight or curved system. For outdoor applications or harsh conditions, the single pole busbars are available with a protective cover of different sizes to protect crane conductor bars of various sizes to ensure overhead travelling crane safety which is antioxidant, UV resistant, impact resistant and is applicable to environments with the temperature of -40 ~ 115℃.

Conductor bar, festooning, or a cable reel are commonly used to power electric overhead cranes, also known as bridge cranes. Each method of electrification has advantages and disadvantages. Overhead cranes are sometimes propelled manually using push or hand geared options, or with air power.

A device such as a conductor bar, a festoon system, or a cable reel will transmit the facility's electrical power supply from a dedicated disconnect to the bridge, allowing it to "travel" or move back and forth down the length of the runways for overhead cranes powered by electricity. Meanwhile, the hoist is powered by the same electrification system for lifting and lowering. Both movements are controlled by an operator using either a wired pedant control or a radio remote control. Consider the supply of available power, the system's capacity, and the operational environment when determining the optimal way for electrifying a crane system.

An insulated system of four bars (L1, L2, L3, Ground) is constructed down the runway to deliver power. It's affordable, simple to install, and the ideal option for powering lengthy or low-headroom systems. This safe and long-lasting form of electrification can be used on a variety of crane systems and can be simply expanded with additional components as needed. However, one downside of the conductor bar system is the necessity to replace wear items such as collector shoes on a regular basis. In addition, a conductor bar system should never be employed in a dangerous site.

Crane festooning systems

Electricity is provided using cable festooning systems, which use a system of lightweight flat or round cable connected to trolleys that transport it along a track or beam. They are suitable for a wide range of applications, including outdoor and high-heat conditions, and are both reliable and safe. Cable festooning is occasionally offered in a DIY "plug and play" arrangement for easy installation on kit cranes, but it is not practicable for systems with more than one bridge or runway.

What is a crane festoon system? Acrane festoonsystem is anelectrification system for overhead travelling crane and monorail crane which utilizes flat or round cable on a trolley traveling on a C track, square rail, or an I-beam. Overhead crane festoon system provides direct contact,highgreater resistance to wear on the system's components.

Festoon systems are extremely reliable and can be used in all kinds of applications from indoor to outdoor applications, high heat environments, and in other demanding environments like in mills and at port facilities. They can also be used to safely provide power and control for explosion proof cranes.

Cable reels

Cable reels, whether motorized or manual spring reels, are a convenient way to operate overhead cranes while also managing long lengths of cable. The reel winds and stores flexible cable and requires very little upkeep. It's simple to set up and may be installed in a permanent or rotating position to allow the cable to expand in multiple directions.

Cable reeling drum for gantry crane, also known as crane cable reel or crane cable drum system is a type of power feeding solution to feed the electricity from the, grid to the gantry crane which can be installed at one end of the operating area or at the center.The gantry crane cable reels are widely used due to the features of small installation space, easy and convenient maintenance, stable & reliable use, and low cost.

Spring cable reels and motorized cable reels are the two main types of gantry crane cable reels which are used to release, retrieve, and store conductor cable for the goliath gantry crane equipment. Our gantry crane cable reels are designed to wind and store flexible cables automatically, with low requirement to maintenance and simple installation, which can be installed stationary, or on a swivel base to enable crane cable to payout in various angles and directions flexibly.

Crane cable reel and crane cable drum are widely adopted in general use gantry cranes, portal cranes, container gantry cranes and other equipment with similar working conditions to provide power supply, power control or power signal, etc.

The commonly used crane cable reels are usually adopted in the temperature between -20-+40℃, and as for lower and higher temperature, the cold resistance and high temperature resistance crane power line or crane cables should be selected according to the actual application conditions.

Cranes that are manually operated either push the load or pull a hand chain that drives a hand wheel. This strategy is often utilized for smaller cranes or maintenance cranes that aren't used very often. A hand-geared crane has a maximum capacity of 5 tons and a span of around 30 feet.

Air-powered overhead cranes are maintained at facilities that operate equipment with air-power, mainly due to the flammable nature of industry. Air-powered cranes operate at 90 PSIG, 80- 10D SF, and can lift up to 30 tons in short distances. This sort of overhead crane is usually powered by cable reels or festoon air hoses.

Seamless Crane busbar

Seamless crane busbar,a type of overhead crane busbar, is one important crane part and component for feeding power to overhead travelling cranes. Seamless crane busbar is fabricated with advanced crane technology and in compliance with relative regulations, which can be grouped into three-pole seamless crane busbar, four-pole seamless crane busbar and six-pole seamless crane busbar seamless has the advantages of Øanoxic copper transmission power supply, good conductivity, contact performance, stable operation, fast speed, low noise, high insulation, high safety and never power failure, etc.

The seamless crane busbar is a type of joint-less slide wire conductor which are available with 3 P and 4 P crane busbar of 50A, 80A, 100A, 120A, and 140A to match your loading. And also3P and 4P crane busbars can be combined into the 6 P crane busbar or other level.

3 P /4P/6P overhead crane busbar

- Rating: 660V, 50A-120A

- Conductor bar: copper

- Insulation cover/jacket: Rigid PVC within 75℃

- Color: Orange (Eye-catching warning color)

- Complete seamless crane busbar system are consisted of the parts and components,such as, hanger clamp, bended joints, Current Collector, towing bracket, end tensioner/feeding, towing arm, carbon brush, support bracket, etc.

Consider aspects such as power availability and environmental safety concerns while deciding on the appropriate power source for your crane system. If you're unsure, call a professional overhead crane installer.