Double Girder Bridge Crane for Sale 5 Ton, 10 Ton, 20 Ton, 30 Ton, 50 Ton +

Double girder bridge crane for sale. Custom double girder crane with top running & underhung crane design for indoor / outdoor general & hazardous material handling.

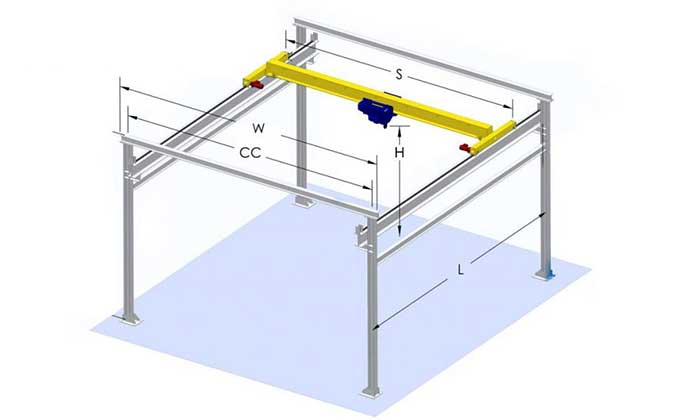

| Crane type | double girder bridge crane |

| Top running design | 3 ton -320 ton |

| Underhung design | 500kg -10 ton |

| Crane span | As customer requirement |

| Lifting height | As customer requirement |

Category: Bridge Crane

Your Trusted Overhead Bridge Crane Manufacturer & Supplier

Double Girder Bridge Cranes Handbook on Types, Uses & Maintenance

Double Girder Bridge Crane for Sale 3 Ton - 100 Ton

Double girder bridge cranes, often referred to as double girder overhead cranes, play a pivotal role in numerous industries, enabling efficient and precise material handling. Their versatility and robust design make them a vital component in applications ranging from manufacturing and construction to logistics and aerospace. In this comprehensive handbook, we'll delve deep into the world of double girder bridge cranes, exploring their types, uses, and maintenance, with a special focus on 10-ton and 15-ton capacity cranes.

The Significance of Double Girder Bridge Cranes

The use of double girder bridge cranes has become integral to modern industrial and commercial operations. They are renowned for their exceptional load-bearing capabilities and flexibility. These cranes offer solutions for lifting heavy loads while optimizing workspace usage. In the following sections, we'll take a closer look at their components, designs, and customization options, followed by a detailed discussion of their various types and tonnage options.

Stay with us as we unravel the diverse applications of double girder bridge cranes, understanding their role in different industries. We'll also provide valuable insights into safety practices and maintenance strategies, ensuring that your double girder bridge crane remains reliable throughout its lifespan. Whether you are considering the purchase of a new crane or planning to upgrade your existing setup, this guide will assist you in making informed decisions.

Join us on this journey to explore the world of double girder bridge cranes, from understanding their fundamental aspects to optimizing their performance, and witness how they drive efficiency and productivity in various sectors.

Key Components and Design

Exploring the Anatomy of Double Girder Bridge Cranes

To understand the capabilities of double girder bridge cranes better, it's essential to delve into their anatomy. These cranes consist of several key components that work in harmony to achieve efficient and precise material handling. Let's explore these components in detail:

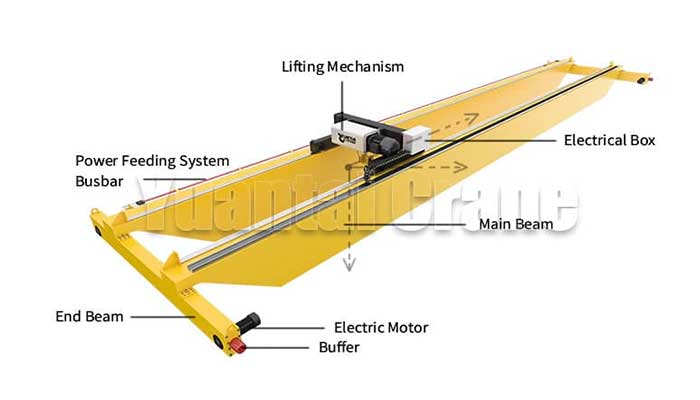

- The Bridge -The bridge, also known as the girder, is the primary horizontal beam that spans the width of the crane's runway. It serves as the foundational structure on which the hoisting machinery travels. Double girder bridge cranes are distinguished by their two parallel girders, providing enhanced stability and load-bearing capacity.

- The Trolley -The trolley is a crucial component responsible for moving the load horizontally along the bridge. It is equipped with wheels or casters that run along the bottom flange of the bridge girders. The trolley holds the hoist and ensures that it can access the entire workspace beneath the crane.

- The Hoist -The hoist is the lifting mechanism attached to the trolley. It features a drum or winch where the wire rope or chain is wound. The hoist is responsible for raising and lowering the load, offering various lifting capacities depending on the crane's specifications.

- End Trucks -The end trucks are the wheels and axles supporting the crane's bridge. They enable the crane to move along the runway beams. These trucks are equipped with wheels or casters that glide smoothly on the runway, ensuring efficient material handling.

- Electrical Systems -Modern double girder bridge cranes rely on electrical systems to control their movements. These systems incorporate various components like motors, sensors, and control panels. They provide precise and responsive operation, contributing to enhanced productivity.

These components work together to provide exceptional load-bearing capabilities and efficiency, making double girder bridge cranes indispensable in various industries. In the following sections, we'll explore different design options, customization features, and crane types to help you choose the right crane for your specific needs and applications.

Double Girder Bridge Crane Types

Double girder bridge cranes come in various types, each tailored to specific industrial applications. To help you navigate the diverse landscape of double girder bridge crane types, we've categorized them based on design, mounting, and capacity. Let's explore these categories and understand the criteria that set each type apart.

Double Girder Bridge Crane Types by Mounting

Top Running Double Girder Bridge Crane:

In this design, the bridge runs on top of the runway beams, and the crane is mounted on the building's runway beams. Top running double girder cranes are known for their stability, making them suitable for heavy-duty lifting applications. They maximize the available workspace beneath the crane, enabling efficient material handling in various industries.

The top running double girder bridge crane is a stalwart in the world of material handling. It stands out due to its distinct characteristics and design, which make it the preferred choice for various industries.

- Stability: One of the standout characteristics of the top running double girder bridge crane is its exceptional stability. The bridge runs atop the runway beams, which provides an incredibly stable platform for lifting heavy loads. This makes it the go-to choice for heavy-duty lifting applications.

- Heavy-Duty Lifting: This crane is engineered to take on the heaviest of loads with ease. It excels in scenarios where loads of substantial weight need to be lifted and moved efficiently. Industries dealing with large machinery, equipment, and materials often rely on top running double girder cranes for their lifting requirements.

- Efficient Material Handling: The design of the top running crane ensures that the workspace beneath the crane is maximized. This efficient utilization of space is highly beneficial in various industries where every inch of workspace counts. It allows for smooth material handling and streamlines operations.

- Wide Range of Applications: The stability, heavy-duty lifting capabilities, and efficient material handling make the top running double girder bridge crane versatile and suitable for an extensive range of applications. You'll find these cranes in industries such as manufacturing, automotive, construction, steel, and more.

In summary, the top running double girder bridge crane is a powerhouse of stability and efficiency. Its ability to handle heavy loads and optimize workspace makes it a valuable asset for industries that demand precision and reliability in their material handling operations.

Under Running Double Girder Bridge Crane:

Under running double girder cranes feature a bridge that runs beneath the runway beams. The crane is suspended from the building's runway beams, allowing for versatile load handling. This design is often chosen when headroom is limited or when the building structure cannot support the crane's weight. Under running cranes are commonly used for lighter loads and in settings with space constraints.

The under running double girder bridge crane has a unique design that sets it apart. It's characterized by the bridge running beneath the runway beams, and its ability to offer versatility in load handling.

- Limited Headroom: Under running double girder cranes are specifically designed to excel in situations where headroom is limited. This design ensures that the crane doesn't occupy valuable vertical space, making it ideal for facilities with height constraints.

- Suspended Crane: In this configuration, the crane is suspended from the building's runway beams. This provides added flexibility in load handling. The crane can be easily maneuvered and positioned as needed, enhancing its adaptability.

- Versatile Load Handling: Under running cranes are known for their versatility. They are capable of handling a wide range of loads and are often used in settings where the loads vary in weight, shape, and size. These cranes are adaptable and can accommodate different lifting requirements.

- Space Constraints: When a facility's layout or structure doesn't allow for the installation of a top running crane, the under running design becomes the solution. Its ability to work within space constraints is a valuable feature for facilities with limited room to spare.

- Lighter Loads: While under running double girder cranes can handle various loads, they are particularly well-suited for applications involving lighter loads. The ease of movement and precise control make them a preferred choice in these scenarios.

In summary, the under running double girder bridge crane is the solution when overhead space is limited and versatility in load handling is required. Its adaptability and efficient use of space ensure that it's a valuable addition to industries with diverse material handling needs.

Double Girder Bridge Crane Types by Design

Box girder bridge cranes feature girders in the shape of a box, which provides exceptional strength and resistance to torsional forces. These cranes are ideal for heavy-duty applications that demand stability and durability.

The box girder bridge cranes can be equipped with different hoists and trolley to meet different industrial needs:

Double girder electric chain hoist bridge crane with top running and underhung design

Double Girder Bridge Cranes for Different Application Environments

General-Purpose Double Girder Bridge Crane

General-purpose double girder bridge cranes are highly versatile solutions that cater to a wide range of applications. Their design and capabilities make them a popular choice for many businesses and industries. Here, we delve deeper into the characteristics that make these cranes an invaluable asset for various material handling tasks.

Versatility: General-purpose double girder bridge cranes are designed to be versatile and adaptable. They can handle an extensive array of lifting and transporting tasks within different sectors. This adaptability is due to their robust structure and design, which accommodates a diverse range of loads and configurations.

Efficient Performance: These cranes are renowned for their efficiency in material handling. Whether it's lifting heavy machinery in a manufacturing facility, handling raw materials in a warehouse, or loading and unloading cargo at a logistics center, they do it with precision and reliability.

Wide Range of Industries: One of the standout features of general-purpose double girder bridge cranes is their ability to cater to a broad spectrum of industries. You'll find these cranes in:

- Manufacturing: They play a crucial role in the production process, assisting with tasks such as assembling, moving, and positioning heavy equipment.

- Warehousing and Distribution: General-purpose cranes facilitate the smooth operation of warehouses by ensuring efficient material flow. They're often used in conjunction with conveyors and other equipment.

- Automotive: In automotive plants, these cranes are used to transport car parts and vehicles during the assembly process.

- Metals and Mining: The mining industry relies on these cranes for the extraction and transportation of minerals. In the metals industry, they help handle and process raw materials.

- Construction: General-purpose double girder bridge cranes assist in lifting and placing heavy building materials and equipment at construction sites.

- Aerospace: They are used to move aircraft components in aircraft manufacturing facilities and repair centers.

- Energy and Utilities: These cranes are vital for maintaining power generation equipment, including generators and turbines.

Customization: General-purpose double girder bridge cranes can be customized to suit specific application requirements. This includes options for specialized hoists, hooks, and other lifting accessories.

Safety: Safety is paramount in any industry, and these cranes are designed with safety features to protect both the operators and the materials being handled. Overload protection, precise controls, and emergency stop functions are among the safety mechanisms incorporated into these cranes.

Reliability and Durability: These cranes are built to last, with robust materials and precise engineering. They can withstand the demands of industrial environments and offer long-term reliability.

Precise Control: General-purpose double girder bridge cranes provide operators with precise control for accurate load positioning and movement. This level of control is crucial for tasks that require careful handling and placement.

In summary, general-purpose double girder bridge cranes are the workhorses of many industries. Their versatility, efficiency, and adaptability allow businesses to optimize their material handling operations. Whether in manufacturing, warehousing, construction, or other sectors, these cranes are a valuable asset for streamlining processes, enhancing productivity, and ensuring the safe and efficient movement of materials and equipment.

Processed bridge cranes for Hazardous environments

In environments where safety is paramount due to hazardous materials or conditions, processed bridge cranes offer specialized solutions. These cranes are engineered with features to ensure safe operations in challenging settings. Some key characteristics of processed bridge cranes for hazardous environments include:

- Explosion-Proof Design: Processed bridge cranes are often designed to prevent electrical sparks or ignition in environments with flammable materials. This design helps minimize the risk of explosions.

- Corrosion Resistance: Cranes operating in corrosive environments, such as chemical plants or coastal areas or cleanroom, are equipped with materials and coatings that resist corrosion, ensuring a longer lifespan.

- Specialized Hoists and Controls: Processed bridge cranes may feature hoists and control systems tailored to the specific needs of hazardous environments, ensuring precise and safe material handling.

- Compliance with Safety Regulations: These cranes adhere to strict safety standards and regulations relevant to hazardous settings, prioritizing the well-being of workers and the protection of valuable equipment.

- Processed bridge cranes play a crucial role in industries like petrochemical, mining, and pharmaceuticals, where safety and reliability are paramount. Their specialized design helps businesses meet stringent safety requirements while maintaining efficient and productive operations in challenging conditions.

Indoor Bridge Cranes 20 Ton Example for Reference

Indoor bridge cranes are a vital component of material handling systems within indoor facilities. They are specifically designed to operate within the controlled environment of a building or structure.

- Climate-Controlled Environments: Indoor bridge cranes are installed in facilities that maintain a controlled environment. These cranes are protected from outdoor elements such as rain, wind, and extreme temperatures. This controlled environment is essential for the preservation and protection of sensitive or valuable materials and products.

- Precise Material Handling: Operating in a controlled setting, indoor bridge cranes offer precise and efficient material handling. They are commonly used in manufacturing facilities, automotive plants, and warehouses for the movement of raw materials, components, and finished products.

- Overhead Space Utilization: These cranes are known for their overhead space utilization. They optimize vertical space within indoor facilities by running on elevated runways. This feature maximizes floor space, ensuring that there is minimal obstruction on the ground level.

- Safety and Efficiency: Due to their predictable indoor environment, safety measures are easier to implement and monitor. Indoor bridge cranes are well-suited for environments where safety and efficiency are paramount.

- Customization: Indoor cranes can be customized to meet the specific needs of the facility. They are available in various sizes, weight capacities, and configurations to match the unique requirements of different industries.

Outdoor Bridge Cranes 20 Ton Example for Reference

Outdoor bridge cranes, in contrast to their indoor counterparts, are designed to operate in open-air environments, where they are exposed to the elements.

- Exposure to Outdoor Elements: These cranes are engineered to withstand exposure to various weather conditions. They are constructed with materials and finishes that can endure rain, wind, sunlight, and temperature fluctuations.

- Heavy-Duty Operations: Outdoor bridge cranes are often used for heavy-duty tasks. Industries like shipping ports, construction sites, and shipyards rely on these cranes for the lifting and movement of large and heavy objects in open-air settings.

- Durability: The components and structural integrity of outdoor bridge cranes are built to last. Their ability to endure harsh outdoor conditions is a testament to their durability. Regular maintenance is essential to ensure their continued performance.

- Portability and Mobility: These cranes are designed to be portable and mobile. They can be moved to different areas of a facility or job site, making them versatile for various applications.

- Enhanced Safety Measures: While outdoor environments present additional safety challenges, outdoor bridge cranes are equipped with enhanced safety features to ensure the well-being of workers and the safe handling of loads.

In summary, the choice between indoor and outdoor bridge cranes depends on the specific needs of the application and the environment in which they will operate. Both types of cranes play crucial roles in their respective settings, facilitating efficient material handling and load movement.

Double Girder Bridge Crane Runway System for indoor and outdoor application

Double girder bridge cranes, whether for indoor or outdoor applications, rely on a runway system for their operation. The runway system is a critical component that provides a stable and guided path for the crane to move along. While the basic concept remains the same for both indoor and outdoor applications, there are specific considerations for each environment.

Indoor Double Girder Bridge Crane Runway System

- Enclosed Structure: The runway system for indoor double girder bridge cranes is typically set up within the enclosed structure of the building. It is supported by the building's framework, such as support columns and overhead beams.

- Weather Protection: Since indoor environments are protected from the outdoor elements, the runway system does not require additional weatherproofing. It is designed to operate in a climate-controlled setting, ensuring the longevity of the system components.

- Customization: Indoor runway systems can be customized to fit the specific layout and available space within the building. This allows for efficient use of the available floor and vertical space.

- Overhead Configuration: The runway system is usually installed overhead, running parallel to the ceiling. This design optimizes the use of vertical space while leaving the floor unobstructed.

- Safety Measures: Safety considerations are paramount in indoor environments. Runway systems are often equipped with features like warning lights, emergency stop buttons, and safety barriers to protect workers and equipment.

- Clean and Controlled Environment: Indoor runways remain free from dirt, debris, and weather-related wear and tear. This cleaner environment helps extend the lifespan of the crane components.

Outdoor Double Girder Bridge Crane Runway System

- Open-Air Design: Outdoor double girder bridge cranes operate in open-air environments. The runway system must withstand exposure to weather conditions like rain, wind, sunlight, and temperature fluctuations.

- Weatherproofing: Runway systems for outdoor cranes are constructed using materials and finishes that are weather-resistant. Special coatings or galvanization are often applied to protect against rust and corrosion.

- Heavy-Duty Applications: Outdoor crane runway systems are designed for heavy-duty operations. They can handle the rigors of lifting and moving large and heavy loads in challenging outdoor conditions.

- Portability and Mobility: Some outdoor crane runway systems are portable and mobile. This feature allows the crane to be easily relocated to different areas of a construction site, shipyard, or other outdoor work environments.

- Enhanced Safety Features: Safety measures are adapted for outdoor environments. Runway systems are equipped with enhanced safety features, including lightning protection, wind stability, and safety warnings related to weather conditions.

- Durability: The runway system must be highly durable to endure the harsh outdoor environment. Regular maintenance is essential to ensure that the system remains reliable and safe.

In summary, the runway system for double girder bridge cranes serves as the foundation for their operation. Whether indoors or outdoors, these systems are tailored to their respective environments, ensuring safe and efficient material handling and load movement. The choice between indoor and outdoor applications depends on the specific needs of the operation and the environmental conditions in which the crane will function.

Double Girder Bridge Crane Tonnage Options

When considering double girder bridge cranes, it's essential to understand the tonnage options available, as this significantly impacts the crane's lifting capabilities. In this section, we will delve into different tonnage options, focusing on both lighter and heavier capacities.

Light-Duty Double Girder Bridge Crane with Electric Chain Hoist :

- Characteristics: Light-duty double girder bridge cranes are designed for applications that involve lighter loads and less frequent use. These cranes provide a cost-effective solution for various industries with moderate material handling requirements. They are known for their efficiency in scenarios where precision and reliability are essential, even with smaller loads.

- Applications: Light-duty double girder bridge cranes are commonly used in industries such as automotive, small manufacturing facilities, and assembly lines. These cranes are well-suited for tasks that require the controlled and efficient movement of materials without the need for excessive lifting capacity.

Heavy-Duty Double Girder Bridge Crane with Buit-in Open Winch Trolley:

- Characteristics: Heavy-duty double girder bridge cranes are engineered to handle significantly heavier loads and frequent use. These cranes offer robust performance and durability, making them suitable for industries with demanding lifting needs. They are known for their strength and capacity to handle substantial materials and equipment.

- Applications: You'll find heavy-duty double girder bridge cranes in industries such as steel mills, foundries, and large manufacturing facilities. They excel in situations where the consistent, efficient handling of heavy materials is crucial. These cranes are the workhorses of industries that demand heavy lifting capabilities.

Selecting the right tonnage for your double girder bridge crane depends on your specific lifting requirements. Light-duty cranes are ideal for applications with smaller loads and the need for precision, while heavy-duty cranes are the go-to choice for industries with substantial lifting demands.

The versatility of light duty and heavy duty double girder bridge cranes means you can customize them to meet your particular needs, whether you're operating an assembly line, a steel manufacturing plant, or any other industry that requires efficient material handling. Consider your capacity needs carefully to ensure that your crane enhances productivity and streamlines your operations.

Double Girder Bridge Crane Tonnage Options

In the world of double girder bridge cranes, various tonnage options are available to cater to the diverse needs of different industries. While there is a broad spectrum of tonnage capacities, we have highlighted specific categories that are frequently requested or hold unique features.

- 5-Ton Bridge Crane: The 5-ton capacity bridge crane is often sought after due to its versatility. It offers a balanced lifting capacity that suits various applications, making it a popular choice for both light and moderate material handling tasks. The 5-ton bridge crane combines efficiency with flexibility, making it a common choice in manufacturing, warehousing, and maintenance facilities.

- 10-Ton Bridge Crane: The 10-ton bridge crane holds a special place in the crane industry. Its capacity strikes a balance between handling substantial loads and maintaining precision. These cranes are often preferred in settings where 10 tons is a standard unit for material transportation, such as construction sites, shipyards, and large storage facilities.

- 15-Ton Bridge Crane: The 15-ton overhead bridge crane stands out as an excellent choice for industries that require substantial lifting power. It can efficiently manage heavier materials and equipment while ensuring accuracy and safety. These cranes are commonly used in industries like steel manufacturing, shipbuilding, and heavy machinery production.Check 15 ton overhead crane designs for sale now.

- 20-Ton Bridge Crane: The 20-ton bridge crane and 25 ton bridge crane is ideal for heavy-duty lifting applications. It's suitable for demanding industries where materials and equipment exceed the capacities of smaller cranes. These cranes are often found in foundries, aerospace manufacturing, and large-scale fabrication facilities.Check types of 20 ton bridge crane designs and configruations to get your custom design.

- 30-Ton Bridge Crane: The 30-ton bridge crane and 35 ton bridge crane is designed to handle even heavier loads. Its robust construction and precision make it indispensable in environments like power plants, paper mills, and mining operations.

- 40-Ton Bridge Crane: For extremely heavy lifting, the 40-ton bridge crane comes into play. It's used in applications where substantial loads must be moved safely and efficiently, such as steel production and large-scale manufacturing.

- 50-Ton and Above Bridge Cranes: These cranes are engineered for the most demanding lifting tasks, typically found in shipyards, industrial facilities, and construction sites. They provide an exceptional level of strength and reliability to handle massive loads efficiently.

Each of these tonnage options offers distinct advantages based on the specific requirements of your industry and applications. Whether you need to move smaller components with precision or handle massive materials with ease, there is a double girder bridge crane designed to meet your needs. It's crucial to assess your capacity requirements carefully to ensure optimal performance and safety in your material handling operations.

Customization Options for Double Girder Bridge Cranes

One of the standout features of double girder bridge cranes is their adaptability to specific applications. Customization options allow businesses to tailor these cranes to their exact needs. In the following sections, we will explore various customization features and add-ons available to help you configure a double girder bridge crane that optimally fits your requirements.

Customization is a key aspect when it comes to double girder bridge cranes. These versatile cranes can be tailored to meet the specific needs of different industries and applications. Let's delve into the various customization options and add-ons that allow you to configure a double girder bridge crane to optimize its performance for your particular requirements.

Customization Options for Double Girder Bridge Cranes

Hoist Type

The choice of hoist type plays a crucial role in the crane's performance. Different hoist mechanisms are suitable for various loads and lifting requirements. Some common hoist types include:

- Wire Rope Hoists: Ideal for heavy-duty lifting, wire rope hoists offer precision and durability. They are often used in industrial applications that demand high-capacity lifts.

- Electric Chain Hoists: Electric chain hoists are a reliable choice for lighter loads. They offer consistent performance and are widely used in various industries.

Control Systems

Selecting the right control system is essential for safety and efficiency. Customized control systems can include:

- Radio Remote Controls: These allow operators to control the crane from a distance, providing improved visibility and flexibility during operation.

- Variable Frequency Drives (VFDs): VFDs offer speed control and energy efficiency, allowing for smooth and precise movements.

Load Monitoring

Integrating load monitoring systems enhances safety and prevents overloading. Some options for load monitoring include:

- Load Cells: Load cells provide real-time data on the weight being lifted, ensuring safe load handling.

- Anti-Sway Systems: Anti-sway systems reduce load swinging during movement, increasing safety and efficiency.

Runway Length and Configuration

The length and configuration of the runway system can be customized to suit your facility's layout and specific requirements. Whether you need a longer span or a unique runway design, customization options are available.

Safety Features

Enhanced safety features are crucial for protecting both personnel and equipment. Customization can include:

- Collision Avoidance Systems: These systems prevent collisions between cranes and other objects in the workspace.

- Emergency Stop Systems: Immediate emergency stopping capability for quick reaction in case of unsafe conditions.

Operator Cab

Customized operator cabs offer improved comfort, visibility, and control for crane operators. These can be equipped with ergonomic seating, climate control, and advanced control interfaces.

Environmental Considerations

For outdoor applications or facilities with specific environmental conditions, customization can include weatherproofing, corrosion-resistant coatings, and protective enclosures to extend the crane's lifespan and maintain its performance.

Power Supply

Customizing the power supply to match your facility's specifications can lead to energy savings and more efficient operation. Options may include:

- Cable Festoon Systems: These systems manage power and control cables, allowing them to move with the crane along the runway.

- Conductor Bars: Conductor bar systems provide power to the crane as it travels along the runway.

Benefits of Customization

- Customizing your double girder bridge crane offers several benefits:

- Enhanced safety and precision.

- Improved productivity and efficiency for your specific tasks.

- Adaptation to your facility's layout and operational needs.

- Extended equipment lifespan and reduced maintenance costs.

By exploring these customization options, you can design a double girder bridge crane that perfectly aligns with your business requirements and industry standards. This not only enhances operational safety but also boosts productivity, making it a valuable investment for your material handling needs.

For Sale and Purchase General Guide of Double Girder Crane

When it comes to purchasing a double girder bridge crane, whether it's a 5-ton crane or a 50-ton crane, it's essential to know where to find reliable sources. Here's a guide on how to source double girder bridge cranes:

- Reputable Manufacturers: One of the most secure ways to acquire a double girder bridge crane is to buy directly from reputable manufacturers. Well-established manufacturers are known for their quality and customer support. They can offer custom solutions tailored to your specific needs. Look for manufacturers with a history of producing durable and reliable cranes. You can find these manufacturers through online searches, trade shows, or industry directories.

- Authorized Dealers and Distributors: Authorized dealers and distributors are another reliable option for purchasing double girder bridge cranes. They work closely with manufacturers and offer a range of crane options. These dealers often provide after-sales services, including installation, maintenance, and spare parts. Be sure to choose authorized dealers who have a track record of delivering quality products and services.

- Online Marketplaces: Online platforms, such as e-commerce websites and industrial equipment marketplaces, are convenient places to explore various options. Many manufacturers and dealers showcase their products online. You can compare prices, features, and specifications from the comfort of your office or home. Remember to research the sellers and read customer reviews to ensure they have a good reputation.

- Industry Networking: Networking within your industry can be an effective way to discover trusted sources for double girder bridge cranes. Attend industry events, join professional associations, and engage with peers to gather recommendations and insights. Many business relationships start with a simple referral from a colleague.

- Quotes and Comparisons: Once you've identified potential sources, request quotes from different manufacturers or dealers. A detailed quote should include crane specifications, pricing, lead times, and any additional services offered. By obtaining multiple quotes, you can make informed comparisons and choose the option that best aligns with your requirements and budget.

- Evaluate After-Sales Services: When considering a purchase, evaluate the after-sales services offered by the seller. This may include installation, training, maintenance, and access to spare parts. Reliable after-sales support is crucial for the long-term performance and safety of your crane.

- Warranties and Certifications: Inquire about product warranties and certifications. A product warranty provides assurance that the manufacturer or dealer stands behind the quality of their crane. Certifications, such as CE, ISO, and others, indicate that the crane meets certain industry standards and safety requirements.

By following these steps and conducting thorough research, you can make a well-informed decision when purchasing a double girder bridge crane. Whether you're looking for a 10-ton crane or a 30-ton crane, the right source will provide you with a dependable, high-quality crane that meets your material handling needs.

Safety Practices for Double Girder Bridge Crane Operators

Safety is paramount when operating double girder bridge cranes. Not following safety practices can have severe consequences, both in terms of human safety and potential damage to equipment and materials. It's crucial for operators to be well-trained and certified to ensure safe crane operations.

Consequences of Not Following Safety Practices:

- Accidents and Injuries: Neglecting safety practices can lead to accidents, which may result in injuries to crane operators and bystanders. In some cases, these injuries can be severe or even fatal.

- Equipment Damage: Improper crane operation can cause damage to the crane itself, including components like hoists, trolleys, and end trucks. Additionally, it can lead to damage to the load being lifted and the structures in the crane's vicinity.

- Material Damage: Mishandling loads due to poor safety practices can result in damage to the materials being lifted. This can lead to financial losses and production delays.

- Legal and Regulatory Consequences: Non-compliance with safety regulations can result in legal actions, fines, and penalties. It can also lead to increased insurance costs for the business.

- Reduced Productivity: Unsafe crane operations can lead to reduced productivity due to frequent accidents, equipment downtime, and damage to materials. This can impact the overall efficiency of operations.

Importance of Operator Training and Certification:

To mitigate these consequences and ensure safe crane operations, operator training and certification are crucial. Here's why they are of utmost importance:

- Safe Operation: Proper training equips crane operators with the knowledge and skills needed to operate double girder bridge cranes safely. This includes understanding the crane's components, controls, load capacities, and how to handle different loads.

- Risk Mitigation: Training emphasizes the importance of safety procedures, risk assessment, and hazard identification. Certified operators are better prepared to minimize risks and respond to unexpected situations.

- Legal Compliance: Many jurisdictions require crane operators to be certified to operate heavy machinery. Ensuring that operators are certified helps businesses comply with legal and regulatory standards.

- Equipment Longevity: Well-trained operators are less likely to subject the crane to unnecessary wear and tear. This, in turn, prolongs the lifespan of the equipment and reduces maintenance costs.

- Efficiency and Productivity: Safe crane operations lead to increased efficiency and productivity. A well-trained and certified operator can handle tasks more quickly and accurately, reducing the risk of accidents and downtime.

By highlighting the potential consequences of not following safety practices and emphasizing the importance of operator training and certification, businesses can create a safer and more productive work environment when using double girder bridge cranes.

Double Girder Bridge Cranes in Different Industries

Double girder bridge cranes find extensive applications in a wide range of industries, demonstrating their adaptability and versatility. Here are some specific examples of successful applications in different sectors:

- Automotive Industry: Double girder bridge cranes are used for efficiently handling heavy car parts during the manufacturing process. They are instrumental in moving engine blocks, car bodies, and other large components within automotive assembly plants.

- Steel Industry: In steel mills, double girder bridge cranes are essential for handling extremely heavy loads like steel coils, beams, and ingots. They facilitate the transportation of raw materials and finished steel products across the production line.

- Construction: These cranes are deployed at construction sites for lifting and positioning construction materials such as concrete blocks, steel beams, and pre-fabricated components. Double girder bridge cranes ensure the safe and efficient movement of materials in construction projects.

- Ports and Shipping: In port facilities, double girder bridge cranes are used to load and unload shipping containers, bulk cargo, and heavy machinery from ships to the dock. They play a pivotal role in speeding up port operations and maintaining efficient cargo handling.

- Aerospace: The aerospace industry employs double girder bridge cranes to maneuver and transport large aircraft components, engines, and other sensitive aviation equipment. The precision and stability of these cranes are vital for aerospace manufacturing.

- Manufacturing and Warehousing: These cranes are widely used in manufacturing and warehousing facilities for the movement of heavy machinery, equipment, and raw materials. They optimize storage space and streamline logistics processes.

- Mining and Quarrying: In mining operations, double girder bridge cranes are utilized for the extraction and transportation of minerals and ores. They are indispensable in the mining and quarrying industry, where materials often weigh several tons.

- Power Plants: Double girder bridge cranes assist in power generation facilities by handling heavy equipment like generators, transformers, and boiler components. They play a crucial role in the maintenance and installation of power plant machinery.

- Paper and Pulp Industry: These cranes are involved in the paper and pulp sector to transport large paper rolls and process heavy paper products. They ensure the efficient flow of materials in paper manufacturing plants.

- Textile Industry: Double girder bridge cranes are employed for the handling of textile machinery, particularly in weaving and spinning mills. They contribute to the smooth operation of textile production lines.

- Waste Management: In recycling and waste management facilities, double girder bridge cranes help manage heavy materials like scrap metal, paper, and plastics. They assist in material separation and recycling processes.

These examples illustrate the diverse applications of double girder bridge cranes, demonstrating their crucial role in enhancing productivity, safety, and efficiency across various industries.

Choosing the Right Double Girder Bridge Crane

Selecting the right double girder bridge crane is a crucial decision that depends on your unique requirements, applications, and industry. To help you make an informed choice, consider the following checklist and decision-making process:

Checklist for Choosing the Right Double Girder Bridge Crane:

- Capacity: Determine the weight and dimensions of the loads you need to lift. Ensure the crane's capacity matches or exceeds your heaviest load.

- Span: Measure the distance between the runway beams or the required coverage area in your facility. Select a crane with an appropriate span that can cover your workspace effectively.

- Mounting Type: Choose between top running and under running cranes based on your building's structure and headroom constraints. Ensure the crane's design aligns with your space.

- Hoist Type: Consider the type of hoist (electric wire rope or electric chain) that suits your lifting requirements, load stability, and precision.

- Frequency of Use: Assess how often the crane will be in operation. Light-duty and heavy-duty cranes are available to match your usage frequency.

- Industry and Application: Determine your specific industry and application needs. Consider any industry-specific requirements or constraints.

- Customization Options: Explore the available customization features, such as radio controls, variable speed controls, and specialized hooks, to tailor the crane to your application.

- Safety and Compliance: Ensure that the crane meets safety standards and regulations applicable to your industry. Verify the safety features and operator training requirements.

- Budget: Establish a budget that accounts for the initial purchase, installation, and ongoing maintenance costs. Be prepared for potential customization expenses.

Decision-Making Process:

- Assess Your Needs: Begin by thoroughly understanding your material handling needs, including load sizes, working environment, and usage frequency.

- Capacity and Span: Determine the crane's capacity and the required span by considering the heaviest load and coverage area in your facility.

- Mounting and Hoist Type: Choose between top running or under running cranes and decide on the appropriate hoist type based on your facility's layout and material handling requirements.

- Customization: Review available customization options to fine-tune the crane to your specific needs.

- Safety and Compliance: Ensure that the crane adheres to safety regulations and industry-specific standards, and consider the level of operator training required.

- Budget: Create a budget that accommodates your crane purchase and installation costs, and account for any customization or maintenance expenses.

- Manufacturer and Supplier: Research reputable crane manufacturers and suppliers who offer the crane that best suits your requirements.

- Reviews and Recommendations: Seek out customer reviews, testimonials, and recommendations to gauge the reputation and reliability of the manufacturer or supplier.

By following this checklist and decision-making process, you'll be better equipped to choose the right double girder bridge crane that aligns with your needs, ensuring optimal performance and safety.

Wrap it Up

In this comprehensive guide, we've explored the world of double girder bridge cranes, delving into their various types, customization options, capacity considerations, and applications across different industries. Whether you're looking for a crane with light-duty performance or a heavy-duty workhorse, the versatility of double girder bridge cranes offers solutions for a wide range of lifting needs.

As you consider the purchase of a double girder bridge crane for your facility, we encourage you to take the knowledge gained here and put it into practice. To help you on your journey, we've compiled some useful resources to assist you in finding and purchasing the right crane for your specific needs:

- Explore our list of reputable manufacturers and suppliers known for their quality double girder bridge cranes. Find a partner that aligns with your requirements and industry standards.

- Read customer reviews and testimonials to gain insights into the experiences of others who have made similar crane investments. Their feedback can provide valuable guidance.

- Stay informed about the latest safety standards and compliance regulations in your industry to ensure your crane meets all necessary requirements.

By making informed decisions based on your unique needs, applications, and industry requirements, you can optimize your material handling operations, enhance safety, and improve overall efficiency. We wish you the best of luck in your pursuit of the perfect double girder bridge crane, and we're here to support you at every step.

Explore further, and let your new crane lift your business to greater heights.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch