Overhead Bridge Crane for Sale 5 Ton, 10 Ton, 20 Ton, 30 Ton, 80 Ton

Overhead bridge crane for sale 1 ton to 80 ton at good price, top running crane, underhung crane, single girder crane & double girder crane, designed for you.

Category: Bridge Crane

Your Trusted Overhead Bridge Crane Manufacturer & Supplier

Overhead Bridge Crane for Sale 5 Ton, 10 Ton, 20 Ton up to 80 Ton

All Types of Overhead Bridge Crane Designs for Various Industrial Sectors

Overhead bridge crane for sale 1 ton to 80 ton at good price, top running crane, underhung crane, single girder crane & double girder crane, designed for you.

Mastering Overhead Bridge Cranes: A Comprehensive Guide

In the world of heavy lifting and material handling, the overhead bridge crane plays a pivotal role. Whether you're in the market for a 5 Ton overhead bridge crane or looking to understand the key components, costs, and manufacturers, this article aims to be your comprehensive guide. We'll explore the various aspects of overhead bridge cranes and provide essential information to assist buyers and users.

Overhead bridge cranes are integral to the world of heavy lifting and material handling, serving as a cornerstone for various industries. To grasp their significance, let's delve into what they are and understand their key components.

What is an Overhead Bridge Crane?

An overhead bridge crane, also known as an over head bridge crane or over bridge crane, stands as a versatile industrial lifting machine meticulously designed to transport substantial loads horizontally within a facility. These cranes are the unsung heroes in manufacturing, construction, and a multitude of other industries. Their pivotal role lies in their ability to streamline the movement of heavy materials, ultimately enhancing efficiency and productivity.

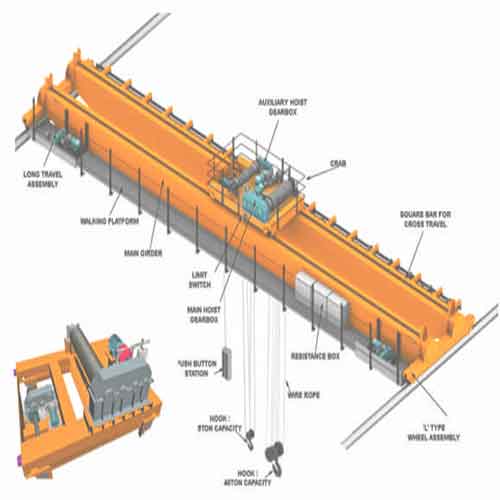

Key Components of Overhead Bridge Cranes

To gain a comprehensive understanding of overhead bridge cranes, it's crucial to acquaint yourself with their key components, each playing a vital role in their operation:

- Bridge Girder: The backbone of the crane, the bridge girder is a horizontal beam that spans along the ceiling, enabling the crane's lateral movement. It provides the necessary structural support for the hoist and the load it carries.

- Hoist: Often considered the heart of the crane, the hoist is the lifting mechanism responsible for raising and lowering the load. It features a hook, chain, or other attachment that securely holds the materials being moved.

- End Trucks: These are the support structures attached to the bridge girder, allowing it to move along the runway. End trucks house the wheels that glide on the tracks, facilitating the crane's movement across the workspace.

- Runway: The crane's pathway is formed by the runway, which comprises a system of tracks installed within the facility. The crane moves along these tracks, and their durability and precision are crucial for the crane's safe and efficient operation.

- Electrical System: The electrical system is the control center of the crane, encompassing various components such as buttons, switches, and a power supply. These elements enable the operator to control the crane's movements with precision. Safety mechanisms and emergency stop functions are also integrated into the electrical system to ensure secure operations.

Understanding these key components is fundamental in appreciating the intricate working of overhead bridge cranes and their significance in modern industrial settings. These cranes are engineering marvels that seamlessly handle the movement of heavy loads, enhancing productivity, and promoting safety within various industries.

Types of Overhead Bridge Cranes

Overhead bridge cranes are a diverse family of lifting equipment, each carefully designed to cater to specific industrial applications. Let's explore the various types, unveiling their unique features and suitable uses:

Single Girder Overhead Bridge Crane:

These cranes are the workhorses for handling light to moderate loads. Their versatility makes them a preferred choice for various manufacturing, warehousing, and assembly line operations. Single girder cranes offer a cost-effective solution for businesses with lower lifting needs, without compromising on efficiency.

Features:

Single Girder: This crane type is characterized by a single horizontal beam (the bridge girder) running along the ceiling.

Light to Moderate Loads: Designed to handle loads typically ranging from 1 to 20 tons.

Economical: Single girder cranes are cost-effective solutions for businesses with lower lifting needs.

Efficient: They are known for their operational efficiency and ease of use.

Benefits:

Versatility: Suitable for various applications in manufacturing, warehousing, and assembly lines.

Cost-Effective: Offers a cost-efficient material handling solution.

Efficiency: Enhances productivity with smooth and precise load handling.

Adaptability: Can be customized to meet specific industry needs.

Common Usage:

Warehouses and distribution centers for moving pallets and goods.

Small to medium manufacturing facilities for assembly and material transport.

Machine shops for positioning workpieces during production.

Double Girder Overhead Bridge Crane:

Designed for heavier lifting applications, double girder cranes are the powerhouse of industrial material handling. They excel in environments like steel mills, automotive plants, and large manufacturing facilities where the demand for lifting substantial loads is a daily routine. Their robust construction and enhanced load-bearing capabilities make them indispensable in heavy-duty operations.

Features:

Double Girder: Distinguished by two horizontal beams (double bridge girders) for added strength.

Heavier Loads: Engineered to handle loads typically ranging from 5 to 200 tons.

Highly Durable: Robust construction ensures long-lasting performance.

Versatile: Suitable for a wide range of heavy-duty applications.

Benefits:

Heavy Lifting: Capable of lifting and transporting substantial loads.

Durability: Designed for long-term, high-intensity use.

Safety: Ensures secure handling of heavy materials.

Efficiency: Optimizes productivity in demanding environments.

Common Usage:

Steel mills for moving steel coils and heavy materials.

Automotive manufacturing plants for handling large components.

Industrial facilities with high-capacity lifting requirements.

In settings with limited headroom, top running bridge cranes prove to be the ideal choice. These cranes glide smoothly on top of the runway beams, optimizing vertical space. They are frequently found in steel service centers and metal fabrication shops, providing efficient and precise material handling in constrained environments.

Features:

Top Running: These cranes run on top of the runway beams, conserving floor space.

Smooth Operation: Provides smooth and precise load handling.

Customizable: Can be tailored to fit specific height and space requirements.

Lifting Capacity: Typically used for loads ranging from 1 to 100 tons.

Benefits:

Space Optimization: Ideal for environments with limited headroom.

Efficiency: Maximizes vertical space utilization.

Versatility: Adaptable to a variety of industries and applications.

Safety: Equipped with safety features for reliable operation.

Common Usage:

Metal fabrication shops for moving large steel sheets and beams.

Manufacturing facilities with restricted overhead space.

Warehouses with high storage racks for efficient material handling.

Under Running Overhead Bridge Crane:

When space is a premium, under running bridge cranes come to the rescue. These cranes are engineered to run beneath the runway beams, making them an excellent fit for smaller work areas. They are commonly seen in workshops, assembly lines, and maintenance bays, ensuring that even confined spaces can benefit from effective material handling solutions.

Under Running Bridge Crane: Features:

Under Running: Operates beneath the runway beams, saving floor space.

Compact Design: Suited for smaller work areas.

Light to Moderate Loads: Typically used for loads ranging from 1 to 10 tons.

Ease of Installation: Can be installed in existing buildings without major modifications.

Benefits:

Space Efficiency: Ideal for facilities with limited floor space.

Adaptability: Fits well in workshops, assembly lines, and maintenance bays.

Cost-Effective: Provides efficient material handling for smaller loads.

Maneuverability: Offers flexibility in moving loads within confined spaces.

Common Usage:

Workshops and small manufacturing facilities with space constraints.

Assembly lines for handling components and products.

Maintenance areas for positioning machinery and equipment.

Each type of overhead bridge crane has its strengths and is tailored to meet specific lifting requirements. By understanding the distinct characteristics of these crane types, businesses can make informed decisions about which crane design best suits their operational needs. Whether it's the efficiency of a single girder crane, the brawn of a double girder crane, or the space-saving advantages of top running and under running cranes, overhead bridge cranes offer versatile solutions to a wide range of industries and applications.

Hot Sale Tonnages, Crane Designs & Configurations of Overhead Bridge Cranes

Overhead bridge cranes are a diverse group of lifting equipment, each tailored to specific tasks and industries. Let's delve into the most popular tonnages and crane designs commonly used across various sectors.

- 5 Ton Overhead Bridge Cranes: Highly versatile, these cranes are often the go-to choice for light to medium lifting operations in manufacturing, warehouses, and assembly lines.

- 10 Ton Overhead Bridge Cranes: Ideal for heavier loads, making them prevalent in steel mills, automotive plants, and large manufacturing facilities.

- 20 Ton Overhead Bridge Cranes: The choice for demanding applications such as shipyards, heavy machinery production, and foundries.

Overhead Bridge Crane Designs

Overhead bridge cranes are designed to suit various needs. Some of the popular designs include:

- Single Girder Overhead Bridge Crane - Suitable for light and moderate loads, these cranes are frequently found in smaller manufacturing facilities.

- Double Girder Overhead Bridge Crane- Ideal for heavy-duty applications, double girder cranes are commonly used in industries such as steel and aerospace.

- Top Running Bridge Crane- Top running cranes are often the choice for facilities with limited headroom and are employed in steel service centers and metal fabrication shops.

- Under Running Bridge Crane- Under running cranes are excellent for smaller work areas and are commonly found in workshops, assembly lines, and maintenance bays.

Crane Configurations

The configuration of an overhead bridge crane can greatly impact its functionality. Some prevalent configurations include:

- Top-Running Single Girder Bridge Crane - These are used for light to medium-duty lifting and are favored in workshops and smaller warehouses.

- Top-Running Double Girder Bridge Crane- Ideal for heavy lifting, these cranes are employed in large manufacturing plants and industrial settings.

- Under-Running Single Girder Bridge Crane- Versatile and fitting well in various industries, including automotive and general manufacturing.

- Under-Running Double Girder Bridge Crane- Found in industries like aerospace, shipping, and foundries, these are ideal for heavy-duty applications.

While these tonnages and configurations are standard, many industries require custom solutions. Overhead bridge cranes can be tailored with various features like specialized hoists, safety systems, and controls to cater to the unique demands of industries such as food processing, nuclear power, and the petrochemical sector.

Customization and Industry-Specific Applications

In the world of overhead bridge cranes, a one-size-fits-all approach doesn't always suffice. Many industries have unique demands and specialized needs that call for custom solutions. Overhead bridge cranes can be tailored with various features like specialized hoists, advanced safety systems, and precision controls to meet the specific requirements of industries such as food processing, nuclear power, and the petrochemical sector.

Food Processing Industry

Challenges:

Stringent Hygiene Requirements: Food processing facilities demand impeccable cleanliness and adherence to strict hygiene standards.

Sanitary Design: Equipment must be designed to prevent contamination and facilitate easy cleaning.

Custom Solutions:

Stainless Steel Components: Overhead bridge cranes with stainless steel components are resistant to corrosion and ideal for food processing environments.

Sealed Controls: Specialized controls with sealed enclosures prevent dust and moisture infiltration.

Washdown Hoists: Hoists equipped for washdown applications ensure cleanliness and sanitation.

Nuclear Power Industry

Challenges:

Precision Handling: Nuclear power plants require precise handling of heavy and sensitive components.

Safety and Reliability: Safety is paramount in nuclear facilities, and equipment must operate flawlessly.

Custom Solutions:

Remote Operation: Cranes can be customized for remote operation to minimize human exposure.

Radiation Shielding: Special materials can be used for radiation shielding in crane components.

Redundant Safety Systems: Multiple safety systems and emergency shutdowns enhance reliability.

Petrochemical Industry

Challenges:

Hazardous Environments: Petrochemical facilities have potentially explosive atmospheres.

Corrosive Materials: Exposure to corrosive chemicals can degrade equipment.

Custom Solutions:

Explosion-Proof Components: Cranes can be designed with explosion-proof features to mitigate the risk.

Corrosion-Resistant Coatings: Protective coatings and materials resist chemical corrosion.

Intrinsically Safe Controls: Intrinsically safe controls prevent electrical hazards in volatile environments.

Automotive Industry

Challenges:

Precision Assembly: The automotive industry requires precise positioning and handling of vehicle components.

High Throughput: Speed and efficiency are crucial in automotive manufacturing.

Custom Solutions:

Automated Controls: Custom controls for automated assembly and production lines.

High-Speed Hoists: Hoists designed for rapid lifting and positioning.

Error-Prevention Systems: Systems to prevent assembly errors and ensure quality control.

Aerospace Industry

Challenges:

Stringent Safety Standards: The aerospace sector demands impeccable safety and quality control.

Delicate Components: Aircraft parts are often delicate and sensitive.

Custom Solutions:

Load Monitoring: Customized load monitoring systems to prevent overloading.

Precision Positioning: Crane controls for precision positioning of aircraft components.

Aerospace-Grade Materials: Use of aerospace-grade materials in crane construction.

The beauty of overhead bridge cranes lies in their adaptability. They can be customized to meet the unique demands of these and many other industries. By tailoring the design, materials, and safety features, overhead bridge cranes can enhance safety, efficiency, and productivity in highly specialized environments. Customization ensures that the crane becomes an indispensable tool perfectly aligned with the specific needs of each industry it serves.

Selecting the Right Overhead Bridge Crane

When it comes to choosing the right overhead bridge crane, two critical factors deserve special attention: capacity and span. Selecting the appropriate capacity and span ensures that the crane effectively meets the demands of your specific application.

Overhead Bridge Crane Capacity

Choosing the right capacity is paramount to ensuring the crane can safely and efficiently handle the loads in your facility. Selecting the appropriate capacity prevents overloading, enhances safety, and promotes optimal performance.

Considerations for Capacity:

- Load Weight: Determine the maximum weight of the loads you need to lift and transport. This weight includes not only the material being handled but also any attachments or rigging.

- Load Size: Take into account the physical dimensions of the loads. Bulky or irregularly shaped loads may require higher capacities.

- Load Frequency: Consider how frequently you'll be moving loads. Frequent lifting and transport may necessitate a higher capacity to prevent overuse and premature wear.

- Future Needs: Anticipate potential growth and future needs. Investing in a crane with slightly more capacity than your current requirements can be a prudent decision to accommodate expansion.

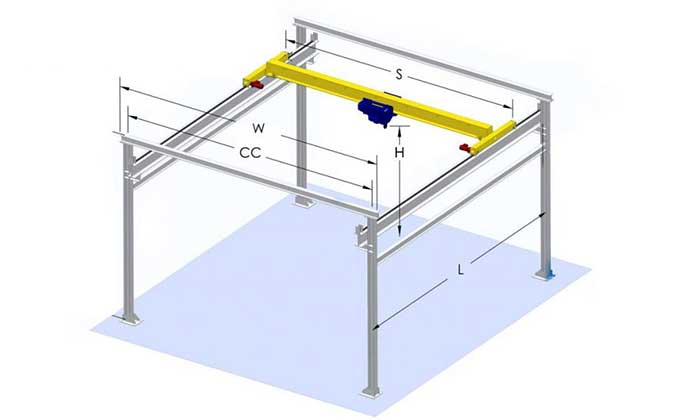

Overhead Bridge Crane Span

The span of the overhead bridge crane is the distance between the runway beams. Selecting the appropriate span is crucial to ensure that the crane effectively covers the required work area without any limitations.

Considerations for Span:

- Work Area Size: Measure the dimensions of the area where the crane will operate. The span should comfortably cover the entire workspace, allowing the crane to access all necessary locations.

- Clearance Requirements: Ensure there is sufficient clearance for the crane to move without obstructions, including walls, machinery, and other equipment.

- Future Layout Changes: Consider potential changes in the layout of your facility. A flexible design that accommodates reconfigurations may be beneficial.

- Load Positioning: Assess how precisely you need to position the loads. A longer span can provide more precise control over load placement.

- Safety: A well-matched span helps prevent accidents and collisions within the workspace.

Selecting the right capacity and span is a crucial step in optimizing the efficiency and safety of your material handling operations. Consulting with a qualified engineer or crane specialist can provide valuable insights and assistance in making these critical decisions. By carefully assessing your specific needs and planning for potential growth, you can ensure that your overhead bridge crane investment delivers the desired results.

Factors Affecting Overhead Bridge Crane Cost

When it comes to investing in an overhead bridge crane, understanding the cost factors is crucial for making an informed decision. The cost of an overhead bridge crane can vary significantly based on various factors. Let's explore the key elements that influence the pricing of these essential pieces of equipment.

Factors Affecting Overhead Bridge Crane Cost

- Type of Crane: Single or Double Girder: The choice between a single girder and a double girder crane significantly impacts the cost. Double girder cranes, with their enhanced load-bearing capacity, tend to be more expensive due to their robust construction and higher lifting capabilities. - Top or Under Running: The design of the crane, whether it's a top running or under running configuration, can also affect the cost. Specialized designs, such as explosion-proof cranes for hazardous environments, may command a premium.

- Capacity: The lifting capacity of the crane is a primary cost driver. Larger capacity cranes require more robust components and structural support, contributing to higher costs. Smaller capacity cranes are generally more cost-effective and suitable for lighter lifting applications.

- Span: The span of the crane, which is the distance between the runway beams, plays a significant role in determining the cost. Longer spans require additional materials and engineering, leading to higher expenses. Shorter spans, on the other hand, are generally more affordable.

- Customization: Tailoring the crane to specific needs, such as adding specialized hoists, safety systems, or unique controls, can impact the overall price. Customization is often necessary to meet industry-specific requirements, but it may increase the cost.

- Installation and Maintenance: The installation process and the long-term maintenance plan can also contribute to the total cost. Proper installation by experienced professionals ensures safety and efficiency. Regular maintenance is essential for the crane's longevity and reliability.

- Additional Accessories: Additional accessories and features, such as remote controls, advanced safety systems, or load monitoring, can add to the overall cost. These extras enhance the crane's functionality and safety.

- Brand and Manufacturer: The reputation and quality of the crane manufacturer can affect pricing. Established brands with a track record of reliability may charge higher prices, but they often provide long-lasting, high-quality equipment.

- Used vs. New: Opting for a used overhead bridge crane can be a cost-effective choice, but it's essential to carefully assess the crane's condition and history to ensure it meets safety and performance standards.

- Local Regulations: Local regulations, building codes, and safety standards may necessitate specific features or design modifications, potentially increasing the cost to ensure compliance.

Understanding these factors and their impact on the cost of an overhead bridge crane is essential for budgeting and selecting the right crane for your specific application. By considering your unique requirements and working closely with reputable crane manufacturers or suppliers, you can make an informed investment that aligns with your operational needs and budget constraints.

Used Overhead Bridge Cranes vs. Newly Buying Overhead Bridge Crane

For those seeking cost-effective solutions, used overhead bridge cranes can be an attractive option. However, it's essential to approach the purchase of a used crane with careful consideration and thorough evaluation.

Advantages of Used Overhead Bridge Cranes:

- Cost Savings: The most evident advantage of buying a used crane is cost savings. Used cranes are generally more affordable than their new counterparts, making them an attractive choice for budget-conscious buyers.

- Immediate Availability: Used cranes are readily available for purchase, and buyers can quickly put them to work, avoiding lead times associated with manufacturing new cranes.

- Proven Performance: Many used cranes have a track record of reliable performance, which can provide confidence in their functionality.

Considerations When Buying Used Overhead Bridge Cranes:

- Condition Assessment: Thoroughly evaluate the condition of the used crane, including its structural components, electrical systems, hoists, and controls. A professional inspection can reveal any wear and tear, damage, or needed repairs.

- Maintenance History: Request information about the crane's maintenance history. Regular and proper maintenance is crucial for ensuring the crane's longevity and performance.

- Safety Compliance: Verify that the used crane complies with safety standards and regulations. Outdated or non-compliant equipment may require costly modifications to meet current safety requirements.

- Manufacturer and Model: Research the manufacturer and model of the used crane. Reputable brands with available spare parts and support can be advantageous in case of maintenance or repairs.

- Load Capacity and Usage: Ensure that the crane's load capacity aligns with your specific needs. Understanding its previous usage can provide insights into its suitability for your application.

- Warranty and Support: Inquire about any remaining warranty or available support from the seller. Some used crane sellers may offer limited warranties or after-purchase service.

- Transport and Installation: Consider the costs and logistics associated with transporting and installing the used crane in your facility.

When to Consider Buying a New Crane:

While used overhead bridge cranes offer cost savings, there are scenarios where investing in a new crane may be a better choice:

- Specific Requirements: If your application has unique demands that necessitate specialized features or customizations, a new crane may be the only viable option.

- Safety and Compliance: In industries with stringent safety regulations, a new crane ensures compliance with the latest safety standards.

- Long-Term Investment: If you're looking for a long-term solution with minimal maintenance and the latest technology, a new crane may be the more cost-effective choice in the long run.

Ultimately, the decision to buy a used or new overhead bridge crane should align with your budget, specific needs, and considerations regarding safety and reliability. Regardless of your choice, a comprehensive evaluation and professional inspection are crucial to ensuring that the crane meets your performance and safety expectations.

Finding Overhead Bridge Crane Manufacturers

When it comes to purchasing a reliable overhead bridge crane, choosing the right manufacturer is paramount. Some well-known manufacturers include:Certainly, here's a concise overview of these well-known overhead bridge crane manufacturers:

Demag Cranes:

Reputation: Demag is renowned for high-quality and reliable cranes. Global Presence: They have a worldwide presence, serving various industries. Custom Solutions: Known for providing tailored solutions to meet unique lifting needs. Safety Focus: Prioritizes safety with advanced safety features in their cranes.

Konecranes:

Global Leader: Konecranes is a global leader offering innovative crane designs and technology. Reliability: Their cranes are reliable, ideal for demanding applications. Diverse Portfolio: Offers a wide range of cranes and services beyond overhead cranes. Maintenance Services: Provides maintenance and service solutions for crane longevity.

Gorbel:

Ergonomic Solutions: Specializes in ergonomic lifting solutions for precision and worker safety. Customization: Offers highly customizable cranes for unique applications. Lightweight Design: Cranes feature lightweight designs, suitable for limited headroom facilities. Quality: Emphasizes quality and durability in crane manufacturing.

Columbus McKinnon:

Innovative Products: Focuses on innovative lifting and motion control products. Broad Application Range: Serves a diverse range of industries internationally. Safety Features: Cranes include advanced safety features and precise motion control technology. Global Reach: Provides a global reach for customers seeking high-quality crane equipment.

When choosing a manufacturer, consider your specific needs, industry requirements, and budget to ensure the best match for your overhead bridge crane investment.

Finding Cost-Effective Overhead Bridge Crane Suppliers

While well-known manufacturers like Demag Cranes, Konecranes, Gorbel, and Columbus McKinnon offer high-quality overhead bridge cranes, their premium price tags may not fit every budget. Fortunately, there are ways to find cost-effective overhead bridge crane suppliers without compromising on quality and safety.

- Local and Regional Manufacturers:Consider exploring local or regional manufacturers. They may offer competitive prices due to lower operating costs and reduced shipping expenses. Local suppliers also provide the advantage of quicker response times, on-site support, and potentially lower installation costs.

- Online Marketplaces:Online platforms and marketplaces, such as Alibaba, Thomasnet, and Global Sources, allow you to connect with a wide range of crane suppliers, including international options. You can compare prices, specifications, and reviews to find cost-effective solutions that meet your requirements.

- Evaluate Lesser-Known Brands:While renowned brands often come with a premium, lesser-known brands can provide quality equipment at a more affordable price. Don't dismiss manufacturers that aren't as widely recognized; instead, carefully research their products, customer reviews, and track record.

- Local Distributors and Resellers:Local distributors or resellers may offer competitive pricing and personalized service. They often have insights into the local market and can recommend suitable crane options that align with your budget.

- Request Multiple Quotes:When searching for a cost-effective supplier, request quotes from multiple manufacturers or suppliers. This allows you to compare prices, specifications, and additional services. Be transparent about your budget and requirements to receive tailored quotes.

- Consider Used Equipment:If your budget is particularly tight, explore the used equipment market. Reputable sellers may offer well-maintained, pre-owned overhead bridge cranes at a fraction of the cost of new ones. Ensure that any used equipment you consider undergoes a thorough inspection.

- Negotiate Terms and Services:Don't hesitate to negotiate terms, especially if you're making a substantial purchase. Suppliers may be open to adjusting pricing, offering discounts, or including additional services as part of the deal.

- Financing Options:Some suppliers offer financing plans that can help you spread the cost of the crane over time. While this may increase the overall expense due to interest, it can make high-quality equipment more accessible in the short term.

- Consider Long-Term Costs:Keep in mind that the initial purchase price is just one aspect of the total cost of ownership. Consider factors like maintenance, spare parts availability, and energy efficiency, as these can impact the long-term costs associated with your overhead bridge crane.

- Seek Recommendations:Ask for recommendations from industry peers and colleagues. They may have insights into cost-effective suppliers who have provided reliable equipment for their operations.

Finding a cost-effective overhead bridge crane supplier requires diligent research, negotiation, and a clear understanding of your budget and needs. By exploring various options and carefully evaluating potential suppliers, you can strike a balance between affordability and quality, ensuring that your investment in an overhead bridge crane remains a valuable one.

Custom Overhead Bridge Crane Buying Process

After identifying the ideal overhead bridge crane and a reputable manufacturer, the buying process involves several key steps to ensure a successful purchase. Here's a breakdown of the process:

- Requesting Quotes:Reach out to your selected manufacturer or supplier to request detailed quotes. Provide specific information about your crane requirements, including capacity, span, and any customization needs. This step helps you receive accurate pricing for your project.

- Considering Customization:Assess whether your application requires any customizations to the crane. Discuss these requirements with the manufacturer to ensure the crane is tailored to your specific needs. Customization may include specialized hoists, controls, or safety features.

- Evaluating Warranty and Service:Inquire about the manufacturer's warranty and after-sales service options. A comprehensive warranty provides assurance against manufacturing defects. Additionally, evaluate the manufacturer's service and support offerings, as ongoing maintenance and prompt service are vital for crane longevity.

- Installation and Safety Measures:Plan for the installation of the overhead bridge crane in your facility. Ensure that the installation is performed by experienced professionals to guarantee safety and optimal performance. Implement strict safety measures and protocols to protect both equipment and personnel during crane operation.

By following these steps, you can navigate the buying process with confidence, knowing that you've made informed decisions about your overhead bridge crane investment.

Maintenance and Safety of Overhead Bridge Cranes

Owning an overhead bridge crane is not just about the initial purchase; it comes with the responsibility of ensuring its proper maintenance and safe operation throughout its lifespan. Here are key aspects to consider for the maintenance and safety of your overhead bridge crane:

- Regular Inspections:Conduct routine inspections to check for any signs of wear, damage, or potential issues. Inspections should cover the crane's structural components, electrical systems, hoists, and controls.

- Preventive Maintenance:Implement a preventive maintenance program to address minor issues before they become major problems. Regular maintenance can extend the crane's lifespan and reduce downtime.

- Operator Training:Ensure that crane operators are well-trained and certified to operate the equipment safely. Proper training includes understanding the controls, load limits, and safety protocols.

- Safety Protocols:Establish and enforce strict safety protocols for crane operation. This includes load capacity limits, personnel access restrictions, and the proper use of safety equipment, such as harnesses and hard hats.

- Emergency Procedures:Develop and communicate emergency procedures in case of equipment malfunction or accidents. This ensures that all personnel know how to respond to unexpected situations.

- Regular Load Testing:Periodically test the crane's load capacity to verify that it can safely handle the specified weights. Load testing is a critical safety measure.

- Upkeep of Electrical Systems:Electrical components are essential for the crane's operation. Regularly check and maintain the electrical system, including controls and power supply.

- Spare Parts and Repairs:Maintain an inventory of essential spare parts to ensure quick repairs when necessary. Work with the manufacturer or supplier to obtain genuine replacement parts.

- Documentation:Keep comprehensive records of all maintenance activities, inspections, repairs, and safety training. These records are vital for regulatory compliance and troubleshooting.

- Regulatory Compliance:Stay informed about industry regulations and safety standards related to overhead bridge cranes. Ensure that your equipment and operation comply with all relevant requirements.

- Professional Assistance:When in doubt or when facing complex maintenance or repair tasks, seek professional assistance. Experienced crane service technicians can address issues effectively and safely.

- Emergency Stop Systems:Ensure that your crane is equipped with an emergency stop system that allows for immediate shutdown in case of an emergency or unsafe conditions.

By prioritizing maintenance and safety measures, you can not only extend the lifespan of your overhead bridge crane but also create a safer working environment for your personnel. A well-maintained and safely operated crane contributes to improved productivity and minimizes the risk of accidents or equipment failures.

Wrap It Up

In the world of heavy lifting and material handling, overhead bridge cranes are indispensable tools that enhance precision and efficiency across various industries. Whether you're in the market for a 5 Ton overhead bridge crane or exploring the diverse options available, a comprehensive understanding of the components, costs, and manufacturers is crucial for making informed decisions.

These versatile industrial lifting machines, offered by well-known manufacturers such as Demag Cranes, Konecranes, Gorbel, and Columbus McKinnon, play a pivotal role in manufacturing, construction, and more. They are designed to move heavy loads horizontally within facilities, making them essential components in modern industrial operations.

To make the most of your investment in an overhead bridge crane, it's vital to prioritize safety and proper maintenance. Regular inspections, preventive maintenance, and operator training are the cornerstones of safe and efficient crane operations.

As you navigate the process of selecting, purchasing, and maintaining your overhead bridge crane, you can enhance productivity, streamline your operations, and contribute to the success of your industry. By harnessing the power of these remarkable machines, you're not only lifting heavy loads but also elevating the overall efficiency of your business.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch