C Hook Coil Handling System &C hook Coil Lifting Device

Coil handling system with for steel coils & metal coil handling in horizontal position. Get your coil handling overhead crane system & device.

| C hook coil handling system | Overhead crane & gantry crane with c hook coil lifter |

| Cranes specifications | Customized based on your lifting requirements. |

Category: Coil Handling

Your Trusted Overhead Crane Manufacturer & Supplier

Overhead & Gantry Crane System wih C Hook for Metal Coil Handling

C Hook Coil Handling System & C hook Coil Lifting Device

Coil handling system with for steel coils & metal coil handling in horizontal position. Get your coil handling overhead crane system & device.

The C Hook coil handling system is a specialized designed coil lifting equipment equipped with c hook coil lifting devices for the steel industry. The electric crane coil handling system are used to transport material between different machines in rolling mills. They may include a rotating trolley to properly position the steel coils in relation to the conveyor. Based on your material handling conditions and lifting requirements, the custom designed overhead coil lifting equipment and coil lifters are provided for you at cost-effective price.

C Hook coil handling system

Overhead crane for steel coil handling

The coil handling systems can be utilized indoors or outdoors, with capacities ranging from 5 to 250 tons and spans ranging from 10.5 to 31.5 meters.

Main series of overhead cranes for coil handling

- Single girder top running overhead crane with capacity up to 20 ton

- Chinese double girder crab trolley overhead crane with capacity up to 63 ton

- European style double girder crab trolley overhead crane with capacity up to 80 ton

- Double girder open winch crane for heavy duty coil handling with European style & Economical traditional style with capacity up to 100 ton, 320 ton.

Overhead gantry crane for steel coil handling

As for outdoor rolled steel handling , there are various types of gantry cranes are available to meet the needs of different coil handling requirements and applications. Mainly, the single girder gantry crane, double girder gantry crane, and L leg gantry crane for your selection.

Main series of gantry cranes for coil handling

- Single girder gantry crane for steel coil handling 32 ton

- Double girder gantry crane for steel coil handling 500 ton

- L leg single girder gantry crane for steel coil handling

- Truss girder gantry crane for coil handling

Fully customized coil lifting equipment solutions are available ahead standard configurations.

Our steel coil handling system is designed with specific features to deal with the higher risk working environment. In an emergency, the emergency brake can stop the crane, protecting both the operator and the goods. Excellent heat resistance thanks to the addition of a thermal-protective coating on the bottom of the main beam! Cabin control with air conditioning to keep operators protected from the weather. The crane beams are constructed of welded steel.

Applications of C hook coil handling system

C Hook coil handling system , also known as coil handling crane equipment, can be manufactured in a variety of forms, providing flexibility and efficiency for your material handling works in the rolling mill and steel service centers. Furthermore, C hook coil handling systems are commonly used for heavy-duty material handling, such as lifting, hauling, and/or stacking steel coils, aluminum coils, copper coils, steel wires, paper rolls, and other commodities.

C Hook coil handling system are widely used for the following application conditions:

- Heavy Duty Material Handling

- Paper Roll Handling

- Slit Coil Handling

- Close stacking C-Hook

- Pivoting coil C-Hook

With the proper overhead crane and gantry crane with tailored C hook type coil lifting devices, they can help your business in the following ways;

- Effective steel coil handling by addressing your lifting efficiency and diverse production needs.

- High operating efficiency -Lift steel coils into production quickly and safely.

- Manipulate coils into tight places to maximize production space.

- Low cost and easy maintenance

C hook coil handling devices, the economical horizontal steel handling solution.

The hook coil lifting devices is mainly used for handling the horizontal coil rolls. The coil lifting device is known as a C shape hook crane spreader because of its shape, which resembles the literal letter C. The structure is straightforward and reasonable, the operation is flexible, the use is simple, and the lifting is secure and reliable. It is widely used in steel plant hot strip mills and cold strip mills for steel coil handling, as well as at work stations, transportation storage yards, freight yards, terminals, and large steel coil users for lifting various types of rolls.

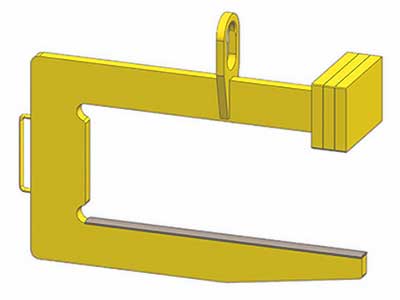

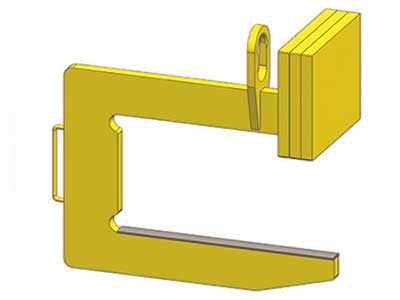

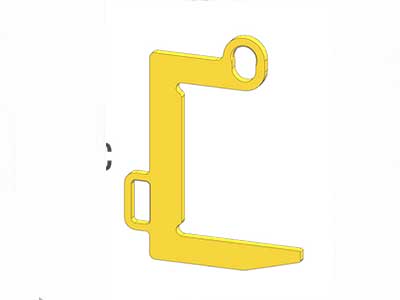

Coil handling c hook drawing

5 ton c hook for horizontal steel coil handling

Main structure of C hook coil lifting devices

Coil handling C hooks are made primarily of hanging steel structure and weighted iron.

- The hanging steel structure: It is made of steel plate (high-quality low-alloy steel) and steel pipe make up the main part of the Crane c hook. The cross-section is a box-type structure with good bending and torsion resistance. The spreader is lightweight and has a long lifespan.

- Counterweight iron: it helps in adjusting the spreader's balance so that the spreader's and lifted object's centers of gravity are parallel.

- Hook Options - Withstand High temperature,Mill duty coil lifters,Storage stands,Protective pads,Bail pins,Motorized rotation,Digital weighing systems,Designs for narrow coils,Remote control features,etc.

Main specifications of c hook coil handling devices

Coil Weight | Coil Width | Coil I.D. | A | B | C | D | E | H | R | Dead weight |

Weight | Width | Thickness | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | Weight |

(t) | (mm) | (mm) | (Kg) | |||||||

3.2 | ≤300 | ≥400 | 300 | 590 | 155 | 845 | 250 | 430 | 50 | 85 |

350 ~500 | ≥400 | 500 | 725 | 155 | 924 | 250 | 450 | 50 | 130 | |

5 | 750 ~900 | ≥400 | 900 | 1225 | 200 | 1144 | 324 | 500 | 60 | 350 |

900 ~1100 | ≥500 | 1100 | 1450 | 200 | 1331 | 318 | 600 | 60 | 420 | |

1100 ~1300 | ≥500 | 1300 | 1670 | 200 | 1332 | 375 | 600 | 60 | 530 | |

10 | 750 ~900 | ≥500 | 900 | 1290 | 300 | 1555 | 435 | 650 | 90 | 570 |

900 ~1120 | ≥500 | 1120 | 1555 | 300 | 1767 | 477 | 850 | 90 | 790 | |

1100 ~1300 | ≥500 | 1300 | 1758 | 300 | 1722 | 478 | 750 | 90 | 795 | |

1300 ~1500 | ≥500 | 1500 | 1955 | 300 | 1854 | 467 | 850 | 90 | 1120 | |

16 | 900 ~1100 | ≥600 | 1100 | 1540 | 310 | 1850 | 594 | 850 | 90 | 1140 |

1100 ~1250 | ≥600 | 1250 | 1710 | 310 | 1871 | 533 | 850 | 90 | 1250 | |

25 | 900 ~1100 | ≥600 | 1100 | 1570 | 370 | 1982 | 633 | 860 | 110 | 1800 |

1100 ~1300 | ≥700 | 1300 | 1810 | 370 | 2058 | 716 | 860 | 110 | 2130 | |

32 | 1400 ~1660 | ≥700 | 1660 | 2240 | 550 | 2450 | 700 | 850 | 130 | 2950 |

Note:

- The arm length of coil lifter allows multiple coil widths to be handled one at a time while not exceeding the maximum coil width.

- All loads must be properly centered under the lifting bail.

- Please ensure that the lifting bail size is compatible with the crane hook.

- Additional capacities and coil lengths are available upon request.

- The sizes and dimensions presented for your reference. As for your particular needs or design, please contact us to get specific drawing.

Types of of C-hook coil handling spreader/C-hook coil spreader

- 1) According to the different sections of the hook body, it can be divided into structural type, plate type and box structure type.

- 2) According to the type of hook mouth lining, it is divided into copper lining type, aluminum lining type and polyurethane lining type.

- 3) According to the coils handling and applications , the coil handling c hooks can be classified into the following types

Slit Coil C-Hooks

The C Hook coil handling system is used for lifting several coils that are equivalent to the maximum coil width using a longer lift arm silt coil c hook. The silt coil C-hook is made of high-strength alloy steel and is ideal for loading and unloading in tight locations.

- Only for heavy-duty applications.

- Handles multiple cut coils at once, maximizing handling effectiveness. When the counterweight is retracted, it reduces interference from equipment or other impediments.

- Physically, high tensile alloy steel plate is lighter and smaller.

- When empty, counterbalance to hang level.

- Hooks with an inside radius keep coil edges from coming into touch.

- Saddles with standard curved coils.

- The C hook lifter may be easily positioned thanks to the guide handles.

- Extra padding is supplied for further coil protection.

Close Stacking C-hook for Narrow Aisles

The C Hook coil handling device is typically fitted with a close staking c hook for narrow place or tight stacking coil handling.From the pick-up point (center of gravity) to the end, the length of the C hook is reduced. Because the lifting arm is shorter, all coil widths within the operational range (from widest to narrowest) can be handled without the lifting arm extending over the coil's outside edge. The decreased overall width of this type of C hook lifter can help reduce the demand for aisle space, increasing storage capacity.

Motorized Rotating C Hook - Steel Mill Crane C Hook

The mill duty coil lifter, the motorized rotating crane C-hook, includes a continuous 360° spinning motorized rotator. This function adds an additional tool to the c hook crane for the secure and exact placement of steel coils.

The steel mill overhead Handling of coils C hooks are designed to endure the severe, continuous environments prevalent in steel mills. To maximize service life, larger sections and corner radii lower stresses.

C-hooks for Narrow Coils

- Deals more sensitively with thin coils.

- Weightlessness allows for easier handling.

- The integrated guiding handle simplifies the coil positioning process.

- With a curved coil saddle that is an optional extra.

- Coil edge contact is avoided by hooks with an inner radius.

Counter Balanced C-hooks 5 ton

Maximum coil width is equal to the lower member length ("L" measurement) of the C-hook. The risk of harm to the inner wraps of lighter gauge coil stock is decreased by increasing the surface area in contact with the steel coil thanks to the whole length providing support of the C-hook.

The C-Hook coil lifters are developed to fulfill the specific coil handling needs of the customer. Our coil handling crane systems and C hooks can assure the safety of your operation, and we can provide CE certificates for your lifting equipment.We understand how critical it is to use the appropriate coil handling system for your needs. As a result, our C hook and all types of C Hook coil handling crane system are developed to meet our clients' needs in order to improve their efficiency and benefit their business.

Storage of coil handing c hook spreaders

- The Coil handling C hooks must be stored by a committed individual on a designated shelf in a factory building that is aired, dry, and clean.

- The surface of the lifting c hook must be protected against rust, and it should not be stored near acids, alkalis, salts, chemical vapors, or moist conditions.

The capitalized C shaped hook should not be stored in areas with high temperatures.

- To avoid dry friction and seizures, clean and lubricate the spinning components on a regular basis.

Routine maintenance of coil handling c hook

If the rotation of the hook is not flexible or in place during operation, it is necessary to check and adjust the adjusting nut, and then check the following parts:

- If the transmission mechanism gets stuck, it may be underlubricated, and lubricating oil (or grease) should be applied to the transmission mechanism's moveable connection. If the guiding pin is excessively tight, properly loosen the nut. If the connection is loose, the transmission pipe or other rods are distorted, they should be rectified; prevent the indicator paint on the spreader's indicator plate from coming off during usage. Once observed, the paint must be replenished with the original instruction mark in time.

- The wire rope on the spreader should be cleaned and oiled with lubricating oil or grease on a regular basis, especially at the bend.

- Under normal use conditions, the primary stress-bearing components, rings, twistlocks, ear plates, and rigging shackles, should be inspected at least once every 3 months, and there should be no cracks or serious deformation.

- The primary moveable joints of all oil cups, including the ratchet mechanism oil cup, the oil cup on the sliding bearing seat, and the oil cup of the twist lock box, should be filled with lubricating oil in a timely way according to usage conditions.

- Check for loose rope clamps and overstretched buffer springs on a regular basis, and address any issues that arise. Check to see if the buffer spring tension is too low. If it is too short, the wire rope connecting it to the buffer spring should be cut.

- The rated lifting capacity of each type of coil lifting device must not be exceeded, and the buffer spring must not be overstretched.

- It should be hoisted smoothly during the hoisting operation to avoid distortion caused by mutual impact between the coil lifter and the coil handling crane or other equipment.

Coil handling C hooks safety inspection

- Human-powered lifting mechanism with an inspection load of 1.5 times the rated load

- Power-driven lifting mechanism with an inspection load that is 2 times the rated load.

- After the hook is removed from the inspection load, there must be no visible faults or deformations, and the increase in opening degree must not exceed 0.25% of the original size.

- The rated weight, factory or factory name, inspection mark, production number, and other information should be printed in the hook's low stress area.

- When you encounter the following situation, it should be abandoned:

- If a crack is found, the Coil handling C hooks should not be used.Section wear of up to 10% of original size is dangerous.

- The degree of opening has been enhanced by 15% over its initial size.The hook twisting deformation exceeds 10°.

- A risky part of a C-hook or plastic deformation of the hook neck.

- The thread on the hook is rusted.

Get your coil handling system & c hook spreader

Not sure which type of coil handling equipment is best for your project? Do you know which type of design and configuraiton would provide the best performance in your production environment? Any interest on equipment comparison for your lifting demands? Contact us to check what we can do for you now!

How to get your customized coil lifter that best fit your application ?

To get your customized coil handling lifting devices, the following information are needed to:

Main parameters needed for metal roll lifter quotation

- What are the dimensions of the rolls:

- Dead weight of rolls :____ t,

- Width of coils:____ m,

- Internal diameter:____ mm

- Outside diameter:____ mm

- If you have any need or want to learn more on coil lifter and coil handling equipment, please feel free to contact us. WhatsApp: 0086 151 3871 1597.

How to get your customized C hook overhead crane ?

The following information are needed :

- What is the type of crane needed: _______?-overhead crane or gantry crane?

- Main parameters of Cranes:

- Capacity___, Crane Span ___, Lifting Height____,

- Travelling Length/ Runway length ________,

- Power Supply:_______(Such as, 380v 50hz3Ph) ,

- Other requirements__________.

- Coil lifter prefered: ___ ? -Steel Coil or Paper Rolls, or other types of metal coils or rolls.

C Hook Overhead Crane 10 Ton for Coil Handling Bangladesh

Steel coil plant is one of the most common factory in steel industry. To improve steel coil handling efficiency, there are types of coil handling equipment and lifting devices for selection. The c hook crane is one types of overhead crane, which quipped with C hook lifting spreader for horizontal steel coil handling, which is one of the most popular lifting equipment, together with tong cranes, magnetic crane, double leg coil lifter, etc. In the following, the 10 ton overhead crane with c hook lifter for a steel coil plant in Bangladesh is presented for your reference.

Background of Bangladesh steel coil plant

The Bangladesh Coil plant was formed in 2000, and it initially began in the manufacturing and distribution of steel coil in the global market. The firm has established a cutting-edge Cold rolling Mill complex in Kumira, 25 kilometers from Chittagong. The 10-acre complex houses a pickling line, a 6 Hi CVC cold rolling mill, a slitting and rewinding line, and a rewinding line with an annual capacity of 250000MT. CRFH (Cold Rolled Full Hard), CRCA (Cold Rolled Closed Annealed), GPFH (Galvanized Plain Full Hard), and GC (Galvanized Corrugated) are the main products.

Coil handling crane requirements

The Bangladesh coil mill requires an overhead crane system to lift standard-sized steel coils that cannot be held by crane hook alone and require specific lifting devices or spreader. Most steel coils are finished goods, wrapped in delicate containers that must be handled with care and without being impolite. Furthermore, the Bangladesh client need material handling overhead cranethat can work nearly 24 hours a day. Finally, and most crucially, the crane pricing must be cost-effective, sturdy, and affordable.

Solution of 10 ton double girder overhead cranes

According to the client requirements and the factory conditions, 1 set of 10 ton double girder overhead crane with c Hook is designed for the Bangladesh steel plant.

Steel coil handling workshop from client in Bangladesh

Main specifications of C Hook overhead cranes - Capacity: 10 ton, Crane span : 15.89m Working duty: A5.

The steel coil handling crane solution of has the following advantages:

- C hook use Schneider electrical, which is more appropriate and cost-effective.

- Equipped with a frequency converter that allows it to modify its speed to help the crane travel more smoothly and steadily.

- The totally meets the needs of the client and increases their working efficiency.

- Less maintenance also saves time and money, which pleases the client.

Features of C hook crane 10 ton

The Bangladesh c hook overhead crane has three distinct characteristics: work duty, crane speed, and high cost performance.

- 1) C hook coil handling work duties - The c hookcrane will be operational 24 hours a day, seven days a week. The total work time is relatively long, and one working cycle lasts around 3 minutes, but with a low working frequency. That is, the pause period between working cycles is long. A5 is sufficient and safe for coil handlingcrane operation conditions, according to the calculations.

- 2) Crane speed of overhead crane system - To lift the steel coils tenderly, the c hook crane uses a Schneider frequency converter to control the crane and hoist speed, which completely solves the problem.

- 3) High cost-effectiveness -Our design team would like to save as much money as possible while yet maintaining crane quality and safety. The best solution for clients is to give high-quality material handling equipment at the most affordable pricing.

10 ton overhead crane with open winch trolley for steel coil plant in Bangladesh

Crane installation and testing and required training for coil handling cranes

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch