Your Trusted Overhead Travelling Crane Manufacturer & Supplier

Overhead Bridge Crane Workshops, Runways & Crane Rails

Crane Basics to Know Your Workshop & Get Custom Bridge Crane Design & Runway System

Knowing the workshop conditions and dimensions is crucial when selecting an overhead crane because it helps to determine the most suitable crane configuration for the specific application. The available headroom, floor space, and lifting height requirements are all important factors to consider when selecting an overhead crane. The capacity of the loads that will be lifted and the types of loads that the crane will handle also need to be taken into account. By understanding the workshop conditions and dimensions, you can select an overhead crane that will operate safely and efficiently within the available space and meet your lifting needs.

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

Workshop Dimensions Affect Your Overhead Bridge Crane Designs

- 1 Height from the ground to the lowest point of the plant

- 2 rail top elevation

- 3 crane spans

- 4 The distance between the center of the track and the side of the factory building

- 5 lifting height

- 6 large car running track models

- 7 rail beam model

- From this, a crane suitable for the plant can be determined

When designing a custom overhead crane for your workshop or facility, there are several key factors to consider:

- Available headroom: The amount of vertical space available in your workshop or facility will determine the maximum lifting height of the crane.

- Floor space: The available floor space will determine the size and configuration of the crane.

- Lifting height requirements: The required lifting height will determine the design of the crane and its components.

- Load capacity: The maximum load capacity and the types of loads that the crane will handle will determine the size and strength of the crane components.

- Building structure: The building structure and its ability to support the weight of the crane and its loads must be taken into account when designing the crane.

By considering these factors, you can design a custom overhead crane that will operate safely and efficiently within your workshop or facility and meet your specific lifting needs. Click to know more about types of crane buildings and facility.

Main specifications or main terms needs to know to get your customized electric travelling bridge crane for indoor workshops

crane runway length, crane columns for indoor workshops Clicke to check more working coverages of overhead bridge cranes

What should be considerable for new workshop or building?

When selecting an overhead crane for a workshop or facility, consider the following factors:

- Span and height: Determined by the distance between the rails and the height of the building, as well as the required lifting height.

- Lifting capacity: Based on the maximum weight of the objects to be lifted and the weight of the pick-up mechanism.

- Working level and speed: Chosen based on the load status and utilization level.

- Power supply: Must be sufficient to meet the crane's power requirements.

- Environmental conditions: Temperature, humidity, and presence of corrosive or explosive materials must be taken into account.

- Safety features: Overhead cranes must be equipped with overload protection, emergency stop systems, and anti-collision devices.

Careful evaluation of these factors is crucial when selecting an overhead crane.

A professional crane manufacturer or supplier can provide guidance and assistance in choosing the right crane for your needs.

For existing workshops

For existing workshops, there are several additional factors to consider when selecting an overhead crane:

- Building structure: The building structure must be able to support the weight and forces of the overhead crane. A structural engineer should evaluate the building to ensure it is suitable for the installation of an overhead crane.

- Obstructions: The presence of any obstructions, such as columns, beams, or equipment, must be considered when selecting the span and height of the overhead crane.

- Floor space: The floor space of the workshop must be sufficient to accommodate the movement of the crane and the placement of loads.

- Access: Adequate access must be provided for the installation, maintenance, and repair of the overhead crane.

- Electrical systems: The existing electrical systems of the workshop must be able to support the power requirements of the overhead crane.

It is important to carefully evaluate these factors when selecting an overhead crane for an existing workshop. A professional crane manufacturer or supplier can provide guidance and assistance in selecting the right overhead crane for your specific needs.

Steel Structure workshops vs. Concrete workshops

how the factors and conditions for overhead crane selection may vary between steel structure and concrete workshops:

Building Structure

When selecting an overhead crane for a workshop or facility, one important factor to consider is the building structure. Steel structure workshops typically have a higher load-bearing capacity due to the strength and rigidity of the steel frame. This allows them to support heavier cranes and loads than concrete workshops, which may have lower load-bearing capacity due to the limitations of the concrete structure. A structural engineer should evaluate the building structure to determine its suitability for the installation of an overhead crane.

- Steel structure workshops:

- Higher load-bearing capacity due to strength and rigidity of steel frame.

- Can support heavier cranes and loads.

- Concrete workshops:

- Lower load-bearing capacity due to limitations of concrete structure.

- May not be able to support as heavy cranes and loads.

For both new and existing workshops, it is important to ensure that the building can support the weight and forces of the overhead crane. A structural engineer should evaluate the building structure to determine its suitability for the installation of an overhead crane.

- For new workshops, you have the opportunity to design the building with the overhead crane in mind. This means you can ensure that the building structure is strong enough to support the crane and that the span and height of the crane are appropriate for your needs.

- For existing workshops, it is important to carefully evaluate the building structure to ensure it can support the weight and forces of the overhead crane. A structural engineer can assess the load-bearing capacity of the building and determine if any modifications or reinforcements are necessary.

Span and Height

Another important factor to consider is the span and height of the overhead crane. The span is determined by the distance between the rails on which the crane will travel, while the height is determined by the height of the building and the required lifting height of the load. Steel structure workshops may have larger spans and higher ceilings than concrete workshops, allowing for larger and taller cranes.

- Steel structure workshops:

- May have larger spans and higher ceilings.

- Can accommodate larger and taller cranes.

- Concrete workshops:

- May have smaller spans and lower ceilings.

- May not be able to accommodate as large or tall cranes.

For new workshops, you can design the building with the span and height of the overhead crane in mind. This means you can ensure that there is enough space for the crane to operate effectively.For existing workshops, it is important to accurately measure the span and height to ensure that the selected crane will fit within the existing workshop space. Any obstructions, such as columns or beams, should also be taken into account.

Lifting Capacity

The lifting capacity of the overhead crane is another important factor to consider. This is determined by the maximum weight of the objects to be lifted and the weight of the pick-up mechanism. Steel structure workshops may be able to support cranes with higher lifting capacities due to their higher load-bearing capacity.

- Steel structure workshops:

- Higher load-bearing capacity allows for cranes with higher lifting capacities.

- Concrete workshops:

- Lower load-bearing capacity may limit crane lifting capacities.

Working Level and Speed

The working level and speed of the overhead crane are also important factors to consider. The working level is chosen based on the load status and utilization level, while the working speed is determined by the required speed of lifting, traveling, and trolley movements. These factors may vary between steel structure and concrete workshops depending on their specific operational requirements.

- Steel structure workshops:

- Working level and speed requirements may vary depending on operational needs.

- Concrete workshops:

- Working level and speed requirements may vary depending on operational needs.

Power Supply

The power supply for the overhead crane must also be considered. It must be sufficient to meet the power requirements of the crane's motors and control systems. Steel structure workshops may have different power supply requirements than concrete workshops due to differences in crane size, lifting capacity, and operational requirements.

- Steel structure workshops:

- Power supply requirements may vary depending on crane size, lifting capacity, and operational needs.

- Concrete workshops:

- Power supply requirements may vary depending on crane size, lifting capacity, and operational needs.

Environmental Conditions

Environmental conditions, such as temperature, humidity, and presence of corrosive or explosive materials, must also be taken into account when selecting an overhead crane. These conditions may vary between steel structure and concrete workshops depending on their specific operational requirements.

- Steel structure workshops:

- Environmental requirements may vary depending on operational needs.

- Concrete workshops:

- Environmental requirements may vary depending on operational needs.

Safety Features

Finally, safety features such as overload protection, emergency stop systems, and anti-collision devices are essential for ensuring safe operation of an overhead crane. These features are important for both steel structure and concrete workshops, but their specific requirements may vary depending on the size, lifting capacity, and operational requirements of the crane.

- Steel structure workshops:

- Safety feature requirements may vary depending on crane size, lifting capacity, and operational needs.

- Concrete workshops:

- Safety feature requirements may vary depending on crane size, lifting capacity, and operational needs.

In summary, factors such as building structure, span, height, lifting capacity, working level, speed, power supply, environmental conditions, and safety features may vary between steel structure and concrete workshops when selecting an overhead crane. A professional crane manufacturer or supplier can provide guidance and assistance in selecting the right overhead crane for your specific workshop type. Click to learn more on cranes workshops and crane building.

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

Bridge Cranes runways and rails

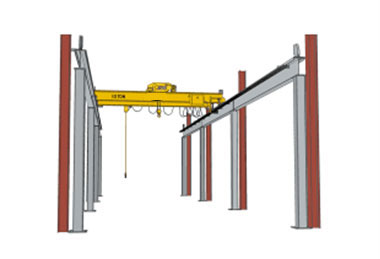

Overhead crane runways are the structural elements of an overhead crane that provide stability and support to the bridge crane structure.

These runways consist of vertical support columns, a bridge girder that supports the rail, and a trolley/hoist assembly. The runway beams offer lateral support to the bridge girder(s) and the rail on which it moves. Overhead crane runways can be built in different configurations, such as top running and underhung.

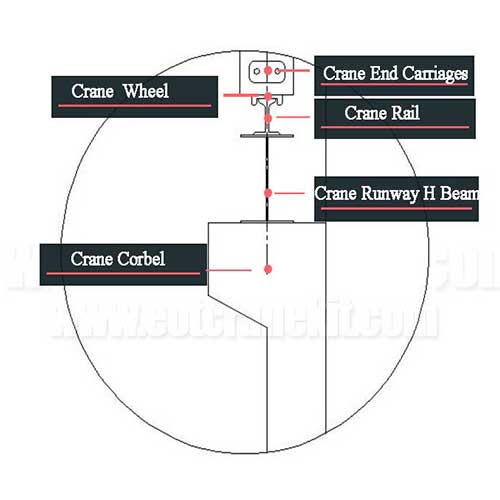

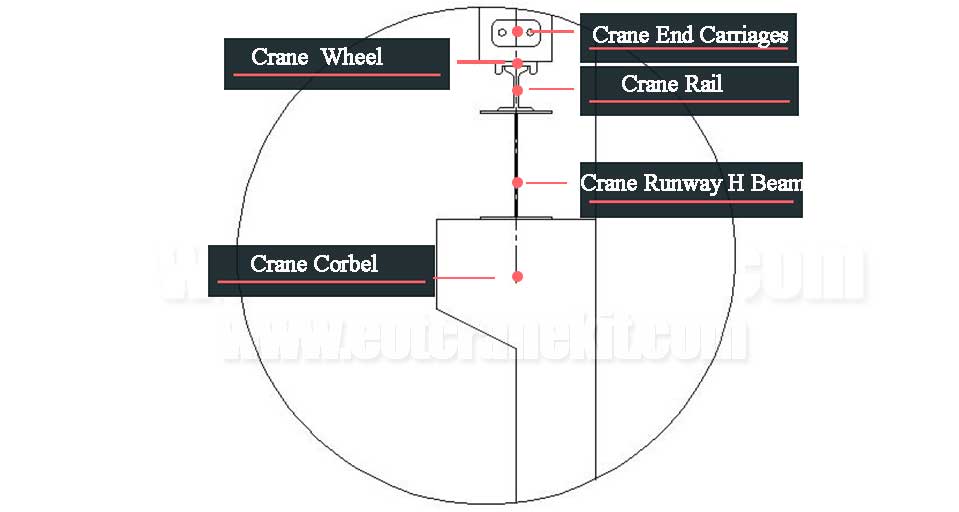

Overhead crane end carriages with wheels running on crane rails

Overhead bridge crane crane rail installation

There are several main types of crane runways, including top-running, underhung, free-standing, and semi-free standing crane runways.

- Top-running crane runways are commonly used for top-running single-girder cranes and top-running double-girder cranes. These runways include a stationary rail mounted to each runway beam, which the end trucks use to transport the bridge and hoist along the crane runway.

- Underhung crane runways utilize a rail mounted under the runway as opposed to on top. This design increases the working range of the crane, making it ideal for spaces with less headroom.

- Free-standing crane runways are self-supporting structures that can be located indoors or outdoors. They do not require support from the building structure and can be used for a variety of overhead crane types.

- Semi-free standing crane runways utilize the structure itself to help support the longitudinal and lateral forces acting on the crane. They do not require as much steel as other designs, making them more cost-effective.

The main components of a crane runway include the vertical support columns, the bridge girder to support the rail, and the trolley/hoist assembly. The crane rail is also an important component of the crane runway, providing a smooth, level surface for the end trucks to travel along. All of these components work together to provide support and rigidity to the bridge crane assembly and ensure safe and efficient operation of the overhead crane.

A semi-free standing crane runway is a type of crane runway that utilizes the structure itself to help support the longitudinal and lateral forces acting on the crane. This type of crane runway is typically used when the building structure is not capable of supporting the full weight and forces of the overhead crane, but can provide some support.

Semi-free standing crane runways do not require as much steel as other designs, making them more cost-effective. They are typically braced back to the building structure to provide additional support and stability.

Some features of semi-free standing crane runways include:

- Utilizes the structure itself to help support the forces acting on the crane

- Does not require as much steel as other designs

- More cost-effective than other designs

- Typically braced back to the building structure for additional support and stability

It is important to carefully evaluate your specific needs and requirements when selecting a crane runway for your overhead crane. A professional crane manufacturer or supplier can provide guidance and assistance in selecting the right type of crane runway for your specific needs.

Free-standing crane runways are self-supporting structures that can be located indoors or outdoors. They do not require support from the building structure and can be used for a variety of overhead crane types.

Features of freestadning crane runways

- Self-supporting structure that can be located indoors or outdoors

- Does not require support from the building structure

- Can be used for a variety of overhead crane types

- A free-standing runway system is used when the building cannot support any loading and footers may be required.

- This type of system requires more steel to fabricate compared to a system that can be tied back.

- Our factory uses moment columns instead of "A" frame columns.

- Moment columns use the foundation to support and stabilize the system.

- No bracing is needed, as there is more steel in the column than in a system tied to the building.

- "A" frame columns may be less expensive, but they take up more space.

- Longitudinal bracing is standard.

Columns mounting

- Footer takes lateral and longitudinal loads imposed on the system.

- Takes up minimal floor space.

- Larger footer design.

- Increases the cost of the system, but the best choice for columns.

Ceiling mounted runways

A ceiling mounted crane runway is a type of crane runway that is mounted to the ceiling of a building. This type of crane runway is typically used for underhung cranes, which are suspended from the ceiling and travel along the bottom flange of the runway beam.

Ceiling mounted crane runways are commonly used in facilities where floor space is limited or where there are obstructions on the floor that would interfere with the operation of a floor-mounted crane. They can also be used to maximize the lifting height of the crane by utilizing the full height of the building.

Ceiling Mounted

Some features of ceiling mounted crane runways include:

- Mounted to the ceiling of a building

- Typically used for underhung cranes

- Ideal for facilities with limited floor space or obstructions on the floor

- Can maximize lifting height by utilizing the full height of the building

- A ceiling mounted crane runway is attached to the building trusses or other support structure.

- Longitudinal bracing is required on both sides.

- Lateral bracing is only required on one side.

- The design of the building and roof trusses may limit the options for a ceiling mounted crane runway.

Crane rails

The crane rail is a key component of the crane runway. It is mounted on top of the runway beam and provides a smooth, level surface for the end trucks of the crane to travel along. The end trucks use the rail to transport the bridge and hoist along the crane runway .

crane rail drawing

Overhead bridge crane rail

Overhead crane rails are tracks that overhead cranes use to move along. These rails are attached to supporting beams, which can be made of steel or concrete. Crane rails come in two types: light rail (P) and heavy rail (QU). P-type railroad rail is used for small and medium tonnage cranes, while QU type crane special rail or square rail is used for large tonnage gantry cranes. There are also special rails designed for specific needs and applications.

- Light rail refers to steel rails weighing less than or equal to 30 kilograms per meter

- Heavy rail refers to steel rails weighing more than 30 kilograms per meter (including overweight machine rails)

- A steel plate is a flat steel material with a large aspect ratio and surface area. According to the thickness, it can be divided into three types: thin plate (thickness <4mm), medium plate (thickness 4-25mm) and thick plate (thickness >25mm). Steel strips are included in the class of steel plates.

Track Model Table | ||||||

light rail, | Model | Height A | Bottom width B | Head width C | Track Waist Thickness | kg/m |

P8 | 65 | 54 | 25 | 7 | 8.42 | |

P12 | 69.85 | 69.85 | 38.1 | 7.54 | 12.2 | |

P15 | 79.37 | 79.37 | 42.86 | 8.33 | 15.2 | |

P18 | 90 | 80 | 40 | 10 | 18.06 | |

P22 | 93.66 | 93.66 | 50.8 | 10.72 | 22.3 | |

P24 | 107 | 92 | 51 | 10.9 | 24.95 | |

P30 | 107.95 | 107.95 | 60.33 | 12.3 | 30.1 | |

heavy rail | Model | Height | Bottom width | Head width | Track Waist Thickness | kg/m |

P38 | 134 | 114 | 68 | 13 | 38.733 | |

P43 | 140 | 114 | 70 | 14.5 | 44.653 | |

P50 | 152 | 132 | 70 | 15.5 | 51.514 | |

How to select crane rail systems

When choosing a crane rail system for your application, several factors need to be considered to ensure optimal performance and safety. Here are some key factors to consider:

- Load requirements: Determine the maximum load capacity and the types of loads your crane rail system will be handling.

- Size of the crane rail: Consider the head width, height, bottom width, and web thickness of the crane rail. The width of the rails head is related to the design of the crane wheel.

- Type of crane rail: Choose between light rail type (P) and heavy rail type (QU) depending on the tonnage of the crane.

- Special needs and applications: Consider if there are any special needs or applications that require a specific type of crane rail.

It may be helpful to consult with a crane rail supplier or manufacturer to determine the best crane rail system for your specific needs. They can provide expert advice and guidance on selecting the right crane rail system for your application.

Matching of Crane wheels and crane rail

To ensure proper matching of crane wheels to crane rails, several factors need to be considered:

- Size of the crane rail: The head width, height, bottom width, and web thickness of the crane rail are related to the design of the crane wheel.

- Hardness of the raw material: The hardness of the raw material used to make the wheels and the heat treating techniques used to enhance the metal's hardness play a role in ensuring proper matching of wheels to tracks.

- Periodic inspection: It is important to periodically inspect cranes, including the wheels, to detect premature wheel wear and correct any issues before they can cause substantial damage.

It may be helpful to consult with a crane rail supplier or manufacturer for specific guidance on ensuring proper matching of crane wheels to crane rails for your application.

Main Projects

22/5 Ton Overhead Crane Double Hook System: Robust double girder crane with 22-ton main and 5-ton auxiliary hooks for heavy lifting. Get double hook crane!

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch