Guide on How to Select Proper Crane Duty for Your Overhead Cranes

Light duty crane or heavy duty crane, how to select the right crane classification duty for your crane to improve efficiency, safety, and productivity?

Category: Crane Basics

Your Trusted Overhead Crane Manufacturer & Supplier

Comprehensive Guide to Selecting the Proper Crane Working Duty

Choosing the right crane working duty might not seem like the most exciting task, but it's a decision that can significantly impact the efficiency, safety, and productivity of your operations.

Overveiw of Crane Duties

Crane working duties are categorized into different classifications based on the intensity of workload they can handle. When a crane builder calculates the duty cycle for your application, they do so using FEM, ASME and CMAA classification systems. FEM classifications are primarily employed in Europe and are the standard for hoist, trolley and bridge duty motion. In North America, crane builders use ASME classifications to provide duty cycle standards for the hoist and CMAA standards for the duty cycle of the trolley and bridge. Each of the following standards are intended to be a guide to manufactures, purchasers or users when defining duty cycles.

Cranes Work duty Classification

Work Duty | Intermittent Service | |||||

| State of loading | FEM | ISO | GB | Cycles/H | Start/H | Ed in % |

| Light | 1DM | M1 | A1 | 15 | 90 | 15 |

| 1CM | M2 | A2 | 20 | 120 | 20 | |

| Moderate | 1BM | M3 | A3 | 25 | 150 | 25 |

| 1AM | M4 | A4 | 30 | 180 | 30 | |

| Heavy | 2M | M5 | A5 | 40 | 240 | 40 |

| 3M | M6 | A6 | 50 | 300 | 50 | |

| Super Heavy | 4M | M7 | A7 | 60 | 360 | 60 |

| 5M | M8 | A8 | 60 | 360 | 60 | |

Crane Duty Classifications in United States and Canada:

In the United States and Canada, various organizations provide standards for defining crane duty classifications, ensuring that lifting equipment meets the specific requirements of different applications. One such organization is the Crane Manufacturers Association of America (CMAA), which outlines duty classifications ranging from Class A to Class F.

| Classification | Description |

|---|---|

| Class A | Standby or infrequent usage, such as cranes found in power utilities or motor rooms, where precise handling of equipment at slow speeds with long idle periods between lifts occurs. |

| Class B | Light service, such as cranes used in repair shops or light warehousing, at slow speeds, with up to five lifts per hour up to maximum rated capacity. |

| Class C | Moderate service, such as those cranes installed in machine shops, including handling an average of 50% of the rated capacity up to 10 times per hour. |

| Class D | Heavy service, such as cranes deployed in heavy machine shops, foundries, container yards, and more, where loads of 50% of the rated capacity are handled constantly. |

| Class E | Severe service, such as cranes found in scrap yards, cement mills, lumber mills, and more, where the crane makes 20 or more lifts per hour at or near its rated capacity. |

| Class F | Continuous severe service, including custom-designed specialty cranes, that handle loads approaching the maximum rated capacity non-stop under extreme conditions. |

You can then use the table below to find your required FEM classification.

Average daily operating time of Light duty to very heavy duty crane based on Iso and fem standards

As you can see on this table, the FEM classification system aligns with the ISO crane duty classification system. The only difference is in the names of the categories: an FEM 1Am category crane is equivalent to an ISO M4 category crane.

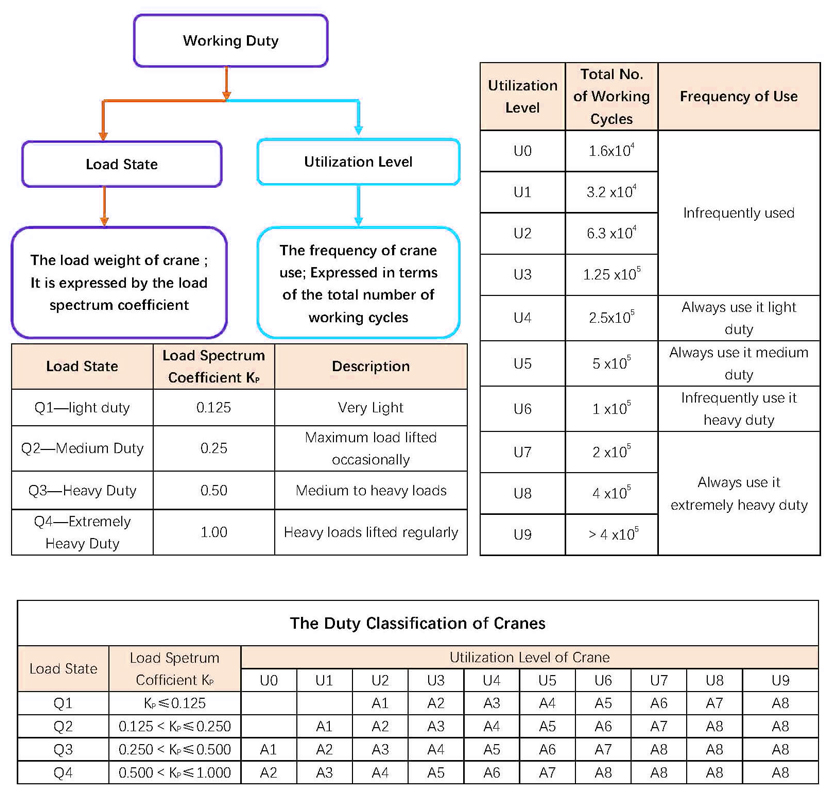

Crane Duty Classifications in China

In China, overhead crane duty classification serves as a primary technical parameter, essentially representing the structural duty classification of the crane. This classification is determined by the lifting mechanism and is denoted by the labels A1 to A8. Specifically, A1 to A4 are considered light duty, A5 and A6 fall into the medium duty category, A7 is classified as heavy duty, and A8 represents extremely heavy duty. These classifications reflect the crane's utilization level, which encompasses the total number of working cycles throughout its entire design life cycle, as well as its load state.

Various countries adopt distinct standards for overhead crane duty classification, with commonly chosen ones including FEA, CMAA, and GB. Despite differences in standards, they share a common load spectrum. For reference, a GB standard table is provided below.

Crane Duty Classifications in China

Classifications of Crane Working Duties

Light Duty:

Light-duty cranes are engineered for tasks involving relatively light loads and infrequent use. Their design prioritizes precision and agility over sheer lifting power, making them suitable for applications where delicate handling and maneuverability are essential. Here are some key characteristics and examples of light-duty cranes:

Characteristics:

Lower lifting capacities compared to heavy-duty counterparts.

Compact and lightweight construction for easy installation and maneuverability.

Designed for intermittent use and occasional lifting tasks.

Versatile and adaptable to various work environments.

Examples:

Small Workshops: Light-duty cranes are commonly used in small workshops where space constraints and occasional lifting requirements are prevalent. These cranes facilitate the handling of lightweight materials, tools, and components with precision and efficiency.

Warehouses: In warehouses with low to moderate lifting demands, light-duty cranes provide a cost-effective solution for loading and unloading goods, organizing inventory, and performing maintenance tasks. They offer flexibility in maneuvering within confined spaces while ensuring safe and efficient material handling operations.

Assembly Lines: Light-duty cranes play a role in assembly line operations, where they assist in positioning and transferring components during manufacturing processes. Their agility and responsiveness enable operators to perform tasks with accuracy and speed, contributing to streamlined production workflows.

Light-duty cranes are ideal for applications where occasional lifting tasks require a balance of performance, affordability, and versatility. By selecting light-duty cranes tailored to their specific requirements, businesses can optimize efficiency, enhance workplace safety, and meet operational needs with precision and agility.

Moderate Duty:

Moderate-duty cranes serve as versatile workhorses capable of handling a diverse range of loads across various applications. They strike a balance between load capacity and frequency of use, making them suitable for a wide array of industrial settings. Here are the key characteristics and applications of moderate-duty cranes:

Characteristics:

Moderate lifting capacities, typically higher than light-duty cranes but lower than heavy-duty counterparts.

Designed to withstand moderate to frequent use, offering a reliable solution for ongoing lifting tasks.

Versatility in handling different loads and adapting to changing operational requirements.

Robust construction and durable components for enhanced longevity and performance.

Applications:

Manufacturing Facilities: Moderate-duty cranes are commonly deployed in manufacturing facilities where they play a crucial role in material handling and production processes. From moving raw materials and components to positioning finished products, these cranes contribute to the efficiency and productivity of assembly lines and manufacturing operations.

Construction Sites: In construction environments, moderate-duty cranes are utilized for lifting and positioning building materials, equipment, and structures. Whether it's lifting steel beams on high-rise construction projects or transporting heavy machinery on job sites, these cranes provide the versatility and reliability required to meet the demands of construction operations.

Warehouses and Distribution Centers: Moderate-duty cranes are integral to warehouse and distribution center operations, where they facilitate the movement of goods, pallets, and containers. These cranes are employed for tasks such as loading and unloading trucks, stacking and retrieving inventory, and optimizing storage space within the facility. Their versatility and adaptability make them essential for maintaining efficient warehouse logistics and maximizing throughput.

Moderate-duty cranes offer a versatile and reliable solution for a wide range of industrial applications. Their ability to handle moderate loads with efficiency and durability makes them indispensable assets in manufacturing, construction, and warehousing environments. By selecting moderate-duty cranes tailored to their specific operational requirements, businesses can optimize productivity, streamline material handling processes, and achieve operational excellence.

Heavy Duty:

Heavy-duty cranes are purpose-built to handle substantial loads and endure the rigors of continuous operation in demanding industrial environments. Designed with robust components and mechanisms, these cranes excel in lifting heavy materials and equipment with precision and reliability. Here are the key characteristics and industries that rely on heavy-duty cranes:

Characteristics:

High lifting capacities, capable of handling heavy loads ranging from several tons to hundreds of tons.

Built with rugged construction and reinforced components to withstand the stress of lifting heavy materials.

Engineered for continuous operation, with durable mechanisms and systems that ensure reliability and longevity.

Equipped with advanced safety features and overload protection systems to mitigate risks associated with heavy lifting.

Industries:

Steel Fabrication Plants: Heavy-duty cranes play a pivotal role in steel fabrication plants, where they are used for handling raw materials, semi-finished products, and finished steel components. These cranes are essential for lifting heavy steel beams, plates, coils, and structures throughout the fabrication process, including cutting, welding, bending, and assembly operations.

Mining Operations: In mining environments, heavy-duty cranes are utilized for various tasks such as ore extraction, material handling, and equipment maintenance. These cranes are deployed in surface mining operations, underground mines, and processing plants to lift heavy machinery, vehicles, and bulk materials such as coal, ore, and minerals.

Shipyards: Shipbuilding and repair facilities rely on heavy-duty cranes for lifting ship components, modules, and sections during construction and maintenance projects. These cranes are essential for handling ship hulls, propulsion systems, decks, and other large-scale components with precision and efficiency.

Heavy-duty cranes are indispensable assets in industries that require the lifting of heavy materials and equipment. Their robust design, high lifting capacities, and reliability make them ideal for demanding applications where safety, efficiency, and productivity are paramount. By investing in heavy-duty cranes tailored to their specific operational needs, businesses can optimize performance, minimize downtime, and ensure the success of their operations in challenging environments.

Severe Duty:

Severe-duty cranes represent the pinnacle of crane engineering, designed to operate flawlessly in the most extreme and challenging conditions. These cranes are built to withstand continuous, high-intensity operations where reliability, durability, and safety are of utmost importance. Here are the key characteristics and applications of severe-duty cranes:

Characteristics:

Exceptional durability and reliability, with robust construction and heavy-duty components capable of enduring harsh operating conditions.

Engineered for continuous operation in extreme environments, including high temperatures, corrosive atmospheres, and heavy dust or debris.

Advanced safety features and redundant systems to ensure the protection of personnel and equipment during high-intensity lifting tasks.

Precision engineering and high-performance mechanisms to maintain accuracy and efficiency under demanding operational requirements.

Applications:

Foundries: Severe-duty cranes are essential in foundry operations where they are subjected to extreme temperatures, heavy loads, and corrosive atmospheres. These cranes are used for handling molten metal, molds, and heavy castings throughout the production process, including pouring, cooling, and finishing operations.

Aerospace Manufacturing: In aerospace manufacturing facilities, severe-duty cranes are employed for lifting and positioning large aircraft components, engines, and assemblies. These cranes operate in cleanroom environments and are designed to meet stringent safety and quality standards while providing precise control and reliability.

Offshore Drilling Platforms: Severe-duty cranes play a critical role on offshore drilling platforms, where they are used for lifting heavy equipment, supplies, and personnel between the platform and supply vessels. These cranes operate in challenging offshore environments characterized by high winds, saltwater exposure, and dynamic load conditions, requiring robust construction and advanced safety features.

Severe-duty cranes are indispensable assets in industries where the operating conditions are exceptionally demanding. Their ability to withstand extreme environments and maintain high levels of performance and reliability make them essential for critical lifting operations in foundries, aerospace manufacturing, offshore drilling, and other specialized applications. By investing in severe-duty cranes engineered to meet their specific operational requirements, businesses can ensure the safety, efficiency, and success of their operations in the most challenging environments.

Factors Influencing the Selection of Working Duty

The selection of crane working duty is influenced by various factors, each playing a crucial role in determining the optimal duty classification. Let's delve deeper into these factors:

Load Capacity:

The primary function of a crane is to lift and move materials safely and efficiently. The weight of the materials being lifted directly impacts the required lifting capacity of the crane. Whether it's handling lightweight components or heavy machinery, selecting a crane with the appropriate load capacity ensures smooth and reliable lifting operations.

The load capacity of a crane is its ability to lift and transport materials safely and efficiently. It is one of the most critical factors to consider when selecting a crane for a specific application. Here's why load capacity is essential:

- Primary Function: The primary purpose of a crane is to lift and move materials. The load capacity determines the maximum weight that the crane can lift without exceeding its structural limitations or compromising safety.

- Safety: Exceeding the load capacity of a crane can lead to equipment failure, structural damage, and potential accidents. Selecting a crane with a sufficient load capacity ensures that lifting operations can be conducted safely without risking overloading or instability.

- Efficiency: Choosing a crane with the appropriate load capacity enhances operational efficiency by allowing for the handling of materials in a single lift, minimizing the need for multiple lifts or manual handling methods.

- Application Specific: Different applications require cranes with varying load capacities to accommodate the weight of the materials being lifted. Whether it's lifting lightweight components in a manufacturing plant or heavy machinery in a construction site, selecting a crane with the right load capacity is essential for meeting the specific requirements of the application.

- Smooth Operation: Cranes operate most effectively within their designed load capacities. Operating within the crane's rated load ensures smooth and reliable lifting operations, minimizing downtime and maximizing productivity.

In summary, the load capacity of a crane is a fundamental consideration in crane selection, ensuring safety, efficiency, and optimal performance in lifting operations across various industries and applications.

Relationship between Crane Duty and Crane Capacity:

- Crane Duty: Crane duty classification is a vital aspect of crane design and selection, encompassing factors such as operational demands, environmental conditions, and usage frequency. It categorizes cranes into different classes, ranging from light-duty (Class A) to severe-duty (Class F), based on their intended application. This classification ensures that the crane is designed and constructed to meet the specific requirements of its operating environment and workload. Factors considered in crane duty classification include the frequency of crane use, the intensity of operation, and the harshness of the operating environment.

- Crane Capacity: Crane capacity refers to the maximum load weight that a crane can safely lift and transport. It is determined by the crane's structural strength, mechanical components, and lifting mechanisms. Crane capacity is crucial for ensuring safe lifting operations and preventing overloading, which can lead to equipment damage, accidents, and injuries. Capacity specifications consider both static and dynamic loads, accounting for factors such as load distribution, impact forces, and safety margins.

While crane duty and crane capacity are related, they represent distinct aspects of crane design and performance. Higher-duty cranes typically have higher lifting capacities to meet the demands of more intensive operations. However, the relationship between duty and capacity is not always linear. Some cranes may have high lifting capacities but lower duty classifications if they are designed for infrequent or specialized usage. Conversely, cranes with lower lifting capacities may have higher duty classifications if they are engineered for continuous or high-frequency operation in demanding environments.

In summary, crane duty and crane capacity are essential considerations when selecting a crane for a specific application. While they are related, they represent different facets of crane performance, each influencing the suitability and effectiveness of the crane for its intended use. By understanding the interplay between duty classification and capacity specifications, businesses can make informed decisions to ensure optimal crane performance and safety in their operations.

Frequency of Use:

How often the crane will be in operation is a key determinant of its duty cycle. Cranes used for frequent lifting tasks require higher-duty classifications to withstand the rigors of continuous operation. Conversely, cranes used infrequently or for lighter lifting tasks may be suitable for lower-duty classifications. Understanding the frequency of crane use helps in selecting a duty classification that matches the operational demands.

The frequency of crane operation is a crucial factor in determining its duty cycle and selecting the appropriate duty classification. Here's why the frequency of use is essential:

- Duty Cycle Determination: The duty cycle of a crane, which refers to its intended usage pattern and workload capacity, is directly influenced by how often the crane will be in operation. Cranes used for frequent lifting tasks require higher-duty classifications to withstand the rigors of continuous operation, while those used infrequently or for lighter lifting tasks may be suitable for lower-duty classifications.

- Operational Demands: Understanding the frequency of crane use helps in assessing the operational demands placed on the crane. Cranes operating in environments with high usage rates and continuous lifting tasks, such as manufacturing plants or construction sites, require heavy-duty classifications to ensure reliability, durability, and safety under demanding conditions.

- Optimizing Performance: Selecting a duty classification that matches the frequency of crane use optimizes performance and extends the crane's service life. Overloading or operating a crane beyond its intended duty cycle can lead to premature wear and tear, increased maintenance requirements, and potential safety hazards. By aligning the duty classification with the frequency of use, crane operators can maximize efficiency and minimize downtime.

- Cost Considerations: Matching the duty classification to the frequency of crane use helps in balancing performance requirements with cost considerations. Investing in a higher-duty classification than necessary for infrequently used cranes may result in unnecessary expenses, while selecting a lower-duty classification for high-frequency use can lead to premature equipment failure and increased long-term costs.

In summary, understanding the frequency of crane use is essential for selecting the appropriate duty classification that aligns with operational demands, optimizes performance, and ensures the safety and reliability of lifting operations. By assessing the frequency of crane use upfront, businesses can make informed decisions when choosing the right crane for their specific application requirements.

Operating Environment:

Environmental conditions have a significant impact on crane performance and longevity. Factors such as temperature, humidity, and exposure to corrosive substances can affect the crane's structural integrity, electrical components, and mechanical systems. Cranes operating in harsh environments, such as outdoor construction sites or chemical processing plants, may require higher-duty classifications and specialized coatings or materials to withstand these conditions effectively.

The operating environment plays a critical role in determining the performance and longevity of a crane. Here's why considering the operating environment is essential:

- Impact on Crane Performance: Environmental factors such as temperature, humidity, and exposure to corrosive substances can affect various aspects of crane operation, including structural integrity, electrical components, and mechanical systems. Extreme temperatures can cause expansion and contraction of crane components, affecting their functionality and reliability. High humidity levels can promote corrosion and rust formation, leading to premature deterioration of crane materials and components.

- Selection of Duty Classification: Cranes operating in harsh environments, such as outdoor construction sites, chemical processing plants, or marine terminals, may require higher-duty classifications to withstand the rigors of these conditions effectively. Higher-duty classifications feature robust construction, corrosion-resistant materials, and specialized coatings to enhance durability and longevity in challenging environments. By selecting the appropriate duty classification based on the operating environment, businesses can ensure the reliability and safety of crane operations.

- Specialized Coatings and Materials: In addition to selecting the right duty classification, cranes operating in harsh environments may benefit from specialized coatings or materials designed to withstand specific environmental challenges. For example, cranes operating in coastal areas or chemical processing plants may require corrosion-resistant coatings to protect against saltwater exposure or chemical fumes. Similarly, cranes operating in high-temperature environments may require heat-resistant materials to prevent degradation and maintain performance.

- Maintenance Requirements: Environmental factors can also influence crane maintenance requirements. Cranes operating in harsh environments may require more frequent inspections, cleaning, and preventive maintenance to mitigate the effects of environmental wear and tear. Implementing a proactive maintenance program tailored to the specific operating environment helps prolong crane service life, minimize downtime, and ensure safe and reliable operation.

In summary, considering the operating environment is essential for selecting the appropriate duty classification and implementing measures to enhance crane performance and longevity. By understanding the environmental challenges faced by the crane and implementing proactive maintenance practices, businesses can optimize crane reliability, safety, and efficiency in diverse operating conditions.

Safety Requirements:

Safety is paramount in crane operations, and compliance with safety regulations and standards is essential to protect personnel and equipment from accidents and hazards. Different industries and jurisdictions have specific safety requirements governing crane design, installation, operation, and maintenance. Selecting a crane with the appropriate duty classification ensures compliance with safety standards and minimizes the risk of accidents due to overload or structural failure.

Safety is paramount in crane operations, and adherence to safety regulations and standards is essential to protect personnel and equipment from accidents and hazards. Here's why considering safety requirements is crucial:

- Regulatory Compliance: Different industries and jurisdictions have specific safety regulations and standards governing crane design, installation, operation, and maintenance. These regulations are put in place to ensure the safety of workers, prevent accidents, and mitigate risks associated with crane operations. Selecting a crane with the appropriate duty classification ensures compliance with these safety standards, minimizing the risk of non-compliance penalties and legal liabilities.

- Personnel Safety: The safety of crane operators, riggers, and other personnel involved in crane operations is of utmost importance. Cranes with higher-duty classifications are engineered with robust structural components, advanced safety features, and redundant systems to enhance personnel safety and mitigate the risk of accidents due to overload or structural failure. Additionally, safety devices such as limit switches, overload protection, and emergency stop systems are integral to crane design to prevent hazardous situations and protect personnel from harm.

- Equipment Safety: In addition to personnel safety, ensuring the safety of crane equipment is essential for preventing damage, downtime, and costly repairs. Cranes operating within their designated duty classifications are less likely to experience overload, fatigue, or structural failure, reducing the risk of equipment damage and associated safety hazards. Regular inspections, preventive maintenance, and adherence to manufacturer's recommendations further enhance equipment safety and reliability.

- Risk Mitigation: Selecting a crane with the appropriate duty classification helps mitigate risks associated with crane operations, including structural failure, overloading, and operational errors. By choosing a crane that is designed and rated for the intended application and workload, businesses can minimize the likelihood of accidents and ensure safe and efficient lifting operations.

In summary, safety requirements are integral to crane selection and operation, and compliance with safety regulations and standards is essential to protect personnel and equipment from accidents and hazards. Selecting a crane with the appropriate duty classification ensures compliance with safety requirements, enhances personnel and equipment safety, and mitigates risks associated with crane operations, contributing to a safer work environment and improved productivity.

Cost Considerations:

Budget constraints often play a significant role in the selection process, balancing performance requirements with financial feasibility. While higher-duty classifications offer enhanced performance and durability, they may come at a higher initial cost. Conversely, lower-duty classifications may be more cost-effective but may require more frequent maintenance and replacement over time. Businesses must weigh the upfront investment against long-term operating costs to determine the most cost-effective solution for their specific needs and budget.

Budget constraints are a critical factor in the selection process when choosing a crane, requiring a balance between performance requirements and financial feasibility. Here's why considering cost is essential:

- Initial Investment: Higher-duty classifications typically offer enhanced performance, durability, and safety features but may come with a higher initial investment cost. These cranes are engineered with robust construction, advanced technology, and additional safety mechanisms to withstand demanding operational conditions. While the upfront cost may be higher, businesses must evaluate the long-term benefits and return on investment (ROI) provided by these cranes in terms of improved productivity, reduced downtime, and lower maintenance expenses.

- Operating Costs: Lower-duty classifications may offer a more cost-effective solution upfront but may incur higher long-term operating costs due to increased maintenance, repairs, and potential downtime. These cranes may require more frequent inspections, preventive maintenance, and component replacements, leading to higher ongoing expenses over the crane's lifecycle. Businesses must consider the total cost of ownership, including maintenance, energy consumption, and downtime costs, when evaluating the financial implications of different duty classifications.

- Lifecycle Cost Analysis: Conducting a lifecycle cost analysis helps businesses assess the total cost of ownership over the crane's lifespan, taking into account initial purchase price, maintenance costs, operational expenses, and potential savings or losses associated with downtime. By comparing the total cost of ownership for different duty classifications, businesses can make informed decisions about the most cost-effective solution that aligns with their specific needs and budget constraints.

- Value Proposition: While cost is an essential consideration, businesses should also consider the value proposition offered by different duty classifications. Investing in higher-duty classifications may provide long-term benefits in terms of improved performance, reliability, safety, and operational efficiency, resulting in a higher overall ROI over the crane's lifespan. Businesses should weigh the upfront investment against the potential long-term benefits and savings when selecting the most suitable crane for their operations.

In summary, cost considerations are integral to crane selection, requiring businesses to evaluate the upfront investment, long-term operating costs, and overall value proposition provided by different duty classifications. By conducting a thorough cost analysis and considering factors such as performance, durability, and safety, businesses can make informed decisions that maximize ROI and meet their specific needs and budget requirements.

By carefully considering these factors, businesses can make informed decisions when selecting the appropriate crane working duty for their specific needs and applications. A thorough understanding of load requirements, operational demands, environmental conditions, safety considerations, and budget constraints ensures that the selected crane meets performance expectations, enhances safety, and delivers long-term value.

Determining the Operating Group of the Hoist

Determining the operating group of a hoist involves evaluating its duty cycle, load capacity, and frequency of use. This classification system helps match hoists to specific applications, ensuring safe and efficient operation. Operating groups range from light-duty to heavy-duty, with each group indicating the hoist's intended workload and performance capabilities. By accurately determining the operating group of a hoist, users can make informed decisions regarding its selection, maintenance, and usage, ultimately enhancing productivity and safety in various industrial settings.

According to the Average daily operating time to separate the lifting mechanism work duty:

Work Duty | Average daily operating time (hours per day) | |||||

≤0.5 | ≤ 1 | ≤ 2 | ≤ 4 | ≤ 8 | ≤ 16 | |

Light duty | M3 | M4 | M5 | M6 | ||

| Moderate | M3 | M4 | M4 | M6 | M7 | |

Heavy | M3 | M4 | M5 | M6 | M7 | |

Super heavy | M4 | M5 | M6 | M7 | ||

How to calculate the Average daily operating time ?

To calculate the average daily operating time of the hoist, you need to know the running time of the hoisting machinery in hours per day. This figure represents the total duration the hoist operates within a 24-hour period. For example, if the hoisting machinery runs for 8 hours per day, the average daily operating time of the hoist is 8 hours. Simply measure or estimate the number of hours the hoist is in operation each day to determine its average daily operating time accurately.

The average daily operating time of the hoist can be calculated from the running time of the hoisting machinery (hours per day):

t = (2 × H ×N × T) ÷ (V × 60)

- T:Average Daily Operating time.

- H:Average lifting height (meter)

- N:Number of Work Cycles Per Hour (cycles/h)

- T:Daily working time (h)

- V:Lifting Speed (m/min)

Assessing Client Requirements

Before selecting the right crane working duty for a client, it's essential to thoroughly assess their requirements. This involves understanding their industry sector, specific lifting needs and applications, as well as environmental factors that may impact crane operations.

Identifying the Client's Industry Sector

Understanding the client's industry sector is crucial in determining the most suitable crane solution tailored to their specific requirements. Let's delve deeper into how different industries have unique demands when it comes to crane operations:

- Manufacturing: In the manufacturing sector, efficient material handling is essential for maintaining production schedules and meeting quality standards. Clients may require cranes capable of handling heavy loads with precision and efficiency to streamline assembly processes. For example, overhead cranes equipped with specialized lifting attachments are commonly used in automotive assembly plants to lift and position large components such as engines, chassis, and body panels. These cranes enable seamless integration into assembly lines, ensuring smooth and uninterrupted production.

- Construction: The construction industry presents unique challenges due to the dynamic nature of building projects and the need to lift materials to great heights in confined spaces. Clients in this sector require cranes that can maneuver in tight spaces and lift heavy materials with precision and reliability. Tower cranes are a common sight on high-rise building sites, offering exceptional height and lifting capacity to facilitate vertical construction. Their tall, slender design and ability to reach over obstacles make them indispensable for lifting materials to elevated work areas, contributing to the efficient completion of construction projects.

- Warehousing: Efficient material handling is critical in warehousing and distribution centers, where the timely movement of goods is essential for meeting customer demands. Clients in this sector may require cranes optimized for space efficiency and rapid material handling to maximize storage capacity and throughput. Gantry cranes are commonly used in distribution centers for loading and unloading goods from trucks and organizing inventory within the warehouse. Their versatility, mobility, and ability to span large distances make them ideal for handling a wide range of products with speed and precision, ensuring efficient warehouse operations.

By identifying the client's industry sector and understanding their specific requirements, crane solutions can be tailored to meet the unique demands of each industry. Whether it's optimizing production processes in manufacturing plants, facilitating vertical construction in the building industry, or maximizing storage efficiency in warehousing facilities, selecting the right crane solution ensures optimal performance, productivity, and safety for clients across various industries.

The Client's Specific Lifting Needs and Applications

Understanding the client's specific lifting needs and applications is paramount in recommending the most suitable crane working duty. Let's explore how different requirements translate into varying duty classifications:

- Heavy-duty Cranes: Clients with operations involving the lifting of large machinery components or heavy materials require cranes with robust lifting capabilities. Heavy-duty cranes are designed to handle substantial loads and endure frequent use in demanding environments. In manufacturing plants, heavy-duty overhead cranes are essential for lifting and maneuvering heavy machinery components such as engines, chassis, and industrial equipment. These cranes are engineered with sturdy structures, powerful hoisting mechanisms, and reinforced components to ensure reliable performance and safety during heavy lifting operations.

- Light-duty Cranes: For clients with occasional lifting tasks or smaller-scale operations, light-duty cranes may be sufficient to meet their requirements. Light-duty cranes are designed for lighter loads and intermittent use, making them suitable for applications in small workshops, maintenance facilities, or warehouses. These cranes offer versatility and agility, allowing for precise handling of lightweight materials and components. Examples include light-duty overhead cranes used for loading and unloading goods from trucks or moving materials within confined spaces.

- Severe-duty Cranes: Clients operating in harsh environments or requiring continuous crane operation may necessitate severe-duty cranes to withstand the rigors of their working conditions. Severe-duty cranes are engineered for high-intensity operations in extreme environments such as foundries, steel mills, or mining sites. These cranes are built with specialized materials, coatings, and components to resist corrosion, abrasion, and environmental factors. They offer unmatched reliability and durability, ensuring uninterrupted performance even in the most challenging applications.

By understanding the client's specific lifting needs and applications, you can recommend the most suitable crane working duty that aligns with their operational requirements and performance expectations. Whether it's lifting heavy machinery components in manufacturing plants, handling occasional tasks in workshops, or operating continuously in harsh environments, selecting the right duty classification ensures optimal crane performance, safety, and efficiency for clients across diverse industries and applications.

Considering Environmental Factors

Environmental conditions play a critical role in determining the suitability of crane solutions for specific applications. Let's explore how various environmental factors can impact crane performance and longevity, and the considerations to keep in mind:

- Temperature: Extreme temperatures can affect crane components and materials, leading to accelerated wear and potential malfunctions. In high-temperature environments, such as steel mills or foundries, cranes may be subjected to intense heat, which can degrade lubricants, weaken structural elements, and impair electrical systems. Conversely, in cold environments, such as freezer warehouses or arctic regions, cranes may experience issues with lubricant viscosity, hydraulic fluid performance, and component stiffness. Selecting cranes with temperature-rated components and implementing appropriate cooling or heating systems can mitigate the effects of temperature extremes and ensure reliable crane operation.

- Humidity: High humidity levels can promote corrosion and rust formation on crane components, particularly in coastal or humid environments. Cranes operating in these conditions may require corrosion-resistant coatings, stainless steel hardware, and regular maintenance to prevent degradation and extend service life. Additionally, humidity can affect electrical components and systems, leading to issues such as moisture ingress, insulation breakdown, and electrical shorts. Implementing proper moisture protection measures and periodic inspections can help safeguard crane electrical systems from humidity-related damage.

- Exposure to Corrosive Substances: Cranes operating in environments with exposure to corrosive substances, such as chemicals, saltwater, or industrial pollutants, are susceptible to corrosion and degradation. Corrosion-resistant materials, protective coatings, and frequent cleaning are essential for preserving crane integrity and preventing premature deterioration. Regular inspections and maintenance routines should include corrosion checks and remedial actions to address any signs of corrosion or material degradation promptly.

Considering these environmental factors when assessing client requirements ensures that crane solutions are tailored to withstand the specific challenges posed by the operating environment. Whether it's implementing weatherproofing measures for outdoor cranes, installing cooling systems for high-temperature environments, or employing corrosion-resistant materials for corrosive environments, proactive measures can enhance crane performance, longevity, and reliability in diverse environmental conditions. By addressing environmental considerations upfront, clients can minimize downtime, maintenance costs, and potential safety hazards associated with environmental-related issues, ensuring optimal crane operation and productivity.

By thoroughly assessing the client's requirements and considering factors such as industry sector, lifting needs, and environmental conditions, you can recommend the most appropriate crane working duty to meet their specific needs and ensure optimal performance and safety.

Types of Cranes and Their Corresponding Duties

When it comes to lifting and moving heavy loads, various types of cranes are available, each designed to fulfill specific requirements. Let's explore the different types of cranes and their corresponding duties:

Overhead Cranes

Overhead cranes, also known as bridge cranes, are versatile lifting devices commonly used in industrial settings. They consist of a horizontal beam (bridge) that travels along elevated runways, supported by end trucks. Base on the crane duty classifications,they can be classifed into Light-duty Overhead Cranes,,Moderate-duty Overhead Cranes, Heavy-duty Overhead Cranes and Severe-duty Overhead Cranes.

In China, light-duty overhead cranes are classified as A1-A4, moderate-duty as A5-A6, heavy-duty as A7, and severe-duty as A8. In the USA, they are categorized as Class A-B for light-duty, Class C for moderate-duty, Class D for heavy-duty, and Class E-F for severe-duty. In Europe, the equivalents are FEM 1Dm/1Cm for light-duty, FEM 1Bm for moderate-duty, FEM 2m for heavy-duty, and FEM 3m for severe-duty.

| Classification | China | USA | Europe |

|---|---|---|---|

| Light-duty | A1-A4 | Class A-B | FEM 1Dm/1Cm |

| Moderate-duty | A5-A6 | Class C | FEM 1Bm |

| Heavy-duty | A7 | Class D | FEM 2m |

| Severe-duty | A8 | Class E-F | FEM 3m |

These classifications provide an overview of the typical duty classifications for each type of overhead crane based on standards set by different countries and organizations.

And the features and typical applications of each type of overhead crane are as following:

Light-duty Overhead Cranes:

These cranes are designed for light lifting tasks and infrequent use. They are suitable for applications where precision and agility are more critical than lifting capacity.

Features:

Lightweight construction for easy maneuverability and installation.

Simple design with basic lifting mechanisms.

Typically equipped with single-speed hoists for light lifting tasks.

Suitable for low-intensity operations and occasional use.

Typical Applications:

Small workshops and garages for lifting lightweight materials and components.

Retail stores or warehouses for occasional stock handling.

Assembly lines for precise positioning of parts during manufacturing processes.

Moderate-duty Overhead Cranes:

Moderate-duty cranes are the workhorses of industrial operations, capable of handling a wide range of loads in various applications. They strike a balance between load capacity and frequency of use, making them suitable for most industrial settings.

Features:

Versatile design capable of handling a wide range of loads.

Balanced combination of load capacity and operational frequency.

Equipped with dual-speed hoists for enhanced efficiency and productivity.

Robust construction with durable components for reliable performance.

Typical Applications:

Manufacturing facilities for general material handling and production tasks.

Warehouses and distribution centers for stock replenishment and order fulfillment.

Construction sites for lifting and positioning building materials such as steel beams and concrete panels.

Heavy-duty Overhead Cranes:

Heavy-duty cranes are built to handle substantial loads and endure frequent use in demanding environments. They are designed with robust components and mechanisms to withstand the rigors of continuous operation.

Features:

High load capacity to handle substantial weights with ease.

Designed for continuous operation in demanding environments.

Heavy-duty components and structural reinforcements for durability.

Equipped with advanced safety features and overload protection systems.

Typical Applications:

Steel fabrication plants for lifting heavy steel structures and components.

Mining operations for ore extraction and material handling.

Shipyards for assembling and launching large vessels and ship components.

Severe-duty Overhead Cranes:

Severe-duty cranes are engineered for continuous, high-intensity operations in extreme conditions. They offer unmatched reliability and durability, making them ideal for applications where downtime is not an option.

Features:

Engineered for extreme conditions and high-intensity operations.

Superior reliability and durability to minimize downtime.

Specialized coatings and materials for corrosion resistance and longevity.

Advanced safety systems and redundant components for enhanced protection.

Typical Applications:

Foundries and metal processing plants for handling molten metal and heavy castings.

Aerospace manufacturing facilities for lifting large aircraft components and assemblies.

Offshore drilling platforms for material handling and equipment maintenance in harsh marine environments.

Each type of overhead crane offers unique features and capabilities tailored to specific operational requirements and environments. By understanding the distinct characteristics and typical applications of light-duty, moderate-duty, heavy-duty, and severe-duty overhead cranes, businesses can select the most suitable crane for their needs, ensuring efficient and reliable lifting operations.

Gantry Cranes

Gantry cranes, also known as portal cranes, are similar to overhead cranes but are supported by legs that run on ground-level rails or wheels. They are commonly used in outdoor environments such as shipyards, construction sites, and storage yards. Gantry cranes are classified into two main categories based on their duty classification: Light-duty Gantry Cranes and Heavy-duty Gantry Cranes.

Here's how the classifications of light-duty and heavy-duty gantry cranes compare across China, the USA, and Europe:

| Classification | China | USA | Europe |

|---|---|---|---|

| Light-duty Gantry Crane | A1-A4 | Class A-B | FEM 1Dm/1Cm |

| Heavy-duty Gantry Crane | A5-A8 | Class C-F | FEM 2m-5m |

In China, light-duty gantry cranes are classified as A1-A4, while heavy-duty gantry cranes fall under A5-A8. In the USA, light-duty gantry cranes are categorized as Class A-B, and heavy-duty gantry cranes are grouped as Class C-F. In Europe, light-duty gantry cranes are equivalent to FEM 1Dm/1Cm, while heavy-duty gantry cranes range from FEM 2m to FEM 5m.

The features and typical applications of both light-duty and heavy-duty gantry cranes:

Light-duty Gantry Cranes:

These cranes are designed for light lifting tasks and occasional use. They are often used in small workshops or outdoor storage yards for loading and unloading lightweight materials. Examples include single girder gantry cranes with lower duty classifications.

Features:

Lightweight construction for easy portability and installation.

Simple design with basic lifting mechanisms.

Typically equipped with single girder configuration for lighter lifting tasks.

Suitable for infrequent use and low-intensity operations.

Typical Applications:

Small workshops and garages for loading and unloading lightweight materials such as pallets and boxes.

Outdoor storage yards for handling goods and materials during temporary storage or transportation.

Retail or wholesale warehouses for occasional stock handling and order picking.

Heavy-duty Gantry Cranes:

Heavy-duty gantry cranes are built to handle heavy loads and endure frequent use in demanding environments. They are commonly used in industries such as construction, shipping, and material handling. Examples include double girder gantry cranes with higher duty classifications.

Features:

Robust construction with heavy-duty components and structural reinforcements.

Designed to handle substantial loads with ease and endurance.

Often equipped with double girder configuration for increased lifting capacity and stability.

Built for continuous operation in demanding industrial environments.

Typical Applications:

Construction sites for lifting and positioning heavy building materials such as steel beams, concrete panels, and prefabricated modules.

Shipping terminals and ports for loading and unloading cargo containers and oversized freight.

Material handling facilities for moving large and heavy equipment, machinery, and components within manufacturing plants or warehouses.

Each type of gantry crane offers distinct features and capabilities suited to specific lifting requirements and operational conditions. By understanding the characteristics and typical applications of light-duty and heavy-duty gantry cranes, businesses can select the most appropriate crane for their needs, ensuring efficient and reliable material handling operations.

Jib Cranes

Jib cranes consist of a horizontal boom (jib) that is mounted to a vertical mast or wall-mounted pillar. They are versatile lifting devices commonly used in workshops, warehouses, and manufacturing facilities. Jib cranes are classified into two main categories based on their duty classification: Light-duty Jib Cranes and Heavy-duty Jib Cranes.

Here's a comparison of the classifications of light-duty and heavy-duty jib cranes across China, the USA, and Europe:

| Classification | China | USA | Europe |

|---|---|---|---|

| Light-duty | A1-A4 | Class A-B | FEM 1Dm/1Cm |

| Heavy-duty | A5-A8 | Class C-F | FEM 2m-5m |

In China, light-duty jib cranes are classified as A1-A4, while heavy-duty jib cranes fall under A5-A8. In the USA, light-duty jib cranes are categorized as Class A-B, and heavy-duty jib cranes are grouped as Class C-F. In Europe, light-duty jib cranes are equivalent to FEM 1Dm/1Cm, while heavy-duty jib cranes range from FEM 2m to FEM 5m.

The features and typical applications of light-duty and heavy-duty jib cranes:

Light-duty Jib Cranes:

These cranes are designed for light lifting tasks and occasional use. They are often used in small workshops or manufacturing cells for loading and unloading lightweight materials. Examples include wall-mounted or floor-mounted jib cranes with lower duty classifications.

Features:

Lightweight and compact design for easy installation and maneuverability.

Simple yet robust construction suitable for light lifting tasks.

Available in wall-mounted or floor-mounted configurations to suit various workspace layouts.

Equipped with a single jib arm for lifting lightweight materials with precision.

Typical Applications:

Small workshops or manufacturing cells for loading and unloading lightweight materials such as components, tools, and parts.

Assembly lines for positioning and transferring small components during production processes.

Maintenance areas or repair shops for lifting and handling tools, equipment, and machinery parts.

Heavy-duty Jib Cranes:

Heavy-duty jib cranes are built to handle heavier loads and endure frequent use in demanding environments. They are commonly used in industries such as automotive manufacturing, metal fabrication, and construction. Examples include articulating or freestanding jib cranes with higher duty classifications.

Features:

Sturdy construction with heavy-duty components and structural reinforcements.

Designed to handle heavier loads and endure frequent use in demanding industrial environments.

Available in articulating or freestanding configurations for increased versatility and lifting capacity.

Equipped with multiple jib arms or longer reach to accommodate larger and heavier materials.

Typical Applications:

Automotive manufacturing facilities for lifting and moving heavy vehicle components, engines, and chassis.

Metal fabrication shops for loading and unloading raw materials, steel plates, and fabricated metal parts.

Construction sites for lifting and positioning building materials, tools, and equipment at various heights and angles.

Each type of jib crane offers unique features and capabilities tailored to specific lifting requirements and operational environments. By understanding the characteristics and typical applications of light-duty and heavy-duty jib cranes, businesses can select the most suitable crane for their needs, ensuring efficient and reliable material handling operations.

Examples of Crane Working Duty Selection

Selecting the appropriate crane working duty is crucial across various industrial sectors to ensure optimal performance and safety. Let's explore examples of crane working duty selection in different sectors:

Steel Fabrication Plants:

Steel fabrication plants require cranes capable of handling heavy loads with precision. Moderate to heavy-duty overhead cranes are often utilized for lifting and transporting steel beams, plates, and structures within the facility. These cranes play a vital role in streamlining production processes and ensuring the safe handling of large steel components.

The typical crane duty of overhead cranes used in steel industrial sectors can vary depending on the country and specific requirements. However, here's a general overview based on different crane duty classifications:

| Country | Crane Duty Classification | Typical Use in Steel Fabrication Plants |

|---|---|---|

| United States | CMAA Class D or E | Handling heavy steel components like beams, plates, and structures |

| Europe | FEM Class M7 or M8 | Lifting and transporting heavy steel components in continuous operation |

| China | A6 or A7 | Handling substantial loads and enduring frequent use in industrial environments |

- United States:

In the United States, overhead cranes used in steel industrial sectors, such as steel fabrication plants, typically fall under the Crane Manufacturers Association of America (CMAA) classifications.

For heavy-duty lifting tasks in steel fabrication plants, CMAA Class D or E cranes are commonly employed. These cranes are designed to handle substantial loads and endure frequent use in demanding environments. - Europe:

In Europe, overhead cranes used in steel industrial sectors adhere to the European Materials Handling Federation (FEM) classifications.

For heavy-duty lifting applications in steel fabrication plants, FEM Class M7 or M8 cranes are often utilized. These cranes are engineered for continuous operation and can withstand the rigors of handling heavy steel components. - China:

China follows its own set of overhead crane duty classifications, which may differ from those in the United States and Europe.

In steel fabrication plants in China, cranes with higher-duty classifications, such as A6 or A7, are commonly employed. These cranes are designed to handle heavy loads and endure frequent use in industrial environments.

In summary, overhead cranes used in steel fabrication plants typically require moderate to heavy-duty classifications to handle the substantial loads and demanding operational conditions characteristic of the steel industry. The specific crane duty classification may vary based on regional standards and industry practices.

Automotive industry

The typical crane duty of overhead cranes used in the automotive industry can also vary based on different crane duty classifications in different countries.

| Country | Crane Duty Classification | Typical Use in Automotive Manufacturing Plants |

|---|---|---|

| United States | CMAA Class D or E | Handling large components like chassis and engines with precision |

| Europe | FEM Class M7 or M8 | Lifting heavy automotive components in continuous production lines |

| China | A6 or A7 | Enduring frequent use and continuous operation in automotive plants |

- United States:

In the United States, overhead cranes used in the automotive industry typically adhere to the Crane Manufacturers Association of America (CMAA) classifications.

Heavy-duty overhead cranes classified under CMAA Class D or E are commonly utilized in automotive manufacturing plants. These cranes are engineered to handle large and heavy components such as chassis and engines with precision and efficiency. - Europe: In Europe, overhead cranes used in the automotive industry may follow the European Materials Handling Federation (FEM) classifications.

For heavy-duty lifting tasks in automotive manufacturing plants, FEM Class M7 or M8 cranes may be employed. These cranes are designed to withstand continuous operation and frequent lifting of heavy loads required in automotive assembly lines. - China: China may have its own set of overhead crane duty classifications tailored to the automotive industry's specific needs.

In automotive manufacturing plants in China, cranes with higher-duty classifications, such as A6 or A7, are commonly utilized. These cranes are capable of handling large components and enduring continuous operation to meet the demands of automotive production lines.

Overall, heavy-duty overhead cranes with higher-duty classifications are typically used in the automotive industry to handle large components and ensure uninterrupted production lines. The specific crane duty classification may vary based on regional standards, industry practices, and the specific requirements of automotive manufacturing facilities.

Construction Sector

Infrastructure Projects (Bridges, Tunnels):

Infrastructure projects such as bridge and tunnel construction require cranes that can maneuver in confined spaces and handle heavy loads with precision. Gantry cranes are often used for assembling bridge segments and tunnel sections due to their versatility and mobility. These cranes play a critical role in accelerating construction timelines and ensuring project efficiency.

| Country | Typical Crane Duty Classification |

|---|---|

| United States | Gantry cranes classified under CMAA Class D or higher |

| Europe | Gantry cranes classified under FEM Class M7 or higher |

| China | Gantry cranes with higher-duty classifications, such as A6 or A7 |

Let's explore the typical crane duty classifications for infrastructure projects like bridges and tunnels in various countries:

Gantry cranes are commonly utilized for infrastructure projects such as bridge and tunnel construction. They offer the necessary versatility and mobility to navigate confined spaces and handle heavy loads with precision, contributing to the efficiency of construction projects.

- United States: In the United States, overhead cranes used in infrastructure projects may adhere to the Crane Manufacturers Association of America (CMAA) classifications.

Gantry cranes, known for their versatility and mobility, are commonly classified under CMAA Class D or higher for infrastructure projects like bridge and tunnel construction. These cranes are designed to maneuver in confined spaces and handle heavy loads with precision, accelerating construction timelines and ensuring project efficiency. - Europe: In Europe, overhead cranes used in infrastructure projects may follow the European Materials Handling Federation (FEM) classifications.

Gantry cranes classified under FEM Class M7 or higher are often utilized for assembling bridge segments and tunnel sections. These cranes offer the necessary versatility and mobility to navigate confined spaces and handle heavy loads with precision, contributing to the efficiency of construction projects. - China: China may have its own set of overhead crane duty classifications specific to infrastructure projects.

Gantry cranes with higher-duty classifications, such as A6 or A7, are commonly employed in bridge and tunnel construction in China. These cranes are engineered to maneuver in confined spaces and handle heavy loads with precision, facilitating the assembly of bridge segments and tunnel sections.

In summary, infrastructure projects like bridge and tunnel construction typically require gantry cranes with the versatility to maneuver in confined spaces and the capability to handle heavy loads with precision. The specific crane duty classification may vary based on regional standards and industry practices, but they are generally designed to accelerate construction timelines and ensure project efficiency.

Warehousing and Logistics Sector

Distribution Centers: Distribution centers rely on efficient material handling equipment to manage inventory and fulfill orders quickly. Light to moderate-duty overhead cranes are commonly used for loading and unloading goods from trucks and organizing inventory within the warehouse. These cranes optimize storage space and streamline logistics operations.

Here's the crane duty classifications for distribution centers in different countries presented in a table format:

| Country | Typical Crane Duty Classification |

|---|---|

| United States | Light to moderate-duty overhead cranes classified under CMAA Class A or B |

| Europe | Overhead cranes classified under FEM Class M5 or M6 |

| China | Overhead cranes with moderate-duty classifications, such as A3 or A4 |

Overhead cranes play a crucial role in distribution centers by facilitating efficient material handling tasks such as loading and unloading goods from trucks and organizing inventory within the warehouse. The specific crane duty classification may vary based on regional standards and industry practices but is generally aimed at optimizing storage space and streamlining logistics operations.

Let's explore the typical crane duty classifications for the warehousing and logistics sector in various countries:

- United States: In the United States, overhead cranes used in distribution centers may fall under the Crane Manufacturers Association of America (CMAA) classifications.

Light to moderate-duty overhead cranes classified under CMAA Class A or B are commonly utilized for loading and unloading goods from trucks and organizing inventory within distribution centers. These cranes optimize storage space and streamline logistics operations by facilitating efficient material handling. - Europe: In Europe, overhead cranes used in distribution centers may adhere to the European Materials Handling Federation (FEM) classifications.

Overhead cranes classified under FEM Class M5 or M6 are often employed in distribution centers for material handling tasks. These cranes are designed to optimize storage space and streamline logistics operations by efficiently loading and unloading goods from trucks and organizing inventory within the warehouse. - China: China may have its own set of overhead crane duty classifications specific to the warehousing and logistics sector.

Overhead cranes with moderate-duty classifications, such as A3 or A4, are commonly used in distribution centers in China. These cranes facilitate efficient material handling by loading and unloading goods from trucks and organizing inventory within the warehouse.

In summary, distribution centers typically require overhead cranes with light to moderate-duty classifications to optimize storage space and streamline logistics operations. The specific crane duty classification may vary based on regional standards and industry practices, but they are generally designed to facilitate efficient material handling within the warehouse.

Cargo Handling Facilities: Cargo handling facilities such as ports and airports require cranes capable of lifting heavy containers and cargo with precision and efficiency. Heavy-duty gantry cranes are often employed for loading and unloading ships and transporting cargo across the facility. These cranes play a vital role in facilitating the smooth flow of goods and ensuring timely deliveries.

| Country | Typical Crane Duty Classification |

|---|---|

| United States | Heavy-duty gantry cranes classified under CMAA Class D or higher |

| Europe | Gantry cranes classified under FEM Class M7 or higher |

| China | Heavy-duty gantry cranes with higher-duty classifications, such as A6 or A7 |

Cargo handling facilities such as ports and airports rely on heavy-duty gantry cranes to efficiently load and unload ships, transport cargo, and ensure timely deliveries. The specific crane duty classification may vary based on regional standards and industry practices but is generally aimed at facilitating the smooth flow of goods and enhancing operational efficiency in cargo handling facilities.

Let's explore the typical crane duty classifications for cargo handling facilities in various countries:

- United States: In the United States, cranes used in cargo handling facilities, such as ports and airports, may fall under the Crane Manufacturers Association of America (CMAA) classifications.

Heavy-duty gantry cranes classified under CMAA Class D or higher are commonly employed for loading and unloading ships and transporting cargo across cargo handling facilities. These cranes are designed to lift heavy containers and cargo with precision and efficiency, facilitating the smooth flow of goods and ensuring timely deliveries. - Europe: In Europe, cranes used in cargo handling facilities may adhere to the European Materials Handling Federation (FEM) classifications.

Gantry cranes classified under FEM Class M7 or higher are often utilized in ports and airports for cargo handling tasks. These heavy-duty cranes are capable of lifting heavy containers and cargo with precision and efficiency, contributing to the smooth flow of goods and timely deliveries. - China: China may have its own set of crane duty classifications specific to cargo handling facilities.

Heavy-duty gantry cranes with higher-duty classifications, such as A6 or A7, are commonly employed in ports and airports in China for cargo handling operations. These cranes are engineered to lift heavy containers and cargo with precision and efficiency, ensuring the smooth flow of goods and timely deliveries.

In summary, cargo handling facilities such as ports and airports typically require heavy-duty gantry cranes to lift heavy containers and cargo with precision and efficiency. The specific crane duty classification may vary based on regional standards and industry practices, but they are generally designed to facilitate the smooth flow of goods and ensure timely deliveries within the facility.

Mining and Extractive Industries

Open-pit Mining Operations: Open-pit mining operations involve the extraction of minerals from large open pits. Heavy-duty overhead cranes are used for lifting and transporting heavy equipment and materials within the mining site. These cranes need to withstand harsh environmental conditions and operate reliably to support mining operations.

Here's the crane duty classifications for mining and extractive industries in different countries presented in a table format:

| Country | Typical Crane Duty Classification |

|---|---|

| United States | Heavy-duty overhead cranes classified under CMAA Class D or higher |

| Europe | Overhead cranes classified under FEM Class M7 or higher |

| China | Heavy-duty overhead cranes with higher-duty classifications, such as A6 or A7 |

Mining and extractive industries rely on heavy-duty overhead cranes to lift and transport heavy equipment and materials within mining sites. The specific crane duty classification may vary based on regional standards and industry practices but is generally aimed at withstanding harsh environmental conditions and ensuring reliable operation to support mining activities.

Let's delve into the typical crane duty classifications for the mining and extractive industries in various countries:

- United States: In the United States, overhead cranes utilized in mining and extractive industries may align with the Crane Manufacturers Association of America (CMAA) classifications.

Heavy-duty overhead cranes classified under CMAA Class D or higher are often deployed in open-pit mining operations. These cranes are engineered to lift and transport heavy equipment and materials within the mining site, withstanding harsh environmental conditions and operating reliably to support mining operations. - Europe: In Europe, overhead cranes employed in mining and extractive industries may adhere to the European Materials Handling Federation (FEM) classifications.

Overhead cranes classified under FEM Class M7 or higher are frequently utilized in open-pit mining operations. These heavy-duty cranes are designed to handle the demanding tasks of lifting and transporting heavy equipment and materials within the mining site, contributing to the efficiency and productivity of mining operations. - China: China may enforce its own set of overhead crane duty classifications tailored to the mining and extractive industries.

Heavy-duty overhead cranes with higher-duty classifications, such as A6 or A7, are commonly employed in open-pit mining operations in China. These cranes are specifically engineered to lift and transport heavy equipment and materials within the mining site, enduring harsh environmental conditions and ensuring reliable operation to support mining activities.

In summary, open-pit mining operations typically necessitate heavy-duty overhead cranes capable of withstanding harsh environmental conditions and reliably lifting and transporting heavy equipment and materials within the mining site. The specific crane duty classification may vary based on regional standards and industry practices but is generally designed to support the efficiency and productivity of mining operations.

Quarrying and Mineral Processing Plants:

Quarrying and mineral processing plants require cranes for handling raw materials such as stone, ore, and aggregates. Heavy-duty gantry cranes are often utilized for loading and unloading materials from trucks and transporting them to processing facilities. These cranes enhance productivity and ensure the efficient processing of raw materials.

| Country | Typical Crane Duty Classification |

|---|---|

| United States | Heavy-duty gantry cranes classified under CMAA Class D or higher |

| Europe | Gantry cranes classified under FEM Class M7 or higher |

| China | Heavy-duty gantry cranes with higher-duty classifications, such as A6 or A7 |

Quarrying and mineral processing plants rely on heavy-duty gantry cranes to handle raw materials such as stone, ore, and aggregates. The specific crane duty classification may vary based on regional standards and industry practices but is generally aimed at efficiently loading and unloading materials from trucks and transporting them to processing facilities, contributing to productivity and efficiency in raw material processing.

Let's explore the typical crane duty classifications for quarrying and mineral processing plants in various countries:

- United States: In the United States, cranes used in quarrying and mineral processing plants may adhere to the Crane Manufacturers Association of America (CMAA) classifications.

Heavy-duty gantry cranes classified under CMAA Class D or higher are commonly employed for loading and unloading materials from trucks and transporting them to processing facilities. These cranes are designed to handle the heavy loads of raw materials such as stone, ore, and aggregates, enhancing productivity and ensuring efficient processing. - Europe: In Europe, cranes utilized in quarrying and mineral processing plants may follow the European Materials Handling Federation (FEM) classifications.

Gantry cranes classified under FEM Class M7 or higher are frequently utilized for material handling tasks in quarrying and mineral processing plants. These heavy-duty cranes are capable of efficiently loading and unloading materials from trucks and transporting them to processing facilities, contributing to productivity and efficiency in raw material processing. - China: China may have its own set of crane duty classifications tailored to quarrying and mineral processing industries.

Heavy-duty gantry cranes with higher-duty classifications, such as A6 or A7, are commonly employed in quarrying and mineral processing plants in China. These cranes are specifically designed to handle the heavy loads of raw materials and ensure efficient material handling and processing operations.

In summary, quarrying and mineral processing plants typically require heavy-duty gantry cranes capable of efficiently handling raw materials such as stone, ore, and aggregates. The specific crane duty classification may vary based on regional standards and industry practices but is generally aimed at enhancing productivity and ensuring the efficient processing of raw materials in these facilities.

By selecting the appropriate crane working duty for specific industrial sectors, businesses can enhance efficiency, improve safety, and optimize their operations for maximum productivity.

Case Studies

Case Study 1: Selecting Crane Working Duty for a Steel Fabrication Plant

Background:

A steel fabrication plant specializes in manufacturing structural steel components for various construction projects. The plant's operations involve cutting, welding, and assembling steel beams, plates, and structures.

Challenge:

The steel fabrication plant requires a crane solution that can handle heavy loads with precision and efficiency. With the diverse range of components being manufactured, the crane must be capable of lifting and transporting materials of varying shapes and sizes safely.

Solution:

After careful assessment of the plant's requirements, a heavy-duty overhead crane was selected for the steel fabrication facility. The crane is equipped with a robust lifting mechanism capable of handling large steel components with ease. Additionally, the crane is fitted with specialized lifting attachments to accommodate different types of loads, ensuring versatility and efficiency in operations.

Outcome:

By choosing a heavy-duty overhead crane tailored to the specific needs of the steel fabrication plant, productivity and safety were significantly enhanced. The crane's reliability and precision in lifting operations have optimized production processes, resulting in faster turnaround times and improved quality of fabricated steel components.

Case Study 2: Choosing the Right Working Duty for an Automotive Manufacturing Facility

Background:

An automotive manufacturing facility produces vehicles on a large scale, requiring continuous and efficient material handling solutions. The facility's operations involve assembly line production, with heavy components such as engines, chassis, and body panels being lifted and maneuvered throughout the production process.

Challenge:

The automotive manufacturing facility requires crane solutions that can withstand the high-intensity demands of assembly line production. With the need for frequent lifting of heavy components, reliability and precision are paramount to prevent downtime and ensure seamless production operations.

Solution:

For the automotive manufacturing facility, a combination of moderate-duty and heavy-duty overhead cranes was selected to meet the diverse lifting requirements across different areas of the production floor. Moderate-duty cranes are deployed in areas with lighter lifting tasks, such as component assembly stations, while heavy-duty cranes are utilized for lifting large assemblies and transferring materials between production stages.

Outcome:

By strategically choosing the right working duty for each area of the automotive manufacturing facility, productivity and efficiency were maximized. The combination of moderate-duty and heavy-duty cranes has enabled smooth and uninterrupted production operations, contributing to the facility's ability to meet production targets and deliver high-quality vehicles to market on time.

Guidelines for Selecting Crane Working Duty

Selecting the appropriate crane working duty involves careful consideration of various factors to ensure optimal performance, safety, and compliance with regulatory requirements. Here are some guidelines to assist in the selection process:

Conducting Load Analysis and Capacity Calculations