Main Specifications, Definitions & Terms of Main Types of Cranes

Basic overhead crane specifications, definitions & terms for reference to get custom overhead crane, gantry crane, jib crane & other hoists and cranes.

Category: Crane Basics

Your Trusted Overhead Crane Manufacturer & Supplier

Main Specifications, Definitions & Terms of Main Types of Cranes

Overhead Crane Basic to know Better Your Overhead Crane Design & Solution

Basics of overhead crane specifications, definitions & terms for reference to get custom overhead crane, gantry crane, jib crane & other hoists and cranes.

Lifting capacity / Rated lifting capacity of crane

The lifting capacity or rated lifting capacity of a crane is commonly referred to as the lifting weight G. It refers to the maximum weight that a crane can lift safely and stably under normal working conditions. The lifting capacity of a crane is determined by its structural design, such as the length of its boom, the strength of its wire ropes, and the capacity of its hoisting mechanism. The lifting capacity is usually expressed in metric tons (t) or kilonewtons (kN).

- Rated lifting capacity Gn refers to the total weight of the material that the crane can lift along with any detachable lifting equipment or attachments such as grab buckets, electromagnetic suction cups, balance beams, etc.

- Total lifting capacity Gz refers to the total weight of the material that the crane can lift along with any detachable lifting equipment and fixed lifting equipment and devices that are permanently attached to the crane (including hooks, pulley blocks, lifting steel wire ropes, and other lifting devices below the crane trolley).

- Effective lifting capacity Gp refers to the net weight of the material that the crane can lift.

Note:The parameters need to be explained as follows:

- First, the lifting capacity marked on the crane nameplate usually refers to the rated lifting capacity of the crane, which should be prominently displayed on an obvious position of the crane structure.

- Second, for jib type cranes, the rated lifting capacity varies with the amplitude, and its lifting characteristic index is characterized by the lifting moment. The value marked on the label is the maximum lifting capacity.

- Third, for cranes with detachable spreaders (such as grab buckets, electromagnetic suckers, balance beams, etc.), the total rated lifting capacity of the spreader and the mass of the material, the mass of the material allowed to be lifted is the effective lifting capacity.

Crane span

- Crane span - Span S refers to the horizontal distance between the centerlines of the running tracks of a bridge-type crane, measured in meters. The span of a bridge crane is usually 1.5-2.0 meters smaller than the span of the building (1.5 meters for cranes under 50 tons).

- Bridge crane gauge - The distance between the centerlines of the running tracks of a bridge crane's trolley is called the gauge of the trolley.

- Gantry crane gauge The distance between the centerlines of the running tracks of a gantry crane that runs on tracks on the ground is called the gauge of the crane.

Lifting height

The lifting height H is the vertical distance from the top surface (or ground) of the crane running track to the uppermost position of the lifted load. The unit of measurement is meters. When using a hook, the measurement is taken to the center of the hook ring, while when using a grab bucket or other containers, the measurement is taken to the bottom of the container. More about crane crane span, lifting height and types of lifting crane working coverage for your reference.

- The vertical distance from the ground to the highest allowable position of the lifting device, marked as H.

- If the hook can be lowered below ground level, then the height below ground level is called the lowering depth (h).

- Long travel refers to the direction of the bridge's movement along the rails.

- Cross travel refers to the movement of the 'crab' from one side of the bridge to the other.

- Hook Height is the distance from the datum to the highest position of the hook, which determines the height of the runway from the floor and is dependent on the clear inside height of the building. Effective lift is the distance between the beam and the floor, minus the height of the hoist.

- Runway Height is the distance between the grade level and the top of the rail.

- Side Clearances are measured from the center of the supporting rail to the face of the supporting column, required for operation, safety, and wheel maintenance.

- Vertical Clearances refer to the space required for the crane to travel within a building while avoiding obstructions such as lights, equipment, and structural framing. The lower the crane headroom, the higher will be the vertical clearance and lower could be the building height.

- Clear Span is the horizontal center distance between the rails of the runway on which the crane travels, typically 500 mm less than the width of the building. The span required depends on the crane coverage width dictated by the application.

- Runway Length is the longitudinal run of the runway rail parallel to the length of the building.

- Hook Approaches refer to the distance from the wall to the nearest possible position of the hook, which affects floor area utilization.

- End Approach refers to the minimum horizontal distance parallel to the runway between the outermost extremities of the crane and the centerline of the hook.

- Bridge, Trolley, and Lift Speeds are specified in feet per minute or FPM and selected to allow safe operation while using a pendant. Dual operating speeds are commonly used, but a variable speed control system is preferred for optimum control.

- Electrical Requirements ideally include 480 volt, 3 phase, 60 hertz for US requirements. The runway power is usually by a conductor bar, and a hoisting trolley by festoon cable. The control circuit voltage at pendant pushbuttons shall not exceed 150 volts for AC and 300 volts for DC.

Radius R:

- For a jib crane in a horizontal position, the distance between the centerline of rotation and the vertical line passing through the center of the load.

- For a non-rotating jib crane, it refers to the distance between the pivot point under the jib and the vertical line passing through the center of the load.

- The maximum radius is achieved when the jib is at its minimum inclination or when the distance between the trolley position and the center of rotation of the crane is at its maximum.

Amplitude L

The amplitude of the rotating jib crane refers to the horizontal distance between the center line of rotation and the plumb line of the pick-up device, and the unit is m. The amplitude of a jib crane of the non-rotating type refers to the horizontal, horizontal distance between the centerline of the spreader and the rear axle of the jib or other typical axis.

When the inclination angle of the jib is the smallest or the distance between the position of the trolley and the center of rotation of the crane is the largest, the amplitude is the maximum amplitude; otherwise, it is the minimum amplitude.

Operating speed:

- Hoisting speed Vq refers to the vertical displacement speed of the rated load when the crane is in a stable operating state, measured in meters per minute.

- Trolley running speed Vk refers to the running speed of the crane with the rated load on a horizontal surface or track, measured in meters per minute.

- Crane running speed Vt refers to the running speed of the trolley with the rated load on a horizontal track in a stable motion state, measured in meters per minute.

- Slewing speed V1 refers to the average linear speed of the horizontal displacement from maximum radius to minimum radius in the slewing plane with the minimum rated load when the crane is in a stable motion state, measured in meters per minute.

- Traveling speed V refers to the smooth running speed of a mobile crane with a rated load while driving on a road, measured in kilometers per hour.

- Rotation speed ω refers to the rotation speed of the crane around its center of rotation when it is in a stable motion state, measured in revolutions per minute.

Working class or working duty of cranes

The working class of a crane is determined by considering the utilization of its lifting capacity and time, as well as the working characteristics of the operating cycles. According to GB/T 3811-2008 "Design rules for cranes," the working class of a crane is divided into the working class of the entire machine, the working class of the mechanism, and the working class of the structural or mechanical components.

The usage level of a crane (i.e., the degree of busyness over time) is classified into different levels based on the number of load cycles and the duration of the operation.

The crane use level indicates how frequently the crane was used over the design life. The general work cycle number N is divided into 10 levels based on the design life period (see table 1).

Crane use level | general work cycle number N | annotation |

U0 | 1.6*10 4 | Not often use |

U1 | 2.2*104 | |

U2 | 3.3*104 | |

U3 | 1.25*105 | |

U4 | 2.5*105 | Free to use |

U5 | 5*105 | Often secondary to use |

U6 | 1*106 | Don't always busy to use |

U7 | 2*106 | Busy use |

Crane load condition

The degree of the crane load is determined by two factors: the ratio of hoisting the load to the rated load Pi/Pmax, and the ratio of the role of various hoisting load numbers to the general work cycles ni/N. The following are the two load spectrum factor and Kp computed by type relationships:

In the formula:

Kp—load spectrum factorand; ni—the effect number of load Pi; N—general work cycles, N= ; Pi—the I hoisting load, i=1,2….n; Pmax—max lifting load; m—index, in here m=3.

The nominal load spectrum coefficient divides the crane load condition into four categories (see table 2)

Table 2:

Crane load condition | nominal load spectrum coefficient (Kp) | Explain |

Q1-light | 0.125 | Rarely lifting load rating |

The load state level is classified into four levels: Q1, Q2, Q3, and Q4, with Q1 being the most frequently used and Q4 being the least frequently used. The load state level is determined based on the ratio of the actual weight of the lifted object to the rated lifting capacity of the crane.

One working cycle: hoisting goods/ loads→lifting→running→lowering→unloading→the empty hook returns to its original position.

The idle time between work cycles of a crane refers to the time required for the crane to complete one work cycle and return to its original position before starting the next work cycle. The idle time depends on the type and configuration of the crane, as well as the specific work environment.

Calculation formula for total working cycles: N=3600YDH/tc

Y: The service life of the crane (generally 20-30 years) .D: The number of working days in a year (265 days) H: The number of working hours in a day. tc: The time of a working cycle (s), which is related to the degree of work busyness

Main specifications of types of cranes

Cranes have different main specifications depending on their type. For bridge cranes, the main specifications include lifting capacity, lifting height, span, lifting speed, trolley traveling speed, bridge traveling speed, working class, and load state level. Gantry cranes have similar specifications, but with crane traveling speed instead of bridge traveling speed. Jib cranes are characterized by lifting capacity, lifting height, arm length, lifting speed, slewing speed, working class, and load state level. It's important to note that these specifications can vary depending on the specific model and manufacturer of the crane.

Main specifications of bridge cranes

Crane Type | Usage Scenarios | Lifting Capacity Range | Span Range | Lift Height Range | Duty Cycle | Control Type | Environmental Factors |

Single Girder Overhead Travelling Crane | Manufacturing, Assembly, Maintenance | 1-20 tons | Up to 60 feet | Up to 30 feet | Light to Medium | Pendant, Radio Remote, or Cab | Indoor, Dry, and Non-corrosive |

Double Girder Overhead Crane | Steel Mills, Power Plants, Heavy Manufacturing | 5-100+ tons | Up to 150 feet | Up to 100 feet | Medium to Heavy | Pendant, Radio Remote, or Cab | Indoor or Outdoor, Dry, and Non-corrosive |

Jib Crane | Machining, Assembly Workstations | 0.5-5 tons | Up to 20 feet | Up to 20 feet | Light to Medium | Pendant or Cantilevered | Indoor, Dry, and Non-corrosive |

Underhung Crane | Low Headroom Applications | 1-10 tons | Up to 60 feet | Up to 30 feet | Light to Medium | Pendant or Radio Remote | Indoor, Dry, and Non-corrosive |

Grab Overhead Crane | Handling Loose Bulk Materials | 5-100+ tons | Up to 150 feet | Up to 100 feet | Medium to Heavy | Pendant, Radio Remote, or Cab | Indoor or Outdoor, Dry, and Non-corrosive |

Electromagnet Overhead Crane | Handling Ferrous Materials | 5-100+ tons | Up to 150 feet | Up to 100 feet | Medium to Heavy | Pendant, Radio Remote, or Cab | Indoor or Outdoor, Dry, and Non-corrosive |

Ladle Overhead Crane | Handling Molten Metal | 5-100+ tons | Up to 150 feet | Up to 100 feet | Medium to Heavy | Pendant, Radio Remote, or Cab | Indoor, High Temperature |

Explosion-proof Overhead Crane | Hazardous Environments | 1-100+ tons | Up to 150 feet | Up to 100 feet | Light to Heavy | Pendant, Radio Remote, or Cab | Indoor, Hazardous |

Clean Room Overhead Crane | Clean Room Environments | 1-20+ tons | Up to 60 feet | Up to 30 feet | Light to Medium | Pendant or Radio Remote | Indoor, Clean |

Automated Overhead Crane | Fully or Partially Automated Material Handling | 1-100+ tons | Up to 150 feet | Up to 100 feet | Light to Heavy | Automated Controls | Varies by Application |

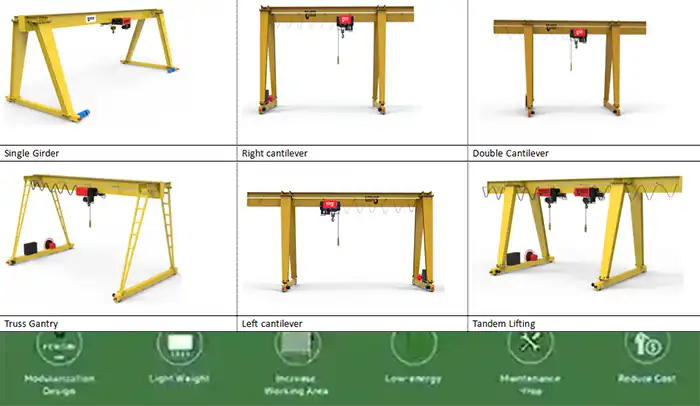

Main specifications of types of gantry cranes

Type | Load Capacity | Span Width | Height Under | Usage Scenarios: |

Portable Gantry Crane | Up to 5 tons | Up to 30 feet | Up to 20 feet | Lifting small loads in warehousesMaintenance work in factories |

Adjustable Gantry Crane | Up to 15 tons | Up to 40 feet | Up to 35 feet | Heavy lifting in workshops Construction projects |

Fixed Gantry Crane | Up to 100 tons | Up to 150 feet | Up to 100 feet | Heavy-duty lifting operations in shipyardsLarge-scale construction projects |

Container Gantry Crane | Up to 100 tons | Up to 200 feet | Up to 100 feet | Loading and unloading of containers in ports and terminals |

Rail Mounted Gantry Crane (RMG) | Up to 120 tons | Up to 100 feet | Up to 80 feet | Container handling in intermodal rail yards and container terminals |

Small Lightweight Gantry Crane | Up to 2 tons | Up to 15 feet | Up to 10 feet | Lifting small loads in workshops and garages |

Mobile Gantry Crane | Up to 20 tons | Up to 40 feet | Up to 20 feet | Lifting and moving heavy loads in outdoor settings or large warehouses |

Main specifictions of types of jib cranes

Crane Type | Usage Scenarios | Lifting Capacity Range | Span Range | Lift Height Range | Duty Cycle | Control Type | Environmental Factors |

Jib Crane | Machining, Assembly Workstations | 0.5-5 tons | Up to 20 feet | Up to 20 feet | Light to Medium | Pendant or remote control | Indoor, Dry, and Non-corrosive |

Pillar jib crane | Indoor and outdoor use | 1-20 ton | 3~12m | 3~8 | Light to Medium | Pendant or remote control | Floor mounted with foundation or foudationless design |

Wall mounted jib crane | Workshop or workstation | 1-5 ton | 2-8m | 3-10m | light | Pendant or remote control | H steel column or concrete column of walls |

Wall travelling jib crane | Workshop or workstation | 1-3 ton | 5~12.5m | 6~30 | light | Pendant or remote control | Linked workshops |

Portable jib cranes | Workshop or workstation and outdoor use | 0.25t -2 ton | 2-6 m | 2-5m | Light | Pendant or remote control | General material handling conditions |

Hoisting and crane machinery terminology

1.1 Light lifting equipments

1.1.2 Rack-pinion jack - A jack that uses a rack as a rigid lifting device. 1.1.3 Hydraulic jack - A jack that uses a plunger or hydraulic cylinder as a rigid lifting device.

1.2 Pulley block - A small and light lifting device consisting of a fixed pulley group, a moving pulley group, and a lifting rope that passes successively over the fixed and moving pulleys.

1.3 Hoist - A small and light lifting device that is mounted on a common hanger and consists of a driving device, a transmission device, a braking device, and a flexible member for winding or clamping, or for lifting and lowering the lifting device.

1.3.1 Chain block - A hoist that is manually operated by pulling a chain and chain wheel to finally lift the lifting chain through a star wheel or nest chain wheel, thereby driving the lifting device to move up and down.

1.3.2 Lever block - A hoist that is manually operated by driving a wire rope or chain with a lever to move the lifting device.

1.3.2.1 Rope lever block - A hoist that is manually operated by driving a wire rope clip with a lever, alternately pulling the wire rope to drive the lifting device to move.

1.3.2.2 Chain lever block - A hoist that is manually operated by driving a nest chain wheel with a lever to wind and unwind the lifting chain, thereby driving the lifting device to move.

1.3.3 Electric hoist - A hoist that is driven by an electric motor and finally lifts the lifting rope or lifting chain through a drum, a star wheel, or a nest chain wheel, thereby driving the lifting device to move.

1.3.4 Pneumatic hoist - A hoist that is powered by compressed air.

1.4 Winch - A hoist that is driven by power through a flexible member to move the lifting device.

1.4.1 Drum hoist - A winch with the end of the lifting flexible member directly fixed on the drum, which has a dual function of winding and storing the lifting flexible member.

1.4.2 Friction hoist - A winch where the lifting flexible member only wraps around the drum for several turns, and when one end is wound up, the other end is released at the same time. The drum relies on the frictional force between the flexible member and the drum wall to create a tension difference between the entrance and exit ends of the flexible member, thereby providing traction force for the flexible member.

1.4.3 Capstan - A single drum frictional winch where the outer periphery of the drum is concave so that the lifted flexible member can slide automatically along the axis of the drum (capstan head) towards the bottom of the arc, without producing axial displacement.

1.5 Underslung monorail system - A light and small lifting device that consists of several simple lifting trolleys traveling along an overhead rail for transporting goods.

2.1 Classification of cranes according to their structure

2.1.1 Overhead type crane - A crane with a lifting device suspended from a hoist or a running trolley that runs along the overhead bridge.

2.1.1.1 Overhead travelling crane - A bridge-type crane supported directly on elevated tracks by running devices at both ends of the bridge.

2.1.1.2 Portal bridge crane (gantry crane) - A bridge-type crane with the bridge supported on the ground track or foundation by two side legs.

2.1.1.3 Semi-portal bridge crane - A bridge-type crane with one side of the bridge directly supported on elevated or high-rise building tracks and the other side supported on the ground track or foundation by legs.

2.1.2 Cable type crane - A crane with a lifting device suspended from a hoist that runs along a cable.

2.1.2.1 Cable crane - A cable-type crane with both ends of the supporting cable fixed to the top of two supports.

2.1.2.2 Portal cable crane - A cable-type crane with the end of the supporting cable fixed to both ends of the bridge, and the bridge supported on the ground track by two side legs.

2.1.3 Jib type crane - A crane with a lifting device suspended from the top of a jib or from a hoist that runs along the jib.

2.1.3.1 Portal slewing crane - A slewing jib-type crane with a portal frame that runs along the ground track and can be passed under by railway or other ground vehicles.

2.1.3.2 Semi-portal slewing crane - A slewing jib-type crane with one side of the semi-portal frame supported on elevated tracks by a running truck and the other side supported on the ground track or foundation by legs and a running truck.

2.1.3.3 Tower crane - A slewing jib-type crane with the jib mounted on the top of a vertical tower.

2.1.3.4 Railway crane - A jib-type crane that operates on railway lines and is used for loading and unloading and for rescuing railway locomotives, vehicles, and overturned trains.

2.1.3.5 Mobile crane - A jib-type crane that can be equipped with columns or towers and can run on an untracked surface with or without a load, relying on its own weight to maintain stability.

2.1.3.6 Floating crane - A jib-type crane supported and operated by a special floating ship, which floats on the waterway and can sail or be towed along the waterway.

2.1.3.7 Deck crane - A slewing jib-type crane mounted on a ship's deck for loading and unloading cargo.

2.1.3.8 Derrick crane - A slewing jib-type crane with its lower end hinged to the lower part of a mast, its upper end connected to the masthead by a wire rope, and the mast itself kept upright by top and bottom supports.

2.1.3.9 Cantilever crane - A jib-type crane with a lifting device suspended from the end of a cantilever or from a hoist that runs along the cantilever.

2.1.3.9.1 Pillar jib crane - A cantilever crane with a cantilever that rotates around a fixed pillar on a base, or where the cantilever is rigidly connected to the turning pillar, rotating together relative to the vertical centerline in the support base composed of pillars and cantilevers.

2.1.3.9.2 Wall crane - A cantilever crane mounted on a wall or column that cannot be inclined.

2.2 Cranes are classified by pick-up device and use

2.2.1 Hook crane / Hook crane - a crane that uses a hook as a retrieval device

2.2.2 Grabbing crane / Grabbing crane - a crane with a grab bucket as a pick-up device

2.2.3 Electromagnetic Crane / Magnet crane - a crane with an electromagnetic suction cup as a pick-up device

2.2.4 Metallurgy crane/ (see GB6974.16) Metallurgy crane - a special crane that adapts to the special requirements of metal smelting, rolling and other thermal processing, and is directly used in the production process

2.2.5 Stacking crane/ (see GB6974.17) Stacking crane - a crane that usually uses a fork as a pick-up device to stack items in a warehouse or workshop

2.2.6 Container cranes/ (see GB6974.19) Container cranes - cranes for loading and unloading container ships and vehicles, stacking and destacking or transshipment of containers at port terminals and station freight yards

2.2.7 Erection crane / Erection crane - a crane for placing prefabricated parts, lifting machinery and equipment, etc.

2.2.8 Rescue crane / Salvage crane - a crane used for emergency rescue and cleaning up the accident scene

2.3 Cranes are classified according to their transportation methods

2.3.1 Fixed base crane - a crane that is fixed to a foundation or support base and can only work in situ

2.3.2 Traveling crane - a rail or trackless crane that can be moved as a whole

2.3.2.1 Self-propelled crane / Self-propelled crane - during operation or transportation, the whole machine can run along the track or trackless by relying on its own operating mechanism

2.3.2.2 Trailer crane / Trailer crane - a running crane that does not have running power itself and is towed by a tractor (tractor, etc.)

2.3.3 Climbing crane / Climbing crane - a crane that is installed on the building components under construction and can continue to climb upwards by its own mechanism as a whole as the building increases

2.3.4 Portable crane / Portable crane - a crane mounted on a base that can be moved from one site to another by manpower or with the aid of auxiliary equipment

2.3.5 Lorry crane / Lorry crane - a crane that is fixed to a truck and is usually used for loading and unloading goods on the truck

2.3.6 Radial crane / Radial crane - a crane that can move along an arc track around a fixed vertical center line

2.4 Cranes are classified according to the driving mode of the working mechanism

2.4.1 Manual crane / Manual crane - a crane driven by human power

2.4.2 Electric crane / Electric crane - a crane driven by electricity

2.4.3 Hydraulic crane / Hydraulic crane - a crane driven by hydraulic or hydraulic power

2.4.4 Internal combustion crane / Diesel crane - a crane driven by an internal combustion engine (diesel engine, gasoline engine)

2.4.5 Steam crane / Steam crane - a crane driven by a steam engine

2.5 Cranes are classified by slewing capacity

2.5.1 Slewing Crane / Slewing Crane - A crane in which the superstructure (on board), or slewing platform, can carry a hoisted load around an axis of rotation, relative to the substructure (on board), or base

2.5.1.1 Full-circle slewing crane / Full-circle slewing crane - a slewing crane in which the upper structure (on the vehicle) or the slewing platform can rotate relative to the lower structure (off the vehicle) or the base within a range of more than 360°

2.5.1.2 Non-full slewing crane / Limited slewing crane - a slewing crane in which the upper structure (on the vehicle) or the slewing platform can rotate relative to the lower structure (on the vehicle) or the base within an included angle of less than 360°

2.5.2 Non-slewing crane / Non-slewing crane - a crane that cannot rotate a lifted load relative to its base or trolley

2.6 Cranes are classified according to their supporting methods

2.6.1 Supported crane / Supported crane - an overhead crane supported on an elevated track and running above the track

2.6.2 Suspension Crane / Underslung crane - An overhead crane that is suspended from the lower flange of an elevated track and operates below it

2.7 Cranes Classified by Application

2.7.1 Workshop crane / Workshop crane - used in processing workshops, repair workshops, assembly workshops, cranes for lifting workpieces and machines

2.7.2 Machine house cranes/ Machine house cranes - cranes used for hoisting and repairing generators, water turbines and other equipment in the machine room

2.7.3 Warehouse crane / Warehouse crane - a crane used for lifting and stacking items in the warehouse and on the yard

2.7.4 Storage yard cranes/ Storage yard cranes - cranes used for stacking and reloading bulk materials on open-air yards

2.7.5 Construction cranes/ Building cranes - cranes used to lift building materials, place prefabricated parts, and hoist machinery and equipment at the construction site

2.7.6 Construction cranes/ Construction cranes - cranes used on earthwork construction sites

2.7.7 Port crane / (see GB6974.18) Port crane - a crane specially designed and manufactured according to the requirements of port loading and unloading operations

2.7.8 Shipyard crane / Shipyard crane - a crane used to build ships in a shipyard

2.7.8.1 Shipway crane / Shipway crane - a crane used to lift the hull and ship's equipment on the shipyard

2.7.8.2 Dock crane - a shipbuilding crane used on a dock (floating dock)

2.7.8.3 Outfitting crane / Crane for finishing shipguilding - After the ship is launched, the shipbuilding crane used to install the ship's auxiliary equipment and supporting components

2.7.9 Dam crane / Dam crane - the crane used for opening and closing gates, lifting equipment, etc. on the hydropower dam

2.7.10 Shipboard crane / Shipboard crane - a crane installed on the deck of a ship for loading and unloading cargo

Main Projects

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch