5 Ton Overhead Crane for Sale Yemen, Explosion Proof Crane

5 ton overhead crane for sale Yemen, explosion proof crane with processed arched bridge girder design. Check arched double girder overhead crane 5 ton now.

| Bridge crane type | explosion proof overhead crane, double beam ,arched bridge girder |

| Crane specifications | 5 ton -3.75 m/5.75 m span- lifting height 9 m |

| Destination country | Yemen |

Category: Custom EOT Crane Manufacturing

Your Trusted Overhead Crane Manufacturer & Supplier

5 Ton Overhead Crane for Sale Yemen, Explosion Proof Crane

Customied Arched Bridge Double Girder Overhead Cranes, 4 Sets

5 ton overhead crane for sale Yemen, explosion proof crane with processed arched bridge girder design. Check arched double girder overhead crane 5ton now

Basics of double girder overhead crane 5 ton for Sale Yemen

- Crane Type:Double girder overhead crane

- Date of Placing Oder: 2019.9.26

- Date of Delivery : 2019.11.10

- Way of Payment: EXW, FCA, 50%

- Destination country: Yemen

- Destination port:CFR Manila

- First Contact:2019.4.15

Processed arched bridge girder overhead crane 5 ton for sale Yemem explosion proof design

General requirements & main specifications of arched bridge girder overhead crane 5 ton

Crane type | Double girder overhead crane, explosion proof | |

Model | LHB | LHB |

Working Class | A3 | A3 |

Capacity | 5 ton | 5 ton |

Span length (m)/ E | 3.75 M( total length of bridge girder is 4 m) | 5.75 M( total length of bridge girder is 6 m) |

Lifting Height(M) | 9 m | 9 m |

Crane control | Pendant control | Pendant control |

Voltage | 380v,50hz,3p | 380v,50hz,3p |

Color | Yellow | Yellow |

Applications | Indoor use | Indoor use |

Quantity | 2 | 2 |

Customized features of 5 ton overhead crane for sale Yemen

- Explosion proof design to ensure safety in hazardous applications

- Arched bridge girder design as per the following overhead crane design drawing

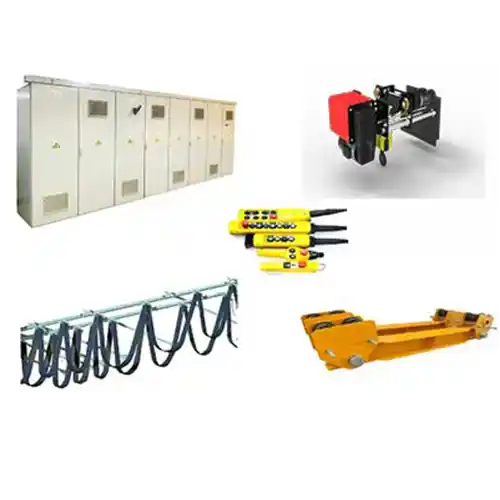

Gallary of explosion proof double girder overhead crane 5 ton Yemen

Main girder of 5 ton double girder overhead crane with arched crane girders for sale Yemen

Customized bridge crane with arched beam for sale Yemen

1 ton & 0.5 ton slewing jib crane for sale Yemen

5 ton double girder overhead crane with explosion proof electric hoist trolley, 4 sets for sale Yemen good price

Explosion proof crane, double girder design, with hoist trolley under construction

Explosion proof electric wire rope hoists for sale Yemem for processed overhead crane projects

How to get process crane for your application?

How to get an overhead crane with processed crane design? Take the following the factors into considerations to get your custom overhead cranes for your applications.

The load. Manufacturers of cranes and hoists must be aware of the object you are lifting, including its size, overall weight, surface features, uniformity (or not) of shape, material, construction, and fragility. Also indicate the application conditionwhether it will bewet, dry, dusty, oily, explosiveor in anothers. It's also crucial to consider whether the crane and hoist will need to carry multiple types of loads. There may be more than one recommended overhead lifting and handling solution, depending on how different one load is from the others.

The working frequency . Duty Cycle Requirements, also known as how frequently and how much of its maximum load capacity the crane and hoist will be operated, have a substantial impact on the service class an application requires. It will be safe and durable if you specify equipment that has been designed to meet the requirements for the class that best fits your application.

The required speed. To ensure overall operational efficiency, it is crucial to determine how rapidly the crane must move and the hoist must raise and lower in order to keep up with manufacturing efficiency. Safety may be compromised by a system that operates too quickly or slowly.

The operational condition. Cranes and hoists are operated both indoors and outdoors; each applicaitonhas unique issues such as temperature, hazardous situations, dust, heat, humidity, liquids, oils, fibers, corrosive chemicals, and more. A customized crane and hoist combination may be recommended depending on the application to improve durability and service life.

The anticipated longevity. All cranes and hoists need regular maintenance in order to function safely and reliably for the duration of their useful lives. An important factor to take into account when planning and specifying a crane and hoist is how frequently (or not) an operation wants the equipment to run between servicing, to replace crucial components, or to replace the complete system.

The Budget. Although it may be alluring to choose the crane and hoist solution with the lowest price, there is a good chance that system was not designed to fulfill the application's actual requirements. It is unlikely that a correctly constructed system will be the cheapest, but it will have a greater chance of lasting longer with fewer operational problems, less downtime, and a higher level of safety. Beyond the initial purchase price, all capital equipment expenditures have further costs. When calculating the equipment's total cost, be careful to include installation, replacement components, maintenance contracts, service agreements, and the desired level of field service teams' issue response.

Contact us to get a processed overhead crane design for your particular applications today.

Main Projects

Related Products

Latest project

32/5 Ton Overhead Crane Sale in India: Case Study

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch