Steel Crane Building & Steel Structured Factory Overhead Cranes

Steel crane building & steel structure factory overhead cranes overviews.One stop services for steel building & bridge cranes to improve your benefits.

Category: Factory Crane

Your Trusted Overhead Crane Manufacturer & Supplier

Steel Crane Building & Overhead Cranes

One stop services for steel building & bridge cranes to improve your benefits

Overviews on steel crane building & steel structured factory overhead cranes . One source services for steel crane building & bridge crane system from design, manufacturing,installation & maintenance to improve your factory efficiency and safety.

Steel structure workshop building is becoming increasingly popular. The steel workshop buildings with overhead cranes have become a very popular plant structure in construction projects due to their lightweight, quick, and easy installation. The overhead bridge cranes installed in the steel structure factory building are used to handle heavy loads objects in various industrial sectors to improve material handling efficiency, to reduce labor intensity and improve operation safety. It is a necessary piece of material handing equipment in industrial production.

Overhead Crane System Designed For Your Steel Structured Facility

Our factory has extensive experience and knowledge in designing and fabricating industrial steel buildings with integrated overhead crane systems to improve material handling and heavy load transportation efficiency. Our clear span design capabilities enable continuous and unobstructed spaces, allowing manufacturing, material handling, and assembly spaces to be strategically arranged to optimize workflow patterns and business operation needs.

Types of overhead crane systems for steel crane buildings

With more than 3 decades of experiences, we can design & fabricate industrial steel buildings that support various types and sizes of cranes, including:

Steel structure workshop with overhead crane systems

Steel structure workshop is a type of building formed by a main framework consisting primarily of steel column, steel beam, and purlin, with the steel structure accounting for the majority of load-bearing members of the steel workshop building. The roof and walls of the steel workshop are made up of various styles of panels that overlap when assembled together, leaving no gaps. As a result, the steel frame structure factory can be protected from outdoor elements. Steel structure has been used in a variety of industrial and non-industrial building construction due to its low cost and short construction time.

We provide high-quality, long-lasting crane steel structures for your workshops and factories, as well as heavy material handling lifting equipment like overhead cranes. Steel structures are a low-cost option for constructing industrial structures such as workshops, warehouses, and industrial sheds. It is classified into two types: heavy steel structure and light steel structure. This building type can be designed and built with a large span thanks to the properties of structural steel. We also provide a variety of steel crane building with bridge crane system to fit your needs.

The popularity of prefabricated steel structure factories can be attributed to the following factors:

- Environment protection and energy saving.

- Light weight and low investment cost.

- Fast construction speed.

- High safety with excellent seismic grade and impact resistance.

- Recyclable.

Importance of Strength to Weight Ratio

Steel is the only building material that has the strength-to-weight ratio necessary for metal buildings with overhead cranes. Before custom engineering your bridge crane and steel building, we will take into account the combined weight of the crane system and the crane's maximum load capacity, and other main crane specifications including the crane span, and the space or distance your travelling crane needs to cover within the building . We can also reduce or eliminate the need for independent crane columns in some cases, saving you space and money.

If you need multiple overhead crane systems installed inside your facility, crane supporting steel structures such as runway beams and supporting columns will be required. The frame structure can be single span, double span, or multi span in design. The overall size is determined by your needs.

When installing an overhead crane system inside a building, the desired crane specifications, such as rated load capacity, lifting height, span, work duty, and so on, should be specified first. We provide a wide range of overhead bridge cranes to meet your lifting needs, from small capacity light duty overhead cranes to large capacity heavy duty overhead cranes. These overhead cranes can be designed for both general lifting and specific lifting applications.

Overview of steel structure factory with bridge cranes systems

A bridge crane steel structure is a metal structure that can be used with overhead cranes. This steel structure is classified as a single span steel structure, a double steel structure, or a multiple steel structure. Our team includes a professional designer who can provide customers with customized services.

Custom design for your crane metal building with overhead crane system is available. The steel structure can be outfitted with doors and walls to meet the needs of the clients. Many customers have additional requirements, such as installing lighting panels around the walls.And the aluminum doors and windows can be provided. And also,if your factory is located at low temperatures area, the steel structure will become cold and brittle, and then it is suggested to use killed steel with good resistance to low-temperature brittle fracture.Contact us to to get your customized steel structure building with overhead crane systems.

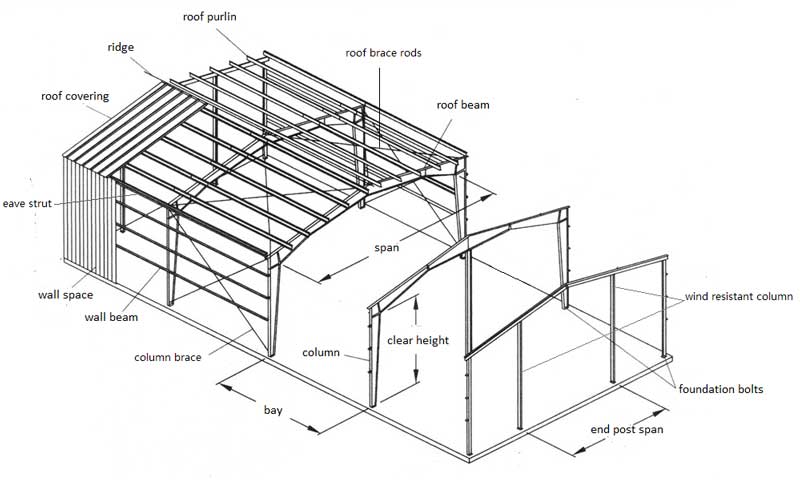

Main parts and components of steel structure factory

The steel building workshop are mainly consisted of Column, Runway beam, Column bracing, Roof beam, Roof brace rod, Roof purlin/Wall beam, Tie bar, and Angle brace and connecting bolts, etc.

Complete steel structures for factory construction and bridge crane supporting

When the complete solution for designing and manufacturing overhead cranes and steel structure of factory building, the complete parts and components of factory steel structure can are required which includes Column,,Bearing-rail beam, Column bracing, Roof beam, Roof brace rod, Roof purlin/Wall beam, Tie bar, and Angle brace and anchor bolts, etc. ( Note: As for the factory walls and construction materials, they are within the responsibility of the steel factory owner and builder. )

Bridge crane supporting steel structure

When the existing structure of facility can not provide adequate strength to supporting the bridge crane, the added steel structure for crane supporting are needed, which are consisted of the columns, runway beam/ bearing rail beam, and column bracing. ( Note: Based on special applications and lifting requirements, the bridge crane supporting steel structure will be designed differently. )

- Column,

- Bearing-rail beam,

- Column bracing,

- Roof beam,

- Roof brace rod,

- Roof purlin/Wall beam,

- Tie bar,

- Angle brace,

- Connecting bolts, etc.

All the above are the main steel structure of steel factory building.

When the crane supporting steel structures are requires, only the first three parts are provided.

Functions of steel structure factory main parts and components

1. Columns

If a steel structure building with cranes is required, the steel column should be equipped with brackets to support the crane beam. Furthermore, the size of the steel column must be sufficient to support overhead cranes. Usually, it is widely made of H-beam columns with either a constant or variable section. The column is simple to build and is made of Q235B or Q345B steel, which is safe and ideal for crane steel structures.

a, Main frame column

It bears the load from the beams and slabs and transmits it to the foundation in a steel frame structure. It is the primary vertical support structure and is distributed in the direction of the factory building's long axis, i.e. the "longitudinal wall" surface.

b. Wind resistant column

The wind-resistant column is a structural component of the "gable" surface of the single-story industrial factory building's short axis direction. The wind-resistant column's primary function is to transfer the wind load of the gable wall, and the upper portion is transmitted to the roof system via the connection between the hinge joint and the steel beam. The load-bearing structure of the entire bent frame is transmitted to the foundation via the connection. In general, the shape is smaller than that of a portal steel column.

Functions :

The column foundation is used to support and secure the steel structure factory building, preventing it from shifting, sinking, tilting, or sustaining other structural damage.

The strict foundation design is closely related to the geotechnical exploration and hydrogeology of the site where the plant is located, and the foundation design also influences the anchor bolt specifications. As a result, under normal circumstances, we do not provide anchor bolts and recommend that customers consult their local civil engineering department. This section of civil engineering includes geological survey, design, and customization.

Construction method:

- 1. For fixed anchor bolts, it is typically equipped with a reinforcement cage, poured alongside the foundation, and finally adjusts the height via upper adjusting bolts.

- 2. If some customers' ground has hardened and the cement layer thickness is 30cm, they can be directly fixed with expansion anchor bolts or chemical anchor bolts, reducing the amount of construction and speeding up the construction process. In general, it is not advised.

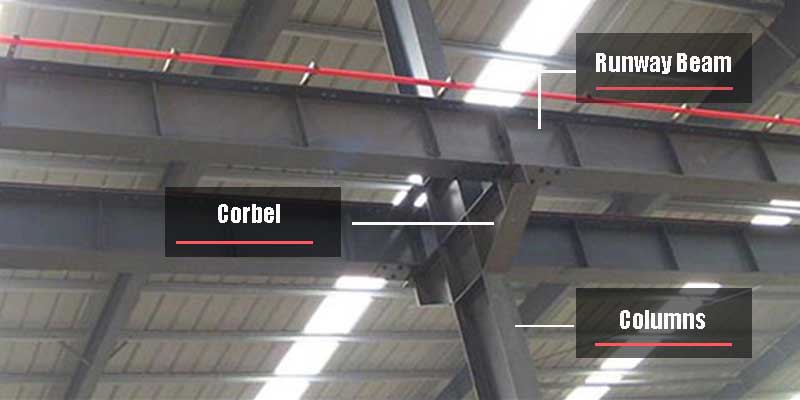

2. Crane Runway Beam/ Crane Runway Bearing Beam / Crane travelling beam,

The steel beam which is specially designed to support the bridge crane is named runway bearing beam, crane runway beam, or crane travelling rail beam., installed on the up part of the factory workshop.

The crane runway bearing beam is the subgrade of the workshop crane. The crane rail is installed on the top of the bearing beam which enables the bridge crane travelling along the crane rails.

The crane runway beam can be classified into the following types: A, H beam,made of H shaped steel beam. B, a fish-belly type runway beam and C, the reinforced concrete crane runway beam. Generally, the bearing beam is made of steel structure or a reinforced concrete structure, and some hydropower projects also have wall crane beams (Figure D ).

A. H beam runway bearing beam ,made of H shaped steel beam

B. A fish-belly type runway beam

C. The reinforced concrete crane runway beam.

D. Wall for supporting crane beams.

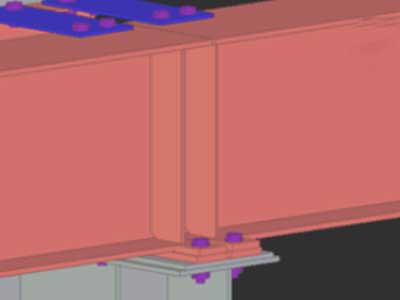

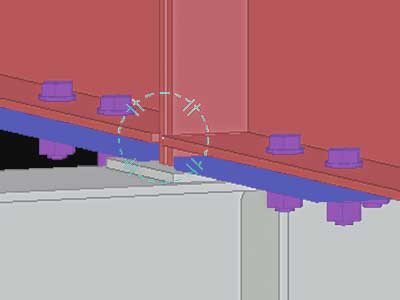

2.1. Corbel

It is used to support the crane runway beam and transmit the pressure of the crane beam to the column.

There are generally two ways to connect the corbel and the crane beam: a. Flat support type (see Figure A) & b. Flange support type (see Figure B)

a. Flat support type (see Figure A)

The main stress-bearing part is the lower flange plate of the crane runway beam. The pressure on the corbel is relatively far from the center line of the corbel. However, the processing accuracy of the crane bearing beam is not high, and it is generally suitable for small tonnage (≤10T) light-weight bridge crane systems. Due to eoconomical price, the types of crane runway beam and corbles are widley used.

b. Flange support type (see Figure B)

The stress-bearing part is the protruding vertical flange at the end of the crane runway beam. The pressure on the corbel is very close to the center line of the corbel. The force is ideal, but the processing accuracy is high, the protruding part is required to be flat, and the welding quality is good. Generally suitable for large-tonnage cranes.

3. Column bracing

It is a connecting rod installed between two adjacent columns to ensure overall structural stability, improve lateral stiffness, and transmit longitudinal horizontal force. Angle irons can be customized to be single-row or double-row. Welded or bolted connections to steel columns are possible.

In general, it is not always necessary to erect every span. Depending on the size of the factory building, the size of the bay, the tonnage of the factor overhead crane, and other factors, it is usually sufficient to arrange 1-2 sets in the direction of the factory building's long axis.

4. Roof beam

It is the main structural component that bears the pressure from purlins and roof panels in the roof structure. It primarily supports bending moment and shear force.

The roof beam in a large-span factory building is usually divided into two or three sections for ease of transportation and fabrication, and the middle is connected with high-strength bolts.

5. Purlin

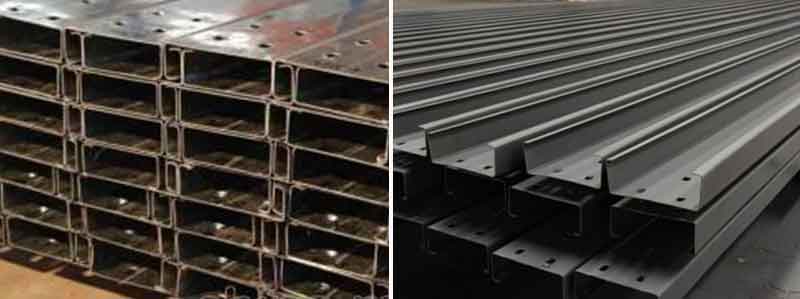

There are two types of wall purlins and roof purlins, generally made of C-shaped steel or Z-shaped steel.

A. Wall purlins (wall beam).

A circle of steel formed around the column, also known as the wall beam. It is used to secure the wallboard (color steel tile) and support the horizontal wind load and self-weight of the wallboard. Ordinary bolts are typically used to connect the columns that form the wall's skeleton.

B. Roof purline.

Refers to the profiled steel laid on the roof along the vertical direction of the portal steel beams to reduce the span of the roof color steel tiles and bear the weight of the color steel tiles to form a roof skeleton.

The C type purling is suitable for supporting roof and wall panels, and the thickness is 2.5mm or 3mm.

The Z type purlin is used for roof with large slope.

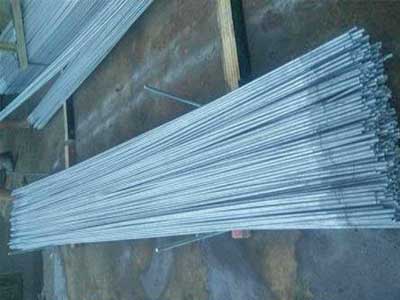

6. Purlin Rods

It is used to adjust and control the stability of two adjacent purlins, generally made of round steel with a diameter of 12 or 14. Divided into oblique and straight bars.

Therefore, generally the walls and roofs will use the braces.

Straight rods

Rods

Wall rods

Roof rods

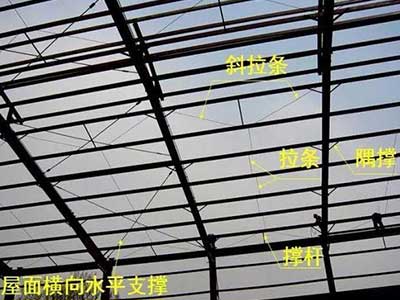

7.Roof brace rods

The roof brace robs are refers to the round steel parts which are used to connect two adjacent portal steel beams in order to increase the roof's overall rigidity and maintain horizontal stability. .

Roof bracing rods vs. Purlin rods

The roof bracing rods has similar functions with that of purlin rods to the support between the columns, but it differs from purlin rods in the following ways:

- The purlin rods are the purlin conditions' connectors, while the roof braces are the steel beams' connectors.

- Roof bracing rods are larger in diameter and length than purlin rods.

8.Tie bar

Through the portal steel beam, the roof is integrally connected, and the components used to improve the lateral stability of the overall steel structure . The tie bars are generally made of steel pipes.

9. Angle brace

The angle braces are the diagonal braces, which are connecting girders and purlins for out-of-plane stability of members. Generally made of angle iron.

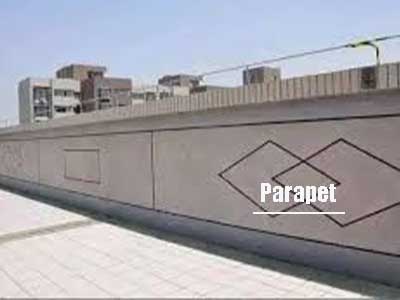

10. Parapet

The term "parapet" refers to the low wall that surrounds the roof. The main function, in addition to ensuring safety, is to apply waterproof pressure bricks to the bottom to prevent water seepage from the waterproof layer or overflow of rainwater on the roof. According to national building codes, the height of the parapet wall on the superior's roof should not be less than 1.1m and should not be greater than 1.5m.

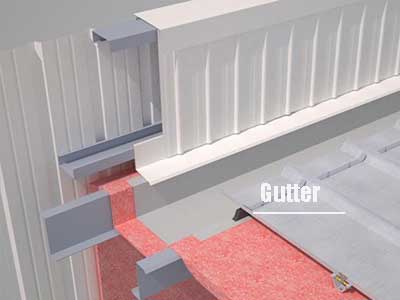

11.Gutter

It is the gutter that collects rainwater on the roof, usually made of stainless steel

12.downpipe

It is the drainage pipe, which is connected to the gutter from the roof and fixed outside the wall to drain the rainwater from the roof. It is generally made of plastic material and can be round or square.

13.awning

Installed above the front door for shade and rain protection

15.steel tile & other material for rook contructions

Color profiled tile is another name for colored steel tile. It is a profiled steel plate made of color coated steel plate that is rolled and cold bent into various wave shapes. It is an important material that forms the edging of roofs and walls. It has light weight, high strength, rich color, easy and quick construction, earthquake resistance, fire prevention, rain resistance, long life, no maintenance, and so on. They are commonly used nowadays.

steel tile

Glass wool - Generally, the glass wool is installed on the inner side of the roof for thermal insulation

wire gauze

The wire gauze is used to stabilizes and supports insulation

Matters needs to be noted:

- About steel structure transportation -Also, the steel structure has irregularities. It is important to choose proper ways of transportation. If the containers are used, it is better to use open top cabinets for easy loading and unloading.

- About Bolts - There are two types of connecting bolts: ordinary and high-strength. Ordinary bolts are generally grade 4.4, grade 4.8, grade 5.6 and grade 8.8. High-strength bolts are generally grade 8.8 and grade 10.9, of which grade 10.9 is the majority. Bolt simple representation method M a*b, a is the diameter, b is the length, such as M10*30 means that the diameter of the threaded rod is 10mm, and the length (excluding the bolt head) is 30mm

What are the types of steel structure workshops?

Steel structure workshop buildings manufactured by our factory are classified as light duty or heavy duty based on the type of steel used. There are also single-span, double-span, and multi-span steel structures, as well as single-story, double-story, and multi-story steel frame workshops to meet your specific application needs.

Types of steel structures buildings for you to selectWe offer a variety of crane steel structure buildings with overhead crane systems for sale. For your consideration, there are two types of steel structures: light and heavy. Light steel buildings are best suited for low-load bearing structures, and these structures are typically constructed using H-beams. The use of heavy steel structures is common when a building must support relatively heavy loads. As a result, you must choose it based on your overhead cranes and other unique requirements.

Our factory primarily offers two types of steel structure crane building .

- Heavy steel building - It is ideal to erect large industrial buildings using this metal framework. It can be built on location very quickly and last for many years. This structural form can be designed for a variety of uses, including the processing, creation, storage, and distribution of materials.

- Additionally, it can be classified as a steel structure building with a single span, double span, or multiple spans. Two rows of steel columns support a single span metal building, and the steel columns are supported by the roof. Two single span steel structures combine to form a double span steel building. For our clients, our company can also offer specialized service. Please feel free to contact our experts so that you can obtain the best possible product for your projects.

- Light steel structure crane building - Light steel construction is a new type of building material that is ideal for small structures. It makes effective use of the available building space and lowers the facility's height by using thin steel sheets. It is also more cost-effective than other structural forms.

Single-Story Steel Structural Workshop building

Multi-Story Steel Structure Building

Multi-Span Steel Structure Workshop Factory

Single-Span Steel Structure Building with Bridge Crane System

Heavy Steel Structure Factory Building

Industrial Steel Workshop Building

Here are some options for the steel structure crane building design:

- To meet your specific needs, the light steel structure workshop can be designed and constructed in any size or shape.

- Steel columns and beams make up the bulk of buildings made of steel, which use Q235B or Q345B H beams. The Q345B H beam is also used in the runway beam for overhead cranes. Three layers will be used in the painting.

- There are three types of wall and roof purlins: C, Z, and U. Roof horizontal bracing system will use angle steel.

- Double layer angle steel will be used for the wall column and cross bracing system.

- The color of the roof and walls can be changed to meet your needs.

- There are two types of panels. Steel or single tiles are one type, and composite panels made of polyphenylene, rock wool, and polyurethane are the other. It is kept warm in the winter and cool in the summer thanks to the foam sandwiched between the two layers of panels. Additionally, sound insulation is a result of it.

Things to consider for steel structure workshop design

Some factors should be considered when designing a steel structure workshop. It includes, but is not limited to:

- Impervious: Rainwater usually enters a metal roof through overlapping seams or nodes. Sealing washers should be used in the screw mouth to achieve impervious function, which will then be hidden fixed. To eliminate laps, a sealant or welding treatment should be applied to the panel overlap.

- Fire proof - In the event of a fire, it must ensure that the metal roof materials do not burn and that the flame does not penetrate the metal roof.

- Wind proof: Taking into account the maximum wind pressure in the surrounding area, the design of the steel structure workshop should ensure that the metal roof panels are not pulled away by negative wind pressure.

- Sound insulation: o stop sound from traveling from indoors to outdoors or from inside to outside, install sound insulation. Insulation materials are typically placed between the layers of metal roof panels. The density and thickness of sound insulation materials have a strong relationship with insulation effectiveness.

- Ventilation: considering air circulation indoors and outdoors, vents should be set on building roof structure.

- Moisture proof: to prevent the condensation of water vapor in the metal roof layer. The solution is to fill the insulation wool in the layer of roof panels and paste waterproof membrane on the roof panels.

- Load-bearing: the steel structure shed workshop should has large load-bearing capacity to withstand the attack of heavy rain and snow as well as bear the construction and maintenance load.

- Ventilation:Considering air circulation both inside and outside, vents ought to be placed on building roof structures.

- Moisture-proof: to stop water vapor from condensing in the metal roof layer. The answer is to apply waterproof membrane to the roof panels and fill the layer of roof panels with insulation wool.

- Load-bearing: The steel shed workshop should have a significant amount of load-bearing capacity in order to withstand attacks from heavy rain and snow as well as bear the construction and maintenance load.

- Lightning protection: to keep lightning from entering the room through the metal roof.

- Lighting:Sunroofs can be used to improve the interior lighting during the day. Lighting panels or glass can be used.

- Control thermal expansion and contraction: Because some areas have large temperature differences, it must ensure that the metal roof panels are not damaged by thermal expansion and contraction stress.

How to Select Steel Structures?

How should I choose steel buildings? Consider the various structural characteristics firstly,

- When there is a large suspended load or moving load in a light steel structure factory, consider the grid frame instead of the portal frame.

- In areas with heavy snowfall, the roof curve, such as a three-center round reticulated shell, should be conducive to snow sliding. The same is true in areas that receive a lot of rain.

- If the building structure permits, placing supports in the frame will be more cost-effective than using a straightforward node-connected frame.

Second, consider the steel structure factory's layout.

The steel structure factory's layout should take into account the system's characteristics, load distribution, and the structure's nature.

Third, take the member's cross-section into account.

Make a rough estimate of the member's cross-section, focusing on the cross-sectional shape and size of beams, columns, and supports, for example.

Our professionals are here to help you design the most appropriate and cost-effective steel structure factory with overhead crane system for your business.

Selection guide on steel structure crane building

The following specifications must be given in order to assist in designing the ideal steel structure frame workshop:

- Functions: what is the function of the steel structure building, as production workshop, warehouse or other?

- Length: the steel structure plant's total length must be determined. Column spacing can be 6m, 7.5m, 9m, or 12m in general.

- Width: generally 9-36m. When the width is large, the number of spans must be determined.

- Height: the net height of the steel metal building plant is measured from the indoor ground to the intersection of the steel column axis and the steel beam axis. If there is no overhead crane in the workshop, it should be 4.5-9m; if there is one crane system , the specific model and lifting height of the bridge crane must be determined.

- Roof panels, doors, and windows must meet certain requirements.

- Furthermore, geological and climatic conditions such as earthquake resistance level, local maximum wind speed, maximum rainfall, and maximum snowfall must be considered for special areas. If there are any issues, please bring them to the attention of our sales manager.

- We can process and produce steel structures for your crane building based on your design drawings if you provide them.

Many Factors Affect Crane Steel Structure Price

- Crane building steel structure length and height: A larger steel structure will require more steel materials, which will increase the cost.

- The span:The span of the metal building is proportional to the span of your overhead crane. A longer span will require more materials.

- Insulation: Determine whether the roofs and walls require insulation. Our company can provide thermal insulation for roofs, but clients will have to pay more.

- Lighting panels: Do you require lighting panels on the walls? Many customers occasionally request it, and the component will raise the price.

- Transportation costs: Because transportation costs have risen recently, the price of our crane steel structures will rise if delivery costs rise.

- Other considerations:The climate should also be considered. If it rains frequently in your area, the roof waterproofing should be considered.

How do I get the price of a steel structure factory?

Please provide the following details so that we can provide you the steel structure of crane building price:

- The structure's dimensions (L*W*H)

- Are there any bridge crane systems are intalled? If so, please provide the overhead crane load capacity, work duty, and so on.

- Other requirements include the thickness and coating of color panels, insulation material and thickness, the presence of a skylight, and so on.

The cost of constructing a steel structure factory is determined by several factors, including the type of structure, dimensions, usage, steel price, and so on. As a result, the specific price should be calculated based on the plant design and the current steel price. Contact us today if you are interested in China steel structure factory.

What are the applications of crane building steel structure?

We can design and deliver a very strong and long-lasting industrial steel crane building, regardless of whether you need a steel production plant that uses the heaviest overhead crane or a warehouse that requires a multi-bridge crane system. You can move heavy loads from one area of a building to another using our steel metal buildings with overhead cranes without sacrificing structural integrity. Our designing team and crane factory can design and deliver a variety of metal buildings and bridge crane systems for the following industrial uses and applications:

Fabrication shop, Distribution facility, Warehouse facility, Processing plant, Metal manufacturing plant, Pipe production, Storage facility, Heavy equipment facility, Automotive factory, Power plant, etc.The steel structure building can be designed as a steel structure workshop, steel structure garage, or other production factory. In these metal structures, the steel structure overhead cranes are available for lifting a variety of industrial materials. Numerous steel structures with various purposes have been produced by us; the product is well-liked due to its many benefits. Additionally, our company sells a variety of overhead cranes in a range of conditions, making it a great choice for you to use us as your steel structure supplier.

Advantages of overhead crane steel buildings

Pre-engineered metal buildings provide the most value and the most cost-effective solutions for all of your industrial steel crane buildings.

- Cost Savings—Our prefabricated metal buildings provide numerous short- and long-term economic benefits. They also reduce loss and damage caused by environmental hazards and exposure. Metal buildings have a longer lifespan and require little to no maintenance. It will significantly reduce the construction time of your buildings, saving you both time and money.

- Clear Span Capabilities— Our steel buildings' clear span capabilities make them ideal for accommodating large overhead cranes. Our metal building systems provide up to 300 feet of column-free space that supports both the crane system and heavy material loads due to the strength of steel framing.

- Design Flexibility and Adaptability—Our industrial metal crane buildings provide superior architectural and design flexibility to meet all of your building needs and requirements. We provide a variety of customizable design options that allow for easy expansion when more space is needed or reconfiguration to accommodate requirement changes and needs.

- Durability and reliability— The steel structure is lightweight but strong, and it is also simple to maintain. It can be used for more than 50 years.

- Excellent security —The prefabricated steel workshop can be isolated from outdoor environments while also avoiding leaks such as water seepage. It is also extremely resistant to fire and corrosion.

- Long-lasting and low-maintenance — Our steel structured crane buildings withstand harsh environments and weather conditions while maintaining structural integrity for your congregation's safety and protection. Their low-maintenance design saves you money over the life of your building. The steel structure fabrication workshop is strong enough to withstand strong winds and heavy snow. It also has a high seismic performance.

- Quick and flexible assembly —The pre-engineered metal crane building kits are simple to put together. Crane building components are engineered for your project using advanced technology and arrive at the construction site ready to be installed. This accelerates the project's time to market while lowering the in-place cost.

- Eco-Friendly and Highly Sustainable Alternative —Steel is a highly sustainable alternative to traditional building materials.— Furthermore, our overhead crane steel buildings are adaptable to energy-efficient insulation systems, allowing you to save money on energy while also providing a safe air environment for all of your valuable assets.

- Beautiful Appearance— We are devoted to provide overhead crane metal structures that are both beautiful and cost-effective. Our construction experts can provide you with a steel building that is both aesthetically pleasing and functionally adequate while staying within your budget.

- High utilization rate —Steel structures buildings are simple to move and relocate, and they can also be recycled without causing pollution.

The structural steel workshop can be an affordable and effective solution for some potential users of electric overhead cranes who are looking to build their own workshops rather than renting facilities or having pre-existing buildings to support the crane.

Steel Crane Building Installation And Maintenance

Our business has a skilled after-sales service team to offer customers after-sales service, including installation, staff training, spare parts supply, technical consulting services, etc. To offer better and quicker services, we also have offices abroad in the Philippines, Malaysia, Indonesia, Pakistan, and Uzbekistan. After-sales support is covered if you purchase our steel structure workshop.

Steel structure installation key points- The installation process of a structural steel fabrication workshop primarily entails installing steel columns, column bracing, temporary seating for steel crane beams, roof beams and bracing, correcting and fixing crane beams, and steel structure future maintenance.

- Due to the large weight and length of the columns, it is impossible to carry out one-time production and transportation. As a result, it will be manufactured in sections and assembled on the construction site.

- A number of precautions should also be taken during installation to guard against component damage. For example, before hoisting the steel columns, a piece of wood should be placed on the column base plate to prevent damage.

Columns of steel structure erection

Wall panel installation of steel structure building with overhead crane system

Steel structure & runway beam installation

How To Install Crane Steel Structures?

When installing crane steel structure, you should consider not only the building steel structure , but also the specifications of your overhead cranes.

- The steel workshop crane beam should be used to build the runway, and the space between the roof and the crane runway beam should be sufficient for you to use your overhead crane.

- The electric travelling crane can be installed with the steel structure at the same time, and then the roof, wall, and floor can be fixed.

- If you want to use electric eot cranes in your steel structure building but your steel column lacks brackets. You can attach the brackets to the steel column at the appropriate location.

To eliminate security risks, the installer must check whether the overhead crane can run smoothly on the runway beam after installation. Furthermore, the staff is responsible for ensuring that all parts of the building steel structure are properly welded. Please contact us if you require installation services.

How to take care of your steel structure building?

For owners of steel structure workshops, here are some maintenance tips:

- Owners of steel structure buildings are not permitted to modify the structure or remove bolts or other parts after the buildings have been installed. You must check with the manufacturer to see if any changes to the building can be made before making them.

- The steel structure needs to be painted and maintained after being in use for about three years to ensure a nice appearance and excellent safety.

- In order to prevent electric shock accidents when using electrical equipment, the wire and cable should be isolated by slot line pine.

- The crane building steel structures need to be cleaned frequently.

- Any surface damage to metal panels must be fixed quickly to stop rain and sunlight from corroding the metal plate.

The service life of the building is greatly influenced by the maintenance of the structural steel design workshop, so the owners must give it adequate attention.

We offer a range of steel structure buildings, including steel structure warehouses, shops, and sheds. We are a professional provider of material handling crane solutions. Contact us today to check what we can do for your overhead crane and crane building steel structure design and manufacturing.

Main Projects

Related Products

Latest project

32/5 Ton Overhead Crane Sale in India: Case Study

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch