Dealer vs. Direct Purchase: Which is Better for 10 Ton Overhead Cranes?

Choosing between dealer and direct purchase for 10 Ton Overhead Cranes? Evaluate costs, support, and customization to determine the best option.

Category: Featured

Your Trusted Overhead Crane Manufacturer & Supplier

Dealer vs. Direct Purchase: Which is Better for 10 Ton Overhead Cranes?

Choosing between dealer and direct purchase for 10 Ton Overhead Cranes? Evaluate costs, support, and customization to determine the best option.

When it comes to acquiring a 10 Ton Overhead Crane, one of the fundamental decisions buyers face is whether to go through a dealer or purchase directly from a manufacturer. But before delving into the intricacies of this decision, let's first clarify what a 10 Ton Overhead Crane entails.

Simply put, a 10 Ton Overhead Crane is a powerful lifting machine designed to hoist and transport heavy loads within industrial settings. These cranes are commonly utilized in warehouses, manufacturing plants, and construction sites to streamline material handling operations.

The decision between purchasing through a dealer or directly from a manufacturer holds significant weight in the procurement process. It's not merely about acquiring equipment; it's about determining the most efficient and cost-effective approach that aligns with your specific needs and goals.

Overview of 10 Ton Overhead Cranes

Before diving into the intricacies of how to acquire a 10 Ton Overhead Crane, it's essential to grasp the fundamentals of this heavy-duty lifting equipment.

Types of 10 Ton Overhead Crane for General Use and Hazarouds Use

When considering 10 Ton Overhead Cranes for general use and hazardous environments, several types are commonly utilized to meet different operational requirements and safety standards:

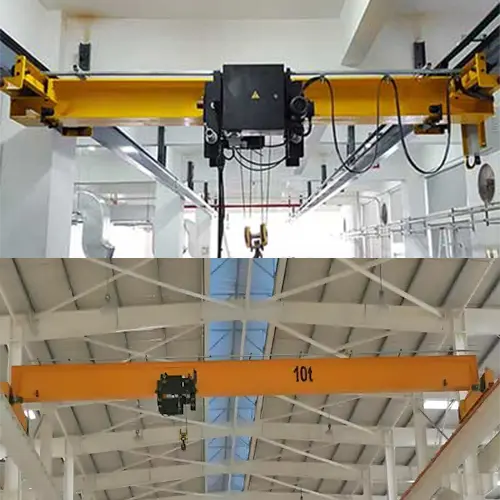

Single Girder Overhead Crane 10 Ton :

General Use: Single girder overhead cranes are versatile and commonly used in general industrial applications, such as warehouses, workshops, and manufacturing facilities. They feature a single bridge beam supported by end trucks and can handle light to moderate loads efficiently.

Hazardous Use: For hazardous environments, single girder overhead cranes can be designed with explosion-proof components and features to mitigate the risk of ignition and ensure compliance with safety regulations.

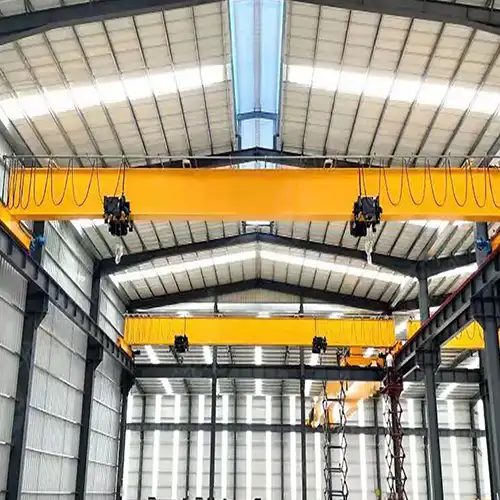

Double Girder Overhead Crane 10 Ton :

General Use: Double girder overhead cranes are ideal for heavy-duty lifting applications and environments requiring high lifting capacities and long spans. They feature two bridge girders supported by end trucks, providing enhanced stability and load-bearing capacity compared to single girder cranes.

Hazardous Use: In hazardous environments, double girder overhead cranes can be equipped with specialized components such as spark-resistant features, sealed electrical enclosures, and explosion-proof hoists to minimize the risk of fire or explosion.

Top Running Overhead Crane 10 Ton:

General Use: Top running overhead cranes are commonly used for lifting and transporting heavy loads over long distances. They run on rails installed on the top of the runway beams and are suitable for applications requiring precise positioning and high lifting heights.

Hazardous Use: In hazardous environments, top running overhead cranes can be designed with additional safety features such as corrosion-resistant materials, sealed electrical components, and redundant systems to ensure safe operation in potentially combustible atmospheres.

Under Running Overhead Crane 1 Ton 10 Ton:

General Use: Under running overhead cranes are designed to run on rails mounted underneath the runway beams, making them ideal for low headroom applications where space constraints are a concern. They are commonly used in facilities with limited overhead clearance.

Hazardous Use: In hazardous environments, under running overhead cranes can be outfitted with specialized components such as explosion-proof wiring, sealed motors, and non-sparking materials to minimize the risk of ignition and ensure safe operation in hazardous areas.

Gantry Crane:

General Use: Gantry cranes are versatile lifting devices that feature a bridge supported by legs or gantry uprights, allowing them to move freely along a runway system installed on the ground. They are commonly used in outdoor settings, construction sites, and shipyards.

Hazardous Use: Gantry cranes for hazardous environments may incorporate features such as spark-resistant materials, explosion-proof controls, and flameproof enclosures to ensure safe operation in potentially hazardous areas.

In both general and hazardous use cases, it's essential to select an overhead crane type that meets the specific operational requirements, safety standards, and environmental conditions of the application. Additionally, adherence to regulatory guidelines and standards such as OSHA, ANSI, and NEC is crucial to ensure the safe and compliant operation of overhead cranes in hazardous environments.

Specialized Types of 10 ton Overhead Cranes

Specialized types of 10 ton overhead cranes are designed to meet specific operational requirements and cater to unique applications across various industries. Here are some specialized types:

Magnet Crane:

Application: Magnet cranes, also known as electromagnetic cranes, are designed for handling ferrous materials such as steel plates, bars, and coils.

Operation: These cranes are equipped with electromagnets that can be switched on and off to attract and release metal loads, facilitating efficient material handling and positioning.

Industries: Commonly used in steel mills, metal fabrication facilities, scrap yards, and recycling centers.

Grab Bucket Crane:

Application: Grab bucket cranes are utilized for handling bulk materials such as sand, gravel, coal, and agricultural products.

Operation: These cranes are equipped with mechanical or hydraulic grab buckets that can scoop up and release materials, enabling efficient loading and unloading of bulk cargo.

Industries: Found in ports, harbors, mining operations, and construction sites where bulk material handling is required.

Foundry Crane:

Application: Foundry cranes are specifically designed for the harsh environments of foundries and metal casting facilities.

Operation: These cranes feature heat-resistant components, protective enclosures, and specialized lifting attachments to handle molten metal ladles, molds, and casting equipment safely.

Industries: Commonly used in steel foundries, aluminum casting facilities, and other metal manufacturing operations.

Clean Room Crane:

Application: Clean room cranes are designed for use in controlled environments with strict cleanliness requirements, such as pharmaceutical and semiconductor manufacturing facilities.

Operation: These cranes feature sealed components, smooth surfaces, and specialized coatings to prevent contamination and maintain cleanliness standards.

Industries: Found in clean rooms, laboratories, and other controlled environments where product purity is essential.

Explosion-Proof Crane:

Application: Explosion-proof cranes are engineered to operate safely in hazardous environments where flammable gases, vapors, or dusts are present.

Operation: These cranes are constructed with spark-resistant materials, sealed electrical components, and explosion-proof enclosures to prevent ignition sources and minimize the risk of fire or explosion.

Industries: Used in chemical plants, oil refineries, petrochemical facilities, and other hazardous environments where safety is paramount.

Shipyard Crane:

Application: Shipyard cranes are designed for heavy-duty lifting and assembly tasks in shipbuilding and repair yards.

Operation: These cranes feature high lifting capacities, extended reach, and specialized lifting attachments such as spreader beams and ship blocks for handling large ship components and structures.

Industries: Commonly used in shipyards, dockyards, and marine construction facilities.

These specialized types of 10 ton overhead cranes are tailored to specific industries and applications, offering unique features and capabilities to meet the diverse needs of modern industrial operations.

Technical Specifications of Standard Single Girder and Double Girder Overhead Cranes

At its core, a 10 Ton Overhead Crane is designed to lift and move objects weighing up to 10 tons within a specified radius. These cranes typically consist of a bridge, hoist, and trolley system, all of which work in tandem to facilitate smooth and efficient material handling. The technical specifications of these cranes may vary depending on factors such as span length, lifting height, and operational environment.

Common Applications:

The versatility of 10 Ton Overhead Cranes makes them indispensable across various industries. From loading and unloading cargo in warehouses to assembling heavy machinery in manufacturing plants, these cranes play a vital role in streamlining processes and enhancing productivity. They are also widely used in construction sites for tasks such as lifting steel beams and concrete panels.

- Warehousing and Logistics: 10 Ton Overhead Cranes are essential for efficiently loading and unloading cargo in warehouses and distribution centers.They facilitate the movement of heavy pallets, containers, and materials, optimizing storage space and expediting the distribution process.

- Manufacturing and Assembly: In manufacturing plants, these cranes are instrumental in assembling heavy machinery, such as automotive components, industrial equipment, and aerospace structures.

They aid in the safe and precise positioning of parts during the assembly process, improving production efficiency and quality control. - Construction and Infrastructure: At construction sites, 10 Ton Overhead Cranes are used for lifting and installing heavy materials, including steel beams, concrete panels, and precast elements.They help streamline construction workflows, accelerate project timelines, and enhance safety by reducing manual handling and labor-intensive tasks.

- Mining and Extraction: In mining operations, these cranes are employed for various tasks, such as transporting ore, equipment maintenance, and constructing infrastructure within mineshafts.They withstand harsh operating conditions and heavy loads, contributing to the efficiency and safety of mining operations.

- Shipbuilding and Marine Industries: Shipyard cranes with a 10 ton capacity are commonly used in shipbuilding and repair yards for lifting ship components, hull sections, and heavy machinery.They support the construction and maintenance of vessels, ensuring precise and efficient handling of large maritime structures.

- Steel and Metal Fabrication: In steel mills and metal fabrication facilities, these cranes assist in handling raw materials, such as steel coils, bars, and plates, as well as finished products.They play a critical role in material processing, storage, and transportation, contributing to the operational efficiency of metalworking industries.

- Power Generation and Utilities: - Within power plants and utilities, 10 Ton Overhead Cranes are utilized for maintenance, repair, and installation of equipment, such as turbines, generators, and transformers.They support outage management and infrastructure upgrades, ensuring reliable and uninterrupted power supply to communities and industries.

These are just a few examples of the diverse applications where 10 Ton Overhead Cranes are indispensable, highlighting their versatility and importance across various sectors. Their ability to handle heavy loads safely and efficiently makes them a cornerstone of modern industrial operations.

To ensure safety and compliance, 10 Ton Overhead Cranes are subject to rigorous industry standards and regulations. These standards govern aspects such as design, installation, operation, and maintenance to mitigate risks and prevent accidents. Adhering to these standards not only safeguards personnel and property but also enhances the longevity and performance of the crane.

By familiarizing oneself with the technical specifications, common applications, and regulatory framework surrounding 10 Ton Overhead Cranes, buyers can make informed decisions when navigating the procurement process. This knowledge forms the foundation for evaluating the suitability of different acquisition methods, whether through dealers or direct from manufacturers.

Overview of Dealer Purchase

Dealers, are intermediary entities that facilitate the sale between manufacturers and end-users. They act as authorized resellers of crane products, representing one or multiple manufacturers in the market.

Role of Dealers:

- Product Representation: Dealers serve as the primary point of contact between manufacturers and buyers, acting as ambassadors for the crane products they represent. They showcase a diverse range of crane models, demonstrating features, specifications, and benefits to potential buyers. By providing comprehensive product information and demonstrations, dealers help buyers make informed decisions that align with their specific needs and operational requirements.

- Expertise and Guidance: Leveraging their extensive knowledge and experience in the crane industry, dealers offer expert guidance and advice to buyers throughout the purchasing process. They possess a deep understanding of crane technologies, applications, and industry standards, enabling them to provide valuable insights and recommendations to buyers. Whether it's determining the appropriate crane configuration, assessing load capacities, or addressing safety considerations, dealers serve as trusted advisors who help buyers navigate through various options and make confident decisions.

- Quotation and Negotiation: Dealers play a crucial role in facilitating the quotation and negotiation process between buyers and manufacturers. They provide buyers with detailed quotations that outline pricing, delivery timelines, and terms of sale, ensuring transparency and clarity in the transaction. Dealers also act as intermediaries in negotiations, advocating for buyers' interests while maintaining positive relationships with manufacturers. By facilitating fair and equitable negotiations, dealers help ensure a mutually beneficial outcome for both parties.

- After-Sales Support: Post-purchase, dealers continue to support customers with valuable after-sales services to maximize the performance and longevity of the crane equipment. This includes assistance with crane installation, operator training, and ongoing maintenance and servicing. Dealers work closely with manufacturers to ensure that customers receive prompt and efficient support, addressing any technical issues or concerns that may arise during the crane's lifecycle. By offering comprehensive after-sales support, dealers enhance customer satisfaction and loyalty, fostering long-term partnerships with buyers.

- Local Presence: Dealers often maintain a physical presence in local markets, establishing themselves as trusted partners within their communities. This local presence enables dealers to provide quick response times for inquiries, troubleshooting, and emergency support, strengthening customer relationships and building trust. By being readily accessible to buyers, dealers demonstrate their commitment to customer satisfaction and ensure that customers receive timely assistance whenever needed.

Overall, dealers play a vital role in representing 10 Ton Overhead Crane products, offering expertise, guidance, and support throughout the purchasing process and beyond. Their dedication to customer satisfaction and their ability to facilitate seamless transactions make them invaluable partners for both buyers and manufacturers in the crane industry.

By collaborating with dealers, buyers can leverage their expertise and support throughout the procurement journey, from initial consultation to post-sale assistance. Dealers play a crucial role in simplifying the purchasing process and ensuring a seamless experience for buyers seeking 10 Ton Overhead Cranes.

Advantages of Purchasing from Dealers

Purchasing a 10 Ton Overhead Crane through a dealer offers several benefits that can streamline the procurement process and enhance the overall buying experience. Let's explore these advantages in detail:

- Access to Various Brands and Models: Dealers typically represent multiple manufacturers in the crane industry, providing buyers with access to a wide range of brands and models. This diverse selection allows buyers to compare features, specifications, and pricing across different crane offerings, empowering them to make informed decisions that align with their specific needs and preferences. Whether it's a specific brand known for durability or a model tailored to unique operational requirements, dealers can offer options that cater to a variety of applications and budgets.

- Expertise and Guidance: One of the primary advantages of purchasing from dealers is the expertise and guidance they offer throughout the buying process. Dealers are knowledgeable about the intricacies of 10 Ton Overhead Cranes, including technical specifications, industry standards, and best practices. They leverage this expertise to provide personalized recommendations and guidance to buyers, helping them navigate through the complexities of crane selection. Whether it's understanding load capacities, determining suitable crane configurations, or addressing specific operational challenges, dealers serve as trusted advisors who assist buyers in making well-informed decisions that maximize the value of their investment.

- After-Sales Support: Beyond the point of sale, dealers play a crucial role in providing after-sales support to buyers. This includes services such as crane installation, operator training, and ongoing maintenance and servicing. Dealers work closely with manufacturers to ensure that buyers receive prompt and efficient support throughout the lifecycle of their crane. Whether it's troubleshooting technical issues, scheduling routine inspections, or procuring replacement parts, dealers serve as reliable partners who are committed to the long-term success and satisfaction of their customers. By offering comprehensive after-sales support, dealers help optimize crane performance, minimize downtime, and maximize return on investment for buyers.

In summary, purchasing a 10 Ton Overhead Crane from a dealer offers distinct advantages, including access to a diverse selection of brands and models, expertise and guidance throughout the buying process, and comprehensive after-sales support. By leveraging the resources and support provided by dealers, buyers can navigate the procurement journey with confidence, knowing that they have a trusted partner to guide them every step of the way.

Disadvantages of Purchasing from Dealers

While purchasing a 10 Ton Overhead Crane through a dealer offers various advantages, it's essential to consider potential drawbacks that buyers may encounter. Let's explore these disadvantages in more detail:

- Higher Prices Due to Middleman Markup: One of the primary concerns associated with purchasing from dealers is the possibility of higher prices due to the middleman markup. Dealers act as intermediaries between manufacturers and buyers, adding a margin to the cost of the crane to cover their overhead expenses and profit margins. As a result, buyers may end up paying a premium compared to purchasing directly from the manufacturer. This markup can significantly impact the overall cost of the crane, particularly for buyers operating on tight budgets or seeking to maximize cost savings.

- Limited Customization Options: Another potential drawback of purchasing from dealers is the limited customization options available to buyers. Dealers typically offer a selection of pre-configured crane models from manufacturers, which may have predefined specifications and features. While these standard models may meet the needs of many buyers, they may not fully align with the specific requirements of certain applications or industries. As a result, buyers seeking highly customized crane solutions may find their options limited when purchasing through dealers, potentially compromising their ability to optimize crane performance and efficiency for their unique operational needs.

- Potential Delays in Procurement: Purchasing through dealers can sometimes lead to delays in procurement due to various factors such as order processing times, inventory availability, and logistical challenges. Dealers rely on manufacturers to fulfill orders and deliver crane products within specified timelines, which may be subject to delays beyond their control. Additionally, coordination between multiple parties involved in the procurement process, including manufacturers, dealers, and buyers, can introduce complexities that may contribute to delays. These delays can disrupt project schedules, impede operational efficiency, and increase downtime for buyers, highlighting the importance of proactive communication and planning when purchasing through dealers.

In summary, while purchasing a 10 Ton Overhead Crane through a dealer offers advantages such as access to multiple brands and models, expertise and guidance, and after-sales support, buyers should also be mindful of potential disadvantages, including higher prices due to middleman markup, limited customization options, and potential delays in procurement. By carefully weighing these factors and considering their specific needs and priorities, buyers can make informed decisions that optimize the value and efficiency of their crane investment.

Overview of Direct Manufacturer Purchase

Direct manufacturer purchase refers to the procurement process wherein buyers acquire a 10 Ton Overhead Crane directly from the crane manufacturer, bypassing the involvement of intermediaries such as dealers or distributors.

Advantages of Direct Manufacturer Purchase:

- Lower Costs: One of the primary advantages of purchasing directly from the manufacturer is the potential for lower costs. By eliminating the middleman markup associated with dealer purchases, buyers can often secure more competitive pricing for crane products. Manufacturers may offer direct pricing incentives, discounts, or promotional offers to encourage buyers to purchase directly, resulting in cost savings that can significantly impact the overall procurement budget. Additionally, direct manufacturer purchase allows buyers to negotiate pricing directly with the manufacturer, leveraging their purchasing power to secure favorable terms and pricing agreements.

- Direct Communication with Engineers: Another significant advantage of purchasing directly from the manufacturer is the opportunity for direct communication with engineers and technical experts. Manufacturers have in-depth knowledge of their crane products, including design specifications, engineering principles, and performance capabilities. By engaging directly with manufacturer engineers, buyers can gain valuable insights into crane design considerations, technical requirements, and customization options. This direct communication allows buyers to address specific concerns, clarify requirements, and collaborate with engineers to tailor crane solutions that meet their exact needs and specifications. Whether it's discussing load capacities, operational constraints, or integration with existing infrastructure, direct communication with engineers enables buyers to make informed decisions that optimize crane performance and efficiency.

- Customization Flexibility: Direct manufacturer purchase offers buyers greater flexibility in customizing 10 Ton Overhead Cranes to suit their unique requirements. Manufacturers have the capability to accommodate a wide range of customization options, including modifications to crane design, functionality, and features. Whether it's adjusting lifting capacities, specifying crane dimensions, or incorporating specialized accessories, buyers can work closely with manufacturers to create bespoke crane solutions that address specific operational challenges and enhance productivity. This customization flexibility enables buyers to tailor crane configurations to their exact specifications, ensuring optimal performance and efficiency in their specific applications.

In summary, purchasing a 10 Ton Overhead Crane directly from the manufacturer offers several advantages, including lower costs, direct communication with engineers, and customization flexibility. By leveraging these benefits, buyers can optimize their procurement process, secure competitive pricing, and tailor crane solutions to meet their exact needs and requirements.

Challenges of Direct Manufacturer Purchase

While direct manufacturer purchase offers several advantages, it also presents certain challenges that buyers need to consider before making a decision. Let's explore these challenges in more detail:

- Limited Brand Options: One of the primary challenges of purchasing directly from a manufacturer is the limited brand options available to buyers. Unlike dealers who represent multiple manufacturers and offer a diverse selection of crane brands and models, manufacturers typically specialize in their own product lines. As a result, buyers may have fewer options to choose from when purchasing directly, especially if they have specific brand preferences or are looking for alternative crane solutions. This limitation in brand options may restrict buyers' ability to explore different offerings and compare features, potentially limiting their ability to find the most suitable crane for their needs.

- Longer Lead Times: Another challenge associated with direct manufacturer purchase is longer lead times for order fulfillment. Manufacturers often operate on production schedules and lead times that may vary depending on factors such as production capacity, order backlog, and supply chain constraints. As a result, buyers may experience delays in receiving their crane products when purchasing directly from the manufacturer, especially during peak demand periods or for custom-built crane configurations. These longer lead times can impact project timelines, delaying the deployment of the crane and potentially disrupting operational schedules. Buyers need to plan ahead and factor in these lead times when considering direct manufacturer purchase to ensure timely delivery of their crane equipment.

- Potential Communication Barriers: Direct communication with manufacturers may sometimes present communication barriers, particularly for buyers who are not familiar with technical jargon or industry-specific terminology. Manufacturers may use specialized language or engineering terminology that may be challenging for non-technical buyers to understand. Additionally, language barriers or cultural differences may pose challenges in effective communication, especially when dealing with international manufacturers. These communication barriers can hinder the exchange of information, lead to misunderstandings, and potentially impact the accuracy and completeness of order specifications. Buyers need to ensure clear and effective communication with manufacturers to minimize the risk of miscommunication and ensure that their requirements are accurately conveyed and understood.

In summary, while direct manufacturer purchase offers advantages such as lower costs, direct communication with engineers, and customization flexibility, buyers need to be aware of potential challenges, including limited brand options, longer lead times, and potential communication barriers. By carefully evaluating these challenges and considering their specific needs and priorities, buyers can make informed decisions that optimize the value and efficiency of their crane procurement process.

Factors Influencing the Decision

When deciding between dealer and direct manufacturer purchase for a 10 Ton Overhead Crane, several factors come into play. Let's explore these factors in more detail:

Budget Constraints:

Budget constraints play a significant role in the decision-making process. Buyers need to assess their budgetary limitations and determine the most cost-effective procurement option. While purchasing directly from the manufacturer may offer potential cost savings due to the absence of middleman markup, buyers should also consider other factors such as customization costs, shipping fees, and long-term maintenance expenses. Conversely, while dealer purchases may involve higher upfront costs, buyers may benefit from additional services and support that justify the investment.

Budget constraints are a primary consideration for buyers when evaluating procurement options for 10 Ton Overhead Cranes. Here's a detailed breakdown of their significance:

- Assessing Budgetary Limitations: - Buyers must carefully assess their budgetary limitations and financial resources to determine the most cost-effective procurement option.This involves evaluating available funds, considering project budgets, and forecasting future expenditures related to crane acquisition and operation.

- Cost-Effectiveness of Procurement Options: - Direct manufacturer purchase may offer potential cost savings due to the elimination of middleman markup associated with dealer purchases.Buyers should compare the total costs associated with each procurement option, including upfront purchase costs, customization expenses, shipping fees, and long-term maintenance expenses.While direct purchase may seem more cost-effective initially, buyers must also consider potential hidden costs and ongoing expenses over the crane's lifecycle.

- Customization Costs: - Customization is often necessary to tailor crane specifications to meet specific operational requirements and industry standards.Buyers should factor in customization costs associated with both dealer and direct manufacturer purchases, considering the extent of modifications required and their associated expenses.While direct manufacturer purchase may offer greater customization flexibility, buyers should ensure that customization costs remain within budgetary constraints.

- Shipping Fees and Logistics: - Shipping fees and logistics expenses can significantly impact the overall cost of crane procurement, particularly for oversized or heavy equipment.Buyers should consider shipping costs associated with both dealer and direct manufacturer purchases, including transportation, handling, and import/export fees.Dealers may offer localized delivery options, potentially reducing shipping costs for buyers in certain regions.

- Long-Term Maintenance Expenses: - In addition to upfront purchase costs, buyers must consider long-term maintenance expenses to ensure the continued operation and performance of the crane.Factors such as spare parts availability, servicing requirements, and warranty coverage should be evaluated to assess the total cost of ownership over the crane's lifecycle.Dealers may provide comprehensive after-sales support, including maintenance services and spare parts availability, which can influence long-term maintenance expenses and overall cost-effectiveness.

In summary, budget constraints play a crucial role in the decision-making process when selecting between dealer and direct manufacturer purchases for 10 Ton Overhead Cranes. By carefully evaluating total costs, customization options, shipping fees, and long-term maintenance expenses, buyers can make informed decisions that align with their budgetary limitations and optimize the value and efficiency of their crane procurement process.

Specific Requirements and Customization Needs:

The specific requirements and customization needs of the buyer's operation are crucial considerations. Buyers should evaluate whether their needs can be adequately met by standard crane models available through dealers or if customization is necessary to address unique operational challenges. Direct manufacturer purchase offers greater flexibility in customization, allowing buyers to tailor crane solutions to their exact specifications. However, buyers should weigh the benefits of customization against potential limitations in brand options and longer lead times associated with direct purchase.

- Evaluation of Operational Requirements:Buyers must thoroughly evaluate their operational requirements, including lifting capacities, span lengths, operating environments, and safety standards.Understanding these requirements is essential for selecting a crane solution that meets the demands of the buyer's application and ensures optimal performance and safety.

- Assessment of Standard vs. Custom Solutions:Buyers should assess whether their needs can be met by standard crane models available through dealers or if customization is necessary to address unique operational challenges.Standard crane models offer predefined configurations and features that may suit many applications but may not fully align with specific requirements.Customization allows buyers to tailor crane solutions to their exact specifications, ensuring optimal performance, efficiency, and safety in their operations.

- Flexibility of Direct Manufacturer Purchase:Direct manufacturer purchase provides greater flexibility in customization, enabling buyers to modify crane specifications to meet their unique requirements.Buyers can work directly with manufacturers to design cranes with specific features, capacities, dimensions, and functionalities tailored to their operational needs.This customization capability empowers buyers to address specific challenges or constraints within their facilities and optimize crane performance accordingly.

- Consideration of Benefits vs. Limitations:While customization offers numerous benefits, buyers should also consider potential limitations associated with direct manufacturer purchase.Customization may entail longer lead times, as the manufacturing process may require additional design, engineering, and production time to implement specialized features.Additionally, buyers should weigh the benefits of customization against potential limitations in brand options, as not all manufacturers may offer the desired customization capabilities or meet specific quality standards.

- Balancing Cost and Value:Buyers must balance the cost of customization against the value it brings to their operations.While customization may incur additional expenses, the enhanced functionality, efficiency, and safety offered by custom crane solutions can deliver significant long-term benefits and return on investment.Buyers should conduct a cost-benefit analysis to determine the most cost-effective approach that aligns with their operational requirements and budget constraints.

In summary, the specific requirements and customization needs of the buyer's operation are critical considerations when selecting between standard and custom crane solutions. By carefully evaluating operational requirements, considering the flexibility of direct manufacturer purchase, and balancing cost and value, buyers can make informed decisions that optimize crane performance and enhance operational efficiency.

Time Sensitivity:

Time sensitivity is another critical factor influencing the decision between dealer and direct purchase. Buyers with urgent project timelines may opt for dealer purchases to expedite the procurement process and minimize delays. Dealers typically maintain inventory stock and can facilitate quicker delivery of crane products compared to manufacturers, who may require longer lead times for production and fulfillment. However, buyers should balance the need for expediency with other factors such as cost-effectiveness and customization flexibility when making their decision.

- Impact on Project Timelines:Time sensitivity plays a critical role in projects with strict deadlines or time-sensitive milestones.Buyers must assess the urgency of their project timelines and the importance of timely crane acquisition to ensure project progress and completion within schedule constraints.

- Expedited Procurement Process with Dealer Purchases:For buyers facing time-sensitive projects, dealer purchases offer the advantage of expedited procurement processes.Dealers typically maintain inventory stock of standard crane models, allowing for quicker availability and delivery compared to direct manufacturer purchases.Buyers can leverage dealers' existing inventory to secure crane products promptly and minimize delays in project execution.

- Inventory Stock and Quick Delivery:Dealers' inventory stock enables them to respond promptly to buyers' needs and facilitate quick delivery of crane products.Buyers benefit from shorter lead times and reduced waiting periods, allowing them to commence project activities sooner and maintain project momentum.

- Consideration of Manufacturer Lead Times:In contrast, direct manufacturer purchases may involve longer lead times for production and fulfillment.Manufacturers may require additional time to manufacture and customize crane products according to buyers' specifications, resulting in delays in delivery and project timelines.

- Balancing Expediency with Other Factors:While expediency is crucial, buyers should balance the need for quick delivery with other factors such as cost-effectiveness and customization flexibility.Expedited dealer purchases may incur higher upfront costs due to the availability of ready-made inventory and expedited shipping options.Buyers must weigh these costs against the benefits of timely crane acquisition and assess whether the trade-off is justified within their budget constraints and project requirements.

- Customization Flexibility vs. Time Constraints:Buyers requiring extensive customization may face challenges with time-sensitive projects when opting for direct manufacturer purchases.While customization offers tailored solutions to meet specific requirements, it may prolong lead times and delay project timelines.Buyers must carefully evaluate the balance between customization flexibility and time constraints, prioritizing the most critical project objectives while ensuring timely delivery of crane equipment.

In summary, time sensitivity is a critical factor that influences the decision between dealer and direct purchase for 10 Ton Overhead Cranes. While dealer purchases offer expedited procurement processes and quick delivery, buyers must carefully consider the trade-offs with cost-effectiveness and customization flexibility to make informed decisions aligned with their project timelines and objectives.

Importance of After-Sales Service and Support:

The importance of after-sales service and support cannot be overstated in the procurement of a 10 Ton Overhead Crane. Buyers should consider the level of support offered by both dealers and manufacturers in terms of installation, training, maintenance, and troubleshooting. While dealers may provide localized support and expertise, manufacturers offer direct access to engineering resources and technical expertise. Buyers should assess their after-sales service needs and evaluate which procurement option best aligns with their requirements for ongoing support and assistance throughout the lifecycle of the crane.

- Installation Assistance:After-sales service begins with installation support, ensuring that the crane is correctly installed and commissioned for safe and efficient operation.Both dealers and manufacturers may offer installation services, providing experienced technicians who are familiar with the crane's specifications and requirements.

- Operator Training:Proper training of crane operators is essential for safe and effective crane operation.Dealers and manufacturers may offer training programs to educate operators on crane functionalities, safety protocols, and maintenance procedures, enhancing operator competency and reducing the risk of accidents.

- Maintenance and Servicing:Regular maintenance and servicing are crucial for prolonging the lifespan and ensuring the reliability of the crane.Buyers should assess the maintenance services offered by dealers and manufacturers, including scheduled inspections, preventive maintenance, and emergency repairs.Dealers may provide localized servicing and spare parts availability, facilitating quick response times and minimizing downtime for maintenance activities.

- Troubleshooting and Technical Support:In the event of technical issues or malfunctions, prompt troubleshooting and technical support are essential for minimizing downtime and restoring crane functionality.Manufacturers may offer direct access to engineering resources and technical expertise, enabling efficient diagnosis and resolution of complex issues.Dealers, with their localized presence, can also provide responsive technical support and troubleshooting assistance, leveraging their knowledge of local regulations and operational environments.

- Warranty Coverage and Support:Warranty coverage is another aspect of after-sales service that buyers should consider when selecting a procurement option.Both dealers and manufacturers may offer warranty protection for crane components and systems, providing assurance against defects and malfunctions.Buyers should review warranty terms and conditions to understand coverage limitations, duration, and warranty extension options available.

- Evaluation of Service Needs:Buyers must assess their after-sales service needs and preferences to determine which procurement option best aligns with their requirements.Factors to consider include the level of expertise, responsiveness, and availability of service personnel, as well as the proximity of service locations to the buyer's facility.

In summary, after-sales service and support are critical considerations in the procurement of 10 Ton Overhead Cranes. Buyers should evaluate the installation assistance, operator training, maintenance services, troubleshooting support, and warranty coverage offered by both dealers and manufacturers to ensure optimal crane performance and reliability throughout its lifecycle. By selecting a procurement option that meets their after-sales service needs, buyers can mitigate risks, minimize downtime, and maximize the return on investment in their crane equipment.

Tips for Making the Decision

In this section, we'll provide actionable tips to help buyers navigate the decision-making process when choosing between dealer and direct manufacturer purchases for 10 Ton Overhead Cranes.

Conducting Thorough Research:

- Explore Available Crane Models and Brands: Begin by researching the various crane models and brands available in the market. Compare features, specifications, and capabilities to identify options that align with your specific requirements and operational needs.

- Understand Technical Specifications and Features: Dive deep into the technical specifications and features of different crane options to gain a comprehensive understanding of their capabilities and limitations. Pay attention to factors such as lifting capacity, span length, hoisting speed, and control mechanisms.

- Consider Industry Standards and Regulatory Requirements: Ensure compliance with industry standards, regulatory requirements, and safety certifications applicable to overhead crane operations. Familiarize yourself with relevant guidelines such as OSHA, ANSI, and CMAA standards to make informed decisions and prioritize safety.

- Utilize Online Resources and Industry Publications: Leverage online resources, industry publications, and forums to gather insights and feedback from other buyers, crane users, and industry professionals. Participate in discussions, read reviews, and seek recommendations to supplement your research and decision-making process.

- Seek Recommendations from Experts and Peers: Reach out to industry experts, crane manufacturers, and experienced peers for advice and recommendations. Their insights and firsthand experiences can provide valuable perspectives and help you make informed decisions when selecting the right overhead crane for your application.

- Evaluate Total Cost of Ownership: Consider the total cost of ownership beyond the initial purchase price, including installation, maintenance, and operating expenses. Assess the long-term value and return on investment offered by each crane option to make a well-informed and financially prudent decision.

By conducting thorough research, you can gather valuable information and insights to guide your decision-making process and ensure the selection of the most suitable 10 Ton Overhead Crane for your specific needs and requirements.

(A) Would you like more information on specific crane manufacturers or brands?

(B) Are you interested in learning more about industry standards and safety certifications for overhead cranes?

(C) Do you need assistance with evaluating the total cost of ownership for different crane options?

Requesting Quotes and Proposals: Reach out to dealers and manufacturers to request quotes and proposals for 10 Ton Overhead Cranes that meet your specific requirements. Compare pricing, delivery timelines, warranty terms, and after-sales support offerings from multiple vendors to assess the overall value proposition. Ask for detailed information on customization options, additional services, and any potential discounts or incentives available.

Evaluating Long-Term Costs and Benefits:

- Beyond Upfront Costs: While upfront costs are important, it's crucial to look beyond them and consider the long-term implications of your procurement decision. Evaluate factors such as maintenance requirements, spare parts availability, and expected lifespan to assess the total cost of ownership (TCO) over the crane's lifecycle.

- Total Cost of Ownership (TCO) Analysis: Conduct a comprehensive TCO analysis that includes all relevant costs associated with each procurement option. Factor in not only the initial purchase price but also ongoing expenses such as maintenance, repairs, spare parts, and energy consumption over the crane's lifespan.

- Maintenance Requirements and Costs: Consider the maintenance requirements of each crane option and the associated costs. Evaluate the frequency and complexity of maintenance tasks, as well as the availability of maintenance services and spare parts, to estimate long-term maintenance expenses.

- Spare Parts Availability: Assess the availability of spare parts for each crane option, as well as the lead times and costs associated with obtaining them. A reliable supply of spare parts is essential for minimizing downtime and ensuring timely repairs and maintenance activities.

- Expected Lifespan and Durability: Consider the expected lifespan and durability of each crane option to assess its long-term value. Evaluate factors such as build quality, materials used, and manufacturer reputation to gauge the reliability and longevity of the crane equipment.

- Impact of Downtime and Productivity: Factor in the potential impact of downtime on your operations and productivity levels. Consider how quickly issues can be resolved and operations restored with each procurement option to minimize downtime and mitigate its associated costs.

- Operational Efficiency and Productivity Gains: Assess the potential for operational efficiency improvements and productivity gains with each crane option. Consider features such as faster hoisting speeds, precise positioning capabilities, and advanced automation technologies that can enhance workflow efficiency and productivity over time.

- Risk Management and Contingency Planning: Mitigate risks associated with unexpected maintenance issues, downtime, and operational disruptions by developing contingency plans and risk management strategies. Consider investing in preventive maintenance programs, spare parts inventories, and backup equipment to minimize the impact of unforeseen events on your operations.

By conducting a thorough evaluation of long-term costs and benefits, you can make a well-informed procurement decision that maximizes the value and performance of your 10 Ton Overhead Crane over its entire lifecycle.

Seeking Recommendations and Reviews:

- Leverage Industry Networks and Peers: Reach out to industry peers, colleagues, and professionals who have experience with purchasing and operating 10 Ton Overhead Cranes. They can provide valuable insights, recommendations, and firsthand experiences to inform your decision-making process. Attend industry conferences, seminars, and trade shows to network with industry experts and connect with potential suppliers and manufacturers.

- Engage with Similar Companies and Organizations: Identify companies or organizations with similar operational needs or challenges to yours and seek their recommendations and insights. Consider contacting these entities directly to inquire about their experiences with specific crane dealers or manufacturers, including feedback on product quality, customer service, and after-sales support.

- Utilize Online Platforms and Professional Networks: Take advantage of online platforms, social media groups, and professional networks to connect with others in the industry and solicit feedback on dealer and manufacturer experiences. Participate in online forums, discussion groups, and industry-specific communities to engage with peers and gather diverse perspectives on crane procurement and operation.

- Review Customer Testimonials and Case Studies: Look for customer testimonials, case studies, and success stories provided by crane dealers and manufacturers. These resources can offer valuable insights into the performance, reliability, and customer satisfaction levels associated with different crane products and suppliers.

- Consult Independent Reviews and Ratings: Explore independent review websites, industry publications, and third-party ratings to assess the reputation and credibility of crane dealers and manufacturers. Pay attention to customer feedback, ratings, and comments to gauge satisfaction levels and identify any potential concerns or red flags.

- Request References from Suppliers: When evaluating potential crane suppliers or manufacturers, don't hesitate to request references from past customers. Contact these references directly to inquire about their experiences with the supplier, including factors such as product quality, delivery reliability, and after-sales support.

By seeking recommendations and reviews from industry peers, colleagues, and trusted sources, you can gain valuable insights and perspectives to guide your decision-making process and ensure the selection of a reputable and reliable supplier for your 10 Ton Overhead Crane needs.

By following these tips and conducting thorough due diligence, buyers can make informed decisions that align with their specific needs, objectives, and budget constraints. Whether opting for a dealer or direct manufacturer purchase, careful planning and research are essential to ensuring a successful procurement process and maximizing the value of the investment in a 10 Ton Overhead Crane.

Conclusion

On selecting the right procurement method for a 10 Ton Overhead Crane, buyers are faced with the choice between dealer and direct manufacturer purchases. Each option offers its own set of advantages and challenges, making it crucial for buyers to conduct a thorough evaluation based on their unique circumstances. Let's check the key points and offer a final recommendation:

Pros and Cons of Dealer and Direct Purchases:

Dealer Purchases:

Pros: Access to various brands and models, expertise and guidance, after-sales support.

Cons: Higher prices due to middleman markup, limited customization options, potential delays in procurement.

Direct Manufacturer Purchases:

Pros: Lower costs, direct communication with engineers, customization flexibility.

Cons: Limited brand options, longer lead times, potential communication barriers.

Emphasizing the Need for Individual Assessment:

It's essential to recognize that there is no one-size-fits-all solution when it comes to choosing between dealer and direct manufacturer purchases. Each buyer's situation is unique, influenced by factors such as budget constraints, specific requirements, time sensitivity, and the importance of after-sales service and support. Therefore, it's crucial for buyers to conduct a thorough assessment of their needs and priorities before making a decision.

For buyers with urgent project timelines or those seeking convenience and localized support, dealer purchases may be the preferred option. Dealers offer guidance, expertise, and after-sales support, albeit at potentially higher costs.

For buyers with strict budget constraints or those requiring extensive customization, direct manufacturer purchases may offer cost savings and flexibility. However, buyers should be prepared for longer lead times and potential communication challenges.

In conclusion, the choice between dealer and direct manufacturer purchases requires careful consideration and evaluation of various factors. By weighing the pros and cons, conducting thorough research, and assessing individual circumstances, buyers can make an informed decision that optimizes the value and efficiency of their 10 Ton Overhead Crane procurement process.

Main Projects

Related Products

22/5 Ton Overhead Crane Double Hook System: Robust double girder crane with 22-ton main and 5-ton auxiliary hooks for heavy lifting. Get double hook crane!

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch