Comprehensive Guide to CE Certified Overhead Cranes & Gantry Cranes

1 Ton to 80 Ton Overhead Cranes and Gantry Cranes, Jib Cranes with CE Certificates for Sale. Advanced Hoist and Cranes with European Style, cost-effective.

Category: Featured

Your Trusted CE Overhead Crane & Gantry Crane Manufacturer & Supplier

Comprehensive Guide to CE Certified Overhead Cranes

1 Ton to 80 Ton Overhead Cranes and Gantry Cranes, Jib Cranes with CE Certificates, Advanced Hoist and Cranes with European Style

Introduction to CE Certification for Overhead Cranes

Welcome to the Comprehensive Guide to CE Certified Overhead Cranes. In this multi-part blog series, we'll delve into the intricacies of CE certification, focusing on its importance in certifying overhead cranes for compliance with European Economic Area (EEA) directives. Let's begin with Part .

The CE marking holds a pivotal role in the certification of products within the European Economic Area. It serves as a visual indicator that a product complies with the applicable EEA directives, ensuring a standardized level of safety and performance. For overhead cranes, the CE marking is a badge of adherence to regulatory standards that manufacturers and users alike rely on for quality assurance.

In the realm of overhead cranes, the CE marking is not just a symbol; it's a commitment to meeting stringent safety and performance criteria. Manufacturers undergo a thorough certification process to affix the CE mark, signifying that their cranes conform to EEA directives. This compliance is crucial for ensuring the safety of operations and fostering trust among users and stakeholders.

CE certification for overhead cranes operates within a well-defined legal framework. The Machinery Directive (200/42/EC) stands as a cornerstone, outlining essential health and safety requirements. Manufacturers must navigate these directives to guarantee that their cranes meet the specified standards and can be freely marketed within the EEA.

The benefits of CE certification extend beyond regulatory compliance. Manufacturers enjoy access to a broader market, and users gain confidence in the safety and reliability of CE-certified overhead cranes. Compliance with CE standards enhances competitiveness, fosters innovation, and contributes to the overall advancement of the industry.

Ensuring full compliance with CE certification requirements is not just a legal obligation; it's a commitment to excellence. Manufacturers play a crucial role in upholding safety standards, contributing to the overall well-being of workers and the efficiency of industrial processes. Compliance is the cornerstone of a responsible and sustainable manufacturing ecosystem.

For users of overhead cranes, the CE marking is a clear signal that safety standards have been rigorously met. It provides assurance that the crane is designed and manufactured to deliver optimal performance while minimizing risks. The CE marking acts as a safeguard, instilling confidence in users who rely on these powerful industrial machines.

The journey of CE certification in the crane industry has evolved over time. As technology advances and safety standards become more robust, the certification process adapts to address new challenges. Understanding this evolution is key to staying current with the latest advancements and ensuring that overhead cranes meet the highest safety standards.

CE certification is not a one-size-fits-all process. Different types and categories of overhead cranes may have specific requirements. Understanding the scope and applicability of CE certification ensures that manufacturers tailor their processes to meet the unique demands of each crane variant.

Users play a pivotal role in maintaining the integrity of the CE certification process. Verifying CE compliance when procuring overhead cranes is not just a formality but a proactive step toward workplace safety. Dealing with certified manufacturers ensures that users receive products that meet the highest regulatory standards.

CE Certification Process for Overhead Cranes

In Part of our Comprehensive Guide, we'll embark on a detailed exploration of the CE certification process for overhead cranes. This step-by-step guide will illuminate the entire journey, from the initial assessment to the moment when the coveted CE marking is affixed.

- Preliminary Assessment -Before the CE certification process commences, manufacturers must conduct a preliminary assessment. This involves a thorough examination of the overhead crane's design, components, and intended use. Manufacturers identify applicable directives and standards, laying the foundation for the certification journey.

- Identification of Applicable Directives -One of the critical steps in the process is identifying the relevant directives that apply to the specific type of overhead crane. The Machinery Directive (200/42/EC) takes center stage, but depending on the crane's features or functions, other directives may come into play. A comprehensive understanding of these directives is crucial for a targeted certification approach.

- Conformity Assessment -The heart of the CE certification process lies in the conformity assessment. Manufacturers rigorously evaluate the overhead crane against the essential health and safety requirements outlined in the identified directives. This assessment covers design, construction, and operational aspects, ensuring that the crane meets the highest standards of safety and performance.

- Risk Assessment -Conducting a comprehensive risk assessment is integral to the certification process. Manufacturers systematically identify potential hazards associated with the overhead crane's design, construction, and operation. The goal is to mitigate risks effectively, ensuring a secure working environment and reducing the likelihood of accidents.

- Technical Documentation -The creation of detailed technical documentation is a pivotal aspect of the CE certification process. Manufacturers compile a comprehensive set of documents that include design specifications, risk assessment results, operation manuals, and any other information required by the applicable directives. This documentation serves as a robust record of compliance.

- CE Marking Affixation -The moment of achievement arrives when the manufacturer affixes the CE marking on the overhead crane. This visual symbol signifies that the crane complies with the identified directives and has successfully undergone the conformity assessment. The CE marking is a clear indication of adherence to European safety and quality standards.

- Declaration of Conformity -Simultaneously with the CE marking, manufacturers issue a Declaration of Conformity. This formal document explicitly states that the overhead crane meets the essential requirements of the applicable directives. The Declaration of Conformity is a vital element of transparency and accountability in the CE certification process.

- Involvement of Notified Bodies (if required) -In some cases, the involvement of a notified body may be necessary, depending on the type of overhead crane or specific circumstances. Notified bodies are third-party organizations designated by authorities to assess certain aspects of the certification process. Their involvement adds an extra layer of scrutiny to ensure compliance.

- User Manual Preparation -A comprehensive user manual is a crucial component of CE certification. Manufacturers prepare a user manual that provides clear instructions on the safe operation, maintenance, and any specific requirements for the overhead crane. This manual serves as a guide for users and operators to ensure ongoing safety and compliance.

- Retention of Technical Documentation -After obtaining the CE marking, manufacturers must retain all technical documentation for a specified period. This retention period is crucial for audits and inspections, allowing authorities to verify ongoing compliance even after the crane has been placed on the market.

Challenges in CE Certification for Overhead Cranes:

Complex Regulatory Landscape

- Challenge: Navigating the intricate web of regulatory requirements, including multiple directives and standards, can pose a significant challenge for manufacturers.

- Strategy: Manufacturers should invest in a thorough understanding of applicable directives and standards. Collaboration with experts or consultants familiar with the regulatory landscape can streamline the process.

Diverse Crane Types and Variations

- Challenge: Different types of overhead cranes, each with its unique features and functions, may require varying approaches to certification.

- Strategy: Tailor the certification process to the specific characteristics of each crane type. Clearly define the scope of certification for different variations to ensure a targeted and efficient assessment.

Risk Assessment Complexity

- Challenge: Conducting a comprehensive risk assessment involves identifying and mitigating potential hazards, a task that can be complex given the diverse operating environments of overhead cranes.

- Strategy: Employ experienced professionals in risk assessment. Use advanced tools and methodologies to thoroughly evaluate potential risks and implement effective mitigation measures.

Technical Documentation Accuracy

- Challenge: Compiling accurate and detailed technical documentation, including risk assessments and design specifications, demands precision.

- Strategy: Establish robust documentation processes and quality control measures. Regularly review and update documentation to ensure accuracy and alignment with evolving standards.

Notified Body Involvement

- Challenge: In cases where the involvement of a notified body is required, coordination and communication with these third-party entities can present challenges.

- Strategy: Establish clear communication channels with notified bodies from the outset. Understand their requirements and expectations to facilitate a smoother collaboration.

Compliance with Evolving Standards

- Challenge: Standards and directives may undergo updates and revisions, requiring manufacturers to stay informed and adapt their processes accordingly.

- Strategy: Implement a system for continuous monitoring of regulatory changes. Regularly update processes and documentation to align with the latest standards and directives.

Resource Allocation

- Challenge: The CE certification process demands significant resources, including time, personnel, and financial investments.

- Strategy: Develop a realistic resource allocation plan from the outset. Prioritize tasks based on their impact on the certification process and allocate resources accordingly.

Language and Cultural Differences

- Challenge: Dealing with international regulations may involve language and cultural challenges, especially for manufacturers operating in diverse global markets.

- Strategy: Engage translators or professionals familiar with the language and cultural nuances of the regions involved. Foster open communication to bridge language gaps.

Documentation Retention and Management

- Challenge: Ensuring proper retention and management of extensive documentation for audit and inspection purposes can be challenging.

- Strategy: Implement a robust document management system. Clearly define retention periods and ensure that documentation is easily accessible when needed.

User Training and Awareness

- Challenge: Ensuring that end-users are adequately trained and aware of the safe operation and maintenance practices outlined in the user manual can be challenging.

- Strategy: Develop comprehensive training programs for end-users. Regularly communicate updates and safety information to ensure continued awareness.

Navigating these challenges requires a proactive and strategic approach. In the next part of our guide, we'll delve into the role of notified bodies in the CE certification process for overhead cranes. Stay tuned for Part : Role of Notified Bodies in Overhead Crane Certification.

Role of Notified Bodies in Overhead Crane Certification:

What Are Notified Bodies? -Notified bodies are independent third-party organizations designated by regulatory authorities to assess and verify compliance with specific directives. Their role is crucial in ensuring that products, including overhead cranes, meet the essential requirements outlined in those directives.

Role of Notified Bodies in CE Certification

Notified bodies play a multifaceted role in the CE certification process for overhead cranes:

- Conformity Assessment -Notified bodies are often involved in the conformity assessment process. They assess whether the overhead crane meets the essential health and safety requirements specified in the applicable directives. This independent evaluation adds an extra layer of scrutiny to ensure thorough compliance.

- Verification of Technical Documentation -Notified bodies review and verify the technical documentation provided by manufacturers. This includes design specifications, risk assessments, and other relevant documentation. Their verification ensures that the documentation aligns with the requirements of the directives.

- Type Examination -For certain types of overhead cranes, a type examination may be required. Notified bodies conduct this examination to verify that a representative sample of the product meets the specified requirements. This is particularly relevant for cranes with unique features or functions.

- Ongoing Surveillance -Notified bodies may engage in ongoing surveillance activities to ensure that the manufacturer maintains consistent compliance with the certified product. This surveillance may involve periodic audits and assessments to confirm that the overhead cranes continue to meet safety standards.

When Is Notified Body Involvement Required?

The involvement of a notified body is not mandatory for all types of overhead cranes. However, there are specific circumstances where their participation is required:

- High Risks and Complexity -For overhead cranes associated with high risks or characterized by complex features, notified body involvement is often mandatory. This ensures that products with elevated safety considerations undergo a thorough and expert assessment.

- Specific Directives -Certain directives explicitly require notified body involvement. Manufacturers must carefully review the relevant directives to determine whether the certification process for their overhead cranes necessitates the participation of a notified body.

- Type Examination Requirement -If a type examination is mandatory for a particular type of overhead crane, the involvement of a notified body becomes essential. This is especially relevant when the crane's design or intended use requires a specialized assessment.

- Collaboration and Communication -Smooth collaboration and communication between manufacturers and notified bodies are vital for a successful certification process. Manufacturers should establish clear channels for sharing information, addressing queries, and facilitating the assessment activities conducted by the notified body.

Requirements for Different Types of Overhead Cranes:

Design Considerations

Bridge cranes, also known as overhead traveling cranes, are characterized by their ability to move horizontally along a runway. Specific requirements for bridge cranes include:

- Structural Integrity: Certification processes must evaluate the structural integrity of the bridge, ensuring it can withstand the loads and forces associated with lifting and moving heavy loads.

- End Carriage Design: Attention to the design of end carriages, which support the bridge and house the trolley mechanism, is crucial. Certification ensures that these components meet safety and performance standards.

Safety Features

- Emergency Stop Systems: Bridge cranes must be equipped with reliable emergency stop systems to promptly halt operations in case of emergencies, contributing to overall workplace safety.

- Overload Protection: Certifying bodies assess the incorporation of overload protection mechanisms to prevent the crane from lifting loads beyond its capacity.

Track and Structure

Gantry cranes differ from bridge cranes in that they are supported by legs on either side of the span. Certification requirements for gantry cranes include:

- Track Stability: Certifying bodies evaluate the stability of the track or rail system on which the gantry crane moves, ensuring it can support the crane and its intended loads.

- Leg Design: The design and construction of supporting legs are examined to ensure they provide sufficient stability and durability.

Lifting Mechanism

- Hoisting Systems: Certification processes scrutinize the hoisting systems, including winches and hooks, to guarantee safe and efficient lifting operations.

- Load Distribution: Certifying bodies assess load distribution mechanisms to prevent uneven loading and potential hazards during lifting and movement.

Rotation Mechanism

Jib cranes are characterized by a horizontal jib or boom that supports a moveable hoist. Certification requirements for jib cranes include:

- Rotation Mechanism: Certifying bodies evaluate the rotation mechanism to ensure smooth and controlled movement of the jib, preventing sudden or unexpected rotations.

- Boom Design: The design and construction of the jib or boom are closely examined to ensure stability and resistance to loads.

Operational Safety

- Slew Limiters: Certifying bodies assess the inclusion of slew limiters to prevent excessive rotation of the jib crane, enhancing operational safety.

- Emergency Procedures: Manufacturers must provide clear and comprehensive emergency procedures in the user manual, detailing steps to be taken in case of malfunctions or emergencies.

Manufacturers must tailor their certification processes to address the unique features and functions of each overhead crane type. Whether it's the horizontal movement of bridge cranes, the support structure of gantry cranes, or the rotational aspect of jib cranes, adherence to specific requirements ensures a comprehensive and effective CE certification.

Intelligent Crane with Advanced Crane Design with Smart Features

Double girder overhead crane with rotary trolley for sale

Double girder gantry cranes with intelligent hoists including main hoist and auxialiry

Intelligent Crane and Smart Hoist Parts and Components

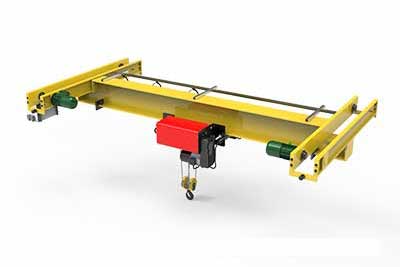

NR mode standard headroom electric hoist

Lifting capacity: 3t~20t

Lifting height: 6m~30m

Work level: M3~M5

Application: For Single Girder Cranes

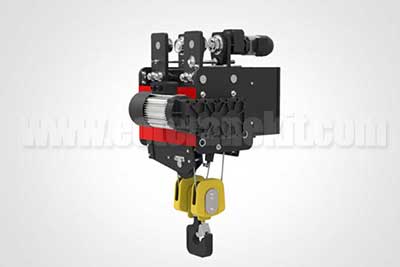

NR mode low headroom electric hoist

Lifting capacity: 3t~20t

Lifting height: 6m~30m

Work level: M3~M5

Application: For Single Girder Cranes

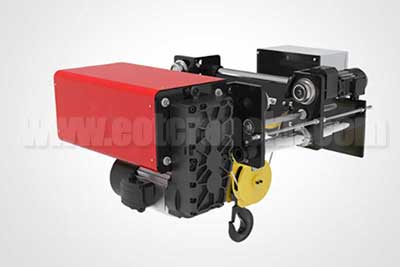

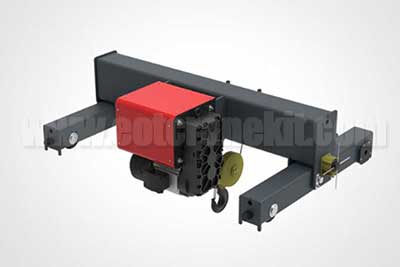

NRT crab electric hoist

Lifting capacity: 3t~80t

Lifting height: 6m~30m

Work level: M3~M5

Application: For Double Girder Cranes

Explosion Proof Electric Wire Rope Hoists

BNR explosion-proof electric hoist for LNG

Lifting capacity: 3t~20t

Lifting height: 6m~30m

Work level: M3~M5

Application: For Single Girder Cranes

BNR low headroom explosion-proof electric hoist

Lifting capacity: 3t~20t

Lifting height: 6m~30m

Work level: M3~M5

Application: For Single Girder Cranes

BNRT crab model explosion-proof electric hoist

Lifting capacity: 3t~30t

Lifting height: 6m~30m

Work level: M3~M5

Application: For Double Girder Cranes

EU Directives Impacting Overhead Crane Certification:

Machinery Directive (200/42/EC)

- Continuous Evolution -The Machinery Directive serves as a cornerstone in the CE certification process for overhead cranes. Manufacturers must stay vigilant as this directive undergoes periodic updates and amendments to reflect advancements in technology, safety standards, and industry practices.

- Impact on Certification -Updates to the Machinery Directive may introduce new requirements or modify existing ones. Manufacturers should closely monitor any changes to ensure that their certification processes align with the latest expectations, ultimately contributing to the production of safer and more efficient overhead cranes.

Harmonized Standards

- Alignment with Directives -Harmonized standards play a crucial role in the CE certification process, providing a reference for manufacturers to demonstrate compliance with specific directives. Updates to these standards may occur to enhance clarity, address emerging risks, or align with international norms.

- Incorporating Changes -Manufacturers must be proactive in incorporating changes to harmonized standards into their certification processes. Adherence to updated standards ensures that overhead cranes meet the latest industry benchmarks and align with the intent of relevant directives.

Notification Procedures

- Changes in Procedures -The procedures related to notifying authorities and obtaining CE certification may experience updates. Manufacturers should familiarize themselves with any changes in notification procedures to ensure a seamless certification process.

- Communication with Authorities -Maintaining open lines of communication with relevant authorities is crucial. Manufacturers should seek guidance on any procedural changes and ensure that their practices align with the expectations of notified bodies and regulatory agencies.

User Manual Requirements

- Clarity and Accessibility -Updates to directives may introduce changes to the requirements for user manuals. Manufacturers must ensure that their user manuals remain clear, comprehensive, and accessible to end-users, providing information necessary for the safe operation and maintenance of overhead cranes.

- Timely Updates -Manufacturers should commit to timely updates of user manuals in response to changes in directives. This ensures that end-users are equipped with the latest information on the safe use of CE-certified overhead cranes.

Industry Communications and Associations

- Information Dissemination -Active participation in industry communications and associations is a valuable strategy for staying informed. Manufacturers can benefit from networks that disseminate updates, share insights, and provide guidance on changes to directives and standards.

- Collaborative Learning -Engaging with industry peers allows manufacturers to share experiences and insights regarding the impact of directive updates. Collaborative learning enhances industry-wide awareness and helps manufacturers adapt their practices collectively.

Continuous Training and Education

- Employee Training -Continuous training and education of employees involved in the certification process is vital. Manufacturers should invest in programs that keep their teams updated on changes to directives, ensuring a well-informed and proficient workforce.

- Professional Development -Encouraging professional development within the organization, such as certifications and industry-specific training, enhances the expertise of personnel responsible for overseeing the CE certification process.

CE certifications of Overhead Cranes, Gantry Cranes, Jib Cranes and Hoists

CE certificates of Overhead Cranes,including single girder overhead crane, double girder ovehread crane, top running overhead crane, underhung overhead crane, explosion proof overhead crane , grab overhead crane, magnetic overhead crane, ladle overhead crane, electric hoist overhead crane, open winch overhead cranes, etc.

CE certificates of gantry cranes, single girder gantry crane, double girder gantry crane, semi gantry crane, portable gantry crane, grab bucket gantry crane, magnetic gantry cranes, double hoist gantry crane, variable speed gantry crane, rmg gantry crane, rtg gantry crane, and custom industrial gantry cranes, etc.

C E certifications of Jib Crane, wall mounted jib crane, floor mounted jib cranes, wall travelling jib cranes, and portable jib cranes , and all type of jib hoists , etc.

CE certificates of electric hoists and electric winch, electric chain hoists, electric wire rope hoists, electric low headroom wire rope hoist, explosion proof wire rope hoists, electric winch, diesel winch, slow speed electric winch, high speed electric winch, etc.

International Standards and Overhead Crane Certification:

ISO Standards

- Global Relevance -The International Organization for Standardization (ISO) develops standards with global relevance. Manufacturers of overhead cranes may find that certain ISO standards align with or complement the requirements of CE certification.

- Harmonization Opportunities -Identifying opportunities for harmonization between ISO standards and CE certification requirements can streamline the certification process. Manufacturers should assess where adherence to ISO standards enhances compliance with the intent of CE directives.

ANSI/ASME Standards

- American National Standards Institute (ANSI) -ANSI standards, particularly those developed in collaboration with the American Society of Mechanical Engineers (ASME), are widely recognized. Manufacturers exporting overhead cranes to the U.S. market may find alignment between ANSI/ASME standards and CE certification beneficial.

- Dual Compliance Considerations -For manufacturers with a global market presence, dual compliance with both ANSI/ASME standards and CE certification requirements may be necessary. Understanding the intersections and differences aids in efficient planning and execution.

IEC Standards

- Electrical Components and Systems -The International Electrotechnical Commission (IEC) develops standards related to electrical components and systems. Overhead cranes often involve electrical elements, and aligning with relevant IEC standards can enhance the safety and reliability of these components.

- Integration with CE Certification -Manufacturers should explore the integration of IEC standards within the CE certification process, particularly when addressing electrical aspects of overhead cranes. This ensures a comprehensive approach to compliance.

EN Standards (European Standards)

- Harmonization with CE Directives -EN standards, specific to Europe, are designed to harmonize with CE directives. Manufacturers engaging with EN standards can ensure a smoother alignment with the essential health and safety requirements outlined in the relevant directives.

- Evolving Standards Landscape -Staying informed about updates to EN standards is essential. Changes may occur to enhance alignment with international best practices or to address emerging safety considerations in the design and operation of overhead cranes.

Benefits of Aligning with International Standards

- Market Access -Aligning with international standards broadens market access. Manufacturers can confidently export overhead cranes to regions adhering to specific international standards, enhancing their global reach.

- Improved Safety and Quality -International standards often incorporate best practices and lessons learned from diverse industrial contexts. By aligning with these standards, manufacturers contribute to the improvement of safety and quality in the design and use of overhead cranes.

Considerations for Manufacturers

- Standard Mapping -Manufacturers should conduct a thorough mapping exercise to identify the intersections and divergences between CE certification requirements and international standards. This mapping aids in developing a comprehensive certification strategy.

- Continuous Monitoring -Given the dynamic nature of standards development, continuous monitoring of updates is crucial. Manufacturers should stay informed about any revisions or new standards that may impact the design, manufacturing, and certification of overhead cranes.

The examination of international standards offers manufacturers valuable insights into global best practices and requirements. By strategically aligning with or complementing CE certification through international standards, manufacturers can elevate the safety, quality, and market competitiveness of their overhead cranes.

Quality Control and Assurance in Overhead Crane Manufacturing:

Design Phase

- Preliminary Design Review - Conduct a thorough preliminary design review to assess compliance with applicable directives. Identify potential risks and ensure that safety considerations are integrated into the initial design phase.

- Design Validation - Implement design validation processes to verify that the overhead crane's design meets the essential health and safety requirements outlined in relevant directives. This includes structural integrity, load capacity, and safety features.

Material Selection and Procurement

- Traceability - Ensure traceability of materials used in the manufacturing process. Maintain records that allow for the identification of material sources and adherence to specified standards.

- Supplier Qualification - Qualify and assess suppliers based on their ability to provide materials that meet the required standards. Establish clear criteria for supplier selection and ongoing evaluation.

Production Processes

- Process Validation - Implement process validation procedures to confirm that manufacturing processes consistently produce overhead cranes that meet design specifications and regulatory requirements.

- Inspection and Testing - Conduct regular inspections and testing at various stages of production. This includes checks for structural integrity, functionality of safety features, and compliance with design specifications.

Documentation and Record-Keeping

- Comprehensive Technical Documentation - Develop comprehensive technical documentation that includes design specifications, risk assessments, operation manuals, and any other information required by applicable directives.

- Record Retention - Establish a robust system for the retention of records. Keep detailed records of design and manufacturing processes, inspections, and testing for future reference and auditing purposes.

Final Inspection and Testing

- Conformity Assessment - Conduct a final conformity assessment to ensure that the completed overhead crane complies with all relevant directives and standards.

- Load Testing - Perform load testing to verify that the crane can safely lift and move loads according to specified capacity limits. Document load testing results for reference and compliance verification.

Quality Management System (QMS)

- Implementation of QMS - Establish and implement a Quality Management System (QMS) that encompasses all aspects of manufacturing, from design to production and testing. Ensure that the QMS aligns with the requirements of CE certification.

- Continuous Improvement - Foster a culture of continuous improvement within the organization. Regularly review and enhance manufacturing processes based on feedback, audit findings, and industry developments.

Training and Skill Development

- Employee Training - Provide comprehensive training to employees involved in the manufacturing process. Ensure that they understand the importance of quality control, compliance with standards, and adherence to safety protocols.

- Skill Development Programs - Implement skill development programs to enhance the expertise of personnel in areas such as welding, assembly, and quality control. Skilled and knowledgeable personnel contribute to the production of high-quality overhead cranes.

Continuous Monitoring and Auditing

- Internal Audits - Conduct regular internal audits to assess the effectiveness of quality control measures and identify areas for improvement. Internal audits help ensure ongoing compliance with CE certification requirements.

- External Audits - Collaborate with external auditors, notified bodies, or relevant authorities for periodic external audits. External audits provide an additional layer of scrutiny and validation of adherence to quality and safety standards.

Implementing robust quality control and assurance measures in overhead crane manufacturing is paramount to achieving and maintaining CE compliance. By integrating these best practices into the manufacturing processes, manufacturers can contribute to the production of safe, reliable, and high-performance industrial equipment.

Post-Certification Audits and Compliance Monitoring:

Continuous Surveillance

- Ongoing Audits - Conduct regular internal audits to assess the continued effectiveness of quality control measures and verify compliance with CE certification requirements.

- External Audits - Collaborate with external auditors, notified bodies, or relevant authorities for periodic external audits. External audits provide an independent evaluation of ongoing compliance.

Documentation Review

- Record Retention - Ensure the retention of comprehensive records related to design, manufacturing, testing, and certification. Review and update documentation as needed to reflect any changes or improvements.

- Accessibility - Maintain easy access to documentation for internal reference and external audits. Accessibility ensures that records can be promptly provided to authorities or auditors when required.

User Training and Awareness

- Periodic Training - Provide periodic training for end-users, operators, and maintenance personnel. Reinforce safe operation practices and ensure awareness of any updates or changes in user manuals.

- Certification Updates - Communicate updates related to CE certification to relevant stakeholders. Keep end-users informed about any changes in safety protocols, operating procedures, or maintenance requirements.

Safety Protocols

- Regular Review - Regularly review and update safety protocols in accordance with industry developments and changes in standards. Ensure that safety measures align with the latest requirements.

- Incident Reporting - Establish a clear process for reporting and documenting any incidents or non-compliance with safety standards. Promptly investigate and address reported issues to prevent recurrence.

Updates to Directives

- Directive Monitoring - Stay informed about updates or changes to relevant directives. Regularly monitor official sources for information on evolving standards that may impact CE certification requirements.

- Directive Implementation - Implement necessary changes to align with updated directives. This may involve adjustments to design specifications, documentation, or manufacturing processes to ensure continued compliance.

Notified Body Interaction

- Communication Channels - Maintain open and transparent communication channels with notified bodies. Seek guidance on any changes in procedures, standards, or requirements that may affect CE certification.

- Collaboration - Collaborate with notified bodies for ongoing support and clarification. Establish a proactive relationship to address queries and ensure a smooth certification process for any new crane models or updates.

Continuous Improvement

- Feedback Mechanisms - Establish feedback mechanisms to gather insights from internal and external stakeholders. Use feedback to identify areas for improvement and implement continuous enhancements.

- Process Optimization - Continuously optimize manufacturing processes based on lessons learned, audit findings, and industry best practices. Aim for efficiency while maintaining the highest quality standards.

Ongoing audits and compliance monitoring are integral components of maintaining CE certification for overhead cranes. By establishing a proactive and continuous approach to surveillance, documentation review, user training, and engagement with relevant authorities, manufacturers ensure that their products consistently meet safety and quality standards.

This concludes our Comprehensive Guide to CE Certified Overhead Cranes. We hope this guide serves as a valuable resource for manufacturers, operators, and stakeholders involved in the design, production, and use of overhead cranes within the European Economic Area. Stay committed to safety, quality, and compliance for a successful and sustainable future in the industrial equipment sector.

Environmental Considerations in Overhead Crane Certification:

Green Design Principles

- Material Selection - Prioritize materials with lower environmental impact. Consider recyclable materials and those with reduced carbon footprints in the manufacturing of overhead cranes.

- Energy Efficiency - Design cranes with a focus on energy efficiency. Optimize motor systems, control mechanisms, and operational processes to minimize energy consumption during use.

Life Cycle Assessment (LCA)

- Comprehensive Analysis - Conduct a Life Cycle Assessment (LCA) to evaluate the environmental impact of overhead cranes from raw material extraction to manufacturing, use, and eventual disposal or recycling.

- Ecodesign Integration - Use LCA findings to inform ecodesign strategies. Implement changes in design and production processes to reduce overall environmental impact across the crane's life cycle.

Compliance with Environmental Standards

- ISO Certification - Seek ISOcertification for environmental management systems. Aligning with this standard demonstrates a commitment to environmentally responsible practices.

- Ecolabeling - Consider obtaining relevant ecolabel certifications to signify adherence to specific environmental criteria. Ecolabeling enhances transparency and consumer confidence in the environmental performance of overhead cranes.

Waste Reduction and Recycling

- Waste Minimization - Implement practices to minimize waste generation during manufacturing. Reduce, reuse, and recycle materials wherever possible to limit the environmental impact of waste.

- End-of-Life Recycling - Design cranes with considerations for end-of-life recycling. Ensure that components are easily separable for recycling, promoting a circular economy approach.

Energy-Efficient Operation

- Smart Control Systems - Integrate smart control systems that optimize energy usage during crane operation. These systems can regulate power consumption based on load requirements and operational conditions.

- Regenerative Braking - Explore the incorporation of regenerative braking systems. Such systems capture and reuse energy during braking, contributing to overall energy efficiency.

Environmental Monitoring and Reporting

- Emissions Tracking - Implement systems to track and monitor emissions generated during the manufacturing process. This information can contribute to the development of strategies for emission reduction.

- Transparent Reporting - Provide transparent reporting on the environmental performance of overhead cranes. Share relevant data with stakeholders, including customers, to foster trust and awareness.

Continuous Improvement

- Innovation and Research - Invest in research and development to explore innovative technologies and materials that further enhance the environmental sustainability of overhead cranes.

- Feedback Integration - Actively seek feedback from environmental experts, stakeholders, and customers. Use feedback to identify areas for improvement and implement measures to enhance environmental performance.

Integrating environmental considerations into the CE certification process for overhead cranes is a pivotal step toward sustainable and eco-friendly manufacturing. By adopting green design principles, conducting life cycle assessments, and complying with environmental standards, manufacturers contribute to a greener future in the industrial equipment sector.

This concludes Part of our guide. Stay tuned for additional insights and updates in the evolving landscape of overhead crane certification.

CE Certification Costs and Budgeting

Certification Process Costs

- Testing and Assessment - Budget for testing and assessment services provided by notified bodies or accredited testing laboratories. Costs may vary based on the complexity and type of overhead crane being certified.

- Documentation Preparation - Allocate funds for the preparation of comprehensive documentation, including technical files, risk assessments, and operation manuals. Clear and detailed documentation is essential for certification.

- Notified Body Fees - Consider fees associated with engaging a notified body, if required. Some overhead cranes may necessitate the involvement of a notified body, adding an additional cost to the certification process.

Design and Manufacturing Adjustments

- Compliance Modifications - Budget for any modifications or adjustments needed to ensure compliance with CE certification requirements. This may involve design changes, material substitutions, or process improvements.

- Quality Management System Implementation - Invest in the establishment and implementation of a Quality Management System (QMS) if not already in place. A well-structured QMS is essential for consistent adherence to certification requirements.

Training and Education

- Employee Training - Allocate funds for training programs to educate employees involved in the certification process. Properly trained personnel contribute to the efficiency and effectiveness of the certification process.

- Professional Development - Consider investing in the professional development of key personnel responsible for overseeing the certification process. Expertise in CE certification processes enhances the overall success of the endeavor.

Continuous Monitoring and Auditing

- Internal Audits - Include costs for conducting regular internal audits to assess ongoing compliance. Internal audits are crucial for identifying areas of improvement and maintaining adherence to certification requirements.

- External Audits - Budget for external audits by notified bodies or relevant authorities. External audits provide an independent evaluation of compliance and may involve additional costs.

Post-Certification Activities

- Surveillance and Monitoring - Account for ongoing surveillance and monitoring activities to ensure continued compliance with CE certification requirements after the initial certification.

- User Training and Awareness - Include budgetary provisions for periodic user training and awareness programs. Keeping end-users informed about safe operation practices and any updates is essential.

Environmental Considerations

- Green Design Integration - Consider the costs associated with incorporating environmentally friendly design principles into the manufacturing process. This may involve material sourcing, energy-efficient technologies, and eco-friendly practices.

- Environmental Certification - If pursuing environmental certifications such as ISO 0 or ecolabeling, allocate funds for the certification process and ongoing adherence to environmental standards.

Unforeseen Challenges - Set aside a contingency fund to address unforeseen challenges or additional requirements that may arise during the certification process. Flexibility in budgeting is crucial for overcoming unexpected hurdles.

Understanding the costs associated with obtaining CE certification for overhead cranes is essential for manufacturers to plan their budgets effectively. By considering various aspects such as testing, documentation, training, and ongoing monitoring, manufacturers can navigate the certification process with financial preparedness.

International Trade Implications of CE Certification:

Global Market Access

- Recognized Standard - CE certification is widely recognized as a standard for safety and compliance. Manufacturers with CE-certified overhead cranes gain easier access to international markets, where adherence to recognized safety standards is a priority.

- Customer Confidence - International buyers often prioritize products with CE certification due to its reputation for stringent safety and quality standards. CE certification instills confidence in customers, fostering trust in the reliability of overhead cranes.

Compliance with European Economic Area (EEA) Standards

- Harmonization with EEA Directives - CE certification ensures harmonization with European Economic Area (EEA) directives. This alignment simplifies the process of meeting standards that are widely accepted in European and other international markets.

- Single Certification for Multiple Markets - Manufacturers can leverage the CE certification process to meet the standards of multiple markets simultaneously. This can streamline the certification process and reduce the need for additional certifications.

Streamlined Import and Export Processes

- Customs Facilitation - CE certification facilitates smoother customs processes. Customs authorities in many countries recognize CE certification as evidence of compliance with essential safety and quality standards.

- Reduced Barriers to Entry - Manufacturers exporting CE-certified overhead cranes may encounter fewer barriers to entry in international markets. Compliance with recognized standards simplifies regulatory approval processes.

Enhanced Competitiveness

- Marketing Advantage - CE certification serves as a powerful marketing tool. Manufacturers can use the CE mark to differentiate their products, highlighting a commitment to safety and quality in promotional materials.

- Preferred Supplier Status - Suppliers with CE-certified overhead cranes may gain preferred status with international buyers. This preference can lead to increased business opportunities and partnerships.

Meeting Industry Requirements

- Industry Recognition - Within specific industries, adherence to CE standards is often a prerequisite. Manufacturers with CE certification align with industry expectations, making their overhead cranes more appealing to sector-specific buyers.

- Participation in Global Projects - CE-certified overhead cranes position manufacturers to participate in global projects that prioritize compliance with recognized safety standards. This opens doors to involvement in large-scale industrial endeavors.

Consideration for International Standards

- Alignment with ISO and Other Standards - The alignment of CE certification with international standards, such as ISO, enhances the global recognition of certified overhead cranes. Manufacturers should consider the complementarity of CE certification with other relevant standards.

- Dual Compliance - Manufacturers may choose to pursue dual compliance, aligning with both CE certification and standards specific to target markets. This comprehensive approach can broaden the appeal of overhead cranes.

CE certification significantly enhances the international trade implications for overhead crane manufacturers. From global market access and streamlined import-export processes to enhanced competitiveness and industry recognition, CE certification plays a pivotal role in facilitating international trade.

This concludes Part of our guide. Stay tuned for additional insights into the multifaceted landscape of overhead crane certification.

User Guide for CE-Certified Overhead Crane Buyers:

Verifying CE Certification

- Check for the CE Marking - Ensure that the overhead crane bears the CE marking, indicating compliance with applicable EU directives.

- Request Declaration of Conformity - Request a Declaration of Conformity from the manufacturer or supplier, confirming that the overhead crane meets the essential requirements of the relevant directives.

Understanding User Manuals

- Thorough User Manual Review - Thoroughly review the provided user manual to understand safe operation practices, maintenance requirements, and any specific guidelines for the overhead crane.

- Clarify Uncertainties - In case of any uncertainties or questions, contact the manufacturer or supplier for clarification and additional information.

Operator and Maintenance Personnel Training

- Verify Training and Certification - Verify that operators and maintenance personnel have received proper training and certification for the safe use and maintenance of the overhead crane.

- Ongoing Training - Ensure ongoing training for operators and maintenance personnel to stay updated on safety practices and compliance with CE certification requirements.

Inspection and Maintenance

- Implement Regular Procedures - Implement regular inspection and maintenance procedures as outlined in the user manual to ensure ongoing safety and compliance.

- Reporting Non-Compliance - Promptly report any issues or non-compliance with safety standards to the manufacturer or relevant authorities.

Compliance with Local Regulations

- Consider Local Standards - Consider and adhere to any local regulations and standards applicable to the use of overhead cranes in the specific region.

- Documentation Retention - Keep records of the Declaration of Conformity, user manual, and any other relevant documentation for reference and auditing purposes.

Stay Informed

- Updates to Directives and Standards - Stay informed about updates to relevant directives, standards, and best practices to ensure continued compliance with safety requirements.

- Communication with Manufacturer - Maintain open communication with the manufacturer or supplier to stay informed about any updates, recalls, or improvements related to the overhead crane.

This user guide aims to empower buyers of CE-certified overhead cranes with the knowledge and tools to ensure safe and compliant usage. By actively participating in the verification process, understanding user manuals, prioritizing training, and staying informed, buyers contribute to a safer working environment and the continued success of the overhead crane.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch