Floor Mounted Gantry Crane, Types & Uses, Your| Gantry Crane Supplier

Floor mounted gantry crane good price for sale. Floor mounted gantry, free standing crane design, economical indoor & outdoor material handling crane 5 -100 ton.

| Crane type | Floor mounted gantry |

| Crane capacity | 0.5 ton -10 ton, 1 ton -20 ton, 3 ton -100 ton |

| Lifting Height | As your request |

| Crane Span | As customer requirement |

| Note | Custom gantry cranes are available. |

Category: Floor Mounted Crane

Your Trusted Gantry Crane Manufacturer & Supplier

Floor mounted Gantry Crane for Indoor & Outdoor Use

Types & Uses of Floor Mounted Gantry Crane 5 Ton, 10 Ton, 20 Ton, 30 Ton, 40 Ton, 5 Ton & up to 100 Ton

Floor mounted gantry crane good price for sale. Floor mounted gantry, free standing crane design, economical indoor & outdoor material handling crane 5 -100 ton.

Overview of Floor Mounted Gantry Cranes

What are Floor-Mounted Gantry Cranes? Unveiling Versatile Lifting Solutions

Floor-mounted gantry cranes stand as stalwarts of the lifting world, revolutionizing material handling across industries. Unlike overhead cranes, these robust structures rely on a strong foundation anchored directly to the ground, offering stability and adaptability in various operational environments. Their versatility shines through their ability to move substantial loads with precision, making them indispensable assets in factories, construction sites, and more.

Main Types of Floor-Mounted Gantry Cranes: Navigating Diverse Solutions

- Light Duty Gantry Cranes: Engineered for smaller loads, these cranes provide agility and cost-effectiveness. They find their niche in workshops and small manufacturing units, where they power tasks with finesse.

- Medium Duty Gantry Cranes: Bridging the gap between light and heavy-duty operations, these cranes handle moderate loads across diverse industrial applications. Their double girder design enhances load-bearing capacity.

- Heavy Duty Gantry Cranes: Built to tackle substantial weights, these cranes are the backbone of heavy industries and construction sites. Their robust construction and safety features ensure reliability under demanding conditions.

- Short Span and Long Span Gantry Cranes: Short span cranes navigate confined spaces with ease, while long span cranes cover extended areas without the need for multiple installations. They adapt to diverse spatial layouts.

- Single Girder and Double Girder Gantry Cranes: Single girder cranes offer simplicity and lightness, while double girder cranes carry heavier loads with greater lifting heights. Both configurations cater to varying load requirements.

- Portable and Fixed Gantry Cranes: Portable cranes provide flexibility with easy transportation, while fixed cranes stand steadfastly in designated areas, delivering reliable lifting solutions tailored to specific operational needs.

The world of floor-mounted gantry cranes is vast and dynamic, offering solutions that align with a range of lifting demands. From optimizing space to addressing safety concerns, each type has a distinct role to play in enhancing efficiency and productivity. As we journey through the intricacies of these crane types, we'll uncover their unique features, benefits, and applications across diverse industries. Stay tuned to explore how these cranes empower your lifting endeavors.

Basics of Floor-Mounted Gantry Cranes: Understanding the Concept

What sets floor-mounted gantry cranes apart is their foundational design. These cranes are constructed with a sturdy base that serves as their support system. By utilizing the ground itself as a solid anchor, they ensure reliable lifting operations and minimize the need for elaborate structural modifications. This intrinsic stability contributes to enhanced safety and precision during material handling tasks.

Strong Foundation: The Importance of Ground Support

The old adage "strong foundation, sturdy structure" rings true in the realm of floor-mounted gantry cranes. This reliance on a solid ground connection brings forth numerous advantages. The cranes can be seamlessly integrated into existing workspaces without the need for extensive groundwork. Whether it's a manufacturing facility, a construction site, or a bustling port, these cranes prove their mettle by offering unparalleled stability, thereby boosting productivity and reducing downtime.

Moreover, the ground-supported nature of these cranes opens doors to innovative solutions. They can be tailored to suit specific lifting requirements, adapting to varied load capacities and work environments. From single girder configurations for lighter loads to double girder setups for heavy-duty tasks, floor-mounted gantry cranes offer a customizable lifting experience that aligns precisely with your needs.

In essence, floor-mounted gantry cranes redefine the possibilities of material handling by merging the strength of a robust foundation with the flexibility to navigate diverse operational challenges. As we embark on this journey to uncover the nuances of these remarkable machines, we'll delve deeper into their types, features, benefits, and the wide array of applications that benefit from their presence.

Stay tuned for the upcoming segments where we explore the various types of floor-mounted gantry cranes and how they are tailored to fit specific needs. From optimizing space utilization to addressing safety concerns, we'll provide insights that empower you to make informed decisions when considering the integration of floor-mounted gantry cranes in your industrial endeavors.

Types of Floor-Mounted Gantry Cranes: Tailored Solutions

In the intricate world of industrial lifting, one size certainly does not fit all. The realm of floor-mounted gantry cranes exemplifies this diversity through its myriad types, each finely tuned to address specific needs. Let's embark on a journey to uncover these tailored solutions, exploring the wide array of types based on load capacity, span, configuration, mobility, power source, rail system, and specific use.

Single Girder and Double Girder Gantry Cranes: The Power Duo

Configuration is key, and single girder and double girder gantry cranes present distinct advantages. Single girder cranes, with their simplicity and lighter weight, cater to moderate lifting needs. On the flip side, double girder cranes step up the game, offering higher load capacities and greater lifting heights. Versatility meets strength as these cranes adapt to your requirements, whether it's a workshop or a heavy industrial setting.

- Single Girder Gantry Cranes: Equipped with one horizontal beam (girder) for lifting, suitable for lighter loads and moderate spans.

- Double Girder Gantry Cranes: Feature two parallel girders for heavier loads and greater lifting height and span capabilities.

Single Girder Gantry Cranes 1 ton - 20 ton, Floor Mounted Ganry for sale

Features: Single girder gantry cranes are equipped with a single horizontal beam (girder) for lifting.

Benefits

- Lighter Weight: The single girder design makes them lighter and easier to move.

- Cost-Effective: Generally more economical to manufacture and install.

- Moderate Spans: Suitable for applications with moderate spans.

Typical Applications

- Workshops: Handling materials and components in small to medium-sized workshops.

- Warehouses: Loading and unloading goods in spaces with limited headroom.

- Fabrication shops: Moving materials during fabrication processes.

Double Girder Gantry Cranes , Floor Mounted Gantry System 3 ton -320 ton

Features: Double girder gantry cranes have two parallel horizontal girders for lifting.

Benefits

- Higher Load Capacity: Capable of handling heavier loads due to the dual girder configuration.

- Greater Height and Span: Offers increased lifting height and span capabilities.

- Enhanced Stability: Provides more stability and strength for demanding tasks.

Typical Applications

- Heavy industries: Transporting large machinery and equipment in heavy manufacturing settings.

- Construction sites: Lifting heavy construction materials and structures.

- Shipbuilding: Handling substantial ship components during ship assembly.

These classifications based on configuration provide options tailored to specific load capacities, spans, and lifting requirements. The choice between single girder and double girder gantry cranes depends on the intended applications, the weight of the loads, and the span needed to cover the work area.

Portable and Fixed Gantry Cranes: Mobility Matters

The need for mobility can shape your choice of gantry crane. Portable gantry cranes bring flexibility to the forefront, offering easy transportation and rapid assembly across changing work environments. Fixed gantry cranes, on the other hand, stand as steadfast pillars within designated areas, consistently delivering reliable lifting solutions.

In the forthcoming segments, we'll journey deeper into each type, unraveling their features, benefits, and the applications that thrive under their capable presence. From container terminals to construction sites, these cranes find their niche, proving that diversity indeed breeds efficiency in the world of lifting technology. Stay tuned as we uncover the secrets of each type and empower you to make informed decisions that elevate your lifting endeavors.

Based on Mobility

- Fixed Gantry Cranes: Stationary and installed in a fixed location.

- Portable Gantry Cranes: Designed for easy transportation and assembly, offering mobility and flexibility.

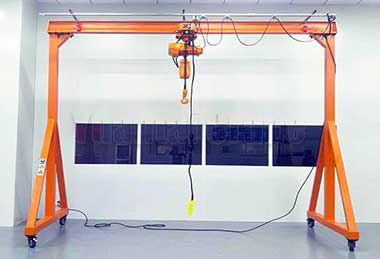

Portable Gantry Cranes , Rolling Gantry Crane on the Floor 1 Ton, 5 Ton, 10 Ton

Features: Portable gantry cranes are designed for easy transportation and assembly in various locations.

Benefits

- Flexibility: Can be moved to different areas to address changing lifting needs.

- Versatility: Suitable for temporary or changing work environments.

- Quick Setup: Designed for rapid assembly and disassembly without specialized tools.

Typical Applications

- Construction sites: Providing lifting capabilities in temporary construction zones.

- Maintenance tasks: Assisting with equipment repairs at various locations.

- Workshops: Offering a flexible lifting solution for different projects.

Fixed Gantry Cranes

Features: Fixed gantry cranes are permanently installed in a specific location and cannot be moved.

Benefits

- Stable Support: Offers consistent lifting solutions in a designated area.

- Precise Positioning: Suitable for applications where the lifting area remains constant.

- Robust Construction: Designed for durability and long-term use.

Typical Applications

- Assembly lines: Lifting and moving components along fixed production processes.

- Dedicated workstations: Providing a reliable lifting solution for specific tasks.

- Loading docks: Assisting with loading and unloading goods in a consistent area.

These classifications based on mobility offer distinct advantages based on whether a fixed or portable solution is required. The choice between fixed and portable gantry cranes depends on the nature of the lifting tasks, the need for adaptability, and the specific work environment. power

Electric & Manual Gantry Cranes

Features: Electric gantry cranes are powered by electricity and offer automated and efficient lifting operations.

Benefits

- Precise Control: Electric operation allows for precise positioning and movement.

- Enhanced Productivity: Automation reduces the need for manual effort and speeds up tasks.

- Reduced Operator Fatigue: Electric cranes ease the physical strain on operators.

Typical Applications

- Manufacturing facilities: Assisting in the production and assembly of goods.

- Warehouses: Streamlining the movement of goods in storage and distribution.

- Industrial operations: Handling heavy loads in a controlled manner.

Features: Manual gantry cranes are operated by hand and are suited for simpler tasks and lighter loads.

Benefits

- Cost-Effective: Typically more affordable due to their simpler design.

- Ease of Use: Simple controls make them easy to operate without extensive training.

- Versatile: Suitable for various applications with lighter lifting requirements.

Typical Applications

- Small workshops: Handling components and materials in a compact workspace.

- Maintenance tasks: Assisting with basic equipment repairs and servicing.

- Low-volume operations: Providing lifting capabilities without the need for complex machinery.

These classifications based on power source offer options based on the level of automation and control required for the lifting tasks. The choice between electric and manual gantry cranes depends on factors such as load capacity, precision needed, and the operational context.

Based on Rail System:

- Rubber Tired Gantry Cranes (RTG): Equipped with rubber tires for movement on paved surfaces without rails.

- Rail Mounted Gantry Cranes (RMG): Operate on rails for efficient movement and stacking of containers in terminals.

Rubber Tired Gantry Cranes (RTG)

Features: RTGs are designed with rubber tires, allowing them to move on paved surfaces without requiring rails.

Benefits

- Flexibility: Can move anywhere on a paved surface, providing freedom of movement.

- No Rail Infrastructure: Eliminates the need for rails and related maintenance.

- Efficient Container Handling: Ideal for stacking and moving containers in ports and terminals.

Typical Applications

- Container terminals: Loading and unloading containers from trucks and stacking them in yards.

- Intermodal facilities: Transferring containers between different modes of transportation.

- Port areas: Efficient handling of containers in busy port environments.

Rail Mounted Gantry Cranes (RMG)

Features: RMGs operate on rails, providing efficient movement and stacking capabilities.

Benefits

- Controlled Movement: Operate on dedicated rails for precise and controlled container handling.

- Stacking Efficiency: Facilitate organized stacking of containers in storage yards.

- Terminal Productivity: Essential for high-volume container terminals requiring quick container transfers.

Typical Applications

- Container yards: Stacking and organizing containers for storage and retrieval.

- Rail terminals: Transferring containers between trains and trucks efficiently.

- Intermodal hubs: Efficiently managing the flow of containers between different transportation modes.

These classifications based on the rail system offer solutions tailored to the specific needs of container handling and terminal operations. The choice between RTGs and RMGs depends on factors such as the infrastructure available, the level of precision required, and the operational context.

Indoor & outdoor gantry cranes

Indoor Gantry Cranes: Enhancing Efficiency Within Confined Spaces

Indoor gantry cranes emerge as the unsung heroes within the controlled environments of factories, warehouses, and manufacturing units. These versatile lifting solutions are specifically designed to thrive within confined spaces, where precision and adaptability are paramount. With their sturdy construction and tailored features, indoor gantry cranes streamline material handling, optimizing workflow while ensuring safety.

Features

- Compact Design: Indoor gantry cranes are engineered to fit seamlessly within limited indoor spaces, ensuring optimal utilization of available area.

- Precision Controls: These cranes boast precise controls, allowing operators to maneuver with finesse, even in tight quarters.

- Sturdy Structure: Built to withstand indoor environments, these cranes are constructed with materials that resist wear and tear.

- Customizable: Indoor gantry cranes can be tailored to suit specific load capacities, lifting heights, and operational requirements.

Benefits

- Space Optimization: Indoor gantry cranes make the most of confined spaces, enabling efficient material handling without the need for expansive layouts.

- Workflow Efficiency: These cranes streamline production processes, reducing downtime and enhancing overall operational efficiency.

- Safety: Precise controls and sturdy construction ensure safe material movement within indoor settings.

- Adaptability: Indoor gantry cranes can be customized to accommodate various lifting needs, enhancing versatility across tasks.

Typical Applications

- Manufacturing Units: Indoor gantry cranes play a crucial role in lifting raw materials, components, and finished products within manufacturing plants.

- Warehouses: These cranes facilitate smooth storage and retrieval of goods in busy warehouses, optimizing inventory management.

- Workshops: From assembling machinery to maintenance tasks, indoor gantry cranes enhance productivity in workshops.

- Indoor Construction Projects: These cranes assist in indoor construction activities, moving heavy materials and equipment with precision.

Outdoor Gantry Cranes: Conquering Open Spaces with Unwavering Strength

In the vast expanse of open-air environments, outdoor gantry cranes reign supreme. These powerhouses of the outdoors are designed to conquer challenging conditions, from construction sites to shipping yards. With their robust engineering and resilience against the elements, outdoor gantry cranes stand as guardians of efficiency, effortlessly lifting heavy loads and transferring materials with unwavering precision.

Features

- Weather Resistance: Outdoor gantry cranes are designed to withstand outdoor conditions, equipped with protective features to resist weather effects.

- Robust Build: These cranes feature a sturdy structure capable of handling heavy loads and harsh environments.

- Flexible Mobility: Outdoor gantry cranes navigate uneven terrains and expansive areas with ease.

- Customization Options: They can be tailored to accommodate specific load capacities and lifting heights required for outdoor tasks.

Benefits

- High Load Capacity: Outdoor gantry cranes are engineered for heavy-duty operations, lifting substantial weights efficiently.

- Durability: Resilient against weather elements, these cranes maintain performance and longevity under challenging conditions.

- Operational Reach: With extended spans, outdoor gantry cranes cover larger areas, enhancing operational flexibility.

- Versatility: These cranes adapt to a variety of outdoor tasks, from construction projects to shipping operations.

Typical Applications

- Construction Sites: Outdoor gantry cranes excel in lifting heavy materials and equipment on construction sites, contributing to efficient project execution.

- Shipping Yards: They play a pivotal role in loading and unloading cargo from ships, ensuring seamless logistics operations.

- Mining Operations: Outdoor gantry cranes assist in the movement of raw materials and machinery within mining sites.

- Large-Scale Manufacturing: These cranes facilitate the transportation of oversized components and machinery in outdoor manufacturing facilities.

As we delve deeper into the world of gantry cranes, the distinction between indoor and outdoor varieties becomes evident. Stay tuned as we uncover the features, benefits, and applications of both indoor and outdoor gantry cranes, each designed to thrive within their distinct operational landscapes. Whether it's optimizing space within four walls or conquering the great outdoors, these cranes offer tailored solutions that redefine lifting capabilities.

Based on Load Capacity:

- Light Duty Gantry Cranes: Designed for relatively light loads, often used in workshops or small manufacturing units.

- Medium Duty Gantry Cranes: Can handle moderately heavy loads and are suitable for various industrial applications.

- Heavy Duty Gantry Cranes: Engineered to lift and transport very heavy loads, common in heavy industries, shipyards, and construction sites.

Light Duty Gantry Cranes: Lightweight Champions

When agility meets efficiency, you have the essence of light duty gantry cranes. These nimble powerhouses are characterized by their ability to handle relatively lighter loads with finesse. Constructed with a single girder configuration, they offer features like ease of maneuverability and cost-effectiveness. Ideal for workshops and small manufacturing units, light duty gantry cranes streamline material handling, powering tasks with precision while optimizing space.

Light Duty Gantry Cranes

Features: Light duty gantry cranes are designed for handling lighter loads, usually up to a few tons. They often have single girder configurations to keep the crane's weight and complexity lower.

Benefits

- Affordable: Light duty cranes are generally more cost-effective to install and maintain.

- Versatile: Suitable for various lifting tasks in smaller workspaces.

- Ease of Installation: The lighter structure makes them easier to install and move.

Typical Applications

- Small workshops: Used for assembly, maintenance, and material handling.

- Warehouses: Efficient loading and unloading of lighter goods.

- Garages: For lifting automotive components and light machinery.

Medium Duty Gantry Cranes: Bridging the Gap

For tasks that demand a touch more muscle, medium duty gantry cranes come to the rescue. With their increased load capacity, these cranes bridge the gap between light and heavy-duty operations. Their flexible double girder design enhances their load-bearing capabilities, making them versatile players across a multitude of industrial applications. From manufacturing floors to fabrication shops, medium duty gantry cranes bring efficiency to the forefront.

Medium Duty Gantry Cranes

Features: Medium duty gantry cranes have a higher load capacity than light duty cranes and offer more flexibility in terms of configuration and span.

Benefits

- Balanced Capacity: Can handle moderate loads without compromising mobility or efficiency.

- Versatility: Suitable for various industrial applications with medium-weight materials.

- Longer Lifespan: Generally more robust construction for longer operational life.

Typical Applications

- Manufacturing: Moving medium-sized components within the production line.

- Fabrication shops: Handling of metal sheets and parts during fabrication.

- Construction sites: Lifting construction materials and equipment.

Heavy Duty Gantry Cranes: Built to Last

In the realm of heavy industries, heavy duty gantry cranes reign supreme. Engineered with durability in mind, these behemoths are designed to lift and transport substantial loads with unwavering reliability. Whether it's shipyards, construction sites, or demanding manufacturing processes, heavy duty gantry cranes rise to the occasion. With their signature strength and advanced safety features, they are the backbone of large-scale operations.

Heavy Duty Gantry Cranes

Features: Heavy duty gantry cranes are designed for substantial load capacities, often exceeding 10 tons or more. They might have double girder configurations for added strength.

Benefits

- High Load Handling: Capable of lifting and transporting heavy machinery and equipment.

- Industrial Strength: Built to withstand the demands of heavy industries.

- Enhanced Safety: Equipped with advanced safety features due to the potential risks associated with heavy loads.

Typical Applications

- Shipbuilding yards: Moving ship components and heavy loads during ship construction.

- Mining operations: Handling large mining equipment and materials.

- Steel mills: Transporting heavy steel coils and machinery.

These different classifications based on load capacity offer various features and benefits tailored to specific lifting needs. As you can see, the type of gantry crane selected depends on the load requirements, operational environment, and intended applications.

Short Span and Long Span Gantry Cranes: Finding Your Perfect Fit

The spatial layout of your operation often dictates the type of gantry crane you need. Short span gantry cranes, with their ability to navigate confined spaces, ensure precise lifting within limited dimensions. On the other end of the spectrum, long span gantry cranes offer extended coverage, optimizing larger areas without the need for multiple installations. Whether it's reaching over obstacles or spanning across expanses, these cranes offer tailored solutions.

- Short Span Gantry Cranes: Designed for shorter distances between the supporting legs, suitable for confined spaces.

- Long Span Gantry Cranes: Have a larger span between the legs, offering more coverage and flexibility in terms of lifting area.

Short Span Gantry Cranes

Features: Short span gantry cranes are designed for limited distances between the supporting legs, making them suitable for tight spaces.

Benefits

- Space Efficiency: Ideal for workshops or areas with limited room for crane movement.

- Maneuverability: Easier to navigate in congested workspaces.

- Precise Handling: Well-suited for tasks requiring accuracy in positioning.

Typical Applications

- Small manufacturing units: Efficient handling of materials and components in restricted spaces.

- Assembly lines: Precise positioning of items during the assembly process.

- Maintenance areas: Lifting and moving equipment in compact maintenance bays.

Long Span Gantry Cranes

Features: Long span gantry cranes are characterized by their larger distance between the supporting legs, allowing for extended coverage.

Benefits

- Wide Coverage: Suitable for covering larger areas without the need for multiple crane installations.

- Flexibility: Can accommodate varied layouts and lifting requirements.

- Bulk Material Handling: Efficient for transporting goods across expansive spaces.

Typical Applications

- Warehouses: Loading and unloading goods in warehouses with open layouts.

- Outdoor yards: Handling materials in outdoor storage areas where space is abundant.

- Shipyards: Moving components and equipment across large ship construction sites.

These classifications based on span offer specialized features and benefits that cater to different spatial requirements. The choice between short span and long span gantry cranes depends on factors such as the available area, lifting tasks, and operational efficiency.

Based on Specific Use:

Features: Cantilever gantry cranes have an extended horizontal beam (cantilever) on one side.

Benefits

- Obstacle Clearance: The cantilever design allows the crane to reach over obstacles or obstacles.

- Versatile Positioning: Suitable for tasks where access might be restricted by structures or obstacles.

- Space Optimization: Utilizes space efficiently by reaching beyond barriers.

Typical Applications

- Foundries: Lifting molten metal or heavy materials from constrained spaces.

- Outdoor yards: Reaching over storage stacks or uneven terrain.

- Loading bays: Accessing areas obstructed by walls or structures.

Features: Semi-gantry cranes have one end supported by a structure while the other is supported by legs.

Benefits

- Space-Efficient: Perfect for scenarios where full leg support is not possible on both sides.

- Accessibility: Provides flexibility for lifting in areas with limited room.

- Stability: The structure support enhances stability while conserving space.

Typical Applications

- Outdoor construction sites: Lifting materials and equipment over construction structures.

- Factories: Handling goods and components near walls or partitions.

- Warehouses: Assisting with loading and unloading tasks in restricted spaces.

These classifications based on specific use offer solutions for scenarios where obstacles or limited space demand specialized crane designs. The choice between cantilever and semi-gantry cranes depends on the specific lifting challenges and constraints present in the operational environment.

These classification criteria provide a way to categorize floor-mounted gantry cranes based on their characteristics, usage scenarios, and design features. The actual classification used may vary depending on industry practices, regulations, and specific needs.

Applications Across Industries: Unleashing the Potential of Floor-Mounted Gantry Cranes

In the grand symphony of industrial operations, where precision, efficiency, and strength are the notes that compose success, floor-mounted gantry cranes emerge as the conductors of seamless material handling. These remarkable machines orchestrate their prowess across a spectrum of industries, redefining the way materials are lifted, moved, and positioned. Let's embark on a journey through the diverse domains where these cranes reign supreme.

Features: Container gantry cranes are designed specifically for the loading and unloading of containers from ships in ports and terminals.

Benefits

- High Load Capacity: Capable of handling heavy containers efficiently.

- Precise Positioning: Ensures accurate placement of containers on ships and on the ground.

- Productivity: Speeds up the loading and unloading process, critical in busy ports.

Typical Applications

- Ports and terminals: Essential for managing large volumes of containerized cargo.

- Intermodal facilities: Facilitating the transfer of containers between ships, trains, and trucks.

- Container storage yards: Stacking and organizing containers for storage.

Workshop Gantry Cranes

Features: Workshop gantry cranes are versatile tools used within workshops and small manufacturing units.

Benefits

- Space Efficiency: Suitable for confined workshop spaces.

- Versatility: Can handle various lifting tasks within a compact environment.

- Easy Integration: Designed to work seamlessly in manufacturing processes.

Typical Applications

- Small manufacturing units: Handling materials and components in production.

- Repair and maintenance shops: Lifting machinery and equipment for servicing.

- Assembly lines: Assisting with component assembly within workshops.

Features: Construction gantry cranes are found on construction sites, aiding in lifting and moving construction materials and equipment.

Benefits

- On-Site Mobility: Provides lifting capabilities at various points on a construction site.

- Heavy Load Handling: Designed to manage the weight of construction materials and machinery.

- Time and Labor Savings: Enhances efficiency by minimizing manual lifting.

Typical Applications

- Building construction: Lifting steel beams, concrete forms, and other building materials.

- Infrastructure projects: Moving heavy components like bridge segments or precast concrete.

- Demolition sites: Removing debris and heavy demolition materials.

These classifications based on industry/application offer specialized solutions tailored to the unique demands of different sectors. The choice of gantry crane type depends on the specific industry requirements, load capacities, and lifting tasks involved.

And More: A Glimpse into Their Impact Across Sectors

The influence of floor-mounted gantry cranes extends far beyond the boundaries of ports, workshops, and construction sites. In every corner of industry, they make their mark. From warehouses optimizing storage to manufacturing units enhancing production, these cranes elevate efficiency and streamline operations. They venture into steel mills, shipyards, mining operations, and beyond, adapting to the unique demands of each sector they grace.

As we traverse these diverse landscapes, one thing becomes evident: the floor-mounted gantry crane is not just a lifting solution; it's a transformative force that shapes industries. It's the embodiment of innovation, reliability, and adaptability, poised to elevate your endeavors and push the boundaries of what's possible. Join us in the upcoming segments as we uncover the top concerns of crane users and potential purchasers, addressing safety, efficiency, customization, and more. The journey of discovery continues, and the possibilities are boundless.

Meeting User Concerns: Elevating Your Crane Experience

In the world of industrial machinery, where precision meets power, user concerns take center stage. At the heart of this symphony of efficiency and safety, floor-mounted gantry cranes shine as beacons of ingenuity. As crane users and potential purchasers, your priorities are our mission. Let's delve into the key concerns that matter most, addressing them with the expertise of a crane manufacturer and supplier.

Safety First: Addressing Safety Measures and Compliance

Safety isn't just a feature; it's a non-negotiable. The realm of floor-mounted gantry cranes takes this commitment seriously. Our cranes are not just lifting solutions; they are guardians of your workforce. From advanced load-limiting systems to fail-safe mechanisms, every facet is designed with safety at its core. We meticulously adhere to industry standards, ensuring that your operations meet compliance requirements while offering peace of mind. When your team steps into the crane's command, they step into an environment built on a foundation of safety.

Efficiency Unleashed: Enhancing Operational Productivity

In the fast-paced world of industry, time is of the essence. Your operations thrive on efficiency, and so do our cranes. Imagine a world where material handling becomes a seamless dance, where heavy loads move with grace and precision. That's the promise of floor-mounted gantry cranes. Their robust design, optimized controls, and smooth movements are the ingredients of enhanced productivity. By reducing downtime and streamlining tasks, these cranes become your partners in elevating output and profitability.

Ease of Use: Simplifying Controls for Seamless Operation

In the complex world of heavy lifting, ease of use is a game-changer. Our floor-mounted gantry cranes are not just powerful; they are designed for intuitive operation. Picture an operator's hands seamlessly guiding the crane, as if an extension of their expertise. Our controls are crafted with user-centric design, ensuring that your team can harness the crane's capabilities without extensive training. From precise positioning to responsive movements, the cranes become an extension of your workforce's skill set.

As we stand at the crossroads of safety, efficiency, and usability, your concerns are our solutions. We stand committed to crafting cranes that not only elevate your operations but also empower your team. Whether it's the secure lifting of heavy loads, the optimization of your workflow, or the simplicity of crane control, we've got you covered.

Q&A: Addressing Common Queries: Navigating Your Crane Choices

Q: How do I choose the right type of gantry crane for my needs?

- Consider load capacity, workspace layout, and specific tasks.

- Opt for light duty, heavy duty, or tailored solutions like short span or long span based on available space.

Q: What factors influence the load capacity of a gantry crane?

- Depends on crane configuration, span length, and load type.

- Double girder cranes handle more weight than single girder ones.

Q: Are floor-mounted gantry cranes suitable for outdoor applications?

- Yes, adaptable to outdoor environments.

- Consider weather protection, load type, and customization for outdoor conditions.

Q: What are the key maintenance considerations for these cranes?

- Regular maintenance is crucial for optimal performance.

- Inspect structural components, lubricate moving parts, and check electrical systems.

- Designed for easy accessibility, making maintenance efficient.

Q: Can these cranes be customized to fit specific workspace requirements?

- Absolutely, customization is a cornerstone of our service.

- Adjust dimensions, add specialized attachments, or integrate automation features to match workspace and tasks.

We're committed to providing crane solutions that seamlessly align with your operational needs. Our expertise extends beyond cranes; it includes sharing knowledge and guiding you toward the optimal lifting solution. The journey toward efficiency, safety, and productivity continues as we delve deeper into the crane experience. Stay tuned for insights on the diverse landscape of floor-mounted gantry cranes, from the perspective of crane users and potential purchasers like you.

Main Projects

Related Products

Latest project

32/5 Ton Overhead Crane Sale in India: Case Study

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch