Chemical Industry

Explosion proof cranes and explosion proof hoist systems are required for chemical industry for handling chemical , acids, lyes , chemical compounds & petrochemical in the chemical processing factory and in the refinery of a petrochemical plant, etc. With the requirements of hazardous environment, the chemical industry cranes are required to be with high safety and reliability to ensure the material handling efficient and smooth in the section of storage, production and transportation, etc. With tailored explosion proof overhead crane system & hoist system to meet specific needs and setups, we provide for safe and efficient in-house material handling & logistics.

Industrial challenges

Due to the hazardous environment, the overhead equipment used in the chemical industry is required to be explosion proof but also to be ensured with durability. The aggressive & hazardous chemicals include acids, lyes and chemical compounds. To select the right electric overhead crane equipment is very important to prevent corrosion damage to ensure durability.

Material handling in explosive atmospheres has a wide different requirements for lifting equipment, ranging from general use overhead travelling cranes and hoist equipment to highly advanced crane with process crane designs to meet different needs of your specific and unique applications and lifting requirements.

Explosion proof protection

How to avoid explosion ? To avoid the creation of an explosive environment or atmosphere is naturally the first option and the most easiest way with high safety. For example, to provide the adequate and effective ventilation or confine the work processes to prevent the appearance of dangerous gases or dusts in the closed system.

Secondly, to prevent the explosive atmosphere from ignition is also an effective to prevent explosion . To justify this aim, the surface temperature of the explosion proof equipment must be limited and the creation of sparks or sources of ignition must be avoided.

Lastly, the effects of an explosion must be controlled and reduced to a negligible level. Usually, it is conducted by isolating the ignition source, e.g. by mounting explosion proof equipment in flameproof enclosures, etc.

Explosion proof hoist and crane use the explosion protection of removal of potential sources of ignition to prevent explosion by adopting specialized hoist parts & components and together with ongoing monitoring of potentially hazardous environments. What's more, the explosion proof hoist and crane are also used in explosion proof and flame proof workshops.

Industrial cranes for chemical industry

Our series of explosion-proof cranes and components are designed and processed particularly for hazardous and explosion environment widely used in the chemical and petrochemical plants, oil refineries, gas power plants, waste-water treatment plants, paint shops and other industrial sites. The hazardous environment lifting equipment includes the industrial overhead cranes, gantry cranes, light duty jib cranes, and manual cranes, as well as electric and manual rope hoists & chain hoists with lifting capacities range from 500kg to 180 tons.

All of our explosion proof cranes and hoists are with the Certification of Conformity of An Instrument for Explosive Atmosphere with the signs of Exd II BT4 and Exd II CT4. All of the hazardous environment used explosion proof overhead crane and hoists are available with different lifting capacities and customization designs with OEM services. Contact us to get more information on the explosion proof crane and hoists

For chemicals storage and transportation

The raw materials for chemical production includes the granulate and chemical primary products which need to be stored and transported temporarily usually within big bags or similar facilities. Our overhead travelling crane, suspension crane and slewing jib cranes can perform these tasks pleasantly, precisely and reliably.

Explosion proof cranes for hazardous applications

The series of explosion-proof cranes and components are designed and processed particularly for hazardous and explosion environment widely used in the chemical and petrochemical plants, oil refineries, gas power plants, waste-water treatment plants, paint shops and other industrial sites

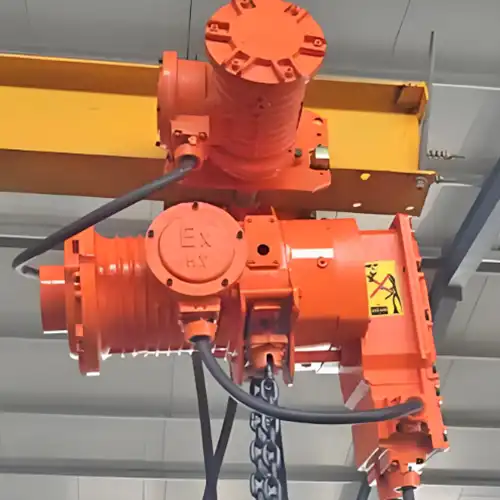

Explosion proof electric chain hoist

Electric chain hoists mounted on hook, lug, manual or electric hoist trolley for types of electric chain hoist cranes with capacity of 500kg, 5 ton, 10 ton, 32 ton.

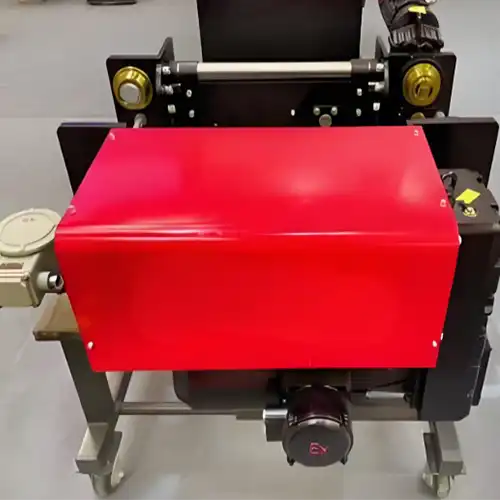

Explosion proof wire rope hoist

Wire rope hoists with explosion proof, flame proof & spark resistant hoist designs to secure your electric hoist crane. Check wire rope explosion proof hoists now.

Explosion proof manual hoist

Explosion-proof manual hoists are widely adopted in the hazard environments with the potential danger of fire and explosion, such as, petroleum, petrochemical, gas station, oil depot and gas extraction, chemical industry, electric power, mining, electronics, railway, etc.

Explosion proof air hoist

Air hoist & pneumatic hoist is a compressed air powered hoist & air operated hoists, various hoist designs, explosion proof, shock proof, wide specification.

Explosion proof pulling & hoisting winch

Mining winch & types of mining winch systems for gold, copper,silver, iron, zinc & coal mine.Underground mining winch & explosion proof winch for sale.

Explosion proof air winch

Air winch & pneumatic winch is an air powered winch or air operated winch for pulling & hoisting loads of 500kg to 10 ton, explosion proof pneumatic winch