Mining Industry

For mining industry, types of industrial material handling cranes are required in the sections of mining and mineral processing & material supplying to improve productivity and ensure safety in harsh conditions. We offer electric overhead travelling crane one stop services from equipment recommendations, installations, modernizations, upgrades and replacements to factories and plants in the mining sector. With specialized industrial crane designs and industrial crane services help you meet the specific challenges of the mine industry.

Industry Challenges

- The heavy loads and hazardous loads are required to be handled by the coal mine industrial cranes & industrial hoist system with safety & reliability.

- The operation condition of the industrial overhead travelling crane systems are hazard and harsh with extreme heat, vibration, abrasive dust, moisture and heavy-duty usage which can cause corrosion and premature wear

- For tight or limited space application, the industrial mining crane and hoists also needs specialized design, such as low headroom and compact structure, etc.

- Made-to-order crane & hoist design may be needed to meet your specific setups & needs, which may include explosion proof design, low headroom design, and spark resistant and corrosion-resistant design, etc.

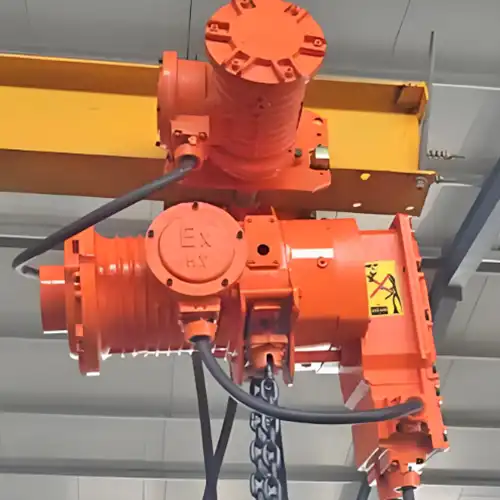

Explosion proof protection

How to avoid explosion ? To avoid the creation of an explosive environment or atmosphere is naturally the first option and the most easiest way with high safety. For example, to provide the adequate and effective ventilation or confine the work processes to prevent the appearance of dangerous gases or dusts in the closed system.

Secondly, to prevent the explosive atmosphere from ignition is also an effective to prevent explosion . To justify this aim, the surface temperature of the explosion proof equipment must be limited and the creation of sparks or sources of ignition must be avoided.

Lastly, the effects of an explosion must be controlled and reduced to a negligible level. Usually, it is conducted by isolating the ignition source, e.g. by mounting explosion proof equipment in flameproof enclosures, etc.

Explosion proof hoist and crane use the explosion protection of removal of potential sources of ignition to prevent explosion by adopting specialized hoist parts & components and together with ongoing monitoring of potentially hazardous environments. What's more, the explosion proof hoist and crane are also used in explosion proof and flame proof workshops.

Safety and durability industrial mining cranes and hoists system

The industrial mining cranes are designed,processed and installed with high safety and durability to meet strict standards and challenges of the mining and coal industry.

Types of industrial cranes and overhead hoist systems are available which include , explosion proof overhead cranes with single girder crane design and double girder crane design, A frame gantry crane with grab and a variety of small-scale mining hoisting equipment like electric chain hoist and electric mining winch, and manual handling hoists, etc. The hand operation hoist are very convenient for material handling in potentially hazardous applications which no electricity supply.

Explosion proof hoist & winch

Explosion proof electric chain hoist

Electric chain hoists mounted on hook, lug, manual or electric hoist trolley for types of electric chain hoist cranes with capacity of 500kg, 5 ton, 10 ton, 32 ton.

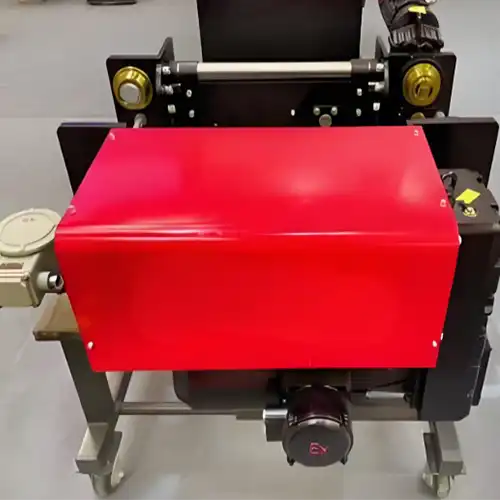

Explosion proof wire rope hoist

Wire rope hoists with explosion proof, flame proof & spark resistant hoist designs to secure your electric hoist crane. Check wire rope explosion proof hoists now.

Explosion proof manual hoist

Explosion-proof manual hoists are widely adopted in the hazard environments with the potential danger of fire and explosion, such as, petroleum, petrochemical, gas station, oil depot and gas extraction, chemical industry, electric power, mining, electronics, railway, etc.

Explosion proof air hoist

Air hoist & pneumatic hoist is a compressed air powered hoist & air operated hoists, various hoist designs, explosion proof, shock proof, wide specification.

Explosion proof pulling & hoisting winch

Mining winch & types of mining winch systems for gold, copper,silver, iron, zinc & coal mine.Underground mining winch & explosion proof winch for sale.

Explosion proof air winch

Air winch & pneumatic winch is an air powered winch or air operated winch for pulling & hoisting loads of 500kg to 10 ton, explosion proof pneumatic winch

Grab bucket for coal mining handling

When working with coal, high output rates are critical. Specialized coal grabs are used to provide high capacity and low dead weight coal and coke handling solutions. The most common coal grabs so far are high enclosed types which are popular for coal unloading with environment friendly design.

Features of coal handling grabs

- Large volume, Light Weight & Durable Quality -Coal is typically handled in huge quantities, therefore high production rates are critical. Due to coal is easy to grasp, and low in density, the coal grab volumes can be fairly large. Because the clamshell grab bucket is constructed of high quality steel, the coal mine grabs are significantly stronger with a reduced dead weight, and what's more, the structure of grab shell can be remained in shape without deformation.

- Easy lubrication, Maintenance & Enhanced safety -Because of the huge volume, the grabs are larger, and for the operating personnel's safety and ease of maintenance, the grab buckets are frequently equipped with a central greasing system. The method ensures that the entire upper structure is properly lubricated without the need to climb the grab.

- Enclosed shell Design, Environment friendly Operation -Most coal grabs have high enclosed model grab structure shells to reduce material loss and contamination. Overlapping lips can reduce material loss and maintenance even further.

Particular bulk coal mining lifting & transporting crane & equipment

In the main girder of lifting equipment for bulk coal handling are presented for your reference.

Container and grab (for handling bulk commodities in specialized containers) cranes with portals;

- Grab bridge cranes or overhead cranes for indoor workshop coal and coke handling

- Grab and container gantry cranes (for handling bulk loads or coal in specialized containers);

- Scraper reclaimers and bucket chain reclaimers for open and closed warehouses, as well as material blending;

- Rotary bucket bridge and boom reclaimers - for material collection in an open or closed warehouse, as well as material blending

- Car dumpers in all configurations, including a novel product, a traverse-car dumper;

- Ship loaders- with a small boom reach and a capacity of up to 3,000 TPH, for sea vessels up to 65,000 DWT and shuttles supporting roadside transshipment.

- Ship loaders - for ocean-class vessels weighing 65 000 to 110 000 DWT and capable of 2,000 to 6,000 TPH;

- Ship unloaders of the continuous type (with a bucket chain elevator inside the unloading equipment).

Main uses of coal mining handing crane & equipment

The mining industrial overhead travelling cranes and hoists can be used widely in power plants, ore, limestone, coke, coal, sand, slag, loose clay and other granular material warehouse.

The mining industrial cranes can be used for material handling in mining and mineral processing & material supplying to improve productivity and ensure safety in harsh conditions where the the potential hazardous gas, steam and air may appear.

The series of the industrial use explosion proof cranes can be used in the application which the explosion proof grade is less than B grade and ignition group is more than T4(135DC) group.

Enrichment plants - Enrichment plants that receive coal by rail from mines and open pits and use car dumpers to unload it, as well as scraper or bucket, chain or rotary reclaimers at open or closed warehouses (for the storage of raw materials or for the blending of raw materials, as well as for the storage of finished products prior to shipment), as well as stackers to arrange materials in a pile.

Power stations - Power plants and stations that receive coal by rail and utilize car dumpers to remove coal from arriving rail cars, a stacker to fill a storage space, and maybe some reclaimers to remove material from the stack. It is common practice to use gantry grab cranes to unload rail cars, feed coal to storage, and remove fuel from storage and feed it to receiving hoppers. Bulldozers are then used to distribute the material around the warehouse area after it has been dumped by a belt loop loader or plow dumper directly from the conveyor gallery to the storage.

Metallurgical and coke plants - Metallurgical and coke factories utilize enormous amounts of the most expensive coal. Such businesses may have up to ten car dumpers to ensure uninterrupted rail car unloading, but they also have much less technological equipment in the storage - they frequently dump coal directly from the conveyor passing over the overpass, and then take coal from the storage using bridge grab cranes. It is also common to load coke onto heavy-duty dump trucks using grab bridge cranes.

Universal & specialized terminals - The universal transshipment sea terminals with portal cranes, used only for coal transshipment, have high costs, are far from optimal in terms of logistics, but do not necessitate large capital investments, have a pool of suppliers and customers that has already been developed over many years, are dynamic and grasping, and rely heavily on key specialists - industry professionals. New specialized terminals with large investments and governmental assistance, focusing on high cargo turnover, high equipment capacity, working with large suppliers and customers, thinking in billions, becoming more bureaucratic and codified, and operating as robotic systems.