Petroleum & Gas

For the petroleum and gas industry, the industrial overhead cranes and industrial gantry cranes are required for material handling from refinement to delivery. In a petrochemical plant, especially in coke pit, the application conditions is very harsh, featured as moisturized, dusty and corrosive.

And also in the coke pit, the production is fast and continuous and repetitive. The industrial used coker crane is required to take hot, fresh coke out of the way of the drum repetitive to clean all of them up. After the coke is cooled and de-watered, the industrial crane will then deliver coke to the crusher, hopper or conveyor. All of the challenges required the industrial hoist and crane systems to be safe, durable and effective to fit the industrial applications and material handling requirements.

Industrial challenges

In the harsh application of petroleum and gas industries, the industrial hoist and cranes systems are required to face the challenge industrial application environment with the following features:

- The industrial electric hoist and cranes used in gas & petroleum plant have to be with high safety even in the high ignition risk areas, such as the refineries, etc.

- The industrial crane systems have to be highly reliable and with constant availability to ensure the continuous production

Explosion proof protection

How to avoid explosion ? To avoid the creation of an explosive environment or atmosphere is naturally the first option and the most easiest way with high safety. For example, to provide the adequate and effective ventilation or confine the work processes to prevent the appearance of dangerous gases or dusts in the closed system.

Secondly, to prevent the explosive atmosphere from ignition is also an effective to prevent explosion . To justify this aim, the surface temperature of the explosion proof equipment must be limited and the creation of sparks or sources of ignition must be avoided.

Lastly, the effects of an explosion must be controlled and reduced to a negligible level. Usually, it is conducted by isolating the ignition source, e.g. by mounting explosion proof equipment in flameproof enclosures, etc.

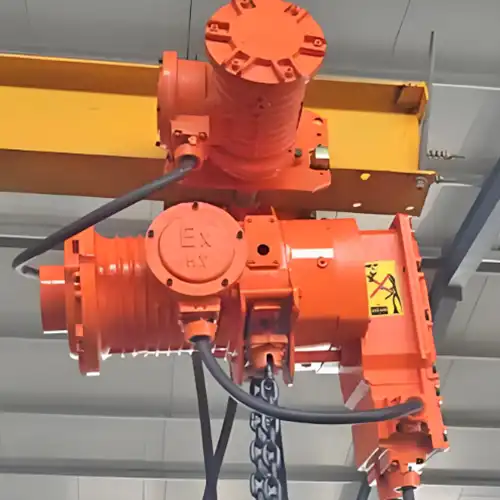

Explosion proof hoist and crane use the explosion protection of removal of potential sources of ignition to prevent explosion by adopting specialized hoist parts & components and together with ongoing monitoring of potentially hazardous environments. What's more, the explosion proof hoist and crane are also used in explosion proof and flame proof workshops.

Industrial cranes for Petroleum and Gas Industry

Enhancing safety and improving profits with tailored industrial cranes and hoists with various crane configurations and specifications in your applications.

The industrial cranes for the hazardous environment are with specialized designs and configurations to offer optimal material handling crane solution for your specific and individualized lifting requirements in application with the potential danger of explosion. Our explosion-proof crane and hoists are carefully selected with high explosion proof performance to improve the safety in chemical and petrochemical plants.

Explosion proof hoist and winch

Explosion proof electric chain hoist

Electric chain hoists mounted on hook, lug, manual or electric hoist trolley for types of electric chain hoist cranes with capacity of 500kg, 5 ton, 10 ton, 32 ton.

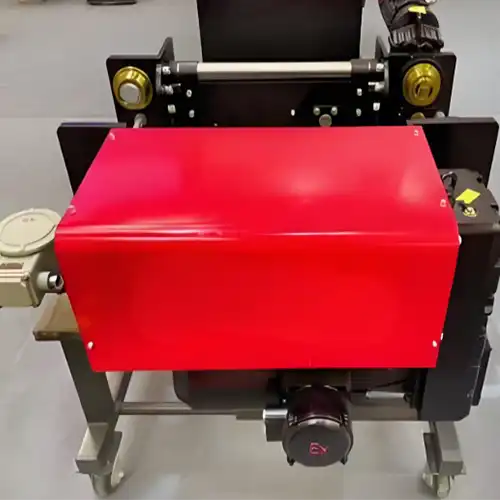

Explosion proof wire rope hoist

Wire rope hoists with explosion proof, flame proof & spark resistant hoist designs to secure your electric hoist crane. Check wire rope explosion proof hoists now.

Explosion proof manual hoist

Explosion-proof manual hoists are widely adopted in the hazard environments with the potential danger of fire and explosion, such as, petroleum, petrochemical, gas station, oil depot and gas extraction, chemical industry, electric power, mining, electronics, railway, etc.

Explosion proof air hoist

Air hoist & pneumatic hoist is a compressed air powered hoist & air operated hoists, various hoist designs, explosion proof, shock proof, wide specification.

Explosion proof pulling & hoisting winch

Mining winch & types of mining winch systems for gold, copper,silver, iron, zinc & coal mine.Underground mining winch & explosion proof winch for sale.

Explosion proof air winch

Air winch & pneumatic winch is an air powered winch or air operated winch for pulling & hoisting loads of 500kg to 10 ton, explosion proof pneumatic winch

Explosion proof cranes

Turnkey services for your industrial application

Our Industrial hoist and cranes system for handling coke in the petroleum sector are designed and manufactured to oppose the hot temperatures, abrasive dust and constant humidity with special materials and reliable safety measures, to ensure your coke handling cranes with high efficiency and safety.

In the petrochemical and natural gas industries, the overhead cranes and gantry cranes are mainly used for valve maintenance. The electric overhead travelling crane has the function of explosion-proof and anti-corrosion. Our hoisting cranes can meet the environmental requirements according to the different environments requirements of users. Check our industrial crane customized for oil and gas industrial material handling or contact us to get free design and crane solution.