Pulp & Paper

Types of industrial overhead crane are used in the pulp and paper making production line for the material handling in the procedures of process, maintenance, and paper scroll transportation and storage, etc. And also the paper making overhead crane are used for woods depositing and transporting, material handling in pulp product line, paper and cardboard processing , scrap basket and tissue manufacturing.

For pulp and paper industry, industrial overhead crane system including the dry end crane & we end crane play a very crucial role to ensure the safe and efficient production of the entire paper processing lines. Due to the demanding application of hot temperature, high humidity & high speed operation, the industrial material handling cranes are required to be operated at a fairly high speed with high reliability, accuracy and safety. One-stop industrial crane services are available to meet your specific application needs and requirements.

Industry Challenges

Due to the harsh application environment and high speed production of the pulp and paper making industry, all the machinery and equipment used including the material handling equipment have to be durable to withstand the harsh conditions and reliable to perform the duty without malfunction.

- Demanding schedules of the production requires the material handling crane and hoist reliable and stable.

- The retrieval and storage of paper rolls by the overhead cranes are required to be smooth and precise to prevent damage

- The paper handling crane system are required to handle heavy paper rolls safely and reliably which needs individualized design and specification to fit your specific inventory levels

- The operation of overhead crane systems can be automatic and semi-automatic to improve efficiency and lower labor costs.

- The material handling cranes and hoists used in the pulp and paper making industry have to withstand the harsh & tough conditions confronted by the industrial application.

Industrial overhead cranes and hoists for paper industry

In the pulp and paper making industry, the wet and dry ends of paper machines needs highly reliable overhead crane system for paper roll handling and maintenance. What's more, the rolls of papers have to be handled gently, precisely and efficiently. Based on the rich experience on pulp and paper making industry, we provide special designed industrial overhead crane and hoist system for pulp and paper industry which can go against the harsh conditions,confront the industrial challenges and meet the specific requirements of your application with the features of high protection level and working duty, efficient automatic operation and detecting systems but with fewer maintenance and repair.

Overhead travelling cranes for paper production

With wide range of industrial overhead cranes and hoists , we are able to supply customized systematic crane solutions for the production of paper making:

- At the dry end of the paper making machine, the paper making cranes are used for handling full reels safely and returning of empty reels effectively.

- At the wet end of the paper making machine, the industrial overhead cranes are used for the maintenance works, such as screens and felts replacement, etc.

- The material handling cranes are also required to help the transporting and replacement of rollers and other components of the paper machine, and all the service and maintenance work in every sections of a paper manufacturing factory.

Paper mill crane types

Overhead travelling crane for paper mill wet end - On the wet end paper mill crane, there are 3 trolleys are travelling on the bridge crane girders. The work duty of this wet end overhead crane is FEM 2m, FEM 3m or FEM 4m. The speed control mode is VFD stepless. The standard capacity of overhead crane for paper mill is from 16 ton, 18 ton, 20 ton to 100 Ton+16 ton, 18 ton, 20 ton to 100Ton. The wet end overhead crane duty is transferring paper rollers from one side to other side in the workshop.

Overhead travelling crane for paper mil dry end - On the wet end paper mill crane, there are 2 trolleys are adoppted to travel on the crane bridge girders. The work duty of this dry end overhead crane is FEM 2m, FEM 3m or FEM 4m. The speed control mode is VFD stepless. The standard capacity of paper mill cranes is from 16 ton, 18ton, 20ton to 100 ton+16 ton, 18 ton, 20 ton to 100 ton. The dry end bridge crane duty is transferring paper rolls from one side to other side in the workshop. This overhead crane for paper mill are also called paper rolls handling cranes.

Overhead crane with fully automated crane design - Paper roll storage workshops typically utilize fully automated overhead canes to handle paper rolls. To change the paper rolls automatically, the automated overhead crane will be connected to a vacuum lifter or a mechanical roll gripper.

Dry End Overhead Crane for Paper Mill

- Capacity of dry end crane: 12.5+12.5 ton - 63+63 ton

- Lift heigh of dry end cranet:Customized

- Hoisting speed of dry end crane:0.4-4m/min or 4-8m/min

- Working duty of dry end crane:FEM 2m/3m/4m

- Protection class of dry end crane:IP55

- Control mode of dry end cranel:Pendent push buttons/wireless radio remote controller

Wet End Overhead Cranes for Paper Mill

- Capacity of wet end crane: 12.5+12.5 ton - 63+63 ton

- Lift height of wet end crane:Customized

- Hoisting speed of wet end crane:0.4-4m/min or 4-8m/min

- Working duty of wet end crane:FEM 2m/3m/4m

- Protection class of wet end crane:IP55

- Control model:Pendent push buttons/wireless radio remote controller

Overhead travelling cranes for paper storage

The efficient production output of a paper machine requires the overhead travelling cranes reliable and versatile. Usually the full automatic or semi-automatic crane are used for paper roll stores which can pickup the the rolls gently and stack them vertically in the storage section.

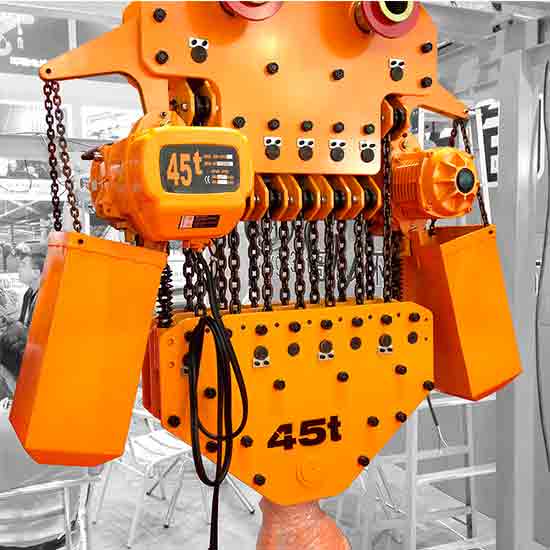

Electric chain hoists mounted on hook, lug, manual or electric hoist trolley for types of electric chain hoist cranes with capacity of 500kg, 5 ton, 10 ton, 32 ton.

Types of wire rope hoists designs for overhead hoist cranes- explosion-proof cable hoist, low profile wire hoist & single & double girder hoists for your hoist cranes.

Safe & fast air operated hoists. Air hoist & pneumatic hoist is a compressed air powered hoist & air operated hoists, various hoist designs,wide specification, good price.

European standard overhead hoist crane, Small overhead crane:European single girder overhead cranes, compact FEM hoist crane design, small & light overhead hoist crane.

1 ton -10 ton underhung bridge crane, light single girder overhead crane design, suspended on overhead roof, free floor space, economical underhung crane.

FEM/ DIN open winch bridge crane-European standard double girder overhead crane with open winch trolley, your heavy duty winch crane up to 320 ton.

Single girder hoist gantry cranes, FEM,DIN & ISO standards: Single beam gantry cranes, European style box girder, FEM hoists for 3 ton, 5 ton, 10 ton, & 16 ton load handling.

European style double girder hoist trolley gantry cranes: European type double girder gantry cranes with FEM standard wire rope hoists trolley with capacity of 5 ton up to 75 ton for sale.

Free standing jib crane-Pillar mounted jib crane is a free standing jib crane with pillar jib mounted on floor, for short & crowded lifting, capacity up to 16 ton.

Wall mounted jib crane & wall bracket jib crane with I beam & tie rod design for light duty handling with capacity up 2 ton. or less building structure changes.

Light crane kbk system-kbk light crane systems, flexible kbk crane & rigid kbk crane, modular crane design, cost-effective workstation crane solution, tailored light duty bridge crane.

Portable gantry crane & Economical mobile gantry-250 kg - 10 ton portable gantry cranes & mobile gantry cranes with adjustable / fixed gantry for small & light material handling.

As one of the best crane manufactuer and supplier in China, we offer crane sevices for turnkey crane projects ie.overhead, gantry & jib cranes and other travelling cranes from crane degin, manufactuering & installation, and crane parts supplying, etc.

Paper roll lifter and tongs

For various heavy paper rolls handling at different industrial applications such as printing, types of paper roll lifters are developed such as, paper roll tongs, paper roll grippers or beam spreaders, etc. Processed roll lifters are available to fit your overhead travelling cranes and meet your specific application requirements to enable rapid and safe paper roll lifting and moving with a long working life.

Parent roll lifter - J hook beam spreader

The J hook beam roll lifter is an excellent ergonomic paper roll lifting devices. The hook of the beam roll lifter pick up rolls by taking a mandrel inserted into the roll. To meet different application requirements, the J hook beam roll lifter can be designed with the features of low Headroom,narrow side clearance and easy operation, etc.

Contact us to get tailored overhead crane design, free CAD overhead crane drawing, defined overhead crane specifications for your particular application with lower overhead crane costs & good overhead crane price. Send an overhead crane inquiry to your latest eot crane price now!

Turnkey project service for overhead travelling cranes

The pulp and paper making industry is one of the key sectors of our industrial overhead travelling crane systems. From precise handling of machine rollers to automatic storing of paper rolls, our made to-order crane and hoist solutions will fully fit your specific applications and requirements. Send us a inquiry now!

With years of experiences and industry-specific expertise, we have supplied process crane solutions around world for biomass processing and recycling, etc.

Hoist & Crane Turn-Key Project Services - Consultation, design, fabrication, Installations. Preventative Maintenance. Renew, & Upgrades.

Free consultation on crane design

Overhead travelling crane design, overall crane project design, processing design, excellent technical and economical crane purchasing plan design are all available from our pre-sale technical support.

Crane after sale services

Crane after-sale services are the very important part of overhead travelling buying. Superior after sale crane services will ensure the safety and reliability of your crane in a long run and make the best value out of your investment.

Crane on-time delivery

Crane for sale to South Africa,Malaysia, United Arab Emirates ,Singapore ,Canada ,Saudi Arabia ,Philippines,Pakistan, Australia, United States ,Thailand, Indonesia, Brazil, etc.

Crane installation & commissioning

Crane installation and commissioning services is one of our important after sale services which will help our clients to install the overhead crane, gantry crane, jib cranes and various process designed industrial cranes correctly and safely to ensure the optimal overhead crane operation operation conditions and efficiency to make the best value out of your investment

Crane training

Crane training services of us are specialized after sale crane services which is exclusively to valuable clients and customers to qualify your staff, improve crane safety &efficiency, maximize your uptime and lower crane maintenance cost to make the best value out of your overhead travelling crane investment in a long run.

Crane inspection & maintenance

Crane inspection and maintenance are effective way to improve the safety and productivity of your overhead travelling cranes, gantry cranes, and jib cranes through a series of preventive inspections, routine maintenance, and corrective maintenance, and modernization service. A lifetime care crane services are available for you.

Crane upgradation & refurbishment1

Crane upgrade and refurbishment is one of the most economical way to renew your overhead travelling crane with new and advanced crane features, extend your crane service life and enhance crane safety.

Crane parts supply

Various types of crane spare parts and components, crane kits, and type of below-the-hook devices supply, etc. If you need crane, hoist or crane parts, Please feel free to contact us. We will reply you in 12 hours.