Wood , Timber & Furniture

Wood and versatile of wood products have a very vital role in our lives. For wood processing industry, various types of customized industrial crane systems, including overhead crane, gantry crane, light kbk cranes and other types of hoist cranes are designed and provided to meet the diverse material handling requirements of the wood processing industry.

The wood and log industry stands as a testament to the symbiotic relationship between human ingenuity and nature's bounty. From towering trees to meticulously crafted timber products, this industry plays a vital role in providing raw materials for construction, furniture, paper, and a myriad of other products that enrich our lives. At the heart of this intricate process lies a critical element: the use of overhead cranes. In this article, we delve into the world of wood processing and explore the significance of overhead cranes in its various stages.

Overview of The Wood and Log Industry

The wood and log industry is a multi-faceted sector that encompasses the extraction, processing, and transformation of wood materials derived from forests. From ancient civilizations to modern times, wood has been an integral part of human existence, serving as a foundational material for shelter, tools, and artistry. Today, the industry has evolved into a complex network of activities, ranging from harvesting logs to crafting intricate wooden products that grace our homes and workspaces.

The wood and log industry, also known as the timber industry or forestry sector, encompasses various activities related to the harvesting, processing, and utilization of wood and timber products from forests. This industry plays a crucial role in providing raw materials for a wide range of products, from construction materials to paper and furniture.

- 1. Harvesting and Logging: This involves the process of cutting down trees in forests for various purposes. Trees are typically selected based on their size, species, and quality. Logging methods can vary, from traditional manual cutting to modern mechanized processes.

- 2. Sawmills and Processing: Once trees are harvested, they are transported to sawmills or processing facilities. Here, the logs are cut into various dimensions and shapes, depending on the intended use. Sawmills use specialized equipment like saws, planers, and kilns to transform raw logs into lumber and other wood products.

- 3. Pulp and Paper Industry: A significant portion of the timber industry is dedicated to producing pulp for paper and paper products. Trees are chipped or converted into wood pulp through mechanical or chemical processes. This pulp is then used to manufacture various types of paper, cardboard, and packaging materials.

- 4. Construction and Building Materials: Lumber produced from the timber industry is a primary material used in construction. It's used for framing, flooring, roofing, and other structural components in residential, commercial, and industrial buildings.

- 5. Furniture and Wood Products: The industry provides the raw materials for crafting furniture and other wood products like cabinetry, doors, windows, and decorative items. Wood is valued for its aesthetic appeal and versatility in design.

- 6. Energy Production: Some wood and log industry byproducts, such as wood chips and sawdust, are used as biomass for energy generation. They can be burned to produce heat or electricity, contributing to renewable energy sources.

- 7. Environmental Considerations: Sustainable forestry practices are essential to maintain the health and biodiversity of forests. Responsible logging and reforestation efforts help ensure that the industry doesn't contribute to deforestation and habitat destruction.

- 8. Regulations and Certifications: Many countries have regulations in place to manage and control logging activities, aiming to balance economic interests with environmental conservation. Additionally, various certification systems (e.g., Forest Stewardship Council or FSC) help consumers identify wood products derived from well-managed forests.

It's important to note that the wood and log industry's impact on the environment, including issues like deforestation, habitat loss, and carbon emissions, has prompted discussions and efforts to promote sustainable practices and the responsible use of forest resources.

Main Types of Overhead Cranes in the Wood and Log Industry

In the wood and log industry, several types of overhead cranes are commonly used to handle the unique requirements of moving, processing, and transporting logs and wood products. Each type of crane has its own features, benefits, functions, and typical applications. Here are some of the most preferred or frequently used types of overhead cranes in the industry:

Featured ovehread logs cranes for timer and logs handlings

Single girder overhead crane with wood grab for indoor log and time handling for your reference

Single Girder Overhead Crane:

- Features: - Consists of a single beam (girder) that supports the hoist and trolley. - Typically used for lighter loads and spans. - Suitable for applications where space is limited.

- Benefits: - Cost-effective solution for light to moderate lifting needs. - Requires less runway support structure due to the single girder design.

- Functions: - Lifting and moving smaller logs and wood products within a limited area.

- Typical Applications: - Small sawmills, wood processing workshops, storage yards.

Double girder overhead crane with log grapple for heavier wood and lumber handling for your reference

Double Girder Overhead Crane:

- Features: - Two parallel girders provide increased load capacity and stability. - Suitable for heavier loads and longer spans.

- Benefits: - Higher lifting capacity compared to single girder cranes. - Offers better stability and precision for heavy loads.

- Functions: - Handling larger logs, timber bundles, and heavier wood products.

- Typical Applications: - Large sawmills, wood processing facilities, timber yards.

Featured gantry cranes and logs cranes for timer and logs handlings

- Features: - Supported on legs that can move on wheels or rails. - Provides versatility in terms of mobility and positioning.

- Benefits: - Offers flexibility to move across a wider area, including outdoor spaces. - Suitable for both indoor and outdoor wood processing operations.

- Functions: - Lifting and moving logs and wood products in outdoor yards or indoor facilities.

- Typical Applications: - Lumber yards, log storage areas, outdoor wood processing sites.

Box girder Gantry crane for outdoor use for your reference

Truss girder gantry crane for high wind place log handling for your reference

- Features: - Consists of a horizontal jib arm that rotates around a vertical support. - Offers localized lifting and positioning capabilities.

- Benefits: - Efficient for precise loading and unloading of wood products. - Takes up minimal floor space.

- Functions: - Handling wood products in specific workstations or limited areas.

- Typical Applications: - Loading and unloading at specific points, woodworking stations.

Timber grab, efficient for log and timber handling

Timber grab is an effective tool suitable for log loading and unloading in ports, forest farms, log storage yards and other operations. Wood grabs are divided into mechanical wood grabs, wireless remote control wood grabs and electro-hydraulic wood grabs.

- Features: - Equipped with a specialized grab or clamshell bucket for material handling. - Allows for bulk material handling and grabbing logs or wood bundles.

- Benefits: - Efficient for loading and unloading wood chips, logs, and other loose materials. - Increases productivity for handling bulk materials.

- Functions: - Collecting and transferring loose wood materials like logs, wood chips, and sawdust.

- Typical Applications: - Timber yards, biomass processing plants, paper and pulp facilities.

Featured four rope timber grab

The four rope timber grab is equipped with a grab for loading and unloading timber for gantry cranes and various bridge cranes. It has the characteristics of reasonable structure, convenient operation and safe operation. It is not only suitable for ports, but also for railways, timber processing mill, timber storage and transportation, etc. The ideal handling lifting devices for the wood processing industry. The log grab is suitable for loading and unloading various types of logs with a double-drum material handling crane. The upper beam of the grab is equipped with a rotatable balance frame and a lifting chain, which can be directly connected with the hoisting rope shackle of the overhead handling crane. The balance frame can be made into a large balance frame (the opening and closing rope is inside the hoisting rope) or a small balance frame (the opening and closing rope is outside the lifting rope) according to the arrangement of the crane pulleys.

Motor Timber Grabs

The electric motor log handling grabs are widely used with overhead handling cranes, applied in dockside operations, in sawing and veneer factories to maximize your log handling volume. With an electric supply, electric motor log grapple can be customized to meet various power supply, and can be fastened either directly, or on slewing units or traverse beams.

Applications of electric motor timber grabs

Typically, the log grapples are used with outdoor Goliath crane and outdoor gantry cranes for efficient timer and log handing .

The electric motor log grabs can be used for various operations including the for the application for individual logs and spars,g large individual trees , large individual hard-timber trees, etc.

Depending on the grab size of timer grabs, for example, it is possible to unload a truck in just one loading operation.

Hydraulic Timber Grabs

Hydraulic Log Grabs are also widely used in in sawmills and timber processing industries, for efficient handling of

spars, bundled timber or individual logs, etc. They are specialized for continuous heavy duty log and timer handling.

Features of hydraulic log grabs

High load bearing capacity rotary head with integrated maximum pressure safeguarding for the lifting cylinders and the rotary function. Warp-resistant steel construction made of hard-wearing special steel. Synchronized toothing ensures uniform closing and opening of the tongs.

Hydraulic components that are efficient ensure high handling efficiency. Because of the optimal tong shape, logs of any size can be efficiently picked up. Depending on the grab type, the two tongs are designed to mesh into one another in an overlap. Even thin logs cannot fall out, ensuring uninterrupted operation sequences and high productivity.

These different types of overhead cranes serve specific functions and cater to various requirements within the wood and log industry. The choice of crane depends on factors such as load capacity, working area, mobility, and the specific tasks involved in moving and processing wood materials.

Main functions of overhead used in the wood and log industry

As technology has advanced, so too has the equipment used in the wood and log industry. Among the most indispensable tools are overhead cranes. These robust machines are designed to lift, move, and position heavy logs, lumber, and other wood materials with remarkable precision. Their significance lies in their ability to streamline processes, improve safety, and increase overall productivity.

- Streamlining Operations: In the realm of wood processing, efficiency is key. Overhead cranes play a pivotal role in this regard by seamlessly moving logs and timber from one stage to another. Whether it's transporting logs from collection sites to processing facilities or moving lumber through sawmills, these cranes cover vast areas efficiently, minimizing delays and optimizing workflows.

- Ensuring Precision: Crafting high-quality wood products demands accuracy. Overhead cranes provide the finesse required for precise positioning of logs and materials during cutting, shaping, and assembly. This precision ensures that each piece of wood is utilized optimally, minimizing waste and maximizing the yield from every log.

- Enhancing Safety: The safety of workers is paramount in any industry, and the wood and log sector is no exception. Overhead cranes are equipped with advanced safety features such as limit switches, emergency stop buttons, and overload protection mechanisms. These features safeguard against accidents, reducing the risk of injuries and promoting a secure working environment.

- Increasing Productivity: Productivity is the cornerstone of successful wood processing. By swiftly and efficiently handling heavy loads, overhead cranes contribute to a faster production cycle. This increased throughput translates to a higher volume of finished products and improved profitability for businesses within the industry.

The wood and log industry, deeply rooted in history and nature, continues to thrive through innovation and adaptation. Overhead cranes stand as a testament to human ingenuity, facilitating the transformation of raw materials into functional and artistic creations. As the industry evolves, the role of overhead cranes remains pivotal, bridging the gap between nature's resources and the products that shape our modern world.

Applications of overhead cranes in wood and log industry

The wood and log industry thrives on a diverse range of processes, each requiring specialized handling equipment. Overhead cranes have emerged as the backbone of these processes, offering tailored solutions to address the unique demands of various stages within the industry. Let's explore the types of overhead cranes utilized in different aspects of wood processing:

What are the typical overhead crane used in each and every procedures of the wood and log industry? In the following, the main types of overhead cranes are presented for your reference. If you need custom overhead crane, please feel free to contact us. WhatsApp: + 86 151 3871 1597.

1. Log Collection and Transport:

- - Overview of Log Collection and Transport: This phase involves collecting logs from forests or logging sites and transporting them to processing facilities or storage yards.

- - Typical Crane Used: Gantry Crane

- - Features: Gantry cranes are equipped with wheels or tracks that allow them to move along a runway. They have a bridge structure that spans the working area, and their legs can straddle the logs for lifting and transport.

- - Benefits: - Versatility in outdoor environments. - Can cover a large area for efficient log collection and transport. - Adjustable height and movement along the runway.

- - Commonly Used Applications in: - Forest and logging sites. - Log collection yards.

2. Log Sorting and Storage:

- - Overview of Log Sorting and Storage: Logs are sorted based on size, species, and quality, and then stored for further processing.

- - Typical Crane Used: Single Girder Overhead Crane

- - Features: Single girder cranes have one horizontal beam and can handle lighter loads. They are well-suited for limited spaces.

- - Benefits: - Cost-effective for lighter log handling. - Ideal for sorting and arranging logs in storage areas.

- - Commonly Used Applications in: - Log sorting areas within processing facilities. - Log storage yards.

3. Log Debarking and Preparation:

- - Overview of Log Debarking and Preparation: Logs are prepared by removing bark and undergoing initial processing steps before further use.

- - Typical Crane Used: Jib Crane

- - Features: Jib cranes have a rotating jib arm and are designed for localized lifting and positioning.

- - Benefits: - Precise control for debarking and initial preparation. - Takes up minimal floor space.

- - Commonly Used Applications in: - Debarking stations. - Initial log preparation areas.

4. Sawmills and Processing:

- - Overview of Sawmills and Processing: Logs are processed into lumber and other wood products in sawmills and processing facilities.

- - Typical Crane Used: Double Girder Overhead Crane

- - Features: Double girder cranes have two parallel beams for increased load capacity and stability. They are suitable for heavy-duty lifting and transportation.

- - Benefits: - High load capacity for heavy logs and lumber. - Stable movement for precise processing.

- - Commonly Used Applications in: - Sawmill operations. - Wood processing facilities.

For wood cutting workplaces in the sawmill industry, the industrial overhead crane or industrial gantry crane with grab or tong or other lift devices can effectively transport the long wooden material to the saws and place them precisely at the required position. What's more, with the help of the effective lifting hoist and crane solutions, the timbers can be stored and shipped with high efficiency and safety at same time lowering your labor cost and reducing working time.

5. Drying and Treatment:

- - Overview of Drying and Treatment: Processed lumber goes through drying and treatment stages to enhance durability and quality.

- - Typical Crane Used: Single or Double Girder Overhead Crane

- - Features: Both single and double girder cranes can be used depending on the size of drying chambers and load requirements.

- - Benefits: - Precise positioning of lumber during drying and treatment. - Flexibility to accommodate various drying setups.

- - Commonly Used Applications in: - Lumber drying chambers. - Treatment facilities.

6. Lumber Stacking and Storage:

- - Overview of Lumber Stacking and Storage: Processed lumber is stacked and stored for future use or distribution.

- - Typical Crane Used: Gantry Crane

- - Features: Gantry cranes offer mobility and can be used in outdoor and indoor settings for effective stacking and storage.

- - Benefits: - Versatility in moving and arranging lumber stacks. - Suitable for open yards and warehouses.

- - Commonly Used Applications in: - Lumber storage yards. - Warehouses.

7. Paper and Pulp Industry:

- - Overview of Paper and Pulp Industry: Wood materials are used in the production of paper and pulp products.

- - Typical Crane Used: Grab Crane (Clamshell Crane)

- - Features: Grab cranes are equipped with specialized grabs or clamshell buckets for bulk material handling.

- - Benefits: - Efficient handling of wood chips and bulk materials. - Suitable for continuous loading and unloading.

- - Commonly Used Applications in: - Paper mills. - Pulp production facilities.

8. Furniture and Product Manufacturing:

- - Overview of Furniture and Product Manufacturing: Wood is processed to create furniture and other wood products.

- - Typical Crane Used: Jib Crane

- - Features: Jib cranes provide localized lifting and positioning capabilities for woodworking stations.

- - Benefits: - Precise control for furniture and product manufacturing. - Space-efficient solution for material handling.

- - Commonly Used Applications in: - Woodworking stations. - Furniture manufacturing workshops.

For the furniture manufacturing industry, our overhead hoists and cranes can help to store profile sections and other raw material and to lift them to the machinery. As for the handling of wooden panels and large furniture elements, the industrial hoist crane system can be lifted and transported with efficiency and ease.

9. Loading and Unloading:

- - Overview of Loading and Unloading: Logs, lumber, and wood products are loaded onto trucks, containers, or other transportation vehicles.

- - Typical Crane Used: Gantry Crane

- - Features: Gantry cranes are used for efficient loading and unloading operations in various environments.

- - Benefits: - Quick and safe loading onto trucks or containers. - Ability to handle heavy loads.

- Commonly Used Applications in: - Loading docks. - Container yards.

10. Biomass and Energy Generation:

- - Overview of Biomass and Energy Generation: Wood materials are used as biomass for energy generation.

- - Typical Crane Used: Grab Crane (Clamshell Crane)

- - Features: Grab cranes are used for handling bulk wood chips and biomass material for energy production.

- - Benefits: - Efficient loading of biomass materials. - Suitable for continuous operations.

- - Commonly Used Applications in: - Biomass power plants. - Energy generation facilities.

11. Wood and prefabricated construction

- Overview of wood and prefabricated construction: For wood and prefabricated building sector, the overhead travelling lifting equipment are frequently adopted to help the handling of the pre-fabricated individual wooden elements to complete wooden houses.

- Typical Crane Used: Overhead crane

- Features :.With overhead rail travelling crane design or ceiling mounted crane design, our overhead travelling crane system do not take your floor space helping you make the most of your ground space.

- Applications: The industrial overhead crane systems are also used to help the intermediate storage of the basic panels, move them to the CNC machine and load the prefabricated wooden elements

These cranes play crucial roles in their respective procedures within the wood and log industry, contributing to the overall efficiency and effectiveness of various processes.

Industrial cranes for wood and log processing industry

Industrial cranes are commonly used in the wood processing industry.

- Light duty overhead crane bridge crane & Rotating jib crane

- Light KBK crane system can move loads overhead without any limitation.

- A frame gantry crane for outdoor timber and log handling.

Customized industrial cranes for specific wood and timber industrial applications.

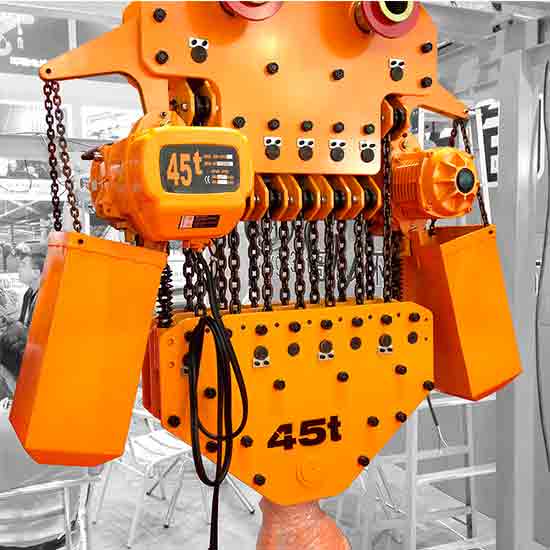

Electric chain hoists mounted on hook, lug, manual or electric hoist trolley for types of electric chain hoist cranes with capacity of 500kg, 5 ton, 10 ton, 32 ton.

Types of wire rope hoists designs for overhead hoist cranes- explosion-proof cable hoist, low profile wire hoist & single & double girder hoists for your hoist cranes.

Safe & fast air operated hoists. Air hoist & pneumatic hoist is a compressed air powered hoist & air operated hoists, various hoist designs,wide specification, good price.

European standard overhead hoist crane, Small overhead crane:European single girder overhead cranes, compact FEM hoist crane design, small & light overhead hoist crane.

1 ton -10 ton underhung bridge crane, light single girder overhead crane design, suspended on overhead roof, free floor space, economical underhung crane.

FEM/ DIN open winch bridge crane-European standard double girder overhead crane with open winch trolley, your heavy duty winch crane up to 320 ton.

Single girder hoist gantry cranes, FEM,DIN & ISO standards: Single beam gantry cranes, European style box girder, FEM hoists for 3 ton, 5 ton, 10 ton, & 16 ton load handling.

European style double girder hoist trolley gantry cranes: European type double girder gantry cranes with FEM standard wire rope hoists trolley with capacity of 5 ton up to 75 ton for sale.

Free standing jib crane-Pillar mounted jib crane is a free standing jib crane with pillar jib mounted on floor, for short & crowded lifting, capacity up to 16 ton.

Wall mounted jib crane & wall bracket jib crane with I beam & tie rod design for light duty handling with capacity up 2 ton. or less building structure changes.

Light crane kbk system-kbk light crane systems, flexible kbk crane & rigid kbk crane, modular crane design, cost-effective workstation crane solution, tailored light duty bridge crane.

Portable gantry crane & Economical mobile gantry-250 kg - 10 ton portable gantry cranes & mobile gantry cranes with adjustable / fixed gantry for small & light material handling.

As one of the best crane manufactuer and supplier in China, we offer crane sevices for turnkey crane projects ie.overhead, gantry & jib cranes and other travelling cranes from crane degin, manufactuering & installation, and crane parts supplying, etc.

Contact us to get tailored overhead crane design, free CAD overhead crane drawing, defined overhead crane specifications for your particular application with lower overhead crane costs & good overhead crane price. Send an overhead crane inquiry to your latest eot crane price now!

Selection Tips for Overhead Cranes in Window and Door Manufacturing Workshops

Manufacturing workshops that focus on creating windows and doors require specialized equipment to ensure precision, efficiency, and safety throughout the production process. Selecting the right overhead crane is a critical decision that can significantly impact workflow and product quality. Here are essential considerations to guide your choice:

- A. Workshop Layout and Space Considerations - Assess available space for crane installation and movement. Consider the workshop's layout and available space. Ensure that the chosen crane type fits comfortably within the workshop without hindering other operations or causing congestion.

- B. Lifting Capacity and Load Types - Determine the maximum weight of window and door materials. Identify the heaviest materials to be lifted during the manufacturing process. Choose a crane with a lifting capacity that comfortably accommodates these loads, factoring in potential growth in production.

- C. Crane Span and Height - Choose the appropriate span and lifting height for workshop needs. Select a crane with the right span and lifting height to cover the entire workspace. Ensure that the crane's range allows for seamless material movement and positioning.

- D. Precision and Positioning - Consider the need for precise positioning during manufacturing. Precision is crucial when crafting windows and doors. Opt for a crane that offers precise control, allowing for accurate material placement and assembly.

- E. Mobility and Accessibility - Choose a crane type that provides optimal mobility within the workshop. Select a crane that can move smoothly across the workshop area. Mobility enhances flexibility in material handling and ensures that the crane can access all workstations.

- F. Safety Features - Evaluate safety features such as limit switches, emergency stop buttons, etc. Prioritize safety by choosing a crane equipped with essential safety features. Limit switches, emergency stop buttons, and overload protection mechanisms ensure a secure working environment.

- G. Integration with Manufacturing Processes - Ensure the crane complements window and door manufacturing steps. The crane should seamlessly integrate with the various manufacturing stages, from material handling to assembly. It should enhance workflow and eliminate bottlenecks.

- H. Environmental Factors - Account for indoor/outdoor use, temperature, and humidity conditions. Consider whether the workshop is indoors or outdoors. Additionally, assess temperature and humidity conditions to choose a crane that can withstand the environment.

- I. Maintenance and Service - Select cranes with easy maintenance requirements and reliable service support. Opt for a crane that is easy to maintain and offers reliable service support. Regular maintenance ensures the longevity and efficiency of the equipment.

- J. Budget Considerations - Balance features and benefits with budget constraints. While it's essential to choose a crane with the required features, ensure that it aligns with your budget. Seek a balance between functionality and affordability.

Selecting the right overhead crane for window and door manufacturing workshops is a strategic investment that contributes to product quality, operational efficiency, and the overall success of the business. By considering these factors, you can make an informed decision that meets the specific needs of your workshop.

Customized Wood Lumber handling Crane Video for Reference

In the intricate world of wood and log processing, the role of overhead cranes stands as a testament to the power of innovation and technology. As we conclude our exploration of these essential tools, it's evident that overhead cranes are not mere machines; they are the backbone of the wood and log industry, orchestrating the seamless flow of materials from forests to finished products.

The selection of the right overhead crane is a decision that reverberates across each stage of the industry's journey. From the initial collection of logs to the final crafting of windows, doors, and countless wood products, overhead cranes enhance efficiency, precision, and safety. They become the conduits through which wood's potential is realized and transformed into the tangible and intangible creations that enrich our lives.

By carefully assessing factors such as workshop layout, lifting capacity, precision requirements, safety features, and budget constraints, businesses can make informed decisions that optimize their manufacturing processes. The choice of the appropriate crane type is not just a technical decision; it's a strategic investment that has a profound impact on overall productivity and product quality.

As we look to the future of the wood and log industry, the significance of overhead cranes remains unwavering. They serve as reminders of human ingenuity and collaboration with nature. They enable us to craft sustainable solutions while respecting the resources the earth provides. Through each choice of overhead crane, we contribute to an industry that continually evolves, adapts, and shapes the world around us.

So, whether it's the towering trees of the forest or the intricately designed windows and doors that adorn our living spaces, let's celebrate the role of overhead cranes—the silent architects that elevate the wood and log industry to new heights.