Jib Crane 500kg to 16 Ton for Sale, Optional Design and Sepecificaitons

Jib Crane for sale, 500kg to 16 tons capacity, customizable designs &specifications to suit your industrial uses.Check jib crane specification table now.

Category: Jib Crane Capacity & Tonnages

Your Trusted Jib Crane Manufacturer & Supplier

Jib Crane 500kg to 16 Ton for Sale, Optional Design and Sepecificaitons

Jib cranes are versatile and efficient lifting solutions commonly used in various industries. They consist of a horizontal arm, or jib, that extends from a vertical mast or pillar. The jib can rotate around the mast, allowing it to cover a wide working area. This design makes jib cranes ideal for tasks such as material handling, assembly operations, and maintenance work in both indoor and outdoor settings.

Jib cranes come in different sizes and configurations to meet specific operational needs. They range from small, lightweight models designed for lighter loads and tighter spaces, to heavy-duty cranes capable of handling substantial weights. Their flexibility in movement and ease of use contribute to their popularity in workplaces where precise and efficient lifting is required.

Importance of Selecting the Right Capacity and Design

Choosing the appropriate capacity and design for a jib crane is crucial for ensuring safety, efficiency, and cost-effectiveness in your operations.

- Capacity: The capacity of a jib crane determines the maximum weight it can safely lift and handle. Selecting a crane with the right capacity is essential to avoid overloading, which can lead to equipment failure, accidents, and damage to the materials being handled. For example, a crane rated for 1 ton might be insufficient for tasks requiring the lifting of 5 tons, leading to potential hazards and operational inefficiencies.

- Design: The design of a jib crane affects its operational range, stability, and suitability for various tasks. Different designs include wall-mounted, floor-mounted, pillar-mounted, and articulating models. Each design offers distinct benefits and is suited to specific environments and applications. For instance, a wall-mounted jib crane is ideal for spaces with limited floor space but requires a solid wall for installation. On the other hand, a floor-mounted jib crane offers greater flexibility and reach but requires more space and a stable foundation.

Selecting the right combination of capacity and design ensures that the jib crane meets the demands of your tasks while maintaining safety and efficiency. It also helps in optimizing workflow, reducing downtime, and extending the lifespan of the equipment.

Overviw of Jib Crane Capacity Ranges and Your Options

500kg to 1 Ton Jib Cranes

- Typical Applications:Jib cranes with capacities ranging from 500kg to 1 ton are well-suited for small-scale, light-duty tasks. These cranes are commonly used in workshops, small manufacturing facilities, and maintenance areas where space is limited but precision handling is needed. They are ideal for lifting small components, tools, and materials in confined spaces or areas with restricted headroom.

- Load Handling Characteristics:Despite their smaller size, these jib cranes offer exceptional maneuverability and precision. They are designed to handle lightweight loads efficiently, with quick and easy adjustments for different tasks. Their compact design allows for easy integration into tight work environments, and their lower lifting capacities ensure they are cost-effective and require minimal maintenance.

1 Ton to 5 Ton Jib Cranes

- Common Use Cases:Jib cranes with capacities between 1 ton and 5 tons are versatile and commonly used in medium-sized industrial environments. They find applications in assembly lines, repair shops, and warehouses where moderate lifting and handling tasks are required. These cranes are suitable for lifting heavier materials and components, such as engine parts or machinery, making them a popular choice for industries like automotive and manufacturing.

- Capacity and Efficiency:Crane models in this range offer a good balance between lifting power and operational efficiency. They are designed to handle a broader range of weights and provide sufficient reach for most industrial tasks. Their efficiency is enhanced by features like electric hoists or manual winches, which streamline operations and improve productivity. The capacity of these cranes ensures they can manage substantial loads while maintaining stability and safety.

5 Ton to 10 Ton Jib Cranes

- Industry-Specific Applications:Jib cranes with capacities of 5 tons to 10 tons are typically used in more demanding industrial settings, such as heavy manufacturing, large-scale warehouses, and construction sites. These cranes are ideal for handling bulky items, large machinery, and heavy components. They are commonly employed in industries like aerospace, automotive, and steel manufacturing where robust lifting solutions are necessary.

- Design Considerations:In this capacity range, design considerations focus on durability and structural integrity. The cranes are built with reinforced materials and advanced engineering to handle the increased load. Features such as extended reach, enhanced stability, and robust base structures are critical for ensuring safe and effective operation. Proper installation and maintenance are essential to maintain performance and longevity.

10 Ton to 20 Ton Jib Cranes

- Heavy-Duty Applications:Jib cranes with capacities between 10 tons and 16 tons are designed for heavy-duty applications where significant lifting power is required. They are commonly used in large manufacturing plants, heavy equipment maintenance areas, and construction sites. These cranes handle very heavy loads, such as large machinery components, structural elements, and industrial equipment, making them essential for high-demand environments.

- Structural and Safety Features:For cranes in this heavy-duty range, structural strength and safety are paramount. These cranes are equipped with heavy-duty materials and reinforced components to ensure they can withstand the stresses of lifting large weights. Safety features include advanced overload protection, robust braking systems, and enhanced stability mechanisms. Additionally, these cranes often include features for precise load control and extensive reach capabilities, ensuring that even the heaviest loads can be handled safely and efficiently.

Optional Jib Crane Designs: Tailoring to Your Needs

- Benefits and Applications:Wall-mounted jib cranes are ideal for environments where floor space is limited. By attaching directly to a wall or building structure, these cranes offer a space-saving solution that maximizes available floor area. They are well-suited for workshops, small manufacturing facilities, and maintenance areas where efficient overhead lifting is needed without the need for extensive floor installation.

- Load Capacities and Reach:These cranes typically handle loads ranging from 500kg to 1 ton and offer a reach of about 2 to 6 meters. The reach and load capacity are influenced by the strength and stability of the wall to which the crane is mounted. Although their reach is constrained by the wall's position, they are effective for light to moderate lifting tasks where space efficiency is a priority.

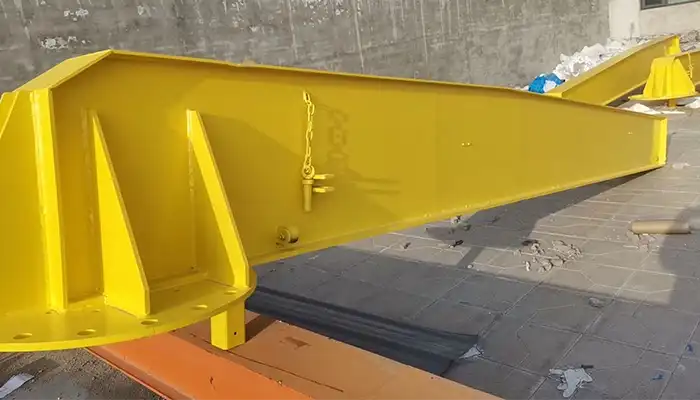

Floor-Mounted Pillar Jib Cranes

- Advantages for High-Traffic Areas:Floor-mounted jib cranes are versatile and can be placed in high-traffic areas where frequent lifting and movement are necessary. Their installation allows for full 360-degree rotation and extensive reach, making them suitable for large industrial spaces, warehouses, and production lines. They are robust enough to handle continuous operation in busy environments.

- Customization Options:These cranes offer a range of customization options to fit specific needs. Adjustments can be made to the arm length, lifting height, and load capacity. Custom features may include electric hoists for ease of operation, safety enhancements like collision sensors, and different base designs to accommodate unique floor layouts or operational requirements.

- Versatility and Space Efficiency: Wall travelling jib cranes are mounted on a horizontal rail attached to a wall or column, allowing them to move along the length of the workspace. This design maximizes floor space and provides excellent flexibility in confined areas, making them ideal for applications requiring frequent lifting across different positions within a facility.

- Ideal Applications: These cranes are perfect for workshops, production lines, and warehouses where space is limited and efficient material handling across multiple workstations is required. They are designed to handle moderate loads, providing a practical solution for diverse lifting tasks in various industrial settings.

Portable Jib Cranes on Mobile Wheels

- Benefits and Applications:Portable jib cranes on mobile wheels offer flexibility and ease of movement within various work areas. Designed to be easily relocated, these cranes are ideal for environments where tasks frequently change locations, such as construction sites, maintenance facilities, and temporary assembly areas. Their mobility enhances operational efficiency by allowing quick setup and repositioning.

- Load Capacities and Reach:Portable jib cranes typically handle lighter loads compared to stationary models, with capacities ranging from 500kg to 2 tons. Their reach varies based on design and model, but they generally offer enough coverage for small to moderate tasks. The mobile base allows for easy maneuvering, making them suitable for diverse applications where quick adjustments are needed.

500kg Jib Cranes Design Options overivew

Jib cranes with capacities ranging from 500kg to 2 tons offer a versatile range of design options tailored to various operational needs. These cranes are designed to handle light to moderate lifting tasks efficiently and are available in several configurations, including pillar-mounted, wall-mounted, and wall-traveling and portble roller travelling jib crane modles. . Each design provides unique benefits suited for different environments, from compact workshops to expansive industrial spaces. By understanding the distinct features and applications of these jib cranes, businesses can select the most suitable option to enhance productivity and optimize space utilization.

Portable Jib Cranes

- Features: Portable jib cranes designed for 500 kg capacity offer excellent mobility and ease of use. Their compact design allows them to be easily moved and repositioned within various workspaces. Equipped with wheels or a mobile base, these cranes can be quickly set up or disassembled, making them highly versatile for changing tasks.

- Applications: Ideal for light maintenance and handling small equipment, these cranes are perfect for environments where tasks vary frequently, such as small workshops or maintenance areas. Their flexibility ensures that they can adapt to different workstations and operational needs.

Wall-Mounted Jib Cranes

- Features: Wall-mounted jib cranes with a 500 kg capacity are fixed to a wall or structural support, providing a space-saving solution. This design optimizes floor space while delivering reliable lifting performance. These cranes typically feature a fixed or adjustable arm, which helps in efficiently covering the work area.

- Applications: Best suited for small workshops or environments with limited floor space, wall-mounted jib cranes are effective for tasks that require lifting along a wall. They are particularly useful where space optimization is essential and where tasks are confined to a specific area.

Pillar Jib Cranes

- Features: Pillar jib cranes with a 500 kg capacity are mounted on a vertical pillar or column, offering stability and rotational flexibility. The pillar provides a solid base, allowing the crane to swivel around the pillar, which enhances its range of motion and stability during operations.

- Applications: These cranes are ideal for light industrial tasks and small-scale manufacturing. They are commonly used in environments where a stable central lifting point is needed. The design is well-suited for areas where the installation of a pillar is feasible and where reliable, flexible lifting is required.

Wall-Traveling Jib Cranes

- Features: Wall-traveling jib cranes with a 500 kg capacity come with a track system that enables horizontal movement along the wall. This design allows for extended reach within a fixed area, making it possible to cover a larger workspace without needing additional floor space.

- Applications: Perfect for large workshops or warehouses, these cranes are useful for tasks requiring extensive coverage along a wall. Their ability to traverse along the track improves space efficiency and is ideal for environments where horizontal movement and extended reach are needed for handling materials.

500kg Jib Crane Design Options: Specifications and Selection Tips

500Kg Jib Crane Design Options Available: 500 kg Pillar Jib Cranes

Design Features

- Fixed Base: Securely mounted on a pillar to provide exceptional stability for lifting operations.

- 360° Rotation: Offers full rotation around the base, enabling efficient and flexible material handling within a designated area.

- Slewing Range: Typically accommodates a 0° to 360° range for versatile maneuvering of loads.

Typical Loads

- Small Machinery or Equipment: Perfect for handling compact machinery with a weight of up to 500 kg.

- Heavy Components in Assembly Lines: Suitable for lifting and positioning heavy parts or components during assembly processes.

- Large Tools or Fixtures: Ideal for managing large tools or fixtures, ensuring precise and reliable handling.

500 kg pillar jib cranes are designed to provide stability and flexibility in various industrial settings, making them an excellent choice for tasks that require reliable load handling and rotation.

500Kg Jib Crane Design Options Available: BZ Portable Jib Cranes

Design Features:

- Adjustable Height: Designed with a height adjustment mechanism to accommodate various lifting needs.

- Mobility: Equipped with wheels or casters for easy relocation and flexibility in different work areas.

- Compact and Lightweight: Ideal for operations requiring a portable and space-saving solution.

Typical Loads:

- Small Machinery or Equipment: Suitable for handling small, portable machinery weighing up to 500 kg.

- Tool Handling: Efficient for moving tools and equipment within confined or variable workspace environments.

- Material Handling: Great for lifting and positioning materials in diverse settings, such as workshops or small production lines.

500Kg Jib Crane Design Options Available: BX Wall-Mounted Jib Crane

Design Features:

- Fixed Installation: Mounted on a wall or structure, providing a space-efficient solution for material handling.

- Space-Efficient: Designed for use in areas with limited floor space, maximizing available room.

- Limited Rotation: Typically offers a rotation range from 0° to 180°, depending on installation.

Typical Loads:

- Small to Medium Machinery: Handles equipment and components up to 500 kg with ease.

- Assembly Line Components: Suitable for lifting and positioning parts within a workshop or production area.

- Storage and Retrieval: Ideal for moving items to and from shelves or storage areas.

500Kg Jib Crane Design Options Available: BB Wall-Traveling Jib Crane

Design Features:

- Track System: Mounted on a track system that allows movement along the wall for extended reach.

- High Flexibility: Provides the ability to cover a large area within a fixed space, enhancing workspace efficiency.

- Adjustable Travel Speed: Typically offers adjustable speeds for precise control of crane movements.

Typical Loads:

- Heavy Components: Handles components and materials weighing up to 500 kg within a fixed area.

- Large Tools: Ideal for managing large tools or fixtures in a workshop or industrial setting.

- Extended Reach: Efficient for operations requiring movement along the length of the track.

These 500 kg jib cranes are designed to meet various operational needs, offering flexibility and efficiency for handling small to medium-sized loads in diverse environments.

500kg Jib Crane Design Options: Specifications and Selection Tips

Technical Parameter | BZ Pillar Slewing Jib Crane | BZ Portable Jib Cranes | BX Wall Mounted Jib Crane | BB Wall Travelling Jib Crane | ||

Capacity | t | 0.5 | 0.5t | 0.5 | Capacity | 0.5 |

Valid radius | R(m) | 3~12 | 1-3m or customized | 3~8 | Valid radius | 5~12.5 |

Lifting height | m | 3~8 | 1-3m or customized | 6~30 | Lifting height | 6~30 |

Lifting speed | m/min | 8(0.8/8) | Manual or customized | 8(0.8/8) | Lifting speed | 8(0.8/8) |

Trolley speed | m/min | 10(20) | Manual or customized | 10(20) | Trolley speed | 10(20) |

Slewing speed | r/min | 0.5~1 | 0.5~1 | 0.5~1 | Crane speed | 20(30) |

Slewing angle | 0°~360° | 0°~180° | 0°~180° | Work duty | A3~A4 | |

Work duty | A3~A4 | A3 | A3~A4 | Track type | P18 | |

Technical Parameters

BZ Pillar Slewing Jib Crane

- Capacity: 0.5 tons

- Valid Radius: 3 to 12 meters

- Lifting Height: 3 to 8 meters

- Lifting Speed: 8 m/min (adjustable between 0.8 and 8 m/min)

- Trolley Speed: 10 m/min (adjustable to 20 m/min)

- Slewing Speed: 0.5 to 1 r/min

- Slewing Angle: 0° to 360°

- Work Duty: A3 to A4

- Track Type: P18

BZ Portable Jib Cranes

- Capacity: 0.5 tons

- Valid Radius: 1 to 3 meters or customized

- Lifting Height: 1 to 3 meters or customized

- Lifting Speed: Manual or customized

- Trolley Speed: Manual or customized

- Slewing Speed: Manual or customized

- Slewing Angle: Adjustable based on requirements

- Work Duty: A3

- Track Type: N/A

BX Wall-Mounted Jib Crane

- Capacity: 0.5 tons

- Valid Radius: 3 to 8 meters

- Lifting Height: 6 to 30 meters

- Lifting Speed: 8 m/min (adjustable between 0.8 and 8 m/min)

- Trolley Speed: 10 m/min (adjustable to 20 m/min)

- Slewing Speed: 0.5 to 1 r/min

- Slewing Angle: 0° to 180°

- Work Duty: A3 to A4

- Track Type: N/A

BB Wall-Traveling Jib Crane

- Capacity: 0.5 tons

- Valid Radius: 5 to 12.5 meters

- Lifting Height: 6 to 30 meters

- Lifting Speed: 8 m/min (adjustable between 0.8 and 8 m/min)

- Trolley Speed: 10 m/min (adjustable to 20 m/min)

- Crane Speed: 20 m/min (adjustable to 30 m/min)

- Slewing Speed: 0.5 to 1 r/min

- Slewing Angle: 0° to 180°

- Work Duty: A3 to A4

- Track Type: P18

Selection Tips

- Determine Your Space Requirements: Choose a jib crane with a valid radius and lifting height that fits your workspace. Portable cranes offer flexible, customizable dimensions, while wall-mounted options are fixed but space-efficient.

- Assess Load Handling Needs: Ensure the crane's capacity and lifting speed meet your load requirements. All options here handle up to 0.5 tons, but performance features vary, such as adjustable lifting speeds and customizable trolley speeds.

- Consider Movement and Flexibility: Depending on your needs, select a crane with the appropriate slewing speed and angle. Wall-traveling and pillar cranes provide extensive movement capabilities, while wall-mounted models are more stationary.

- Evaluate Work Duty Ratings: Ensure the crane's work duty rating aligns with your operational demands. For more intense usage, choose models with higher ratings and robust design features.

- Check Track Types and Compatibility: If applicable, confirm that the track type matches your installation requirements. For example, the BB Wall-Traveling Jib Crane uses P18 track type for its operations.

1 Ton Jib Crane Design Options for Your Selections

The 1-ton jib crane is a versatile lifting solution designed for efficient material handling in various settings. With its balanced capacity, it caters to medium-duty tasks, offering reliable performance for lifting and moving loads up to one ton. Available in multiple design configurations, such as pillar-mounted, wall-mounted, and roller travelling models, the 1-ton jib crane is adaptable to both compact and expansive work environments. Its flexibility and practical features make it an ideal choice for industries needing dependable lifting equipment for tasks ranging from assembly and maintenance to warehousing and production.

1 Ton Jib Crane Design Options Available:

Design Options Available: 1 Ton Jib Cranes

1 Ton Jib Crane Design Option: Pillar Jib Cranes (1 Ton)

Design Features:

- Fixed Base: The 1-ton pillar jib crane is mounted on a robust pillar, ensuring high stability and strength for heavy-duty lifting tasks.

- Full Rotation Capability: Allows a complete 360° rotation around the base, providing excellent versatility for a wide range of lifting and positioning applications.

- Durable Construction: Built with high-quality materials to withstand frequent use and support loads up to 1 ton.

Typical Loads:

- Machinery and Equipment: Perfect for lifting and moving medium-sized machinery or equipment weighing up to 1 ton.

- Assembly Line Components: Ideal for handling various components on assembly lines, such as motors, pumps, and other industrial parts.

- Large Tools and Fixtures: Efficient for positioning large tools or fixtures in workshops or manufacturing facilities.

1 Ton Jib Crane Design Option: Portable Jib Cranes (1 Ton)

Design Features:

- Adjustable Height: Features height-adjustable arms, allowing operators to tailor the crane's reach and height to specific tasks and spaces.

- Mobility and Portability: Equipped with casters or wheels, enabling easy transportation between different work areas or job sites.

- Compact and Space-Efficient: Designed to be easily maneuverable and stored, making it ideal for temporary setups or small spaces.

Typical Loads:

- Medium-Duty Equipment: Suitable for lifting and positioning equipment weighing up to 1 ton in various work environments.

- Tool Handling: Effective for moving tools or materials quickly across different areas, enhancing productivity in workshops.

- Versatile Material Handling: Ideal for construction sites, warehouses, and other environments where flexibility and mobility are required.

1 Ton Jib Crane Design Option:Wall-Mounted Jib Cranes (1 Ton)

Design Features:

- Space-Saving Installation: Mounted on a wall to save floor space, making it perfect for crowded workspaces or where floor space is limited.

- Controlled Rotation: Typically offers a rotation range of 0° to 180°, depending on the mounting setup, providing controlled material handling.

- Strong Arm Design: Built to handle loads up to 1 ton, suitable for consistent use in industrial and commercial settings.

Typical Loads:

- Machinery Parts: Efficient for lifting and positioning smaller machinery parts in manufacturing or repair shops.

- Assembly Tasks: Well-suited for repetitive tasks that require lifting and holding parts in place, such as welding or assembly operations.

- Storage Management: Helps manage storage by moving items to and from shelves or workstations efficiently.

1 Ton Jib Crane Design Option:Wall-Traveling Jib Cranes (1 Ton)

Design Features:

- Horizontal Mobility: Mounted on a wall but travels along a fixed track system, offering extended coverage across a work area.

- Variable Speed Control: Provides adjustable travel speeds for precise positioning and handling of materials.

- Efficient Coverage: Ideal for tasks requiring horizontal movement over longer distances within the crane's track range.

Typical Loads:

- Heavy Components: Capable of handling loads up to 1 ton, ideal for transferring heavy components along the length of a wall-mounted track.

- Flexible Tool Handling: Suitable for moving tools and fixtures in a dynamic workshop or manufacturing environment.

- Extended Reach Operations: Perfect for operations that require extended reach and flexibility without occupying floor space.

These 1-ton jib cranes offer versatile design options to suit various lifting needs, enhancing operational efficiency and safety in diverse industrial settings. Whether you need a stable base, mobility, space efficiency, or extended reach, these cranes provide tailored solutions for lifting and handling loads up to 1 ton.

1 Ton Jib Crane Design Options: Specifications and Selection Tips

Technical Parameter | BZ Pillar Slewing Jib Crane | BZ Portable Jib Cranes | BX Wall Mounted Jib Crane | BB Wall Travelling Jib Crane | ||

Capacity | t | 1 | 1 | 1 | Capacity | 1 |

Valid radius | R(m) | 3~12 | 1-3m or customized | 3~8 | Valid radius | 5~12.5 |

Lifting height | m | 3~8 | 1-3m or customized | 6~30 | Lifting height | 6~30 |

Lifting speed | m/min | 8(0.8/8) | Manual or customized | 8(0.8/8) | Lifting speed | 8(0.8/8) |

Trolley speed | m/min | 10(20) | Manual or customized | 10(20) | Trolley speed | 10(20) |

Slewing speed | r/min | 0.5~1 | 0.5~1 | 0.5~1 | Crane speed | 20(30) |

Slewing angle | 0°~360° | 0°~180° | 0°~180° | Work duty | A3~A4 | |

Work duty | A3~A4 | A3 | A3~A4 | Track type | P18 | |

Technical Parameters

BZ Pillar Slewing Jib Crane

- Capacity: 1 ton

- Valid Radius: 3 to 12 meters

- Lifting Height: 3 to 8 meters

- Lifting Speed: 8 m/min (adjustable between 0.8 and 8 m/min)

- Trolley Speed: 10 m/min (adjustable to 20 m/min)

- Slewing Speed: 0.5 to 1 r/min

- Slewing Angle: 0° to 360°

- Work Duty: A3 to A4

BZ Portable Jib Cranes

- Capacity: 1 ton

- Valid Radius: 1 to 3 meters or customized

- Lifting Height: 1 to 3 meters or customized

- Lifting Speed: Manual or customized

- Trolley Speed: Manual or customized

- Slewing Speed: Manual or customized

- Slewing Angle: Adjustable based on requirements

- Work Duty: A3

BX Wall-Mounted Jib Crane

- Capacity: 1 ton

- Valid Radius: 3 to 8 meters

- Lifting Height: 6 to 30 meters

- Lifting Speed: 8 m/min (adjustable between 0.8 and 8 m/min)

- Trolley Speed: 10 m/min (adjustable to 20 m/min)

- Slewing Speed: 0.5 to 1 r/min

- Slewing Angle: 0° to 180°

- Work Duty: A3 to A4

BB Wall-Traveling Jib Crane

- Capacity: 1 ton

- Valid Radius: 5 to 12.5 meters

- Lifting Height: 6 to 30 meters

- Lifting Speed: 8 m/min (adjustable between 0.8 and 8 m/min)

- Trolley Speed: 10 m/min (adjustable to 20 m/min)

- Crane Speed: 20 m/min (adjustable to 30 m/min)

- Slewing Speed: 0.5 to 1 r/min

- Slewing Angle: 0° to 180°

- Work Duty: A3 to A4

- Track Type: P18

Selection Tips

- Determine Space Requirements: Choose a crane with a valid radius and lifting height suitable for your workspace. Portable models are customizable for small areas, while wall-mounted and wall-traveling cranes are designed for larger, fixed areas.

- Assess Load Handling Needs: Ensure the crane's capacity and lifting speed meet your operational demands. All models here handle up to 1 ton, but the lifting speed and customization options vary, impacting performance and efficiency.

- Consider Movement and Flexibility: Select a crane with the appropriate slewing speed and angle based on your needs. Wall-traveling and pillar cranes offer extensive movement options, while wall-mounted models provide fixed but space-efficient solutions.

- Evaluate Work Duty Ratings: Match the crane's work duty rating with your operational requirements. Higher duty ratings are suited for more intensive use, ensuring the crane can handle frequent and heavy lifting tasks.

- Check Track Compatibility: For wall-traveling cranes, ensure the track type aligns with your installation requirements. The BB Wall-Traveling Jib Crane uses P18 track type, suitable for various operational settings.

2 Ton Jib Crane Design Options for Your Selections

2 Ton Jib Crane Design Design Options: Pillar Jib Cranes (2 Ton)

Design Features:

- Robust Construction: Mounted on a solid pillar base to ensure maximum stability and durability for handling heavy loads up to 2 tons.

- 360° Rotation: Offers a full 360-degree rotation, providing flexibility in lifting and positioning heavy objects around the entire workspace.

- Heavy-Duty Design: Built with reinforced materials to handle frequent and demanding lifting tasks, suitable for industrial environments.

Typical Loads:

- Large Machinery Components: Capable of lifting and moving large machinery parts, such as engines, gearboxes, and turbines weighing up to 2 tons.

- Heavy Manufacturing Equipment: Ideal for positioning heavy equipment used in manufacturing processes, including presses and CNC machines.

- Structural Elements: Efficient for handling structural components like beams and frames in construction or assembly settings.

2 Ton Jib Crane Design Design Options: Portable Jib Cranes (2 Ton)

Design Features:

- Height Adjustable: Allows for adjustments in height to accommodate various lifting tasks and work environments, offering flexibility in handling loads.

- Mobility with Stability: Designed with a wheeled base that provides both mobility and stability, making it easy to move heavy loads up to 2 tons across different workstations or sites.

- Compact Design: Space-efficient, suitable for applications where mobility and easy repositioning are necessary, such as in maintenance and repair shops.

Typical Loads:

- Medium to Heavy-Duty Tools: Suitable for lifting medium to heavy tools or parts in workshops and repair facilities.

- Flexible Object Handling: Effective for transporting heavy objects, such as machine parts or pallets, between different areas of a facility.

- On-Site Material Handling: Ideal for construction sites or large warehouses where materials need to be moved over various distances.

2 Ton Jib Crane Design Design Options: Wall-Mounted Jib Cranes (2 Ton)

Design Features:

- Space Optimization: Mounted directly on walls, freeing up valuable floor space and providing efficient use of limited areas.

- Controlled Movement: Typically offers a slewing range between 0° to 180°, depending on installation, for precise lifting and placement of loads.

- High Load Capacity: Engineered to handle loads up to 2 tons, with reinforced arm structures to support heavy and consistent use.

Typical Loads:

- Parts Assembly and Disassembly: Perfect for lifting and positioning parts during assembly or disassembly processes in production lines.

- Workstation Assistance: Aids in moving materials to and from workstations, improving workflow and efficiency in manufacturing settings.

- Tool and Material Handling: Effective for handling large tools and materials that need to be frequently accessed and moved.

2 Ton Jib Crane Design Design Options: Wall-Traveling Jib Cranes (2 Ton)

Design Features:

- Extended Reach with Mobility: Installed on a wall-mounted track, allowing the crane to travel horizontally for extended coverage along the work area.

- Smooth Travel Control: Features smooth travel mechanisms to move heavy loads along the wall, enhancing operational efficiency in longer production lines.

- Flexible Load Handling: Ideal for operations that require frequent relocation of loads across different sections of the workspace.

Typical Loads:

- Heavy Materials and Supplies: Ideal for transporting heavy materials and supplies across the production area, enhancing material flow and efficiency.

- Longer Span Tasks: Suitable for handling tasks that span longer distances, such as transferring items between different sections of a warehouse or workshop.

- Tool Management: Helps in organizing and transporting heavy tools and components along a production line or assembly area.

These 2-ton jib cranes are designed to meet the specific needs of various industrial and commercial environments. Each type offers unique features that enhance operational efficiency, safety, and flexibility, making them suitable for a wide range of heavy lifting applications.

2 Ton Jib Crane Design Options: Specifications and Selection Tips

Technical Parameter | BZ Pillar Slewing Jib Crane | BZ Portable Jib Cranes | BX Wall Mounted Jib Crane | BB Wall Travelling Jib Crane | ||

Capacity | t | 2 | 2 | 2 | Capacity | 2 |

Valid radius | R(m) | 3~12 | 1-3m or customized | 3~8 | Valid radius | 5~12.5 |

Lifting height | m | 3~8 | 1-3m or customized | 6~30 | Lifting height | 6~30 |

Lifting speed | m/min | 8(0.8/8) | Manual or customized | 8(0.8/8) | Lifting speed | 8(0.8/8) |

Trolley speed | m/min | 10(20) | Manual or customized | 10(20) | Trolley speed | 10(20) |

Slewing speed | r/min | 0.5~1 | 0.5~1 | 0.5~1 | Crane speed | 20(30) |

Slewing angle | 0°~360° | 0°~180° | 0°~180° | Work duty | A3~A4 | |

Work duty | A3~A4 | A3 | A3~A4 | Track type | P18 | |

Technical Parameters

BZ Pillar Slewing Jib Crane

- Capacity: 2 tons

- Valid Radius: 3 to 12 meters

- Lifting Height: 3 to 8 meters

- Lifting Speed: 8 m/min (adjustable between 0.8 and 8 m/min)

- Trolley Speed: 10 m/min (adjustable to 20 m/min)

- Slewing Speed: 0.5 to 1 r/min

- Slewing Angle: 0° to 360°

- Work Duty: A3 to A4

BZ Portable Jib Cranes

- Capacity: 2 tons

- Valid Radius: 1 to 3 meters or customized

- Lifting Height: 1 to 3 meters or customized

- Lifting Speed: Manual or customized

- Trolley Speed: Manual or customized

- Slewing Speed: Manual or customized

- Slewing Angle: Adjustable based on requirements

- Work Duty: A3

BX Wall-Mounted Jib Crane

- Capacity: 2 tons

- Valid Radius: 3 to 8 meters

- Lifting Height: 6 to 30 meters

- Lifting Speed: 8 m/min (adjustable between 0.8 and 8 m/min)

- Trolley Speed: 10 m/min (adjustable to 20 m/min)

- Slewing Speed: 0.5 to 1 r/min

- Slewing Angle: 0° to 180°

- Work Duty: A3 to A4

BB Wall-Traveling Jib Crane

- Capacity: 2 tons

- Valid Radius: 5 to 12.5 meters

- Lifting Height: 6 to 30 meters

- Lifting Speed: 8 m/min (adjustable between 0.8 and 8 m/min)

- Trolley Speed: 10 m/min (adjustable to 20 m/min)

- Crane Speed: 20 m/min (adjustable to 30 m/min)

- Slewing Speed: 0.5 to 1 r/min

- Slewing Angle: 0° to 180°

- Work Duty: A3 to A4

- Track Type: P18

Selection Tips

- Capacity Requirements: Ensure the crane can handle up to 2 tons efficiently. All models listed are capable of lifting up to 2 tons, suitable for medium to heavy-duty tasks.

- Radius and Height Needs: Select a crane based on the required radius and lifting height for your application. The BZ Pillar and BX Wall-Mounted models offer a wide radius and height range, while the BZ Portable and BB Wall-Traveling models offer customizable options.

- Speed and Performance: Consider the lifting and trolley speeds. For fast and efficient lifting, the models offer adjustable speeds, with the BB Wall-Traveling Crane providing higher speeds for extensive movement.

- Work Duty Classification: Match the crane's work duty rating with your operational demands. The BZ Pillar, BX Wall-Mounted, and BB Wall-Traveling Cranes are rated for A3 to A4, suitable for various working conditions, while the BZ Portable Crane has an A3 rating for lighter tasks.

- Design and Space Constraints: Choose between pillar-mounted, portable, wall-mounted, or wall-traveling designs based on your workspace configuration and movement needs. Each design offers specific benefits, from fixed installations to mobile and adjustable setups.

3 Ton Jib Crane Design Options for Your Selections

3 Ton Jib Crane Design Design Options: Pillar Jib Cranes (3 Ton)

Design Features:

- Heavy-Duty Construction: Built with a robust pillar base, ensuring stability and strength to safely handle loads up to 3 tons.

- 360° Full Rotation: Allows a full range of motion for lifting and moving heavy objects around the workspace without limitations, making it ideal for versatile operations.

- Enhanced Load Capacity: Engineered with reinforced materials to support heavier loads and withstand continuous use in demanding industrial settings.

Typical Loads:

- Large Machinery Parts: Suitable for lifting large machinery components, such as engine blocks, transmission assemblies, and heavy pumps.

- Industrial Equipment: Efficient for moving heavy industrial equipment like presses, mills, and other large machines within a manufacturing facility.

- Construction Materials: Ideal for handling and positioning heavy structural materials, including steel beams and concrete slabs.

3 Ton Jib Crane Design Design Options:Portable Jib Cranes (3 Ton)

Design Features:

- Adjustable Height: Features adjustable heights to cater to different lifting tasks, providing flexibility in diverse work environments.

- Mobility and Stability: Equipped with a mobile base for easy relocation, while still providing the stability needed to handle 3-ton loads securely.

- Compact and Versatile: Space-saving design that can be easily maneuvered in tight or restricted spaces, making it suitable for on-site and off-site applications.

Typical Loads:

- Heavy Tools and Parts: Ideal for lifting and transporting heavy tools or parts, such as molds, dies, and equipment components, in various workstations.

- Flexible Lifting Solutions: Perfect for handling diverse heavy objects across different areas in a warehouse or job site, enhancing operational flexibility.

- On-Site Construction Tasks: Effective for moving heavy construction materials and equipment across multiple locations within a site.

3 Ton Jib Crane Design Design Options:Wall-Mounted Jib Cranes (3 Ton)

Design Features:

- Space-Efficient: Mounted on walls to save floor space, providing an efficient lifting solution for areas with space constraints.

- Controlled Lifting Range: Typically offers a slewing range of 0° to 180°, allowing precise placement of heavy loads up to 3 tons.

- High Capacity Arm Design: Reinforced arm structure designed to support heavier loads while ensuring stability and safety during lifting operations.

Typical Loads:

- Assembly Line Components: Suitable for moving and positioning heavy parts in assembly lines, such as large machine parts and subassemblies.

- Tool and Material Storage: Ideal for transferring heavy tools and materials to and from storage areas in industrial settings, optimizing space and workflow.

- Maintenance Operations: Useful for maintenance tasks involving heavy equipment, providing easy access and maneuverability in tight spaces.

3 Ton Jib Crane Design Design Options:Wall-Traveling Jib Cranes (3 Ton)

Design Features:

- Extended Operational Reach: Mounted on a wall-mounted track, allowing the crane to travel along the wall for extended lifting coverage across the workspace.

- Smooth and Controlled Movement: Equipped with advanced travel mechanisms to ensure smooth movement of 3-ton loads along the wall, improving efficiency and safety.

- Adaptable Load Handling: Capable of handling diverse heavy loads over longer spans, making it ideal for use in expansive production lines or warehouses.

Typical Loads:

- Material Handling in Long Facilities: Perfect for moving heavy materials and equipment across extended areas, such as long assembly lines or storage facilities.

- Heavy Tool Transportation: Efficient for transferring heavy tools and components along the production line, facilitating workflow and reducing manual handling.

- Logistical Support: Ideal for logistical tasks requiring the transport of heavy goods across different sections of a facility, ensuring smooth and efficient operations.

These 3-ton jib cranes are specifically designed to cater to the needs of heavy lifting in various industrial environments. Each type of crane offers distinct features that enhance performance, safety, and flexibility, making them suitable for a wide range of applications involving the handling of heavy loads.

3 Ton Jib Crane Design Options: Specifications and Selection Tips

Technical Parameter | BZ Pillar Slewing Jib Crane | BX Wall Mounted Jib Crane | BB Wall Travelling Jib Crane | ||

Capacity | t | 3 | 3 | Capacity | 3 |

Valid radius | R(m) | 3~12 | 3~8 | Valid radius | 5~12.5 |

Lifting height | m | 3~8 | 6~30 | Lifting height | 6~30 |

Lifting speed | m/min | 8(0.8/8) | 8(0.8/8) | Lifting speed | 8(0.8/8) |

Trolley speed | m/min | 10(20) | 10(20) | Trolley speed | 10(20) |

Slewing speed | r/min | 0.5~1 | 0.5~1 | Crane speed | 20(30) |

Slewing angle | 0°~360° | 0°~180° | Work duty | A3~A4 | |

Work duty | A3~A4 | A3~A4 | Track type | P24 | |

Technical Parameters

BZ Pillar Mounted Jib Crane

- Capacity: 3 tons

- Valid Radius: 3 to 12 meters

- Lifting Height: 3 to 8 meters

- Lifting Speed: 8 m/min (adjustable between 0.8 and 8 m/min)

- Trolley Speed: 10 m/min (adjustable to 20 m/min)

- Slewing Speed: 0.5 to 1 r/min

- Slewing Angle: 0° to 360°

- Work Duty: A3 to A4

BX Wall-Mounted Jib Crane

- Capacity: 3 tons

- Valid Radius: 3 to 8 meters

- Lifting Height: 6 to 30 meters

- Lifting Speed: 8 m/min (adjustable between 0.8 and 8 m/min)

- Trolley Speed: 10 m/min (adjustable to 20 m/min)

- Slewing Speed: 0.5 to 1 r/min

- Slewing Angle: 0° to 180°

- Work Duty: A3 to A4

BB Wall-Traveling Jib Crane

- Capacity: 3 tons

- Valid Radius: 5 to 12.5 meters

- Lifting Height: 6 to 30 meters

- Lifting Speed: 8 m/min (adjustable between 0.8 and 8 m/min)

- Trolley Speed: 10 m/min (adjustable to 20 m/min)

- Crane Speed: 20 m/min (adjustable to 30 m/min)

- Slewing Speed: 0.5 to 1 r/min

- Slewing Angle: 0° to 180°

- Work Duty: A3 to A4

- Track Type: P24

Selection Tips

- Capacity Needs: All three models are designed to handle loads up to 3 tons, making them suitable for various medium to heavy-duty tasks.

- Radius and Height Requirements: Choose based on the reach and lifting height needed. The BZ Pillar Jib Crane offers a flexible radius of 3 to 12 meters and a height of 3 to 8 meters. The BX Wall-Mounted Crane supports a taller lifting height range (6 to 30 meters) and a smaller radius (3 to 8 meters). The BB Wall-Traveling Crane provides a broad radius (5 to 12.5 meters) and height (6 to 30 meters) for extensive coverage.

- Speed Considerations: Evaluate the lifting, trolley, and crane speeds relative to your operational needs. The BZ and BX models offer similar lifting and trolley speeds, while the BB model allows for higher crane speeds, suitable for more dynamic operations.

- Work Duty Classification: Match the crane's work duty rating to your usage. The BZ and BX models are rated A3 to A4, accommodating moderate to heavy usage, while the BB model, with an A3 to A4 rating, supports versatile applications.

- Design and Space Constraints: Select the design based on your workspace. The BZ Pillar model offers rotational flexibility and stability. The BX Wall-Mounted Crane is ideal for fixed installations with limited floor space, and the BB Wall-Traveling Crane is suited for large areas where track-based movement is advantageous.

4 Ton Jib Crane Design Options for Your Selections

Design Options Available: 4 Ton Jib Cranes

Pillar Jib Cranes (4 Ton)

Design Features:

- Reinforced Structure: Built with a strong, stable pillar base to safely support loads up to 4 tons, ideal for heavy-duty lifting tasks.

- 360° Full Rotation: Offers a complete 360-degree range of motion, allowing for versatile handling of heavy materials in all directions.

- High Load Capacity: Designed with durable materials and engineering to withstand continuous use, ensuring safety and reliability in demanding industrial environments.

Typical Loads:

- Heavy Machine Components: Effective for lifting and moving large machine parts such as engine blocks, gears, and turbines in manufacturing facilities.

- Industrial Equipment: Suitable for transporting heavy equipment like large pumps, compressors, and heavy-duty motors across a workshop or production floor.

- Construction Materials: Ideal for handling bulky construction materials like steel beams, concrete blocks, and prefabricated components on job sites.

Portable Jib Cranes (4 Ton)

Design Features:

- Adjustable Height and Reach: Features adjustable height and arm reach, providing flexibility for various lifting tasks and environments.

- Easy Mobility: Equipped with a movable base that allows easy relocation, while maintaining the stability needed for handling 4-ton loads.

- Compact Design: Space-saving design that allows operation in tight or confined spaces, making it suitable for both indoor and outdoor applications.

Typical Loads:

- Heavy-Duty Tools and Parts: Perfect for lifting and transporting heavy tools, dies, and molds in different work areas within a facility.

- Versatile Lifting Solutions: Ideal for handling a variety of heavy objects in warehouses or construction sites, enhancing operational flexibility.

- On-Site Construction Tasks: Effective for lifting and moving heavy construction equipment and materials across different locations on a site.

Wall-Mounted Jib Cranes (4 Ton)

Design Features:

- Space-Saving Installation: Mounted directly on walls to save valuable floor space, making it suitable for areas with limited room.

- Controlled Slewing Range: Typically offers a slewing range of 0° to 180°, enabling precise lifting and positioning of 4-ton loads in confined spaces.

- Robust Arm Design: Built with a reinforced arm to support heavier loads while ensuring stability and safety during lifting operations.

Typical Loads:

- Large Assembly Line Parts: Perfect for handling and positioning heavy parts in assembly lines, such as large machinery components and subassemblies.

- Tool and Material Handling: Suitable for moving heavy tools and materials to and from storage areas, optimizing space and workflow in industrial settings.

- Maintenance and Repair: Ideal for maintenance tasks involving heavy machinery, providing easy access and maneuverability in restricted spaces.

Wall-Traveling Jib Cranes (4 Ton)

Design Features:

- Extended Operational Coverage: Mounted on a wall-mounted track, allowing the crane to travel along the wall, providing extended lifting coverage across the workspace.

- Smooth Travel Mechanism: Designed with advanced travel mechanisms to ensure smooth and controlled movement of 4-ton loads along the wall.

- Enhanced Load Handling Flexibility: Capable of handling diverse heavy loads over longer spans, making it ideal for use in large production areas or warehouses.

Typical Loads:

- Material Handling in Expansive Areas: Suitable for moving heavy materials and equipment across long assembly lines or storage facilities.

- Heavy Tool Transportation: Efficient for transporting heavy tools and components along production lines, facilitating workflow and reducing manual handling.

- Logistical Operations: Ideal for transporting heavy goods across different sections of a facility, ensuring smooth and efficient operations in logistics and material handling.

Each type of 4-ton jib crane is specifically designed to handle heavy lifting in various industrial applications. These cranes offer unique features that enhance performance, safety, and flexibility, making them ideal for a wide range of uses involving the handling of substantial loads.

4 Ton Jib Crane Design Options: Specifications and Selection Tips

Technical Parameter | BZ Pillar Slewing Jib Crane | BX Wall Mounted Jib Crane | BB Wall Travelling Jib Crane | ||

Capacity | t | 4 | 4 | Capacity | 4 |

Valid radius | R(m) | 3~12 | 3~8 | Valid radius | 5~12.5 |

Lifting height | m | 3~8 | 6~30 | Lifting height | 6~30 |

Lifting speed | m/min | 8(0.8/8) | 8(0.8/8) | Lifting speed | 8(0.8/8) |

Trolley speed | m/min | 10(20) | 10(20) | Trolley speed | 10(20) |

Slewing speed | r/min | 0.5~1 | 0.5~1 | Crane speed | 20(30) |

Slewing angle | 0°~360° | 0°~180° | Work duty | A3~A4 | |

Work duty | A3~A4 | A3~A4 | Track type | P24 | |

Technical Parameters

BZ Pillar Slewing Jib Crane

- Capacity: 4 tons

- Valid Radius: 3 to 12 meters

- Lifting Height: 3 to 8 meters

- Lifting Speed: 8 m/min (adjustable between 0.8 and 8 m/min)

- Trolley Speed: 10 m/min (adjustable to 20 m/min)

- Slewing Speed: 0.5 to 1 r/min

- Slewing Angle: 0° to 360°

- Work Duty: A3 to A4

BX Wall-Mounted Jib Crane

- Capacity: 4 tons

- Valid Radius: 3 to 8 meters

- Lifting Height: 6 to 30 meters

- Lifting Speed: 8 m/min (adjustable between 0.8 and 8 m/min)

- Trolley Speed: 10 m/min (adjustable to 20 m/min)

- Slewing Speed: 0.5 to 1 r/min

- Slewing Angle: 0° to 180°

- Work Duty: A3 to A4

BB Wall-Traveling Jib Crane

- Capacity: 4 tons

- Valid Radius: 5 to 12.5 meters

- Lifting Height: 6 to 30 meters

- Lifting Speed: 8 m/min (adjustable between 0.8 and 8 m/min)

- Trolley Speed: 10 m/min (adjustable to 20 m/min)

- Crane Speed: 20 m/min (adjustable to 30 m/min)

- Slewing Speed: 0.5 to 1 r/min

- Slewing Angle: 0° to 180°

- Work Duty: A3 to A4

- Track Type: P24

Selection Tips

- Capacity Requirements: All models are designed to handle loads up to 4 tons, suitable for heavy-duty tasks and robust lifting applications.

- Radius and Height: Select based on your spatial needs. The BZ Pillar Jib Crane offers flexibility with a radius of 3 to 12 meters and a height of 3 to 8 meters. The BX Wall-Mounted Crane supports a taller lifting range (6 to 30 meters) and a smaller radius (3 to 8 meters). The BB Wall-Traveling Crane provides a broad radius (5 to 12.5 meters) and height (6 to 30 meters), making it ideal for extensive coverage.

- Speed Considerations: The lifting and trolley speeds are consistent across models, but the BB model offers higher crane speeds, which is beneficial for dynamic operations.

- Work Duty Rating: Ensure the crane's work duty rating aligns with your operational demands. The BZ and BX models are rated A3 to A4, accommodating moderate to heavy usage, while the BB model, also rated A3 to A4, supports versatile applications.

- Design and Space Utilization: Choose based on your workspace configuration. The BZ Pillar Jib Crane provides rotational freedom and high stability. The BX Wall-Mounted Crane is optimal for installations with limited floor space, while the BB Wall-Traveling Crane is ideal for larger areas requiring track-based movement and extended reach.

5 Ton Jib Crane Design Options for Your Selections

Design Options Available: 5 Ton Jib Cranes

Pillar Jib Cranes (5 Ton)

Design Features:

- Heavy-Duty Construction: Engineered with a robust pillar base to provide maximum stability and support for lifting up to 5 tons, ensuring safe and efficient operation.

- Full 360° Rotation: Capable of a full 360-degree swivel, allowing unrestricted movement for versatile material handling across various directions.

- High Load Capacity: Designed for continuous heavy lifting, ideal for demanding industrial applications where reliability and durability are essential.

Typical Loads:

- Large Industrial Machinery: Suitable for lifting and transporting heavy machinery components, such as large motors, pumps, and compressors in manufacturing and repair facilities.

- Construction and Building Materials: Ideal for handling substantial construction materials like steel beams, concrete slabs, and prefabricated building sections on-site.

- Assembly Line Equipment: Perfect for moving heavy equipment and parts along assembly lines in automotive, aerospace, and other heavy industries.

Portable Jib Cranes (5 Ton)

Design Features:

- Adjustable Arm and Height: Features adjustable settings for height and reach, allowing for customized lifting operations to fit various tasks and environments.

- Mobility with Stability: Equipped with a movable base that provides both portability and the stability needed to handle heavy loads up to 5 tons.

- Compact and Flexible: Compact design facilitates use in limited spaces, making it suitable for both indoor and outdoor applications where space and flexibility are required.

Typical Loads:

- Heavy Equipment and Tools: Excellent for lifting and moving heavy-duty tools, equipment, and machinery parts across different areas of a worksite.

- Construction Site Flexibility: Ideal for lifting and transporting heavy materials and equipment to various locations on construction sites, enhancing operational efficiency.

- Warehouse Operations: Perfect for handling bulky items and heavy packages in warehouses, allowing for quick and efficient movement of goods.

Wall-Mounted Jib Cranes (5 Ton)

Design Features:

- Space-Efficient Installation: Mounted directly on walls to conserve floor space, making it ideal for facilities with space constraints.

- Controlled Rotation: Offers a slewing range typically between 0° to 180°, allowing for precise lifting and placement of heavy loads within a confined area.

- Reinforced Structure: Built with a strong arm to support heavy loads, ensuring safe and stable lifting operations.

Typical Loads:

- Industrial Assembly Tasks: Ideal for positioning heavy parts and machinery in assembly lines, particularly in automotive and heavy manufacturing industries.

- Maintenance of Large Machinery: Suitable for lifting heavy parts during maintenance and repair work, allowing for easy access and maneuverability in tight spaces.

- Tool and Material Handling: Efficient for moving heavy tools and materials in workshops and storage areas, optimizing workflow and reducing manual labor.

Wall-Traveling Jib Cranes (5 Ton)

Design Features:

- Extended Reach and Coverage: Mounted on a wall-mounted track, this crane type can travel along the wall, offering extended lifting coverage across expansive workspaces.

- Smooth and Controlled Movement: Designed with advanced tracking mechanisms to ensure smooth and precise handling of heavy loads up to 5 tons along the wall.

- Versatile Load Handling: Capable of managing diverse heavy loads over longer spans, making it suitable for large-scale manufacturing and warehousing operations.

Typical Loads:

- Heavy Material Handling Across Large Areas: Ideal for moving heavy materials and equipment along extended assembly lines or within expansive storage facilities.

- Logistics and Distribution: Perfect for transporting heavy goods across different sections of a logistics center or warehouse, ensuring efficient workflow and material handling.

- Heavy Equipment Transport: Efficient for moving substantial machinery and parts across a facility, supporting maintenance, assembly, and production processes.

Each type of 5-ton jib crane is uniquely designed to handle significant lifting tasks across various industrial settings. These cranes offer tailored features that enhance safety, performance, and flexibility, making them ideal for handling a wide range of heavy loads.

5 Ton Jib CraneDesign Options, Specifications and Selection Tips

Technical Parameter | BZ Pillar Slewing Jib Crane | BX Wall Mounted Jib Crane | BB Wall Travelling Jib Crane | ||

Capacity | t | 5 | 5 | Capacity | 5 |

Valid radius | R(m) | 3~12 | 3~8 | Valid radius | 5~12.5 |

Lifting height | m | 3~8 | 6~30 | Lifting height | 6~30 |

Lifting speed | m/min | 8(0.8/8) | 8(0.8/8) | Lifting speed | 8(0.8/8) |

Trolley speed | m/min | 10(20) | 10(20) | Trolley speed | 10(20) |

Slewing speed | r/min | 0.5~1 | 0.5~1 | Crane speed | 20(30) |

Slewing angle | 0°~360° | 0°~180° | Work duty | A3~A4 | |

Work duty | A3~A4 | A3~A4 | Track type | P24 | |

Technical Parameters

BZ Pillar Slewing Jib Crane

- Capacity: 5 tons

- Valid Radius: 3 to 12 meters

- Lifting Height: 3 to 8 meters

- Lifting Speed: 8 m/min (adjustable between 0.8 and 8 m/min)

- Trolley Speed: 10 m/min (adjustable to 20 m/min)

- Slewing Speed: 0.5 to 1 r/min

- Slewing Angle: 0° to 360°

- Work Duty: A3 to A4

- Track Type: P24

BX Wall-Mounted Jib Crane

- Capacity: 5 tons

- Valid Radius: 3 to 8 meters

- Lifting Height: 6 to 30 meters

- Lifting Speed: 8 m/min (adjustable between 0.8 and 8 m/min)

- Trolley Speed: 10 m/min (adjustable to 20 m/min)

- Slewing Speed: 0.5 to 1 r/min

- Slewing Angle: 0° to 180°

- Work Duty: A3 to A4

- Track Type: N/A

BB Wall-Traveling Jib Crane

- Capacity: 5 tons

- Valid Radius: 5 to 12.5 meters

- Lifting Height: 6 to 30 meters

- Lifting Speed: 8 m/min (adjustable between 0.8 and 8 m/min)

- Trolley Speed: 10 m/min (adjustable to 20 m/min)

- Crane Speed: 20 m/min (adjustable to 30 m/min)

- Slewing Speed: 0.5 to 1 r/min

- Slewing Angle: 0° to 180°

- Work Duty: A3 to A4

- Track Type: P24

Selection Tips

- Capacity Requirements: All models are capable of handling loads up to 5 tons, making them suitable for medium to heavy-duty lifting tasks.

- Radius and Height: The BZ Pillar Jib Crane offers flexibility with a radius of 3 to 12 meters and a height of 3 to 8 meters. The BX Wall-Mounted Crane supports a greater lifting height (6 to 30 meters) with a radius of 3 to 8 meters, while the BB Wall-Traveling Crane provides extensive reach and height (5 to 12.5 meters radius and 6 to 30 meters height).

- Speed Considerations: Lifting and trolley speeds are consistent across models, but the BB model features higher crane speeds, which may be advantageous for more dynamic operations.

- Work Duty Rating: All models are rated A3 to A4, accommodating various operational intensities from moderate to heavy usage.

- Design and Space Utilization: Choose based on workspace requirements:

- BZ Pillar Jib Crane: Ideal for applications requiring high stability and 360° rotation.

- BX Wall-Mounted Jib Crane: Best for installations in constrained spaces with fixed rotation.

- BB Wall-Traveling Jib Crane: Suitable for large areas needing extensive coverage and movement along tracks.

6 Ton, 7Ton, 8 Ton Jib Crane Design Options for Your Selections

Pillar Jib Cranes (6 Ton, 7 Ton, and 8 Ton)

Design Features:

- Robust Construction: Built with a sturdy pillar base to provide high stability for lifting loads up to 8 tons, ensuring safe and reliable operations in industrial environments.

- Full 360° Rotation: Offers a full 360-degree rotation, allowing for maximum flexibility and coverage when handling heavy materials across different sections of a workspace.

- High Load Capacity: Engineered for continuous and intensive lifting tasks, suitable for applications where durability and heavy-duty performance are essential.

Typical Loads:

- Large-Scale Industrial Machinery: Perfect for lifting and moving substantial machinery components such as large valves, turbines, and gearboxes in heavy manufacturing plants.

- Heavy Construction Materials: Ideal for transporting heavy construction elements like steel frames, large pipes, and precast concrete blocks on-site.

- Automotive and Aerospace Parts: Well-suited for handling heavy parts in assembly lines, including large engine components and chassis in automotive and aerospace industries.

6 Ton, 7 Ton, 8 Ton Jib Crane Design Options: Specifications and Selection Tips

Technical Parameters

AQ-BZ Pillar Slewing Jib Crane

- Capacity: 6 tons, 7 tons, 8 tons

- Valid Radius: 3 to 15 meters

- Lifting Height: 3 to 8 meters

- Lifting Speed: 7 m/min (adjustable between 0.7 and 7 m/min)

- Trolley Speed: 10 m/min (adjustable to 20 m/min)

- Slewing Speed: 0.5 to 1 r/min

- Slewing Angle: 0° to 360°

- Work Duty: A3 to A4

Selection Tips

- Capacity Needs: TheBZ Pillar Slewing Jib Crane supports lifting capacities of 6, 7, and 8 tons, making it suitable for heavy-duty applications across various industries.

- Radius and Height: With a valid radius range of 3 to 15 meters and a lifting height of 3 to 8 meters, this crane provides flexibility for a wide range of lifting tasks and spatial configurations.

- Speed and Performance: The lifting speed of 7 m/min, with adjustable settings, ensures efficient handling of heavy loads. The trolley speed can be adjusted up to 20 m/min to suit different operational requirements.

- Slewing Capability: The crane's slewing speed ranges from 0.5 to 1 r/min, allowing smooth and controlled rotation of loads. The full 360° slewing angle maximizes operational flexibility.

- Work Duty Rating: Rated A3 to A4, theBZ Pillar Jib Crane is designed to handle moderate to heavy-duty tasks, making it ideal for various industrial and manufacturing environments.

Design Considerations:

- 6 Ton Jib Crane: Suitable for medium to large-scale lifting operations where moderate reach and lifting height are required.

- 7 Ton Jib Crane: Offers slightly higher capacity and flexibility, ideal for more demanding lifting tasks.

- 8 Ton Jib Crane: Provides the highest capacity among the options, making it ideal for handling very heavy loads and extensive operational needs.

Choose theBZ Pillar Slewing Jib Crane based on your specific lifting capacity requirements, workspace dimensions, and operational intensity to ensure optimal performance and efficiency in your lifting operations.

10 Ton Jib Crane Design Options for Your Selections

Design Options Available: 10 Ton Jib Cranes

Pillar Jib Cranes (10 Ton)

Design Features:

- Heavy-Duty Construction: Built with a reinforced pillar base to support substantial loads up to 10 tons, offering exceptional stability and durability for intensive industrial use.

- Full 360° Rotation: Enables complete rotational flexibility, allowing for efficient material handling in large areas and providing broad coverage within workspaces.

- High Lifting Capacity and Reach: Designed for high-capacity lifting tasks, with a substantial reach to accommodate various operational needs in heavy industries.

Typical Loads:

- Large Industrial Equipment: Ideal for lifting and moving heavy machinery such as industrial presses, milling machines, and heavy-duty compressors in manufacturing environments.

- Construction Components: Suitable for transporting large structural elements like steel beams, concrete slabs, and prefabricated sections, commonly used in construction projects.

- Automotive and Aerospace Assemblies: Perfect for handling substantial components in automotive and aerospace assembly lines, including large engine blocks, transmissions, and aircraft parts.

10 Ton Jib Crane Design Options: Specifications and Selection Tips

Technical Parameter ofBZ Pillar Slewing Jib Crane | ||

Capacity | t | 10 |

Valid radius | R(m) | 3~15 |

Lifting height | m | 3~8 |

Lifting speed | m/min | 7(0.7/7) |

Trolley speed | m/min | 10(20) |

Slewing speed | r/min | 0.5~1 |

Slewing angle | 0°~360° | |

Work duty | A3~A4 | |

Technical Parameters

AQ-BZ Pillar Slewing Jib Crane

- Capacity: 10 tons

- Valid Radius: 3 to 15 meters

- Lifting Height: 3 to 8 meters

- Lifting Speed: 7 m/min (adjustable between 0.7 and 7 m/min)

- Trolley Speed: 10 m/min (adjustable to 20 m/min)

- Slewing Speed: 0.5 to 1 r/min

- Slewing Angle: 0° to 360°

- Work Duty: A3 to A4

Design Options and Selection Tips

- Capacity and Reach: With a 10-ton capacity, this jib crane is designed for handling substantial loads, making it ideal for heavy-duty applications in manufacturing, construction, and large-scale material handling. The valid radius of 3 to 15 meters allows for flexible coverage within your workspace.

- Lifting Height and Speed: The lifting height ranges from 3 to 8 meters, accommodating a variety of vertical lifting needs. The crane's lifting speed of 7 m/min ensures efficient operation, with adjustable settings to match specific operational requirements.

- Trolley and Slewing Performance: The trolley speed, adjustable up to 20 m/min, enhances the crane's versatility, while the slewing speed ranges from 0.5 to 1 r/min, allowing for controlled and precise movement. The full 360° slewing angle provides maximum flexibility in load positioning and maneuverability.

- Work Duty Rating: Rated A3 to A4, theBZ Pillar Slewing Jib Crane is suited for moderate to heavy-duty applications, ensuring reliability and performance in various industrial settings.

- Design Considerations:

- Operational Efficiency: The adjustable lifting and trolley speeds, along with the wide radius and height range, make this crane adaptable to diverse tasks and environments.

- Space Utilization: With its extensive slewing range and high capacity, the 10-ton jib crane is well-suited for facilities where space optimization and efficient material handling are critical.

- Durability and Maintenance: Designed for durability, the crane's robust construction and adjustable features ensure long-term performance and ease of maintenance.

Select theBZ Pillar Slewing Jib Crane for your heavy-duty lifting needs, balancing capacity, reach, and speed to enhance your operational efficiency and productivity.

15 Ton, 16 Ton Jib Crane Design Options for Your Selections

Design Options Available: 15 Ton and 16 Ton Jib Cranes

Pillar Jib Cranes (15 Ton and 16 Ton)

Design Features:

- Robust Construction: Engineered with a reinforced pillar base to handle extremely heavy loads, these cranes are designed to offer maximum stability and durability for industrial applications.

- Full 360° Rotation: Capable of a full circular rotation, allowing for comprehensive coverage in large workspaces, ideal for environments that require extensive reach and flexibility in material handling.

- High Capacity and Extended Reach: Specifically built for heavy-duty lifting tasks, these cranes provide substantial lifting height and radius to manage demanding applications.

Typical Loads:

- Massive Industrial Machinery: Suitable for lifting and maneuvering extremely heavy machinery such as turbines, large presses, and foundry equipment in manufacturing and industrial facilities.

- Construction and Infrastructure Components: Ideal for handling large-scale construction materials, including heavy steel girders, prefabricated concrete sections, and other bulky items needed in infrastructure projects.

- Heavy Vehicle Parts and Assemblies: Perfect for transporting large and heavy components in automotive, aerospace, and marine industries, such as complete vehicle frames, aircraft engines, and ship sections.

15 Ton, 16 Ton Jib Crane Design Options: Specifications and Selection Tips

Technical Parameter of BZ Pillar Slewing Jib Crane | ||

Capacity | t | 15, 16 |

Valid radius | R(m) | 3~15 |

Lifting height | m | 3~8 |

Lifting speed | m/min | 5(0.35/5) |

Trolley speed | m/min | 18 |

Slewing speed | r/min | 0.4~0.7 |

Slewing angle | 0°~360° | |

Work duty | A3~A4 | |

Technical Parameters

AQ-BZ Pillar Slewing Jib Crane

- Capacity: 15 tons

- Valid Radius: 3 to 15 meters

- Lifting Height: 3 to 8 meters

- Lifting Speed: 5 m/min (adjustable between 0.35 and 5 m/min)

- Trolley Speed: 18 m/min

- Slewing Speed: 0.4 to 0.7 r/min

- Slewing Angle: 0° to 360°

- Work Duty: A3 to A4

Design Options and Selection Tips

- Capacity and Range: The 15-ton capacity makes this crane ideal for handling heavy loads in demanding industrial environments. The crane covers a radius of 3 to 15 meters, providing ample reach for large-scale operations.

- Lifting Performance: With a lifting height range of 3 to 8 meters and a lifting speed of 5 m/min, this crane is designed for heavy-duty lifting tasks. The adjustable lifting speed allows for precise control based on the specific needs of the job.

- Trolley and Slewing Functionality: The high trolley speed of 18 m/min enhances operational efficiency, while the slewing speed range of 0.4 to 0.7 r/min ensures smooth and controlled rotation. The crane's 360° slewing angle maximizes maneuverability and flexibility in load positioning.

- Work Duty Rating: Rated A3 to A4, theBZ Pillar Slewing Jib Crane is suitable for moderate to heavy-duty applications, ensuring reliable performance and durability in industrial settings.

Design Considerations:

- Heavy-Duty Applications: The robust capacity and adjustable features make this crane suitable for environments where high load capacities and efficient material handling are essential.

- Flexibility and Reach: The wide valid radius and full slewing angle provide flexibility in handling and positioning, making it a versatile choice for various operational needs.

- Operational Efficiency: The combination of high trolley speed and adjustable lifting speed contributes to effective and efficient material handling, improving overall productivity.

Choose theBZ Pillar Slewing Jib Crane for robust, reliable performance in heavy-duty lifting applications, offering a balance of capacity, reach, and operational flexibility.

Specifications: Key Factors to Consider

Load Capacity and Reach

How to Choose Based on Your Needs:

- Load Capacity: Ensure that the crane's capacity meets or exceeds the maximum weight of the loads you plan to handle. For example, a 3-ton crane should be selected if your heaviest load is 3 tons or less. Overestimating the required capacity can lead to cost inefficiencies, while underestimating can risk safety and equipment damage.

- Reach: The valid radius (the distance from the center of the crane to the farthest point it can lift) must match your operational space requirements. Choose a crane with a reach that accommodates the layout of your workspace, ensuring that it can effectively cover all necessary areas.

Impact on Crane Performance:

- Performance: Load capacity and reach directly impact the crane's performance, including its stability, lifting speed, and operational efficiency. A well-matched crane will operate smoothly, with reduced strain on components and enhanced productivity.

Material and Build Quality

Durability and Maintenance:

- Material Options: Cranes are commonly constructed from materials such as steel or aluminum. Steel offers greater strength and durability, making it suitable for heavy-duty applications, while aluminum is lighter and can be ideal for lighter loads and environments where weight is a concern.

- Build Quality: High-quality construction materials and precision engineering enhance durability, reduce maintenance needs, and extend the crane's service life. Regular maintenance and inspections are essential to prevent wear and tear from affecting performance.

Material Options (Steel, Aluminum, etc.):

- Steel: Provides high strength and is suitable for heavy lifting tasks. It is often used in environments where durability and load capacity are critical.

- Aluminum: Offers a lightweight alternative, making it easier to maneuver and install. It is ideal for lighter loads and applications where corrosion resistance is important.

Operational Features

Manual vs. Electric Operation:

- Manual Operation: Typically less expensive and simpler, manual cranes rely on hand cranks or levers. They are suitable for environments where the frequency of use is low and where cost considerations are paramount.

- Electric Operation: Provides greater ease of use, especially for frequent lifting tasks. Electric cranes can handle higher loads with less physical effort from operators and offer programmable features for improved efficiency and precision.

Safety Features and Controls:

- Safety Features: Look for cranes equipped with safety systems such as overload protection, emergency stop buttons, and limit switches to prevent accidents and equipment damage.

- Controls: Ensure that controls are user-friendly and allow for precise maneuvering of the crane. Advanced options may include remote controls and automated systems for enhanced operational safety and efficiency.

Design Customization

Adjustable Reach and Height:

- Adjustable Reach: Cranes with adjustable reach can be tailored to various workspace configurations, offering greater flexibility and adaptability in handling different tasks.

- Adjustable Height: Height adjustments can be crucial for tasks that require lifting to different elevations. Ensure the crane can be modified to meet varying height requirements in your operational environment.

Specialized Attachments:

- Attachments: Consider cranes that can be equipped with specialized attachments to handle specific types of loads or tasks. Examples include hooks, grabs, and magnets, which can enhance the crane's versatility and functionality for your specific needs.

Safety and Compliance

Regulatory Standards

Key Certifications and Standards:

- ISO 9001: This certification ensures that the crane manufacturer adheres to international quality management standards, focusing on consistent quality and customer satisfaction.

- CE Marking: The CE mark indicates that the crane meets European safety, health, and environmental protection requirements. It is a mandatory conformity mark for products sold in the European Economic Area (EEA).

- ANSI/ASME Standards: In the United States, cranes should comply with the American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME) standards, which cover safety, design, and operational guidelines for cranes.

- OSHA Regulations: The Occupational Safety and Health Administration (OSHA) sets safety standards for cranes in the workplace. Compliance with OSHA regulations helps ensure a safe working environment and reduces the risk of accidents.

Importance of Compliance:

- Legal Requirements: Compliance with regulatory standards is legally required in many regions. Failure to adhere to these standards can result in fines, legal action, and restrictions on operations.

- Safety Assurance: Compliance ensures that the crane is built to recognized safety and performance standards, reducing the risk of accidents and ensuring safe operation.

- Operational Efficiency: Cranes that meet regulatory standards are often more reliable and efficient, leading to smoother operations and reduced downtime.

Safety Features

Emergency Stop Functions:

- Emergency Stop Buttons: Cranes should be equipped with easily accessible emergency stop buttons that immediately halt all operations in case of an emergency. This feature is crucial for quickly addressing unexpected situations and preventing accidents.

- Emergency Power-Off: In addition to physical buttons, some cranes have emergency power-off systems that cut off electrical power to prevent further movement and ensure safety.

Overload Protection:

- Load Limit Switches: Cranes should have load limit switches to prevent lifting beyond the crane's rated capacity. These switches trigger alarms or automatic shutdowns when the load exceeds the crane's safe working limit.

- Safety Sensors: Advanced cranes may include sensors that monitor the load and other operational parameters, providing real-time data to ensure that the crane operates within safe limits and alerting operators to potential issues.

Regular Maintenance and Inspections:

- Scheduled Inspections: Regular inspections and maintenance are essential to keep the crane in safe working condition. These inspections should check for wear and tear, ensuring that safety features like emergency stops and overload protection are functioning correctly.

- Operator Training: Proper training for crane operators is vital to ensure they understand how to use safety features and recognize potential hazards. Well-trained operators can effectively manage the crane and respond to emergencies.

Cost Considerations

Factors Affecting Cost

Capacity and Design Complexity:

- Load Capacity: The crane's capacity significantly impacts the cost. Higher capacity cranes generally require more robust materials, advanced design features, and more intricate engineering, leading to increased costs.

- Design Complexity: Cranes with more complex designs, such as those with extended reach, specialized attachments, or unique configurations, typically cost more. Custom designs or non-standard features also contribute to higher costs due to additional engineering and manufacturing efforts.

Optional Features and Customizations:

- Operational Features: Features such as electric vs. manual operation, advanced control systems, or automation options can affect the overall cost. Electric and automated systems generally incur higher upfront costs but can offer enhanced performance and ease of use.

- Safety Features: Enhanced safety features like overload protection, emergency stop functions, and additional sensors or alarms can increase the cost. However, these features are crucial for ensuring safe operations and compliance with regulations.