Workshop Cranes: 500kg -320 ton Workshop Cranes for Your Workshops

Workshop Cranes is a material handling crane which is used in your garages or shopes. As a crane manufactuerer and supplier, various types of workshop cranes, shop cranes and warehouse cranes to meet your needs for material handling.

Introduction to Workshop Cranes

As a leading manufacturer and supplier of Workshop Cranes, we invite you to embark on a journey to discover the fundamental aspects, applications, and benefits of these indispensable tools.

Understanding the Basics: What Are Workshop Cranes?

Workshop Cranes, as the name suggests, are robust lifting machines meticulously designed for industrial workshops, manufacturing facilities, and various craft and trade environments. They are the muscle behind the scenes, lifting, positioning, and transporting materials with precision and ease.

These mechanical marvels come in a variety of types, each tailored to specific needs:

- Overhead Bridge Cranes: The stalwarts of heavy lifting, these cranes traverse overhead runways and provide a wide range of lifting capacities.

- Gantry Cranes: Renowned for their mobility, gantry cranes excel in versatile applications, offering the freedom to move within your workspace.

- Jib Cranes: Designed for limited spaces, jib cranes offer pinpoint accuracy, making them ideal for tasks that require finesse.

The Importance of Workshop Cranes in Industrial Operations

Picture a manufacturing workshop without the relentless hum of Workshop Cranes. It's like a symphony missing its orchestra. Workshop Cranes are the unsung heroes that orchestrate the movements, ensuring raw materials and components arrive precisely where they're needed in the intricate dance of production.

From the automotive industry to woodworking studios, metalworking shops to electronics manufacturing labs, and even the realms of art and science, Workshop Cranes are the reliable backbone of numerous operations.

They aren't just tools; they are the embodiment of efficiency, safety, and precision, consistently elevating productivity and enabling you to reach greater heights in your endeavors.

In the chapters that follow, we'll delve deeper into the world of Workshop Cranes, exploring their diverse types, exceptional features, and how they benefit various industries. Whether you're a seasoned industry professional or a potential purchaser seeking to optimize your workspace, join us on this journey as we unveil the remarkable capabilities of Workshop Cranes.

Main types of workshop cranes

Based on crane design, the types of workshop cranes can be grouped into workshop gantry crane with capacity from 0.25 ton to 10 ton, workshop jib cranes with capacity from 0.25 ton to 2 ton, and garage overhead cranes which also can be grouped into free standing overhead cranes and customized garage overhead cranes, etc.As per your specific garage or shop conditions, the workshop cranes can be tailored to improve your material handling efficiency and safety.

Workshop Cranes is a material handling crane which is used in your garages or shopes. As a crane manufactuerer and supplier, various types of workshop cranes, shop cranes and warehouse cranes to meet your needs for material handling.

Workshop gantry crane

Workshop portable gantry crane specifications: Capacity:0.25 ton -10ton, Span length: 2~16m,Lifting height : 2~12m, Working class : A2. Ask for workshop crane price.

Workshop overhead crane

Workshop underslung overhead crane specifications: Capacity:0.5 ton to 10 ton, Span: 3m to 31.5m, Lifting Height: 6m to 18m,Working Class:A3 to A5. Ask for workshop crane price.

Workshop jib crane

Wall mounted jib crane specifications-Capacity: 0.25 ton-2 ton, Arm length: 2-6m, Lifting height: 2-6m, Rotating : 180, Working class: A3.Ask for workshop crane price.

Workshop overhead crane with free standing crane design

Workshop overhead kbk crane specifications: Capacity: 125Kg-5000Kg,Lifting Height: 2.5m-12m,Maximum Span : 3-10m,Working Class: A3. Ask for workshop crane price.

Advantages of workshop cranes

- The workshop crane will make you work easier, faster, better and safer.

- The workshop crane with two parallel steel tracks makes a steel bridge work smoothly on your workshop.

- The workshop crane can move your loads and objects left and right, or forward and right with easy operation.

- The workshop crane can be used to handle various types of loads and objects with rare limitation.

- The garage bridge crane can be moved to anywhere at any time in the factory.

Workshop Gantry Crane

A workshop gantry crane is a type of light duty or tiny gantry crane that is used for lifting. Because of its restricted loading capacity, it is not suitable for heavy-duty lifting. As a result, it's commonly used to lift and move small and medium-sized goods. This type of lifting equipment is a common garage option, but it may also be utilized to handle various items in a shop, warehouse, workstation, and other locations. The gantry crane in a garage is increasingly being used for many different sectors as well as for household use as a highly effective material handling solution.

As a leading gantry crane manufacturer in China, our company manufactures and customizes a variety of workshop gantry cranes to meet the needs of our customers, including portable gantry cranes, steel gantry cranes for garages, and more. We'll create the greatest material handling solution for you, one that maximizes your benefits and meets your requirements. Please do not hesitate to contact us via the internet.

Types of workshop gantry cranes

Workshop gantry cranes come in a variety of shapes and sizes to accommodate diverse lifting requirements. It is more frequently equipped with wheels to allow for more flexibility in movement. We may also provide different forms of lifting equipment for garages, such as a garage bridge crane, depending on your needs and the structure of your building. Steel workshop gantry cranes with fixed or adjustable height and span designs are available.

Garage gantry crane with singl girder crane design

Workshop single girder gantry crane specifications: Capacity: 1ton-20ton, Span Length: 8~30m, Working Class: A3, A4. Ask for workshop crane price.

Garage gantry crane with double girder crane design

Workshop double girder gantry crane specifications: Capacity: 5 ton - 500 ton, Span Length: 12~35m, Working Class: A5, A6Ask for workshop crane price.

Small workshop gantry crane

Workshop portable gantry crane specifications: Capacity:0.25 ton -10ton, Span length: 2~16m,Lifting height : 2~12m, Working class : A2.Ask for workshop crane price.

Workshop gantry crane with sem gantry design

Workshop semi-gantry crane specifications: Capacity: 2 ton- 10 ton, Span Length: 8~20m, Working Class: A3, A4.Ask for workshop crane price.

Features of a workshop gantry crane

The workshop gantry cranes are built in accordance with industry and international standards and principles. Here are some of the benefits of workshop gantry cranes:

- The portable workshop gantry crane is available in a variety of design options, including steel, varied sizes, and wheels, and can handle practically all lifting operations in the garage and other workplaces.

- The tiny portable gantry cranes we make are made using high-quality materials and components, as well as precise machining, to ensure that they are of the highest quality. The tiny workshop crane is simple to assemble and disassemble, making it ideal for storage and transit. It may also be easily transported to various work spaces.

- The movement is safer and more stable because to the robust structure, I-beam, and spring support wheel designs. This gantry crane can help enhance garage output while also saving time and money.

Workshop jib cranes

As a workshop jib crane manufacturer and supplier, types of workshop jib cranes are provided and turnkey workshop jib crane projects services including workshop jib crane design, workshop jib crane production, to jib crane installation and maintenance for over the world.

Types of workshop jib cranes

Generally workshop jib cranes can be grouped into fixed workshop jib crane, including, floor mounted workshop jib crane and wall mounted workshop jib crane, wall travelling workshop jib crane, and mobile workshop jib crane, etc.

Workshop jib crane with pillar jib design

Workshop pillar jib crane specifications-Capacity:0.5 ton -10 ton, Arm length: 3-12m, Lifting height: 3-8m, Rotating : 180, 270, 360 ,Working class: Ask for workshop crane price.

Workshop jib crane with wall mounted crane design

Workshop wall mounted jib crane specifications-Capacity: 0.25 ton-2 ton, Arm length: 2-6m, Lifting height: 2-6m, Rotating : 180, Working class: A3.Ask for workshop crane price.

Workshop jib crane with wall travelling crane design

Workshop wall-travelling jib crane specifications-Capacity: 0.25 ton-10 ton, Span: 3-10m, Lifting height: 3-8m, Rotating : 180,Working class: A3. Ask for workshop crane price.

Workshop jib crane with portable crane design

Workshop portable jib crane specifications- Capacity: 0.08 ton,1 ton, Lifting Height: 1.5- 3m, Turning Radius: 2m, 3m, Rotation Angle: 360°, Working class: A3.Ask for workshop crane price.

Workshop overhead crane

In factories, warehouses, and storage yards, overhead cranes are widely used for loading, unloading, transporting, and lifting materials and items. Overhead workshop cranes are classified into two types based on the crane girder: single girder and double girder. They are designed to satisfy a variety of industrial lifting work capacities, ranging from medium to heavy, and they are suitable for use in all stages of the manufacturing process.

Workshop overhead crane with top running crane design

Workshop single girder overhead crane specifications: Capacity:3.2 ton to 16 ton, Span: 7.5m to 28.5m,Lifting Height: 6m to 18m,Working Class:A5. Ask for workshop crane price.

Workshop overhead crane with suspension crane design

Workshop underslung overhead crane specifications: Capacity:0.5 ton to 10 ton, Span: 3m to 31.5m, Lifting Height: 6m to 18m,Working Class:A3 to A5. Ask for workshop crane price.

Workshop overhead crane with free standing kbk crane

Workshop kbk crane specifications: Capacity: 125 kg -5000 kg, Span Length: 3~15m, Working Class: A3. Ask for workshop crane price.

Workshop overhead crane with free standing monorail crane

Workshop monorail crane specifications: Capacity: 50kg- 3.2 ton, Span Length: 0.7~12m, Working Class: A3, A4.Ask for workshop crane price.

You will make your work easier, faster, better, and safer if you have a garage overhead crane. A steel bridge is easily installed on your workshop with the help of a garage overhead crane with two parallel steel tracks. The garage overhead crane can function more easily in any direction, whether left or right, forward or backward. Furthermore, there are no set limits for what you can lift or transport with a garage overhead crane. The garage overhead crane's main advantage is that it can move anywhere in the plant at any moment.

Please do not hesitate to contact us if you require a garage overhead crane.

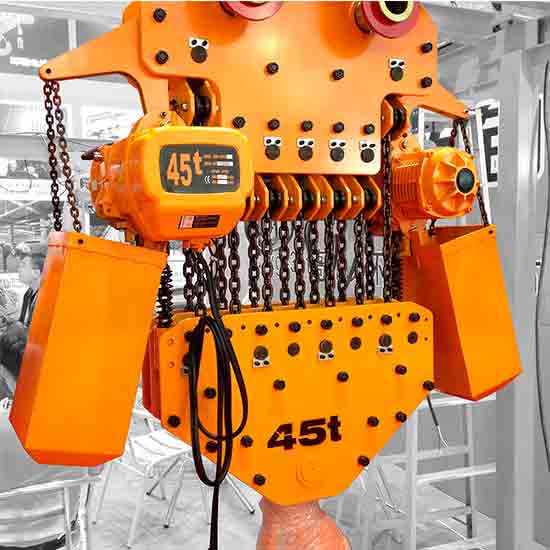

Workshop crane hoist

As for different workshop cranes, there are several workshop crane hoists are available for your selection.

Manual workshop crane hoist

Manual chain block & manual chain hoist for sale. Light,economical & handy manual hoists & hand hoists of 250kg, 1 ton, 1.5 ton , 2 ton , 3 ton , 4 ton , 5 ton , 6 ton,etc.Get workshop crane hoist price.

Electric workshop crane hoist

DIN/FEM wire rope hoists - European standard low profile & low headroom hoists - Affordable crane hoists up 80 ton for types of overhead travelling cranes.Get workshop crane hoist price.

Workshop electric chain hoist

500kg-35 ton electric chain hoist with motorized trolley for overhead chain hoist crane, gantry chain hoist crane & jib chain hoist crane. Get workshop crane hoist price.

Workshop electric wire rope hoist

Chinese style electric crane hoist specifications: Capacity: 0.25 ton -80 ton. Get workshop crane hoist price.

Features and Benefits of Workshop Cranes: The Engine of Productivity

As we delve deeper into the world of Workshop Cranes, we find ourselves at a pivotal juncture—the features and benefits that make these mechanical marvels indispensable in the industrial landscape. These are the very qualities that transform Workshop Cranes from mere machines into the engines of productivity. Join us as we explore the precision, control, and efficiency that Workshop Cranes bring to your operations.

Precision and Control: Key Features of Workshop Cranes

At the heart of Workshop Cranes lies the essence of precision and control. These cranes are engineered with features that grant you absolute command over your material handling tasks.

- 1. Smooth Maneuverability: Workshop Cranes, regardless of their type, offer smooth and precise maneuverability. Whether you're lifting heavy machinery components or delicate materials, these cranes ensure that every motion is executed with finesse.

- 2. Responsive Controls: Featuring state-of-the-art controls, Workshop Cranes respond to your commands with lightning-fast precision. You dictate the pace, ensuring that your materials are precisely positioned, every time.

- 3. Safety Enhancements: Safety is paramount. Workshop Cranes come equipped with advanced safety features, such as emergency stop mechanisms and overload protection, safeguarding both your materials and personnel.

- 4. Durability: Crafted from high-quality materials, Workshop Cranes are built to withstand the rigors of industrial environments. They endure years of heavy lifting with minimal maintenance.

Efficiency Boosters: How Workshop Cranes Benefit Your Operations

The true magic of Workshop Cranes lies in their ability to boost operational efficiency, offering a multitude of benefits that significantly impact your bottom line.

- 1. Time Savings: Workshop Cranes reduce material handling time, allowing you to complete tasks faster and meet production deadlines with ease. Time saved is money earned.

- 2. Increased Productivity: With the heavy lifting taken care of, your workforce can focus on value-added tasks, leading to increased overall productivity.

- 3. Space Optimization: Workshop Cranes are designed to maximize space utilization. They can access confined areas, making the most of your available workspace.

- 4. Error Reduction: Precision handling minimizes the risk of accidents and material damage. This, in turn, reduces costly errors and rework.

- 5. Versatility: Workshop Cranes adapt to various applications, from manufacturing and construction to laboratory research and artistic endeavors. Their versatility is a game-changer.

- 6. Longevity: By investing in Workshop Cranes, you're investing in longevity. These robust machines have a long service life, providing an excellent return on investment.

In the forthcoming sections, we'll delve deeper into the specific benefits and applications of Workshop Cranes across various industries. As you navigate this journey, you'll discover how these efficiency engines can elevate your operations to new heights, providing a competitive edge in today's demanding industrial landscape. Stay tuned for insights that will transform your approach to material handling.

Typical Industrial Applications of Workshop Cranes: Brilliance Across Industries

In the world of industrial operations, Workshop Cranes shine as versatile workhorses, seamlessly integrating into a wide array of applications. From bustling assembly lines to the meticulous settings of laboratories, these cranes are pivotal in enhancing efficiency, safety, and precision.

From Assembly Lines to Laboratories: Where Workshop Cranes Shine

- Manufacturing and Assembly Lines: In bustling manufacturing facilities, Workshop Cranes streamline production processes. They effortlessly move raw materials, heavy components, and finished products along assembly lines, ensuring a smooth workflow. Whether it's the automotive, electronics, or machinery manufacturing sector, these cranes are the backbone of production.

- Construction Sites: Construction sites are dynamic environments that require heavy lifting and precise positioning. Gantry Cranes are commonly employed in construction for tasks like erecting structural steel, lifting concrete panels, and positioning heavy machinery.

- Laboratories and Cleanrooms: Laboratories demand precision, cleanliness, and contamination control. Workshop Cranes designed for cleanroom compatibility play a crucial role in handling sensitive scientific equipment and materials. They are essential in research and development, pharmaceuticals, and biotechnology labs.

- Warehouses and Distribution Centers: Efficient material handling is key in warehouses and distribution centers. Gantry Cranes and jib cranes are often used for loading and unloading heavy cargo, optimizing storage, and enhancing logistics operations.

- Aerospace and Aviation Hangars: In the aerospace and aviation industry, Workshop Cranes are indispensable in the assembly and maintenance of aircraft. These cranes ensure the safe handling of large and heavy aircraft components within vast hangars.

- Food Processing Plants: Food processing plants require equipment that meets strict hygiene standards. Workshop Cranes designed for food-grade applications help safeguard food quality by efficiently handling ingredients and products.

- Art Studios and Workshops: Artists and craftsmen rely on Workshop Cranes, especially jib cranes, to move and position materials for their creative projects. These cranes enable artistic expression in a variety of art studios and workshops.

- Maintenance and Repair Facilities: Maintenance and repair facilities across industries, including automotive, aviation, and manufacturing, rely on Workshop Cranes for lifting and servicing heavy machinery and vehicles.

- Educational Institutions: Workshop Cranes are used in vocational training and technical education programs to teach students essential skills in material handling and crane operation.

- Energy and Power Plants: In the energy sector, Workshop Cranes play a vital role in power plant maintenance, turbine assembly, and the handling of heavy equipment and materials.

From heavy-duty manufacturing to intricate scientific research, Workshop Cranes adapt to diverse environments and applications, ensuring that operations run smoothly and efficiently. In the following sections, we will explore the specific features, benefits, and advantages of Workshop Cranes in each of these industrial settings, providing a deeper understanding of their exceptional contributions.

Workshop cranes customized for different industrial sectors

Workshop designs, configurations, layouts, and features vary significantly depending on the specific industrial sector and the nature of the work being carried out. Each industry has unique requirements and considerations for workshop design to optimize efficiency, safety, and productivity. Here are different workshop designs and features tailored to various industrial sectors:

- Design: Manufacturing workshops are often designed with open floor plans to accommodate production lines. Workflow efficiency is a primary consideration, with a focus on minimizing material movement and optimizing space.

- Configurations: These workshops may have dedicated areas for machining, assembly, quality control, and warehousing, with well-defined material flow paths.

- Layout Features: Conveyor systems, robotics, and automated machinery are common features. Lighting, ventilation, and safety measures are crucial.

- Main types of manufacturing workshop cranes: Overhead bridge cranes (single and double girder) are commonly used for heavy lifting and material transport.

- Features of workshop cranes for manufacturing workshop: Manufacturing workshop cranes are equipped with precise controls, high lifting capacities, and reliability to support continuous production.

- Main functions and applications of workshop cranes for manufacturing: These cranes efficiently move raw materials, work-in-progress, and finished products within the manufacturing workspace, enhancing productivity and safety.

- Design: Automotive workshops are organized to support vehicle repair and maintenance tasks. They include service bays with lift systems, tool storage, and diagnostic equipment.

- Configurations: Layouts are designed for efficient vehicle access and maneuverability within service areas.

- Layout Features: Automotive workshops feature specialized equipment like hydraulic lifts, vehicle diagnostic tools, and well-organized tool cabinets.

- Main types of automotive workshop cranes: Mobile gantry cranes are often used for lifting and positioning vehicle engines, transmissions, and chassis components.

- Features of workshop cranes for automotive workshop: Automotive workshop cranes are designed for durability and ease of use in tight spaces, with precise controls.

- Main functions and applications of workshop cranes for automotive: They assist in tasks such as engine removal, transmission handling, and vehicle assembly, improving efficiency in auto repair and maintenance.

3. Woodworking and Carpentry Workshops:

- Design: Woodworking workshops are configured for cutting, shaping, and assembling wood products. Layouts typically have workbenches with ample workspace.

- Configurations: Machines for cutting, planing, and sanding are strategically placed to optimize material flow.

- Layout Features: Dust collection systems, woodworking machinery, and storage for various wood types are essential.

- Main types of woodworking workshop cranes: Jib cranes are commonly used for positioning and moving heavy wood materials and machinery.

- Features of workshop cranes for woodworking: Jib cranes provide flexibility and precision in woodworking tasks and can be adapted to specific needs.

- Main functions and applications of workshop cranes for woodworking: They assist in handling large lumber, boards, and finished pieces, aiding in assembly and positioning in woodworking shops.

- Design: Metalworking workshops are equipped for metal fabrication, welding, and machining processes. Layouts consider safety and ventilation needed for hot work.

- Configurations: Work areas are set up for welding booths, CNC machines, and metal cutting equipment.

- Layout Features: Welding booths with fume extraction, machining centers, and specialized welding and cutting tools are common.

- Main types of metalworking workshop cranes: Overhead bridge cranes, gantry cranes, or jib cranes are used, depending on the size of the metal components.

- Features of workshop cranes for metalworking: These cranes are equipped with lifting attachments suitable for metalworking tasks like welding and machining.

- Main functions and applications of workshop cranes for metalworking: They facilitate the handling of metal sheets, bars, and components during fabrication and welding processes.

5. Electronics Manufacturing Labs:

- Design: Electronics manufacturing labs require controlled environments to prevent ESD (electrostatic discharge) and contamination. Layouts prioritize cleanroom conditions.

- Configurations: Workstations for PCB assembly, soldering, and testing are arranged in an assembly line format.

- Layout Features: Anti-static flooring, cleanroom filtration, ESD-safe workstations, and precision testing equipment are key features.

- Main types of workshop cranes for electronics manufacturing labs: Overhead bridge cranes or monorail systems designed for cleanroom compatibility.

- Features of workshop cranes for electronics manufacturing: These cranes adhere to strict cleanliness and contamination control standards in pharmaceutical and biotech environments.

- Main functions and applications of workshop cranes for electronics manufacturing: They handle sensitive electronic components and equipment in controlled environments, ensuring product quality and reliability.

6. Aerospace and Aviation Workshops:

- Design: Aerospace workshops focus on aircraft maintenance, repair, and component manufacturing. Layouts are often spacious and well-ventilated.

- Configurations: Hangar-style layouts accommodate large aircraft, with areas for inspection, overhaul, and component assembly.

- Layout Features: Aircraft lifting equipment, inspection pits, and specialized tools for aircraft maintenance are essential.

- Main types of workshop cranes for aerospace and aviation: Overhead bridge cranes with high lifting capacities are used, along with mobile gantry cranes.

- Features of workshop cranes for aerospace and aviation: These cranes are designed for precision and safety in handling large and heavy aircraft parts.

- Main functions and applications of workshop cranes for aerospace and aviation: They assist in aircraft component handling, maintenance, and assembly tasks, ensuring aircraft safety and performance.

7. Pharmaceutical and Biotechnology Cleanrooms:

- Design: Cleanrooms in pharmaceutical and biotech industries are designed to meet stringent cleanliness standards. Layouts prioritize contamination control.

- Configurations: Workstations for drug production, sterile processing, and equipment testing adhere to strict protocols.

- Layout Features: HEPA filtration, controlled temperature and humidity, sterile equipment, and gowning areas are critical.

- Main types of workshop cranes for pharmaceutical and biotechnology cleanrooms: Cleanroom-compatible overhead bridge cranes or monorail systems.

- Features of workshop cranes for pharmaceutical and biotechnology: These cranes maintain cleanliness standards and adhere to contamination control protocols.

- Main functions and applications of workshop cranes for pharmaceutical and biotechnology: They handle sterile materials and equipment in controlled environments, ensuring pharmaceutical product quality and safety.

- Design: Food processing workshops are designed for hygiene and food safety. Layouts separate processing areas from packaging

and storage.

- Configurations: Stations for washing, cutting, cooking, and packaging are organized for a streamlined food production line.

- Layout Features: Stainless steel surfaces, food-grade equipment, and sanitation facilities are fundamental.

- Main types of workshop cranes for food processing: Stainless steel jib cranes or overhead bridge cranes suitable for food-grade applications.

- Features of workshop cranes for food processing: These cranes are corrosion-resistant and easy to clean, meeting food safety standards.

- Main functions and applications of workshop cranes for food processing: They assist in handling food ingredients and products within the processing and packaging areas, ensuring food safety and quality.

9. Research and Development Labs:

- Design: R&D labs accommodate diverse research activities. Flexible layouts allow for reconfiguration as research priorities change.

- Configurations: Bench spaces, equipment areas, and chemical storage are allocated based on research needs.

- Layout Features: Fume hoods, specialized research equipment, and flexible lab furniture are incorporated.

- Main types of workshop cranes for research and development labs: Overhead bridge cranes or jib cranes, depending on the lab's layout and equipment.

- Features of workshop cranes for research and development labs: These cranes provide precise control and flexibility for varying research needs.

- Main functions and applications of workshop cranes for research and development: They assist in handling research equipment and materials, supporting various scientific experiments and investigations.

10. Art and Craft Studios:

- Design: Art and craft studios cater to artistic expression. Layouts are adaptable to accommodate various art forms.

- Configurations: Workspaces are customized for painting, sculpture, pottery, and other artistic activities.

- Layout Features: Art supplies storage, workstations, and specialized tools for each art form are provided.

- Main types of workshop cranes for art and craft studios: Jib cranes are commonly used for positioning and moving art materials, sculptures, and other creative projects.

- Features of workshop cranes for art and craft studios: Jib cranes are chosen for their ease of use and adaptability in artistic environments.

- Main functions and applications of workshop cranes for art and craft studios: They assist artists and craftsmen in handling materials, creating art pieces, and optimizing workspace organization for creative endeavors.

Workshop Cranes Used for Different Workshops

- Traditional Workshops: These are often standalone structures or rooms dedicated to a particular craft or trade. They typically have workbenches, hand tools, and specialized equipment relevant to the specific craft or trade they serve.

- Modular Workshops: Modular workshops are designed with interchangeable or movable components, allowing for flexibility in layout and usage. They may include modular workbenches, partition walls, and equipment that can be reconfigured to accommodate changing needs.

- Mobile Workshops: These workshops are mounted on vehicles, trailers, or containers, providing portability and on-site capabilities. They are equipped with tools, equipment, and supplies needed for remote work or service calls.

- Cleanrooms: Cleanrooms are specialized workshops with controlled environments to minimize dust, particles, and contaminants. They feature air filtration systems, controlled temperature and humidity, and strict cleanliness protocols. Cleanrooms are common in electronics manufacturing and biotechnology.

Traditional Workshop Cranes:

Traditional Workshop Description: Traditional workshops are standalone structures or dedicated rooms tailored to specific crafts or trades. They are equipped with workbenches, hand tools, and specialized equipment relevant to the craft or trade they serve. These workshops provide a controlled and focused environment for skilled artisans and craftsmen to carry out their work.

Main Types of Workshop Cranes Used: In traditional workshops, you will often find overhead crane systems, particularly single girder or double girder overhead cranes. These cranes are mounted on the workshop ceiling and feature a trolley and hoist for lifting and moving materials and workpieces within the workspace. Single girder cranes are suitable for lighter loads, while double girder cranes offer higher lifting capacities for heavier materials.

Typical Industrial Application: Traditional workshop cranes are used in various craft and trade settings, including:

- Woodworking Workshops: These cranes help woodworkers handle large lumber, boards, and finished pieces, aiding in assembly and positioning.

- Metalworking Workshops: Metalworkers utilize cranes for lifting and moving metal sheets, bars, and components during fabrication and welding.

- Artisanal Craft Studios: Craftsmen and artists in areas like pottery, sculpture, and glasswork use these cranes to manipulate materials and artworks efficiently.

- Automotive Repair Shops: Traditional auto repair workshops employ cranes for tasks such as engine removal, transmission handling, and vehicle assembly.

Traditional workshop cranes enhance productivity by facilitating material handling tasks, assisting with assembly, and ensuring the safe movement of materials within the workshop's dedicated environment.

Modular Workshop Cranes:

Modular Workshop Description: Modular workshops are designed with adaptability and flexibility in mind. They feature interchangeable or movable components that allow for easy changes in layout and usage. These workshops provide an efficient workspace for various tasks and activities, accommodating changing needs and requirements.

Main Types of Workshop Cranes Used: In modular workshops, overhead crane systems can be integrated into the workspace to optimize material handling. Both single girder and double girder overhead cranes are suitable, depending on the workshop's size and lifting capacity needs. The crane installation is designed to work seamlessly with the modular components and adaptable layout.

Typical Industrial Application: Modular workshop cranes find applications in versatile workspaces, including:

- Manufacturing Facilities: Modular workshops within manufacturing plants benefit from crane systems for efficient material transport between workstations.

- Research and Prototyping Labs: Laboratories with modular workspaces utilize cranes for handling sensitive equipment and prototypes.

- Multi-Purpose Workshops: Workshops that serve various functions, from assembly and testing to repair and maintenance, make use of cranes to facilitate diverse tasks.

- Flexible Production Lines: In facilities with changing production requirements, modular workshop cranes assist in adjusting layouts and optimizing workflows.

Modular workshop cranes support the dynamic nature of modular workshops by enhancing material handling capabilities and adaptability, allowing for efficient space utilization and layout changes as needed.

Mobile Workshop Cranes:

Mobile Workshop Description: Mobile workshops are mounted on vehicles, trailers, or containers, providing portability and on-site capabilities. These workshops are fully equipped with tools, equipment, and supplies necessary for remote work, service calls, or emergency repairs.

Main Types of Workshop Cranes Used: Gantry cranes are commonly employed in mobile workshops due to their mobility and self-contained design. These cranes can be positioned on the workshop vehicle or trailer and are equipped with trolley and hoist systems for lifting and moving materials.

Typical Industrial Application: Mobile workshop cranes are indispensable in various industries and settings, including:

- Field Service and Maintenance: Mobile workshops equipped with gantry cranes are deployed to remote sites for equipment repairs and maintenance.

- Construction Sites: Construction companies use mobile workshops with cranes to handle construction materials and perform on-site tasks.

- Emergency Services: Mobile workshops equipped with cranes assist emergency response teams in disaster relief, rescue operations, and infrastructure repairs.

- Utilities and Infrastructure: Utility companies employ mobile workshops with cranes to maintain and repair electrical and telecommunication infrastructure.

Mobile workshop cranes provide the flexibility and convenience needed for on-the-go operations, ensuring that essential tools and equipment are readily available for work at remote locations.

Cleanroom Workshop Cranes:

Cleanroom Workshop Description: Cleanrooms are highly controlled environments designed to minimize dust, particles, and contaminants. They maintain precise conditions, including air filtration, controlled temperature, humidity, and strict cleanliness protocols, making them suitable for industries like electronics manufacturing and biotechnology.

Main Types of Workshop Cranes Used: Cleanroom workshops require specialized cleanroom-compatible crane systems designed to meet cleanroom specifications. These cranes have cleanroom-grade materials and sealing to ensure they do not compromise the controlled environment. Typically, cleanroom-compatible overhead cranes, including single girder and double girder configurations, are used.

- Typical Industrial Application: Cleanroom workshop cranes are essential in industries where contamination control is critical, including:

- Electronics Manufacturing: In semiconductor fabrication and electronics assembly, cleanroom cranes handle delicate components without introducing contaminants.

- Pharmaceuticals: Cleanroom cranes are used in pharmaceutical manufacturing, ensuring a sterile environment for drug production and packaging.

- Biotechnology: Research and development labs rely on cleanroom cranes for handling sensitive biological samples and equipment.

- Aerospace: Cleanroom cranes assist in spacecraft and satellite assembly, where precision and contamination control are paramount.

Cleanroom workshop cranes play a vital role in maintaining the pristine conditions required for manufacturing and research processes within cleanroom environments. They contribute to product quality, reliability, and compliance with industry standards.

Each type of workshop crane—whether in traditional workshops, modular workshops, mobile workshops, or cleanrooms—serves specific needs and provides significant benefits. These cranes enhance material handling capabilities, improve safety, and contribute to the overall efficiency of the workshop environment, ensuring that tasks are carried out effectively and with precision.

These overviews provide insight into how workshop cranes are integrated into various workshop types across different industrial sectors, considering specific design, configuration, and application requirements. Workshop cranes play a vital role in enhancing productivity, safety, and efficiency in each of these diverse workshop environments.

Workshop Crane Cost and Price Considerations: Balancing Your Budget with Quality

When it comes to Workshop Cranes, the cost and price considerations are significant factors in your decision-making process. As a responsible manufacturer and supplier, we understand the importance of transparency and informed choices. In this section, we'll delve into the factors that influence Workshop Crane costs and provide insights on how to strike the perfect balance between quality and budget.

Factors Influencing Workshop Crane Costs

The cost of Workshop Cranes can vary widely, influenced by several key factors:

- Type of Crane: The choice of crane type plays a significant role in cost. Overhead Bridge Cranes, gantry cranes, and jib cranes each come with different price points due to their varying complexities and capabilities.

- Lifting Capacity: The lifting capacity of the crane directly affects its cost. Cranes designed for heavier loads generally come at a higher price.

- Span and Reach: The span (distance between runway rails) and reach (horizontal distance the crane can travel) impact the cost, as longer spans and greater reaches require more robust structures.

- Customization: If your operations require specific customizations or features, such as specialized attachments or cleanroom compatibility, expect additional costs.

- Quality and Durability: High-quality Workshop Cranes built with durable materials may have a higher upfront cost but can provide a longer service life, reducing long-term maintenance expenses.

- Manufacturer Reputation: Established manufacturers with a strong reputation for quality and reliability often command higher prices, but they offer the assurance of superior products.

Balancing Quality and Budget: Workshop Crane Price Insights

While cost is a crucial consideration, it's equally vital to ensure that you're investing in a Workshop Crane that meets your needs and aligns with your budget. Here are some valuable insights to help you strike that balance:

- Define Your Requirements: Start by clearly defining your material handling needs. Assess the lifting capacity, reach, and any specialized features required for your specific operations.

- Consider Long-Term Value: Workshop Cranes are long-term investments. It's often wise to prioritize quality over the lowest initial price. A high-quality crane may have a higher upfront cost but can save you money in the long run through reduced maintenance and downtime.

- Explore Financing Options: Many manufacturers offer financing or leasing options, making it easier to acquire a Workshop Crane without a significant upfront payment.

- Seek Expert Advice: Consult with Workshop Crane experts who can help you evaluate your needs and recommend cost-effective solutions that meet your requirements.

- Compare Quotes: Obtain quotes from multiple reputable manufacturers and suppliers. Compare not only the prices but also the included features, warranties, and support services.

- Consider Total Cost of Ownership: Look beyond the initial purchase price and consider the total cost of ownership, including maintenance, repairs, and operational costs.

At our crane factory , we believe in providing Workshop Cranes that offer exceptional value for your investment. Our commitment to quality, durability, and customer satisfaction ensures that you receive a Workshop Crane that meets your needs and budget. We're here to assist you in making an informed decision, balancing cost considerations with the assurance of a reliable and efficient Workshop Crane solution.

Top Concerns of Workshop Crane Users: Prioritizing Safety, Maintenance, and Customization

As a responsible Workshop Crane manufacturer and supplier, we understand that addressing the concerns of Workshop Crane users is of paramount importance. Your peace of mind and operational efficiency are our top priorities. In this section, we'll delve into the key concerns of Workshop Crane users and provide insights on how to address them effectively.

Safety First: Ensuring Secure Crane Operations

Safety is non-negotiable in any industrial setting. Workshop Cranes are powerful machines, and their safe operation is a top concern. Here's how you can ensure secure crane operations:

- Training and Certification: Properly train and certify crane operators to ensure they understand safe operating procedures, load limits, and emergency protocols.

- Regular Inspections: Implement a regular inspection and maintenance schedule to identify and address any issues promptly.

- Safety Features: Ensure your Workshop Crane is equipped with essential safety features like emergency stop buttons, overload protection, and limit switches.

- Load Capacity Awareness: Always adhere to load capacity limits and avoid overloading the crane, which can lead to accidents.

- Clear Communication: Maintain clear communication between operators and ground personnel using signals or radios to prevent accidents during crane operation.

Maintenance Matters: Prolonging Crane Lifespan

Proper maintenance is key to extending the lifespan of your Workshop Crane and preventing unexpected downtime. Here are some maintenance tips:

- Scheduled Inspections: Conduct regular inspections to identify wear and tear, and address issues promptly.

- Lubrication: Keep all moving parts properly lubricated to reduce friction and prevent premature wear.

- Repairs and Replacements: Address any issues promptly by making necessary repairs or replacements of worn-out components.

- Record Keeping: Maintain detailed maintenance records to track the crane's history and schedule future maintenance.

- Professional Support: Engage with a qualified service provider for routine maintenance and inspections.

Customization Needs: Tailoring Cranes to Unique Requirements

Every industry and operation has its unique requirements, and Workshop Cranes should be adaptable to meet them. Here's how to address customization needs:

- Consultation: Engage with a crane manufacturer or supplier that offers customization services. Discuss your specific requirements, and explore solutions tailored to your needs.

- Specialized Attachments: Consider specialized attachments or lifting equipment to enhance your crane's capabilities for unique tasks.

- Cleanroom Compatibility: If you operate in a cleanroom environment, ensure your Workshop Crane is designed for cleanroom use, with features that meet cleanliness and contamination control standards.

- Unique Space Considerations: If your workspace has limited or unconventional configurations, discuss custom crane solutions to maximize space utilization.

At our crane factory, we prioritize safety, maintenance, and customization to meet the unique needs of our customers. Our Workshop Cranes are designed with robust safety features, and we offer comprehensive maintenance and support services to ensure the longevity of your crane. Moreover, we provide customization options to tailor our cranes to your specific operational requirements. Your concerns are our concerns, and we are committed to delivering Workshop Crane solutions that address them effectively.

Frequently Asked Questions About Workshop Cranes: Your Queries Answered

At our crane factory, we understand that choosing the right Workshop Crane can raise numerous questions. To provide clarity and assist you in making informed decisions, we've compiled a list of frequently asked questions (FAQs) about Workshop Cranes.

Q1: What are the main types of Workshop Cranes?

A1: Workshop Cranes come in three main types: Overhead Bridge Cranes, Gantry Cranes, and Jib Cranes. Each type serves specific material handling needs, with varying capabilities and applications.

Q2: How do I determine the right Workshop Crane for my needs?

A2: The choice depends on factors like lifting capacity, workspace layout, and the specific tasks you need to perform. Our experts can guide you through the selection process to ensure you choose the most suitable crane.

Q3: What safety features are essential in Workshop Cranes?

A3: Essential safety features include emergency stop buttons, overload protection, limit switches, and proper operator training. These features ensure safe crane operations and protect both personnel and materials.

Q4: How often should I schedule maintenance for my Workshop Crane?

A4: Regular maintenance is crucial for crane longevity. The frequency depends on usage, but it's generally recommended to schedule inspections at least annually, if not more frequently for heavy-use cranes.

Q5: Can Workshop Cranes be customized for unique requirements?

A5: Yes, Workshop Cranes can be customized to meet unique operational needs. Discuss your requirements with us, and we'll explore customization options, including specialized attachments and cleanroom compatibility.

Q6: What is the typical lifespan of a Workshop Crane?

A6: The lifespan varies based on usage and maintenance. High-quality Workshop Cranes, properly maintained, can last for decades, providing an excellent return on investment.

Q7: Do Workshop Cranes come with warranties?

A7: Yes, Workshop Cranes typically come with warranties that vary depending on the manufacturer and crane type. Be sure to inquire about warranty details when making your purchase.

Q8: Can Workshop Cranes be relocated within a facility?

A8: Yes, many Workshop Cranes are designed for mobility or can be disassembled and relocated within a facility to adapt to changing operational needs.

Q9: Are Workshop Cranes suitable for cleanroom environments?

A9: Yes, Workshop Cranes can be designed for cleanroom compatibility. These cranes meet strict cleanliness and contamination control standards, making them suitable for industries like pharmaceuticals and biotechnology.

Q10: What is the lead time for ordering a Workshop Crane?

A10: Lead times vary depending on the crane type, specifications, and manufacturer. It's advisable to discuss lead times with your chosen manufacturer or supplier to plan your acquisition accordingly.

We hope these FAQs provide you with valuable insights into Workshop Cranes. If you have more questions or require further information, don't hesitate to reach out to us.

Conclusion: Elevate Your Operations with Workshop Cranes

Our factory's explored the world of Workshop Cranes, uncovering their diverse applications, essential features, and the valuable benefits they bring to various industries. We've addressed your concerns, provided insights into cost considerations, and answered your frequently asked questions. Now, let's conclude our journey by highlighting the transformative power of Workshop Cranes and the impact they can have on your business.

Partnering for Success: How Our Workshop Cranes Empower Your Business

Workshop Cranes are not just machines; they are partners in your success story. They elevate your operations in numerous ways:

- Enhanced Efficiency: Workshop Cranes streamline material handling, reducing manual labor and material movement time. This translates into increased productivity and faster project completion.

- Precision and Control: With Workshop Cranes, you gain unmatched precision and control over lifting and positioning. This precision minimizes the risk of accidents and costly errors.

- Space Optimization: Workshop Cranes are designed to maximize workspace utilization, even in confined areas. They help you make the most of your available square footage.

- Versatility: Whether you're in manufacturing, construction, research, or any other industry, Workshop Cranes adapt to your needs. Their versatility means you can tackle a wide range of tasks with a single machine.

- Longevity and Value: Workshop Cranes are built to last. When properly maintained, they provide a long service life, ensuring a great return on your investment.

- Safety: Safety is paramount, and Workshop Cranes are equipped with advanced safety features to protect your personnel and materials during operations.

- Customization: Tailoring Workshop Cranes to your unique requirements is not just possible; it's our expertise. We work closely with you to provide crane solutions that precisely fit your needs.

- Cleanroom Compatibility: If you operate in cleanroom environments, our Workshop Cranes are designed to meet the strictest cleanliness and contamination control standards.

- Reliability: Trust in the reliability of our Workshop Cranes. They are engineered with durability in mind, reducing downtime and maintenance costs.

By choosing us as your Workshop Crane partner, you're not only investing in high-quality equipment but also gaining a partner committed to your success. We stand by our promise to deliver crane solutions that empower your business, streamline your operations, and contribute to your growth.

In conclusion, Workshop Cranes are more than machines; they are enablers of progress, precision, and efficiency. They are the silent heroes that keep your operations running smoothly. Whether you're in manufacturing, construction, research, or any other industry, Workshop Cranes have a role to play in elevating your success.

Get your workshop crane & workshop hoist

For sale is a workshop crane. Garage material handling cranes include garage bridge cranes, garage overhead cranes, workshop gantry cranes, and workshop jib cranes. Workshop Cranes of various types are available for purchase at a reasonable price. Now is the time to get your workshop crane. Get more information on the workshop crane by contacting us right now.