Overhead Cranes for All Types of Billets Handling in Steel Mill

Steel Mill Billet Handling Overhead Crane Practical Guide: All Types of Overhead Cranes & Below Hook Devices for Steel Billet Production and Handling. Click!

Category: Steel

Your Trusted Overhead Crane Manufacturer & Supplier

Overhead Cranes for All Types of Billets Handling, Your Billet Crane

Practical Guide: Overhead Cranes & Below Hook Devices for Steel Billet Production and Handling

In the world of steel production, where strength, precision, and efficiency are paramount, the role of overhead cranes and below-hook devices cannot be overstated. These industrial workhorses are the unsung heroes that ensure the seamless handling of steel billets, a critical step in the production of a wide range of steel products.

Defining Overhead Cranes

Let's begin by understanding what overhead cranes are and why they are indispensable in the steel manufacturing process. At its core, an overhead crane is a complex system of hoists and trolleys that move along elevated tracks, enabling the lifting and transportation of heavy loads within a defined area. These cranes are commonly referred to as EOT cranes, which stands for Electric Overhead Travel cranes.

The Significance of Billet Handling in Steel Production

Now, let's delve into the significance of billet handling within the realm of steel production. Billets are intermediate steel products that serve as the raw material for a multitude of downstream manufacturing processes. They come in various shapes and sizes, each tailored to meet specific industry needs. The types of billets include square billets, round billets, blooms, slabs, ingots, continuous casting billets, specialty billets, and extrusion billets. These versatile building blocks form the foundation upon which countless steel products are created, from sturdy I-beams to slender wires and everything in between.

Understanding the Types of Billets

- 1. Square Billets: These billets boast a square cross-section and are often employed in processes like hot rolling to produce various steel products, including bars, rods, and wire.

- 2. Round Billets: With a circular cross-section, round billets are used to create products such as pipes, tubes, and round bars.

- 3. Blooms: Blooms are larger, square, or rectangular billets typically used in heavy forging and rolling processes to produce larger structural components like I-beams, rails, and large-diameter pipes.

- 4. Slabs: Slabs, on the other hand, have a wide width-to-height ratio and are used in hot rolling mills to produce steel sheets, coils, and plates.

- 5. Ingots: Though less common, ingots play a role in traditional steelmaking processes. These irregularly shaped initial products can be further processed into billets or other forms.

- 6. Continuous Casting Billets: In modern steel production, continuous casting is a common method. Continuous casting billets have a specific shape suitable for this process, featuring rounded or square cross-sections that are continuously cast into long lengths, which are then cut into shorter billet-sized pieces.

- 7. Specialty Billets: Depending on the intended end use, steel producers may create specialty billets with specific dimensions and chemical compositions tailored for particular industries or applications, such as automotive, construction, or aerospace.

- 8. Extrusion Billets: These billets are designed for extrusion processes, where steel is forced through a die to create products with a consistent cross-sectional shape, such as extruded profiles and shapes.

Understanding the diversity of billets is crucial because the type of billet used profoundly impacts the manufacturing process and the final steel product's quality and characteristics.

In the forthcoming sections of this practical guide, we will explore the various types of overhead cranes and their custom configurations tailored to the specific needs of billet handling. From bridge cranes to gantry cranes, each type serves a unique purpose in ensuring the seamless flow of billets through the steel production process. Moreover, we will delve into the world of below-hook devices, the unsung heroes that complement overhead cranes, enhancing their capabilities and efficiency in billet handling. So, join us on this journey through the steel mill, where precision and strength combine to shape the world of steel.

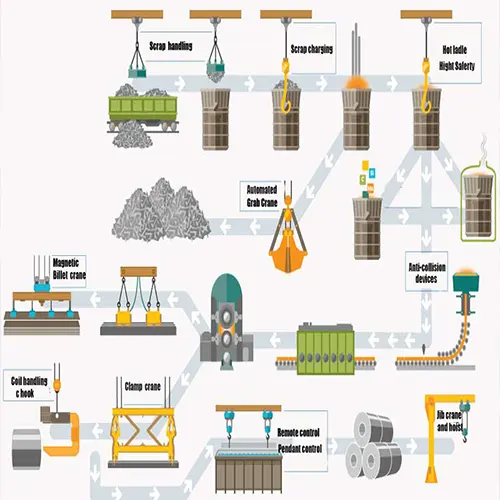

Types of Overhead Cranes for Billet Production & Handling

Now that we have a solid grasp of the importance of billet handling in steel production, let's dive into the world of overhead cranes. These mechanical marvels are the backbone of material handling in steel mills and plants, ensuring that billets are moved efficiently, safely, and precisely. In this section, we'll explore the different types of overhead cranes tailored for billet handling.

Bridge Cranes (EOT Cranes - Electric Overhead Travel Cranes)

- Tailored Crane Design & Configuration: Bridge cranes are highly adaptable and can be customized to suit specific requirements. They come in single or double beam configurations, with lifting capacities and spans tailored to the facility's needs.

- Crane Features & Benefits: Bridge cranes provide precise and efficient movement of billets within the production area. They can be equipped with various lifting attachments, such as hooks, magnets, and specialized billet handling devices. Their ability to travel along parallel runways provides excellent coverage and flexibility in billet handling.

- Commonly Used Applications: Bridge cranes are workhorses in steel mills and billet production facilities. They play integral roles in various stages of the steelmaking process, including loading and unloading from furnaces or casting areas, as well as storage and transportation within the facility.

- Typical Below Hook Devices: Bridge cranes can be paired with a range of below-hook devices, including C-hooks, electromagnets, and specialized billet lifting attachments. These devices ensure secure and efficient billet handling.

Magnet Cranes

- Tailored Crane Design & Configuration: Magnet cranes are designed with a focus on the electromagnetic system, which can be customized to match the size and weight of the billets being handled.

- Crane Features & Benefits: Magnet cranes are ideal for efficiently handling ferrous metal billets, including steel billets. The powerful electromagnets provide a strong grip on the billets, enabling quick and secure transport. They are particularly valuable for processes that require the rapid movement of large quantities of heavy billets.

- Commonly Used Applications: Magnet billet handling cranes are frequently used in steel mills and foundries for tasks such as loading billets into reheating furnaces, transferring them between production stages, and loading them onto trucks or railcars for shipment.

- Typical Below Hook Devices: The primary below-hook device for magnet cranes is, of course, the electromagnet. These magnets come in various sizes and strengths, tailored to the specific billet handling needs.

Grab Bucket Cranes

- Tailored Crane Design & Configuration: Grab bucket cranes are designed with mechanical or hydraulic grab bucket attachments that can be customized to handle various types and sizes of billets.

- Crane Features & Benefits: These cranes excel in handling bulk materials like scrap steel or ore, but they can also be adapted for billet handling. The grab buckets securely grip and release billets, allowing for efficient loading, unloading, and transportation.

- Commonly Used Applications: Grab bucket cranes find application in steel mills for tasks like loading scrap steel into melting furnaces and handling raw materials. They can be adapted for billet handling when billets are part of the production process.

- Typical Below Hook Devices: The star of the show here is the grab bucket attachment itself, which can be configured to suit the specific billet sizes and types encountered in production.

- Tailored Crane Design & Configuration: Gantry cranes come in various configurations, including single and double girder designs, and can be mobile or fixed based on the specific needs of the outdoor yard or facility.

- Crane Features & Benefits: Gantry cranes are well-suited for outdoor areas, such as loading docks and yards, where billets need to be loaded onto trucks or railcars. They offer the advantage of versatility in outdoor environments.

- Commonly Used Applications: Gantry cranes are commonly used for loading and unloading billets from trucks and railcars in outdoor yards of steel mills and distribution centers. They can efficiently handle large billets and heavy loads.

- Typical Below Hook Devices: Gantry cranes can be paired with various below-hook devices, such as spreader beams or C-hooks, depending on the specific billet handling requirements.

- Tailored Crane Design & Configuration: Jib cranes have a vertical mast and a horizontal jib arm that can be configured to rotate to reach specific areas within a limited radius.

- Crane Features & Benefits: Jib cranes are suitable for smaller-scale billet handling tasks within machine shops or confined production areas. They provide flexibility in moving billets within a defined workspace.

- Commonly Used Applications: Jib cranes are frequently used for tasks such as loading billets onto machining centers, positioning billets for processing, or moving billets from one work area to another within smaller manufacturing facilities.

- Typical Below Hook Devices: Jib cranes can be equipped with various below-hook devices, including hooks, hoists, and specialized billet lifting attachments.

- Tailored Crane Design & Configuration: Ladle cranes are designed specifically for handling ladles containing molten metal, and their configuration is adapted to accommodate the size and weight of the ladles.

- Crane Features & Benefits: While not directly involved in billet handling, ladle cranes are vital in the steelmaking process. They safely transport ladles filled with molten metal within the production area, enabling precise pouring into molds or other production equipment.

- Commonly Used Applications: Ladle cranes are an essential component of steelmaking facilities, ensuring the controlled and safe movement of ladles filled with molten steel.

- Typical Below Hook Devices: Ladle cranes are equipped with ladle hooks or specialized ladle lifting attachments to secure and transport the ladles containing molten metal.

These various types of overhead cranes cater to the diverse needs of billet handling within the steel industry. Each crane type offers unique features and benefits, making them suitable for specific applications in steel mills and manufacturing plants. Additionally, their ability to be tailored to precise design and configuration requirements ensures that they can meet the demands of even the most specialized billet handling tasks.

In the upcoming sections of this practical guide, we will further explore each crane type, including their tailored designs, specific features, and benefits, as well as commonly used applications and typical below-hook devices. Whether you're a seasoned steel industry professional or new to the world of billet handling, this guide aims to provide valuable insights into optimizing your material handling processes and enhancing productivity.

Hot sale Capacity of billet handling cranes

5-Ton Overhead Cranes:

- Features:

- Compact and maneuverable design.

- Single girder or double girder configuration.

- Can be equipped with wire rope or chain hoists.

- Precision control for precise billet handling.

- Suitable for indoor use in machine shops and smaller manufacturing facilities.

- Applications:

- Handling smaller billets with ease.

- Transporting billets between different production stages.

- Loading and unloading materials and products.

- Ideal for light to medium-duty billet handling tasks.

10-Ton Overhead Cranes:

- Features:

- Versatile design for a wide range of billet sizes.

- Available in both single and double girder configurations.

- Efficient and reliable lifting mechanisms.

- Robust construction for durability.

- Suitable for both indoor and outdoor use.

- Applications:

- Handling various billet sizes and weights.

- Loading and unloading materials in mid-sized steel mills and manufacturing plants.

- Transporting billets within the production facility.

- Suitable for light to medium-duty billet handling needs.

20-Ton Overhead Cranes:

- Features:

- High lifting capacity for heavier billets.

- Typically configured with double girders for added strength.

- Precise control for safe handling.

- Designed for heavy-duty billet handling applications.

- Can be customized for specific facility requirements.

- Applications:

- Handling heavy billets in larger steel mills.

- Loading and unloading materials in heavy manufacturing environments.

- Transporting larger billets within the facility.

- Ideal for heavy-duty billet handling tasks.

30-Ton Overhead Cranes:

- Features:

- Robust construction for heavy lifting.

- Excellent load control and stability.

- Can have advanced safety features.

- Customizable for specific production needs.

- Suitable for continuous operation.

- Applications:

- Handling very heavy billets with ease.

- Frequent use in facilities with high production volumes.

- Loading and unloading large and heavy billets.

- Transporting billets in larger steel production environments.

50-Ton Overhead Cranes:

- Features:

- Extremely high lifting capacity for massive billets.

- Designed for handling the largest and heaviest billets.

- Advanced control systems for precision.

- Robust and durable construction.

- Suitable for the heaviest billet handling tasks.

- Applications:

- Handling massive and exceptionally heavy billets.

- Commonly used in large steel mills, foundries, and industrial facilities.

- Loading and unloading the heaviest materials and products.

- Essential for handling very large and heavy billets in demanding environments.

These features and applications provide an overview of the capabilities and versatility of overhead cranes of different capacities commonly used in the steel industry for billet handling. The choice of crane capacity depends on the specific needs of the facility and the size and weight of the billets being handled. Contact us to get your customized billet handling by leave a message down below or Contact us vis WhatsApp : + 86 151 3871 1597.

Overhead Cranes for Different Billets Handling

In the steel industry, the diversity of billet types and sizes requires a range of overhead crane solutions to meet specific handling needs. Let's explore how different types of overhead cranes are tailored for handling various types of billets, from square billets to extrusion billets.

Square Billets Handling

- Tailored Crane Design & Configuration: Overhead cranes for square billets are designed to accommodate the dimensions and weights of these billets. The crane's span and lifting capacity are customized to ensure efficient handling.

- Crane Features & Benefits: These cranes offer precise control and flexibility when moving square billets. They can be equipped with specialized lifting attachments, ensuring a secure grip on the billets.

- Commonly Used Applications: Square billets are often used in processes like hot rolling to produce steel bars, rods, and wire. Overhead cranes for square billets are instrumental in loading and unloading these billets from various production stages.

- Typical Below Hook Devices: The below-hook devices commonly used for square billets include, billet clamp, electromagnetic lifting devices, and specialized billet lifting attachments designed for square billet handling.

Round Billets Handling

- Tailored Crane Design & Configuration: Cranes for round billets are configured to safely handle the circular shape of these billets. Their lifting capacity and span are adjusted accordingly.

- Crane Features & Benefits: The design of these cranes allows for efficient and secure handling of round billets. They are equipped with attachments that ensure a firm grip on the billets, preventing any damage during transport.

- Commonly Used Applications: Round billets are essential in the production of steel pipes, tubes, and round bars. Overhead cranes for round billets are utilized for transferring these billets between various stages of the manufacturing process.

- Typical Below Hook Devices: Below-hook devices for round billets include specialized lifting attachments, clamps, tongs and magnetic lifting devices designed to handle the unique shape and characteristics of round billets.

Bloom Billets Handling

- Tailored Crane Design & Configuration: Bloom billets are larger and heavier, requiring cranes with substantial lifting capacities and spans. These cranes are engineered to handle the dimensions of bloom billets.

- Crane Features & Benefits: The robust construction of these cranes allows for the safe and efficient handling of bloom billets, which are typically used in heavy forging and rolling processes.

- Commonly Used Applications: Bloom billets find their purpose in the production of larger structural components like I-beams, rails, and large-diameter pipes. Overhead cranes for bloom billets play a crucial role in loading, unloading, and positioning these heavy billets.

- Typical Below Hook Devices: Specialized lifting attachments, such as clamps, grippers and customized lifting devices, are commonly used for handling bloom billets. These attachments are designed to securely grip the billets during transport.

Slabs Handling

- Tailored Crane Design & Configuration: Cranes for slabs are designed with a focus on handling rectangular billets with a wide width-to-height ratio. They are configured to safely and efficiently move slabs of various sizes.

- Crane Features & Benefits: The design of these cranes ensures the stability and precise positioning of slabs. They are commonly used in hot rolling mills for producing steel sheets, coils, and plates.

- Commonly Used Applications: Slabs are crucial in the production of flat steel products. Overhead cranes for slabs play a pivotal role in transporting slabs within the hot rolling mill, enabling the production of high-quality steel sheets and plates.

- Typical Below Hook Devices: Below-hook devices for slabs often include specialized lifting attachments, clamps, and magnetic lifting devices designed to securely grip and handle slabs.

Ingots Handling

- Tailored Crane Design & Configuration: Cranes for ingots are adapted to handle irregularly shaped initial products in the steel casting process. Their configurations accommodate the unique shapes of ingots.

- Crane Features & Benefits: While less common than other billet forms, ingots are sometimes used in traditional steelmaking processes. Overhead cranes for ingots facilitate their safe movement within the facility.

- Commonly Used Applications: Ingots are typically the initial product in the steel casting process, and they can be further processed into various forms, including billets. Overhead cranes for ingots assist in the transportation of these raw materials within the production area.

- Typical Below Hook Devices: Below-hook devices for ingots may include lifting attachments specifically designed to handle irregularly shaped ingots safely.

Continuous Casting Billets Handling

- Tailored Crane Design & Configuration: Overhead cranes for continuous casting billets are designed to handle long lengths of continuously cast steel. Their configurations ensure efficient handling of these billet-sized pieces.

- Crane Features & Benefits: Continuous casting is a modern steel production method, and these cranes are integral to the process. They transport the continuously cast billets for further processing.

- Commonly Used Applications: Continuous casting billets have a rounded or square cross-section and are continuously cast into long lengths. Overhead cranes for continuous casting billets move these pieces to the cutting and processing areas.

- Typical Below Hook Devices: Below-hook devices for continuous casting billets can include specialized lifting attachments designed to securely handle the unique shape and length of these billets.

Specialty Billets Handling

- Tailored Crane Design & Configuration: Specialty billets may come in various shapes and sizes. Cranes designed for handling specialty billets are adaptable to accommodate these specific dimensions.

- Crane Features & Benefits: Specialty billets are often tailored for particular industries or applications, such as automotive or aerospace. Overhead cranes for specialty billets provide the flexibility required to handle these unique products.

- Commonly Used Applications: Specialty billets are utilized in industries where precise dimensions and chemical compositions are crucial. Overhead cranes for specialty billets are employed in transporting these billets within the facility for specialized processing.

- Typical Below Hook Devices: Below-hook devices for specialty billets can vary widely, depending on the unique requirements of the billets and the industries they serve.

Extrusion Billets Handling

- Tailored Crane Design & Configuration: Extrusion billets are designed for specific extrusion processes. Cranes for handling extrusion billets are configured to efficiently move and position these billets for extrusion.

- Crane Features & Benefits: These cranes are essential for the extrusion process, where steel is forced through a die to create products with a consistent cross-sectional shape, such as extruded profiles and shapes.

- Commonly Used Applications: Extrusion billets are used to create products with precise cross-sectional shapes. Overhead cranes for extrusion billets assist in positioning and transporting these billets within the extrusion process.

- Typical Below Hook Devices: Below-hook devices for extrusion billets are designed to facilitate the handling and positioning of billets within the extrusion equipment.

- Understanding the specific requirements and characteristics of each type of billet is crucial when selecting the appropriate overhead crane for your steel production facility. These tailored cranes ensure efficient, safe, and precise handling of billets, ultimately contributing to the quality of the final steel products.

Types of Below Hook Devices for Different Billets Handling

Billet Tongs:

- Features: Billet tongs consist of two curved arms with gripping mechanisms to secure square or rectangular billets from both sides. They can often be customized with various jaw designs for different billet sizes.

- Applications: Billet tongs are suitable for handling square or rectangular billets and are widely used in steel mills, forging shops, and other manufacturing operations.

- Typical used for handling billets (Billet types, Sizes & Weight): Billet tongs are versatile and can handle various types of billets, including square, rectangular, and round shapes, across a range of sizes and weights.

Magnet Lifters:

- Features: Magnet lifters use powerful electromagnetic systems to lift and transport ferrous metal billets. They offer a secure grip on the billet for efficient handling.

- Applications: Magnet lifters are commonly used in steel mills, foundries, and manufacturing facilities where ferrous billets, such as steel billets, need to be moved.

- Typical used for handling billets (Billet types, Sizes & Weight): Magnet lifters are ideal for handling ferrous billets of various sizes and weights.

Grabs and Clamps:

- Features: Grabs and clamps have adjustable arms or jaws that can be customized to grip and lift various types of materials, including billets.

- Applications: Grabs and clamps are versatile and can be adapted for billet handling in steel mills and manufacturing facilities.

- Typical used for handling billets (Billet types, Sizes & Weight): Grabs and clamps can handle a wide range of billet types, sizes, and weights.

Spreader Beams:

- Features: Spreader beams are horizontal lifting devices with multiple attachment points. They distribute the load evenly when lifting and handling heavy materials.

- Applications: Spreader beams are often used in conjunction with other lifting devices or overhead cranes to handle large and heavy billets.

- Typical used for handling billets (Billet types, Sizes & Weight): Spreader beams enhance the capacity of lifting equipment and can handle larger and heavier billets effectively.

Specialty Lifters:

- Features: Specialty lifters are custom-designed lifting devices tailored to specific applications or unique billet handling requirements.

- Applications: Specialty lifters are used when standard lifting devices may not meet the specialized needs of a particular billet handling task.

- Typical used for handling billets (Billet types, Sizes & Weight): Specialty lifters are adaptable to handle various billet types, sizes, and weights based on their customized design.

These below hook devices play a crucial role in efficiently handling different types, sizes, and weights of billets in steel production and related industries. The choice of the right below hook device depends on the specific billet handling needs and the type of materials being transported.

Clamp Cranes:

- Features: Clamp cranes are equipped with specialized clamping mechanisms that can securely grip and lift various types of materials, including billets. These clamps can be customized to match the shape and size of the billets being handled.

- Applications: Clamp cranes are versatile and find applications in steel mills, foundries, and manufacturing facilities for efficiently handling different types of billets.

- Typical used for handling billets (Billet types, Sizes & Weight): Clamp cranes are suitable for handling various billet types, including square, rectangular, round, and specialty shapes, across a range of sizes and weights. They offer flexibility in billet handling.

Tong Cranes:

- Features: Tong cranes are designed with tongs or grippers attached to their hooks, allowing them to lift and transport billets securely. The tongs can often be customized to match different billet sizes.

- Applications: Tong cranes are commonly used in steel mills, forging shops, and manufacturing facilities for handling billets, particularly square and rectangular billets.

- Typical used for handling billets (Billet types, Sizes & Weight): Tong cranes are well-suited for handling square and rectangular billets of various sizes and weights. They provide a stable and controlled grip for efficient billet handling.

Both clamp cranes and tong cranes offer reliable solutions for billet handling in steel production and related industries. They provide the necessary grip and control to safely move different types of billets to their desired locations within a facility. The choice between these devices depends on specific billet handling requirements and preferences.

Selecting the Right Overhead Crane for Your Needs

Choosing the right overhead crane for your steel billet handling needs is a critical decision that can significantly impact the efficiency and safety of your operations. In this section, we will explore the key factors to consider when selecting an overhead crane, how to match crane types to billet handling requirements, and gain insights into understanding crane costs and pricing.

Factors to Consider When Choosing an Overhead Crane

Selecting the ideal overhead crane involves a thoughtful evaluation of several essential factors:

- 1. Billet Type and Characteristics: The type, size, weight, and shape of the billets you handle will determine the crane's specifications. Consider whether you handle square billets, round billets, slabs, or other specialty billets.

- 2. Production Volume: Assess your facility's production volume and the frequency of billet handling. High production volumes may require cranes with higher lifting capacities and faster speeds.

- 3. Space and Facility Layout: The layout of your facility, including ceiling height and available floor space, plays a crucial role in selecting the crane's configuration and span.

- 4. Safety Requirements: Ensure that the chosen crane complies with safety regulations and standards. Safety features like overload protection and emergency stop systems are vital.

- 5. Environmental Conditions: Consider the operating environment, including temperature, humidity, and the presence of corrosive materials, as these factors can affect crane durability.

- 6. Automation and Integration: Determine whether you require automation features, such as programmable logic controllers (PLCs) and integration with your facility's management systems.

- 7. Maintenance and Service Accessibility: Easy access for maintenance and servicing is essential to minimize downtime and ensure crane longevity.

Matching Crane Types to Billet Handling Requirements

Different billet types and handling tasks call for specific crane types:

- For handling square billets, bridge cranes with specialized billet lifting attachments are commonly used.

- Round billets are efficiently handled by cranes with clamps, specialized lifting attachments, or magnetic lifting devices.

- Bloom billets, due to their size and weight, often require gantry cranes with high lifting capacities.

- Slabs are best handled with overhead cranes equipped with below-hook devices designed for slab gripping.

- Ingots may be handled using jib cranes or overhead cranes with customized lifting attachments.

- Continuous casting billets benefit from bridge cranes with the ability to handle long lengths.

- Specialty billets may require custom-designed cranes based on their unique characteristics.

- Extrusion billets are best handled with cranes that facilitate their precise positioning within extrusion equipment.

Understanding Crane Costs and Pricing

When assessing the cost of an overhead crane, it's essential to consider not only the initial purchase price but also the total cost of ownership, including:

- Purchase Price: The upfront cost of the crane, which varies based on its specifications and features.

- Installation Costs: Expenses associated with crane installation, including labor, materials, and any modifications to the facility.

- Operating Costs: Ongoing expenses for crane operation, including electricity, maintenance, and repairs.

- Downtime Costs: The cost of production losses due to crane downtime or maintenance.

- Lifecycle Costs: Consider the crane's expected lifespan and the costs associated with replacement or major component repairs.

- Safety Costs: Investments in safety features and training to ensure safe crane operation.

It's crucial to work closely with crane manufacturers and suppliers who can provide detailed cost breakdowns, including long-term operating and maintenance expenses. This comprehensive approach allows you to make an informed decision that aligns with your budget and operational requirements.

Overhead Crane Maintenance and Safety

Ensuring the ongoing reliability and safety of your overhead crane is paramount for seamless billet handling in steel production. In this section, we will emphasize the importance of regular maintenance, discuss essential safety measures for billet handling, and address common concerns and FAQs about crane safety.

Importance of Regular Maintenance

- Regular maintenance is the backbone of crane reliability and longevity. Here's why it's crucial:

- 1. Safety: Well-maintained cranes are safer to operate, reducing the risk of accidents and injuries.

- 2. Minimized Downtime: Preventive maintenance helps identify and address issues before they lead to costly breakdowns and production delays.

- 3. Extended Lifespan: Proper care and maintenance can significantly extend the lifespan of your overhead crane, maximizing your investment.

- 4. Optimal Performance: Routine maintenance ensures that your crane operates at its peak performance, enhancing efficiency.

Maintenance tasks may include:

- Visual Inspections: Regular visual checks for signs of wear, damage, or loose components.

- Lubrication: Proper lubrication of moving parts to reduce friction and wear. - Electrical System Inspections: Ensuring that electrical connections and components are in good working condition.

- Load Testing: Periodic load testing to confirm that the crane can handle its specified capacity safely.

- Replacement of Worn Parts: Timely replacement of worn or damaged components.

Safety Measures for Billet Handling

Safety is non-negotiable when it comes to billet handling with overhead cranes. Implement these essential safety measures:

- 1. Operator Training: Ensure that crane operators receive comprehensive training and certification to operate the equipment safely.

- 2. Load Limits: Never exceed the crane's specified load capacity, and always verify the weight of the billets being lifted.

- 3. Load Securement: Properly secure billets to the lifting attachment to prevent accidents or drops during handling.

- 4. Clear Communication: Establish clear communication protocols between operators and ground personnel to avoid accidents.

- 5. Safety Devices: Ensure that safety devices, such as limit switches and emergency stop buttons, are functioning correctly.

- 6. Regular Inspections: Schedule regular inspections by qualified technicians to identify and address potential safety hazards.

- 7. Fall Protection: Implement fall protection measures for personnel working near the crane, including guardrails and safety harnesses.

Common Concerns and FAQs About Crane Safety

Here are answers to some common concerns and frequently asked questions about crane safety:

Q: How often should overhead cranes undergo maintenance?

A: The frequency of maintenance depends on usage, but cranes should typically receive regular inspections and maintenance, with more intensive inspections performed annually or semi-annually.

Q: Can an overhead crane lift loads beyond its rated capacity temporarily?

A: No, it's crucial to never exceed the crane's rated capacity, even for short durations, as it can lead to structural damage and accidents.

Q: What should I do if I notice a safety issue during crane operation?

A: Immediately stop crane operations and report the issue to a supervisor or maintenance team. Safety should always come first.

Q: Are there any specific safety considerations for working in extreme environments, such as high temperatures or corrosive atmospheres?

A: Yes, extreme environments can accelerate wear and corrosion. It's essential to select cranes and materials designed for these conditions and implement regular inspections and maintenance tailored to the environment.

By prioritizing regular maintenance and adhering to strict safety measures, you can ensure the safe and efficient operation of your overhead crane in billet handling applications.

Success Stories: Industrial Applications of Overhead Cranes

Real-world examples of how overhead cranes have been utilized in various industries provide valuable insights into their versatility and effectiveness. In this section, we will explore success stories that showcase the diverse industrial applications of overhead cranes and how they contribute to enhanced efficiency and productivity.

Real-world Examples of Overhead Crane Use

- 1. Steel Manufacturing: In a steel mill, overhead cranes are the workhorses of billet handling. They efficiently transport steel billets from the casting area to rolling mills, ensuring a continuous flow of material for production. By doing so, they contribute to the seamless operation of the entire steel manufacturing process.

- 2. Automotive Production: Automotive assembly lines rely on overhead cranes to lift and position heavy vehicle components, such as engine blocks and chassis. These cranes facilitate precise and efficient assembly, reducing production time and ensuring product quality.

- 3. Aerospace Manufacturing: Overhead cranes play a crucial role in aerospace manufacturing facilities by handling large and complex aircraft components. They enable the precise positioning of aircraft fuselages, wings, and engines during assembly, ensuring the structural integrity and safety of the aircraft.

- 4. Shipbuilding: Building massive ships requires the use of heavy materials and components. Overhead cranes are instrumental in shipyards, where they move and position ship sections and equipment with precision. This accelerates ship construction and minimizes downtime.

- 5. Warehouse and Logistics: Warehouses and distribution centers employ overhead cranes for material handling tasks, such as loading and unloading cargo containers, stacking pallets, and moving goods within the facility. This enhances the efficiency of supply chain operations.

Achieving Efficiency and Productivity in Different Industries

The success stories mentioned above underscore the significant impact overhead cranes have on efficiency and productivity across diverse industries. Here's how they contribute to success:

- Streamlined Operations: Overhead cranes facilitate the smooth movement of materials, reducing manual handling and streamlining production or logistics processes.

- Reduced Downtime: Cranes enable rapid and precise positioning, reducing downtime associated with material handling and assembly.

- Enhanced Safety: With proper training and safety measures in place, overhead cranes minimize the risk of accidents and injuries, promoting a safer work environment.

- Cost Savings: By automating material handling tasks and improving efficiency, overhead cranes contribute to cost savings in terms of labor, energy, and production time.

- Customization: Overhead cranes can be customized to meet the unique needs of each industry, from specialized lifting attachments to automation features tailored to specific applications.

These success stories illustrate that overhead cranes are not just tools; they are critical assets that drive efficiency, safety, and productivity across various industrial sectors. As you explore their potential applications in your industry, consider how they can be tailored to meet your specific needs and enhance your operational capabilities.

Expert Insights: Answers to Your Overhead Crane Questions

In the final part of our practical guide, we delve into expert insights to address common questions and concerns related to overhead crane installation, operation, troubleshooting, and maintenance. Whether you are a seasoned crane operator or new to the world of overhead cranes, this section will provide valuable knowledge to optimize your crane's lifespan and performance.

FAQs on Overhead Crane Installation and Operation

Q1: How do I determine the right type and capacity of an overhead crane for my facility?

A1: Choosing the right overhead crane involves assessing your facility's specific needs, including the size and weight of the loads to be handled. It's crucial to work with crane experts who can perform a detailed analysis to recommend the most suitable crane type and capacity.

Q2: What safety measures should be in place for crane operators?

A2: Crane operators must receive thorough training and certification. Safety measures include regular equipment inspections, load capacity adherence, proper load attachment, and clear communication protocols with ground personnel.

Q3: Can overhead cranes be automated for specific tasks?

A3: Yes, overhead cranes can be equipped with automation features such as programmable logic controllers (PLCs) and remote control systems to perform repetitive tasks with precision. Automation enhances efficiency and reduces the risk of human error.

Troubleshooting Common Crane Issues

Issue 1: Crane Jerking or Vibrating During Operation

- Possible Causes: Misalignment of wheels, worn-out components, or electrical issues.

- Solution: Schedule a comprehensive inspection to identify and address the root cause. This may involve realigning wheels, replacing worn parts, or fixing electrical connections.

Issue 2: Unusual Noises During Crane Movement

- Possible Causes: Lubrication issues, loose components, or worn-out bearings.

- Solution: Regularly lubricate moving parts, tighten loose components, and replace any worn-out bearings to eliminate noise.

Issue 3: Crane Drifting or Swaying When Stationary

- Possible Causes: Improper brake adjustment or misalignment.

- Solution: Adjust the brakes correctly, and if misalignment is the issue, realign the crane's components.

Maximizing the Lifespan of Your Overhead Crane

To ensure a long and productive lifespan for your overhead crane:

- 1. Regular Maintenance: Stick to a scheduled maintenance program, including visual inspections, lubrication, and load testing.

- 2. Timely Repairs: Address any issues promptly, rather than letting them worsen over time.

- 3. Operator Training: Continuously train and retrain operators to keep them updated on safety and operational procedures.

- 4. Load Awareness: Always operate within the crane's rated capacity and pay attention to load sway during lifting.

- 5. Documentation: Maintain detailed records of inspections, maintenance, and repairs for reference.

By following these expert insights and best practices, you can maximize the efficiency, safety, and lifespan of your overhead crane, ensuring it continues to be a valuable asset for your operations.

Conclusion: Elevate Your Billet Handling with the Right Crane

In conclusion, your choice of overhead crane plays a pivotal role in optimizing billet handling efficiency, safety, and productivity in steel production and various other industries. Throughout this practical guide, we've delved into the world of overhead cranes, explored their diverse applications, and shared expert insights on their installation, operation, troubleshooting, and maintenance.

Let's recap the key takeaways:

1. Overhead Crane Types and Their Benefits

We've introduced you to several types of overhead cranes tailored for specific applications:

- Bridge Cranes (EOT Cranes): These versatile cranes offer precise and efficient movement of billets, customizable to your facility's needs.

- Magnet Cranes: Equipped with powerful electromagnets, these cranes are ideal for handling ferrous metal billets with speed and precision.

- Grab Bucket Cranes: Designed with mechanical or hydraulic grab bucket attachments, they excel in handling bulk materials, including billets.

- Gantry Cranes: Perfect for outdoor yards, gantry cranes efficiently load and unload billets from trucks and railcars.

- Jib Cranes: In smaller-scale applications, jib cranes provide flexibility in moving billets within a defined workspace.

- Automated Guided Vehicles (AGVs): AGVs offer automation for billet transport, reducing the need for manual handling.

- Ladle Cranes: While not directly involved in billet handling, they are essential for transporting and pouring molten metal in steelmaking.

2. Optimizing Billet Handling Efficiency

To optimize billet handling efficiency, consider the following:

- Selecting the Right Crane: Match the crane type and capacity to your facility's specific needs, accounting for load size and weight.

- Safety First: Prioritize safety measures, including operator training, equipment inspections, and load capacity adherence.

- Automation Potential: Explore automation features to enhance efficiency, reduce downtime, and minimize human error.

3. Regular Maintenance and Safety

Regular maintenance is paramount to ensure crane longevity. Implement safety measures, conduct inspections, and promptly address any issues to maintain a safe working environment.

4. Success Stories: Industrial Applications of Overhead Cranes

Real-world examples have demonstrated how overhead cranes significantly impact efficiency, safety, and productivity across various industries. Whether in steel manufacturing, automotive production, aerospace, shipbuilding, or logistics, overhead cranes streamline operations and reduce downtime.

5. Expert Insights: Answers to Your Overhead Crane Questions

We've addressed frequently asked questions about overhead crane installation, operation, and maintenance. By following best practices and expert insights, you can maximize the efficiency and lifespan of your overhead crane.

Now, armed with a comprehensive understanding of overhead cranes and their role in billet handling, you have the tools and knowledge to elevate your operations. To explore tailored overhead crane solutions, consult with crane experts who can guide you in selecting, operating, and maintaining the right crane for your unique needs.

Thank you for embarking on this journey through the world of overhead cranes with us. As you strive to optimize billet handling efficiency, we are here to support you every step of the way.

Main Projects

Related Products

Latest project

32/5 Ton Overhead Crane Sale in India: Case Study

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch