Overhead Crane for Slab Handling in Steel Mill, Slab Clamp Crane

Overhead crane for slab handling. Custom bridge crane for steel mill slab handling with capacity 5 ton - 50 ton. Get custom slab clamp crane & eot crane.

Category: Steel

Your Trusted Slab Handling Overhead Crane Manufacturer & Supplier

Overhead Crane for Slab Handling in Steel Mill, Slab Clamp Crane

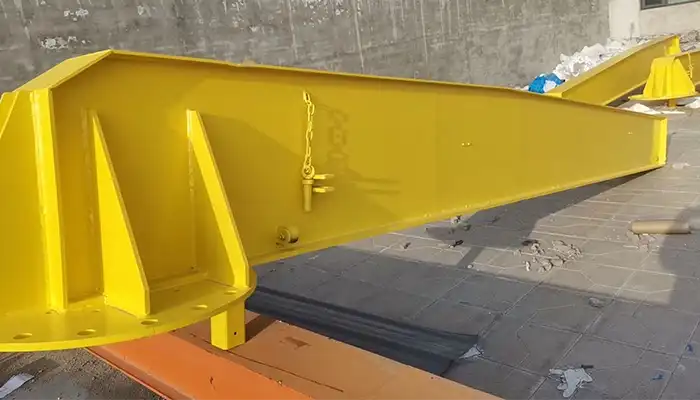

Custom Bridge Crane for Steel Mill Slab Handling with Capacity 5 Ton - 50 Ton

Overhead crane for slab handling. Custom bridge crane for steel mill slab handling with capacity 5 ton - 50 ton. Get custom slab clamp crane & eot crane.

An overhead crane, also known as a bridge crane or a suspended crane, is a powerful piece of material handling equipment that operates on an elevated track or runway system. It is designed to lift and transport heavy loads horizontally within a specific area. Overhead cranes are particularly well-suited for tasks that involve moving heavy or bulky materials, such as steel slabs, with precision and safety.

The Role of Overhead Cranes in Steel Slab Handling

When it comes to the steel industry, the role of overhead cranes cannot be overstated. Steel slabs are a fundamental intermediate product in steel manufacturing, and their handling requires specialized equipment due to their size, weight, and unique properties. Overhead cranes are the workhorses of steel slab handling operations, enabling the safe and efficient movement of slabs from one location to another within a facility.

The primary functions of overhead cranes in steel slab handling include:

- Transportation: Overhead cranes are used to transport steel slabs from one part of the production process to another. This can involve moving slabs from a storage area to a processing line, transferring them between machines, or loading them onto trucks or railcars for distribution.

- Positioning: Precision is key in steel slab handling. Overhead cranes are equipped with advanced controls that allow operators to position slabs with great accuracy, ensuring they are placed exactly where they are needed for further processing.

- Safety: Safety is a top priority in steel manufacturing, and overhead cranes are designed with safety features to protect both the operator and the valuable cargo. These features include anti-collision systems, overload protection, and emergency stop mechanisms.

- Efficiency: Overhead cranes streamline the material handling process, reducing the time and labor required to move steel slabs. This increased efficiency leads to higher productivity and cost savings.

Safety Considerations

Safety is an integral part of overhead crane operations, especially when handling heavy and potentially hazardous materials like steel slabs. Operators must undergo rigorous training to operate cranes safely, and strict safety protocols are enforced.

Some key safety considerations when working with overhead cranes for steel slab handling include:

- Regular equipment inspections and maintenance to ensure safe operation.Proper load weight calculations to prevent overloading.Adequate training for crane operators to operate the equipment safely.Clear communication between operators and ground personnel.Adherence to safety standards and regulations specific to crane operations.

In the world of steel slab handling, overhead cranes are indispensable tools that combine power, precision, and safety. Their ability to efficiently move, position, and transport steel slabs makes them essential in the steel manufacturing and processing industry. As we continue our journey through the world of overhead cranes, we will explore the different types of cranes, their features, and their applications in steel slab handling in greater detail.

Types of Overhead Cranes: Navigating the World of Bridge Cranes

Bridge Cranes

As we venture deeper into the world of double girder overhead cranes for steel slab handling, we encounter various types of cranes, each with its own set of features and applications. One of the most prominent among them is the bridge crane. In this section, we'll explore bridge cranes, their key attributes, and their pivotal role in the efficient handling of steel slabs.

Bridge cranes, also known as overhead bridge cranes or overhead traveling cranes, are a popular choice in industrial settings for their ability to handle heavy loads with precision and ease. These cranes are aptly named for the horizontal bridge-like structure that spans the working area. The bridge is supported by rails on either side, allowing the crane to move along the length of the facility.

Components of a Bridge Crane

- Bridge: The horizontal beam that spans the width of the facility.

- Hoist: The lifting mechanism that suspends from the bridge and carries the load.

- Trolley: The component that moves horizontally along the bridge, positioning the hoist precisely.

- End Trucks: The wheeled structures that support the bridge and allow it to move along the runway rails.

- Runway Rails: The rails or tracks along which the bridge travels.

- Features and Benefits

Bridge cranes are favored in steel slab handling for several compelling reasons:

- High Load Capacity:Bridge cranes are designed to handle heavy loads, making them ideal for the robust demands of the steel industry. They can lift and transport steel slabs of varying sizes and weights with ease.

- Precise Control:Advanced control systems enable operators to position steel slabs with exceptional accuracy. This precision is crucial in processes that require careful alignment and handling.

- Adaptability:Bridge cranes can be customized to suit specific requirements, including varying slab sizes and material types. They are versatile tools that can be tailored to diverse applications.

- Efficiency:These cranes streamline material handling operations, reducing the time and labor needed to move steel slabs. Enhanced efficiency translates into increased productivity and cost savings.

- Safety Features:Safety is paramount in crane operations. Bridge cranes are equipped with safety features such as anti-collision systems, overload protection, and emergency stop mechanisms to protect both operators and valuable cargo.

Applications in Steel Slab Handling

Bridge cranes play a central role in various aspects of steel slab handling within the industry:

- Transportation: They are used to move steel slabs from storage areas to processing lines or from one part of the facility to another. This includes loading and unloading trucks or railcars.

- Positioning: Bridge cranes excel at precisely positioning steel slabs, ensuring they are placed accurately for further processing, such as rolling or cutting.

- Storage: In large steel manufacturing facilities, bridge cranes are often employed for efficient slab storage in designated areas.

- Loading and Unloading: They are crucial for loading steel slabs onto trucks or railcars for distribution, ensuring the safe and secure handling of valuable cargo.

Common Questions About Bridge Cranes

As you navigate the world of bridge cranes for steel slab handling, you might have some questions:

- Q1: What is the typical load capacity of bridge cranes used in steel slab handling?A1: Bridge cranes can be designed with varying load capacities, often ranging from a few tons to several dozen tons, depending on the specific application and facility requirements.

- Q2: Are bridge cranes suitable for outdoor use in steel yards?A2: Yes, bridge cranes can be designed for outdoor use and are often used in steel yards and storage areas.

- Q3: How do bridge cranes ensure safety during operation?A3: Bridge cranes incorporate multiple safety features, including anti-collision systems, load monitoring, emergency stop buttons, and operator training to ensure safe and secure operation.

Bridge cranes have earned their place as indispensable tools in the steel manufacturing industry. Their ability to combine power, precision, and adaptability makes them invaluable for efficiently handling steel slabs and ensuring the smooth flow of operations in steel facilities. As we continue our exploration of overhead cranes, we will dive into other types of cranes, each with its unique features and applications.

Gantry Cranes

In our journey through the world of overhead cranes for steel slab handling, we now turn our attention to gantry cranes. Gantry cranes are heavy-duty, versatile machines that have found their niche in various industries, including the demanding steel manufacturing sector. Let's delve into what makes gantry cranes special, their standout features, and why they are favored for steel slab handling.

Gantry cranes, sometimes referred to as portal cranes, are similar in concept to bridge cranes, but with a crucial distinction—they are not confined to a fixed runway system. Instead, gantry cranes are mounted on sturdy legs or supports that run along tracks on the ground. This design provides them with exceptional mobility and versatility in terms of positioning and reach.

Components of a Gantry Crane

- Gantry Legs: The upright supports that give the crane its stability.

- Bridge: The horizontal beam that spans between the legs and carries the lifting mechanism.

- Hoist: The lifting apparatus suspended from the bridge, which secures and transports the load.

- Trolley: The component that moves horizontally along the bridge, allowing for precise positioning of the hoist.

- Wheels or Tracks: These enable the movement of the gantry crane along the ground.

Key Features and Advantages

Gantry cranes offer several distinct features and advantages that make them a preferred choice for steel slab handling:

- Exceptional Mobility:Gantry cranes can move freely along tracks on the ground, providing them with unmatched flexibility in reaching different areas of the facility.

- High Load Capacity:These cranes are designed for heavy lifting. They can handle substantial loads, making them ideal for steel slabs, which are known for their weight.

- Versatility:Gantry cranes can be customized with various lifting attachments, allowing them to handle different types and sizes of steel slabs.

- Precise Positioning:Advanced control systems ensure precise positioning of steel slabs, which is crucial for operations like rolling, cutting, and stacking.

- No Overhead Runway Required:Unlike bridge cranes, gantry cranes do not necessitate an overhead runway, making them a more cost-effective choice in some scenarios.

Gantry cranes are particularly well-suited for various aspects of steel slab handling within steel manufacturing facilities:

- Transportation: Gantry cranes efficiently transport steel slabs from one location to another, whether it's within a processing area, from a storage yard to a production line, or onto trucks for distribution.

- Positioning: Their precise control allows for accurate placement of steel slabs, ensuring they are in the correct orientation and location for subsequent processing.

- Outdoor Use: Gantry cranes are often employed in outdoor environments, such as steel yards, where their mobility and adaptability shine.

- Stacking and Storage: These cranes are valuable for stacking steel slabs in storage areas, optimizing space utilization.

- Frequently Asked Questions About Gantry Cranes

As you explore the world of gantry cranes, you may have some questions:

- Q1: What are the key differences between gantry cranes and bridge cranes?A1: The primary difference is that gantry cranes are not confined to an overhead runway and move along tracks on the ground. This gives them greater mobility and versatility in terms of reach.

- Q2: Can gantry cranes be used indoors as well?A2: Yes, gantry cranes can be used both indoors and outdoors, making them adaptable to various industrial settings.

- Q3: What safety features are integrated into gantry cranes for steel slab handling?A3: Gantry cranes come equipped with safety features such as anti-collision systems, overload protection, and emergency stop mechanisms to ensure safe operations.

Gantry cranes are powerhouses in the world of steel slab handling. Their ability to combine heavy lifting capacity, mobility, and precision positioning makes them invaluable in steel manufacturing facilities. Whether it's moving, positioning, stacking, or transporting steel slabs, gantry cranes excel at ensuring the smooth flow of operations in the steel industry. Stay with us as we continue our journey to explore more types of overhead cranes and their roles in steel slab handling.

Harnessing Magnetic Power: Magnet Cranes for Steel Slab Handling

Magnetic overhead crane

In our exploration of overhead cranes tailored for steel slab handling, we now venture into the fascinating realm of magnet cranes. These specialized lifting solutions rely on magnetic force to securely transport and position steel slabs. Join us as we delve into the intricacies of magnet cranes, their innovative magnetic lifting technology, and the advantages they offer in steel slab handling.

Magnet Cranes for Steel Slab Handling

Magnet cranes, as the name suggests, are equipped with powerful electromagnets designed specifically for lifting and transporting ferrous materials like steel slabs. Unlike traditional cranes that rely on hooks or clamps, magnet cranes use magnetic force to securely grip and maneuver steel slabs.

How Magnet Cranes Work

The core of a magnet crane's operation lies in its electromagnetic system. When the electromagnet is energized, it generates a strong magnetic field that attracts and holds onto ferrous materials, such as steel slabs. When the magnet is de-energized, the magnetic force diminishes, allowing the crane to release the load.

Magnetic Lifting Technology

Magnet cranes employ cutting-edge magnetic lifting technology that provides several distinct advantages:

- Secure Grip:The powerful magnets ensure a secure and reliable grip on steel slabs, minimizing the risk of accidents or drops during handling.

- Speed and Efficiency:Magnet cranes offer rapid and efficient loading and unloading of steel slabs. The quick attachment and detachment of loads streamline operations.

- Damage Prevention:Since magnet cranes lift materials without direct contact, they reduce the risk of damage to the steel slabs, preserving their quality and integrity.

- Precise Positioning:These cranes allow for precise positioning of steel slabs, ensuring they are placed accurately for further processing or storage.

- Versatility:Magnet cranes are adaptable and can handle a wide range of steel slab sizes and thicknesses, making them versatile tools in steel manufacturing.

Typical Applications and Benefits

Magnet cranes find their niche in various applications within the steel industry, where their unique capabilities shine:

- Steel Slab Transportation: Magnet cranes are ideal for moving steel slabs from storage areas to processing lines or loading them onto trucks and railcars for distribution.

- Precision Handling: They excel at precisely positioning steel slabs during rolling, cutting, and stacking processes, optimizing efficiency.

- Heavy-Duty Operations: Magnet cranes are designed to handle heavy loads, making them invaluable for the robust demands of steel slab handling.

- Safety: Their secure grip and safety features, such as load monitoring and anti-collision systems, enhance workplace safety.

Addressing Magnet Crane FAQs

As you delve into the world of magnet cranes, you might have some questions:

- Q1: Are magnet cranes suitable for outdoor use in harsh weather conditions?A1: Magnet cranes can be designed for outdoor use, but special consideration should be given to protect the electromagnet components from adverse weather.

- Q2: How are the magnetic lifting capacities of these cranes determined?A2: The lifting capacity of a magnet crane depends on factors like the size and strength of the electromagnet, as well as the thickness and surface condition of the steel slabs being lifted.

- Q3: What happens if there is a power failure while lifting a load with a magnet crane?A3: Magnet cranes typically have safety features that ensure the load remains securely attached even in the event of a power failure. This prevents accidental drops.

Magnet cranes offer a captivating blend of technology and efficiency in the world of steel slab handling. Their ability to securely grip and transport steel slabs using magnetic force makes them invaluable tools in steel manufacturing, ensuring both safety and precision in operations. As we continue our journey through overhead cranes, we will explore more specialized crane types and their roles in the steel industry.

A Firm Grip on Efficiency: Grab Bucket Cranes in Steel Slab Handling

Grab Bucket Cranes in Steel Slab Handling

As we continue our journey through the world of overhead cranes for steel slab handling, we now turn our attention to grab bucket cranes. These specialized cranes are equipped with grab mechanisms that allow them to securely grasp and manipulate steel slabs. Join us as we explore the role of grab bucket cranes, their innovative grab mechanism technology, and the advantages they bring to steel slab handling.

Grab bucket cranes are tailored for the precise and efficient handling of materials, including steel slabs, using a specialized grab or clamshell bucket. Unlike other cranes that rely on hooks, magnets, or clamps, grab bucket cranes feature a bucket-like attachment that can open and close, enabling them to grip and release loads as needed.

How Grab Mechanism Works

The core of a grab bucket crane's functionality lies in its grab mechanism technology:

The grab bucket is attached to the crane's hoisting cable.The operator uses controls to open or close the grab bucket.When the grab bucket is closed, it securely clamps onto the load, such as a steel slab.When the grab bucket is opened, the load is released.

Versatile Applications and Advantages

Grab bucket cranes find wide-ranging applications in the steel industry and offer several distinct advantages:

- Efficient Bulk Handling: - These cranes excel in efficiently handling bulk materials, making them ideal for moving multiple steel slabs at once.

- Precise Control: - The grab mechanism allows for precise control during loading and unloading, ensuring accurate placement of steel slabs.

- Handling Varied Loads: - Grab bucket cranes are versatile and can handle different sizes and types of steel slabs, adapting to specific requirements.

- Reduced Spillage: - The grab bucket design minimizes material spillage during handling, which is particularly valuable when working with valuable steel slabs.

- Enhanced Safety: - These cranes often incorporate safety features, such as load monitoring and anti-collision systems, to ensure safe and secure operations.

Common Queries About Grab Bucket Cranes

As you delve into the world of grab bucket cranes, you may have some questions:

- Q1: Are grab bucket cranes suitable for handling steel slabs of varying sizes and shapes?A1: Yes, grab bucket cranes can be customized with different grab bucket designs to handle various sizes and shapes of steel slabs.

- Q2: How does the grab bucket ensure a secure grip on the load?A2: The grab bucket is designed with mechanisms that enable it to securely clamp onto the load when closed, ensuring a firm grip during transport.

- Q3: What is the typical lifting capacity of grab bucket cranes used in steel slab handling?A3: The lifting capacity of grab bucket cranes can vary widely, ranging from a few tons to much higher capacities, depending on the specific crane design and application.

Grab bucket cranes are adept at efficiently managing steel slabs, particularly in scenarios involving bulk materials. Their grab mechanism technology provides precision, control, and adaptability, making them valuable assets in the steel manufacturing industry. As our exploration of overhead cranes continues, we will delve into more specialized crane types and their roles in steel slab handling.

Features and Benefits of Overhead Cranes

- Precision ControlsImportance: Precision is crucial for safety, quality, and efficiency in slab handling.Control Systems: Advanced crane control systems enable precise movements.Advantages: Reduces waste, improves productivity, enhances safety, and saves energy.

- High Load CapacityConsiderations: Cranes must handle a variety of slab sizes and weights.Safety: High load capacity cranes are designed with safety margins and structural integrity.Efficiency: Ensures efficient and safe handling of heavy slabs.

- Customization OptionsTailoring: Customization allows cranes to match specific facility needs.Attachments: Various attachments (hooks, magnets, grab buckets, clamps) suit different slab types.Efficiency: Optimizes workflows, adapts to changing needs, and reduces costs.

- Safety FeaturesPriority: Safety is paramount in crane design.Anti-Collision Systems: Sensors and technology prevent collisions.Operator and Material Safety: Load monitoring, emergency stops, operator training, and maintenance ensure safety.

These concise points highlight the key features and benefits of overhead cranes in steel slab handling.

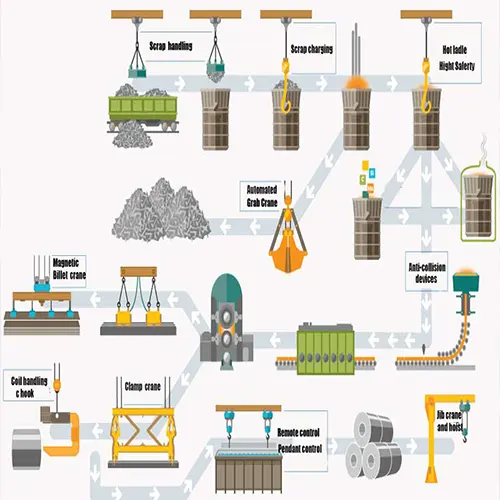

Typical Applications of Overhead Cranes in Steel Slab Handling

overhead crane for steel mill slab handling

gantry crane for steel mill slab handling

Overhead Cranes in Rolling Mill Operations

Rolling mills are the backbone of steel production, where steel slabs undergo the transformation into various shapes and forms. Overhead cranes play a pivotal role in these operations, ensuring the efficient movement of slabs within the mill. Here's how overhead cranes are instrumental in rolling mill operations:

- Slab Transport: Overhead cranes transport steel slabs from storage areas to the rolling mill, ensuring a continuous supply for the rolling process.

- Precise Positioning: Cranes precisely position slabs on the entry table of the rolling mill, ensuring they enter the rolls accurately for proper shaping.

- Roll Change Assistance: Overhead cranes assist in roll changes, where rolls are replaced to accommodate different product specifications.

Enhancing Efficiency in Rolling Processes

Efficiency is paramount in rolling mills to meet production targets and maintain product quality. Overhead cranes contribute to efficiency in several ways:

- Reduced Downtime: Swift and accurate slab handling minimizes downtime, optimizing production output.

- Quality Assurance: Precise positioning and handling prevent damage to slabs, ensuring the quality of the final product.

- Versatility: Overhead cranes are adaptable and can handle various slab sizes and types, accommodating different rolling requirements.

Common Steel Products Produced

Rolling mills produce a wide range of steel products, and overhead cranes are essential for their production:

- Steel Sheets and Coils: Overhead cranes assist in rolling slabs into flat sheets and coils, used in industries like automotive and construction.

- Structural Sections: Cranes handle slabs that are rolled into structural sections for building and infrastructure projects.

- Plates: Thick steel plates are produced for applications in shipbuilding, heavy machinery, and construction.

- Rails: Overhead cranes aid in rolling slabs into rails for the transportation industry.

- Wire Rods: Cranes handle slabs that are rolled into wire rods used in construction and manufacturing.

Rolling mills rely on the precision and efficiency of overhead cranes to transform steel slabs into a wide array of products vital to numerous industries.

Utilizing Cranes for Steel Forging

Forging is a manufacturing process that involves shaping steel slabs through controlled deformation. Overhead cranes play a crucial role in steel forging operations, contributing to precision and efficiency. Here's how cranes are used in forging:

- Material Handling: Cranes transport steel slabs to and from forging equipment, ensuring a constant supply of raw material.

- Die Changes: Overhead cranes assist in die changes, enabling quick transitions between different forging processes and product types.

- Controlled Placement: Cranes precisely position slabs within the forging equipment, ensuring proper alignment for effective deformation.

Precision Handling in Forging Operations

Precision is vital in forging to achieve desired product shapes and properties. Overhead cranes contribute to precision handling in the following ways:

- Uniform Deformation: Accurate placement of slabs ensures uniform deformation, resulting in consistent product quality.

- Safety: Precise control prevents accidents during the forging process, protecting both personnel and materials.

- Efficiency: Precision handling minimizes material wastage and reduces the need for rework.

Forged Products for Diverse Industries

Forging produces a wide range of steel components used in various industries:

- Automotive: Forged steel components are used in automotive engines, transmissions, and suspension systems.

- Aerospace: Precision-forged parts are essential for aircraft and spacecraft construction.

- Oil and Gas: Forged components are used in drilling equipment and pipelines.

- Machinery: Forging produces high-strength components for heavy machinery and equipment.

- Energy: Forged parts are used in power generation and transmission systems.

Overhead cranes ensure that steel slabs are efficiently and accurately transformed into forged products that meet the demanding requirements of these industries.

Typical Applications of Overhead Cranes in Steel Slab Handling

Heat Treatment

Overhead Cranes in Heat Treatment Facilities

Heat treatment is a critical process in steel manufacturing, where slabs undergo controlled heating and cooling to modify their physical and metallurgical properties. Overhead cranes play a vital role in heat treatment facilities, ensuring the efficient handling of slabs. Here's how overhead cranes are utilized in heat treatment:

- Material Transfer: Cranes transport steel slabs from storage to heat treatment furnaces and quenching tanks, maintaining a continuous workflow.

- Precise Placement: Overhead cranes precisely position slabs within furnaces and quenching tanks, ensuring uniform heat treatment.

- Quenching Assistance: Cranes assist in the controlled immersion of slabs into quenching tanks, a critical step in the heat treatment process.

Heat Treatment of Slabs

Heat treatment processes for steel slabs can include annealing, tempering, normalizing, and quenching, among others. Overhead cranes contribute to the success of these processes by:

- Ensuring Consistency: Precise handling ensures that slabs are uniformly heated and cooled, leading to consistent metallurgical properties.

- Minimizing Distortion: Careful positioning during heating and cooling phases helps minimize distortion, preserving slab shape and integrity.

- Optimizing Time: Efficient handling reduces the time slabs spend in the heat treatment process, improving overall production efficiency.

Ensuring Metallurgical Integrity

Metallurgical integrity is paramount in heat treatment, as it determines the final properties of the steel. Overhead cranes play a role in ensuring this integrity by:

- Preventing Contamination: Cranes handle slabs without direct contact, minimizing the risk of contamination during the heat treatment process.

- Reducing Handling Stress: Precise positioning and gentle handling reduce the mechanical stress on slabs, preventing metallurgical defects.

- Safety Protocols: Overhead cranes are equipped with safety features to prevent accidents during the heat treatment process, safeguarding both materials and personnel.

Cladding

Clad Slab Handling with Overhead Cranes

Cladding involves layering different materials onto a steel slab to combine the desirable properties of each. Overhead cranes are integral to cladding processes, ensuring the precise handling of clad slabs. Here's how cranes are involved:

- Material Transport: Cranes move clad slabs between processing stations, facilitating the cladding process.

- Gentle Handling: Overhead cranes handle clad slabs delicately to prevent damage to the cladding layers.

- Precision Positioning: Cranes position clad slabs accurately for welding and bonding, ensuring the integrity of the cladding.

Precision Handling in Cladding Processes

Precision handling is critical in cladding to achieve the desired properties and durability of clad slabs. Overhead cranes contribute to precision in the following ways:

- Alignment: Accurate placement of clad slabs ensures proper alignment of cladding layers, preventing defects.

- Minimized Damage: Gentle handling by cranes minimizes the risk of delamination or damage to the cladding during transport and processing.

- Efficiency: Efficient handling reduces production time, improving overall workflow in cladding facilities.

Applications in Harsh Environments

Clad slabs find applications in harsh environments where corrosion resistance, wear resistance, or other specialized properties are needed. Overhead cranes help create clad slabs for:

- Chemical Processing: Clad slabs are used in vessels, tanks, and piping systems for chemical processing.

- Offshore Drilling: Clad materials are vital for offshore oil and gas equipment operating in corrosive seawater.

- Power Generation: Clad components are used in power plants where resistance to high temperatures and pressure is required.

- Aerospace: Clad materials are used in aircraft components for their strength and lightweight properties.

Overhead cranes play a crucial role in the production of clad slabs, ensuring they meet the stringent requirements of these demanding applications.

Cutting and Fabrication

Overhead Cranes in Cutting and Fabrication Shops

Cutting and fabrication shops are where steel slabs are transformed into various components and products for diverse industries. Overhead cranes are indispensable in these facilities, supporting the efficient processing of slabs. Here's how overhead cranes are utilized:

- Material Handling: Cranes transport steel slabs to cutting and fabrication stations, maintaining a smooth workflow.

- Precise Positioning: Overhead cranes precisely position slabs for cutting, machining, and welding processes.

- Load Manipulation: Cranes assist in manipulating slabs during various fabrication steps, ensuring accuracy and efficiency.

Versatility for Varied Slab Processing

Steel slabs in cutting and fabrication shops undergo a wide range of processes to create diverse products. Overhead cranes adapt to these varied processing needs by:

- Custom Attachments: Cranes can be equipped with custom attachments, such as lifting magnets or clamps, to handle different slab types and sizes.

- Quick Changeovers: Overhead cranes facilitate quick changeovers between fabrication processes, minimizing downtime.

- Work Area Coverage: Cranes are designed to cover the entire work area, providing flexibility in material handling.

Efficient Fabrication for Industries

Cutting and fabrication shops cater to industries such as construction, automotive, aerospace, and manufacturing. Overhead cranes support these industries by enabling:

- Efficiency: Efficient handling and positioning of slabs reduce production time, leading to higher productivity.

- Quality: Precise handling ensures that fabricated components meet strict quality standards.

- Customization: Overhead cranes can be customized to match the specific needs of different fabrication processes and industries.

Overhead cranes are the workhorses of cutting and fabrication shops, contributing to the timely and precise production of components that drive various industrial sectors.

Overhead Cranes for Different Types of Steel Slabs Handling

Steel slabs are flat, rectangular pieces of steel that serve as a semi-finished product in the steel manufacturing process. They are typically produced through a process known as continuous casting or ingot casting, where molten steel is solidified into a slab shape. These slabs are then further processed in rolling mills to produce various steel products like sheets, plates, coils, and more. Overhead cranes are used for handling various types of steel slabs, including hot slabs, cold slabs, thin slabs, heavy slabs, alloy slabs, micro-alloyed slabs, clad slabs, and stainless steel slabs, following the requested format:

Overhead gantry crane for cold slab handling

Overhead crane for hot slab handling

Hot slabs:

Hot Rolled Slabs (HRS): These slabs are produced at high temperatures and are used for manufacturing a wide range of steel products, including sheets, plates, structural sections, and pipes. Hot rolled slabs have a scale on their surface that must be removed through processes like pickling or shot blasting. Hot slabs are steel slabs that have been recently cast and are at a high temperature, often exceeding 1,000°C (1,832°F). They are semi-finished products in steel manufacturing.

- Thickness: Typically ranges from 150 mm (6 inches) to 250 mm (10 inches) or more.

- Width: Can vary from around 800 mm (31 inches) to 2,200 mm (87 inches) or more.

- Length: Usually between 4 meters (13 feet) and 12 meters (39 feet).

- Weight: Can range from 5 tons to 30 tons or more, depending on the dimensions.

Overhead crane for hot slabs handling:

- Overhead cranes for hot slabs are designed to handle the extreme heat and weight of freshly cast slabs.

- Tailored Features for hot slabs handling: Heat-resistant materials, insulating features, and cooling systems to protect the crane and operator from extreme temperatures.

- Typical hot rolled slabs handled: Hot rolled slabs are typically thicker and larger, with temperatures exceeding 1,000°C (1,832°F).

- Typical functions and applications condition: Handling slabs from the continuous casting process to cooling beds or further processing, such as rolling mills. The crane must operate in a hot and demanding environment.

- Benefits of overhead cranes for slabs handling: Ensure efficient and safe movement of hot slabs, reducing the risk of accidents and minimizing handling time.

- Below hook devices for slabs handling: Specialized equipment such as slab tongs or C-hooks designed to securely grip hot slabs during transport.

Cold Slabs:

Cold Rolled Slabs (CRS): Cold rolled slabs are produced at lower temperatures compared to hot rolled slabs. They are often used for producing steel products that require a higher degree of precision and surface finish, such as automotive components, appliances, and electrical equipment.

Overview of cold slabs:

- Cold slabs are steel slabs at room temperature, often used in various steel manufacturing processes.

- Thickness: Typically thinner than HRS, often ranging from 5 mm to 6 mm.

- Width: Similar to HRS, varying from 800 mm to 2,200 mm.

- Length: Similar to HRS, typically between 4 meters and 12 meters.

- Weight: Lighter than HRS slabs due to their thinner profile, with weights ranging from 1 ton to 10 tons or more.

Overhead crane for cold slabs handling:

- Overhead cranes for cold slabs are designed for general-purpose material handling and are versatile.

- Tailored Features for cold slabs handling: While not specifically tailored for cold slabs, these cranes may have features like precise positioning controls.

- Typical cold slabs handled: Cold slabs are usually at room temperature and are thinner and lighter than their hot counterparts.

- Typical functions and applications condition: Handling slabs in storage yards, transporting them to processing areas, or loading/unloading trucks and railcars.

- Benefits of overhead cranes for slabs handling: Versatility and adaptability for handling slabs in various temperature conditions.

- Below hook devices for slabs handling: Hooks, C-hooks, or magnets for lifting and transporting cold slabs as needed.

Thin Slabs:

Thin Slabs: Thin slabs are a type of hot rolled slab that is thinner than traditional slabs. They are typically used in mini-mills for the production of steel sheets and coils. Thin slabs offer advantages like reduced energy consumption and faster production times.

- Thin slabs are steel slabs characterized by their reduced thickness, often less than 100 mm.

- Thickness: Generally less than 100 mm, often in the range of 20 mm to 50 mm.

- Width: Similar to HRS, ranging from 800 mm to 2,200 mm.

- Length: Typically between 4 meters and 12 meters.

- Weight: Lighter than traditional HRS slabs, with weights usually between 1 ton and 5 tons.

Overhead crane for thin slabs handling:

- Overhead cranes for thin slabs may have features like precise controls and lightweight construction to handle thinner and lighter slabs efficiently.

- Tailored Features for thin slabs handling: Precise positioning capabilities to handle thin slabs with care.

- Typical thin slabs handled: Thin slabs are characterized by their reduced thickness, often less than 100 mm.

- Typical functions and applications condition: Transporting thin slabs to rolling mills or other processing equipment, often requiring delicate handling.

- Benefits of overhead cranes for slabs handling: Ensure precise and efficient movement of thin slabs, minimizing material waste.

- Below hook devices for slabs handling: Slab tongs, C-hooks, or magnets designed for thin slab handling.

Overview of heavy slabs:

Heavy Slabs: Heavy slabs are thicker and wider than standard slabs. They are used in applications where high strength and durability are required, such as for the production of large structural sections, shipbuilding, and pressure vessels.

- Heavy slabs are steel slabs that are exceptionally thick and heavy, often weighing several tons each.

- Thickness: Thicker than standard slabs, often exceeding 250 mm.

- Width: Can be wide, depending on the application, but typically in the range of 1,000 mm to 2,200 mm.

- Length: Similar to HRS slabs, between 4 meters and 12 meters.

- Weight: Heavier than standard slabs, with weights commonly ranging from 20 tons to 50 tons or more.

Overhead crane for heavy slabs handling:

- Overhead cranes for heavy slabs are designed with high lifting capacities and robust structures.

- Tailored Features for heavy slabs handling: High load capacities, reinforced structures, and specialized controls for safe and precise heavy slab handling.

- Typical heavy slabs handled: Heavy slabs can weigh several tons each.

- Typical functions and applications condition: Transporting heavy slabs from storage to processing areas or loading them onto trucks or railcars.

- Benefits of overhead cranes for slabs handling: Safely and efficiently move heavy slabs, reducing the risk of accidents and injuries.

- Below hook devices for slabs handling: Heavy-duty slab tongs, C-hooks, or magnets designed for heavy slab lifting.

Alloy Slabs:

- Alloy Slabs: Alloy steel slabs are made from steel that has been alloyed with various elements to enhance specific properties such as corrosion resistance, strength, or heat resistance. These slabs are used in industries like aerospace, defense, and petrochemicals.

- Thickness, width, length, and weight can vary widely depending on the specific alloy and intended use. These slabs are often produced in custom sizes to meet the needs of specialized industries.

- Alloy slabs are steel slabs that have been alloyed with various elements to enhance specific properties such as corrosion resistance, strength, or heat resistance.

Overhead crane for alloy slabs handling:

- Overhead cranes for alloy slabs are often equipped with specialized lifting equipment suitable for handling alloyed steel.

- Tailored Features for alloy slabs handling: Lifting attachments designed for alloy slab characteristics, such as increased strength or corrosion resistance.

- Typical alloy slabs handled: Alloy slabs can vary widely depending on the specific alloy composition and application.

- Typical functions and applications condition: Handling alloy slabs in various production processes, such as aerospace or petrochemical applications.

- Benefits of overhead cranes for slabs handling: Ensure safe and efficient handling of alloy slabs, preserving their unique properties.

- Below hook devices for slabs handling: Custom lifting attachments tailored to the alloy slab requirements.

Overview of micro-alloyed slabs:

- Micro-alloyed slabs are steel slabs that contain small amounts of alloying elements like niobium or vanadium to improve strength and toughness.

- Micro-Alloyed Slabs: These slabs are made from steel that has been micro-alloyed with small amounts of elements like niobium, vanadium, or titanium. Micro-alloying helps improve the strength and toughness of the steel, making it suitable for applications like pipelines and automotive components.

- Similar to standard HRS slabs, but the addition of micro-alloying elements may slightly alter the thickness, width, and weight specifications

Overhead crane for micro-alloyed slabs handling:

- Overhead cranes for micro-alloyed slabs may have features that accommodate the unique characteristics of micro-alloyed steel.

- Tailored Features for micro-alloyed slabs handling: Precise controls and specialized lifting equipment suitable for micro-alloyed steel.

- Typical micro-alloyed slabs handled: Micro-alloyed slabs contain small amounts of alloying elements like niobium or vanadium to improve strength and toughness.

- Typical functions and applications condition: Handling micro-alloyed slabs in industries like pipeline production or automotive manufacturing.

- Benefits of overhead cranes for slabs handling: Ensure the safe and efficient movement of micro-alloyed slabs, preserving their specific properties.

- Below hook devices for slabs handling: Customized lifting attachments designed for micro-alloyed slab requirements.

Overview of clad slabs:

- Clad Slabs: Clad slabs consist of multiple layers of different steel types or other materials bonded together. These slabs are used in applications where the combination of different properties is required, such as in the production of corrosion-resistant or high-temperature-resistant materials.

- Sizes and weights can vary significantly based on the materials being bonded together and the application. These slabs are often custom-made to meet specific requirements.

- Clad slabs consist of multiple layers of different materials bonded together, offering specific properties for various applications.

Overhead crane for clad slabs handling:

- Overhead cranes for clad slabs are equipped with specialized lifting equipment suitable for handling composite materials.

- Tailored Features for clad slabs handling: Custom lifting attachments designed for clad slabs, which consist of multiple layers of different materials bonded together.

- Typical clad slabs handled: Clad slabs can vary widely in terms

- of the materials and properties of the layers.

- Typical functions and applications condition: Handling clad slabs in industries like chemical processing or offshore drilling.

- Benefits of overhead cranes for slabs handling: Ensure the safe and precise handling of clad slabs, which require careful material management.

- Below hook devices for slabs handling: Customized lifting attachments tailored to the composition and structure of clad slabs.

Overview of stainless steel slabs:

Stainless steel slabs contain chromium and nickel to provide corrosion resistance and are used in various industries.

These slabs are made from stainless steel, which contains chromium and nickel to provide resistance to corrosion and staining. Stainless steel slabs are used in various industries, including food processing, chemical processing, and construction.

Overhead crane for stainless steel slabs handling:

- Overhead cranes for stainless steel slabs may have features that accommodate the unique characteristics of stainless steel, such as corrosion resistance.

- Tailored Features for stainless steel slabs handling: Lifting attachments designed for stainless steel slab characteristics, including the ability to protect against contamination.

- Typical stainless steel slabs handled: Stainless steel slabs vary widely depending on their specific alloy composition and application.

- Typical functions and applications condition: Handling stainless steel slabs in applications like food processing, chemical processing, and construction.

- Benefits of overhead cranes for slabs handling: Ensure the safe and efficient movement of stainless steel slabs while preserving their corrosion-resistant properties.

- Below hook devices for slabs handling: Customized lifting attachments designed for stainless steel slab requirements.

Top Concerns of Overhead Crane Users

Maintenance and Service

The Importance of Regular Maintenance

Regular maintenance is the lifeblood of overhead cranes. It ensures their longevity, reliability, and safe operation. Here's why maintenance is crucial:

- Preventative Measures: Maintenance helps identify and address potential issues before they escalate, preventing costly breakdowns.

- Safety: Well-maintained cranes are safer to operate, protecting both personnel and materials.

- Efficiency: Properly maintained cranes operate more efficiently, reducing downtime and increasing productivity.

Ensuring Longevity and Reliability

To maximize the longevity and reliability of overhead cranes:

- Scheduled Inspections: Regular inspections and servicing schedules are essential to catch wear and tear early.

- Component Replacement: Timely replacement of worn components extends the crane's lifespan.

- Lubrication: Proper lubrication of moving parts reduces friction and wear.

Maintenance FAQs

Common questions about crane maintenance include:

- How often should maintenance be performed?: Frequency depends on usage and manufacturer recommendations. Regular monthly checks and annual inspections are common.

- Can we perform maintenance in-house?: Some basic maintenance tasks can be done in-house, but specialized tasks should be handled by trained technicians.

- What's the cost of maintenance?: Costs vary based on crane type and usage. Preventative maintenance is an investment that saves on costly repairs.

Operator Training

Training Operators for Safe and Efficient Handling

Operator training is essential for safe and efficient crane operation. Proper training includes:

- Safety Protocols: Operators must learn safety procedures, emergency response, and load handling best practices.

- Equipment Familiarity: Training covers crane controls, attachments, and equipment-specific knowledge.

- Certification: Operators should receive certification or licensing based on local regulations.

Compliance with Safety Regulations

Safety regulations are in place to protect crane operators and others in the workspace. Compliance includes:

- Safety Standards: Overhead cranes must meet national and international safety standards.

- Regular Audits: Authorities may conduct audits to ensure compliance with safety regulations.

Operator Training Questions Answered

Common questions about operator training include:

- How long does training take?: Training duration varies but typically lasts several weeks to ensure proficiency.

- Can existing operators be retrained?: Yes, experienced operators can benefit from refresher courses to stay updated on safety and best practices.

- What if operators aren't certified?: Operating cranes without certification can lead to legal and safety issues. Certification is typically a legal requirement.

Compliance and Regulations

Understanding Safety and Regulatory Standards

Compliance with safety and regulatory standards is paramount in crane operations. Understanding these standards involves:

- Safety Codes: Familiarity with safety codes and standards specific to the region and industry.

- Equipment Compliance: Ensuring cranes meet all safety and design standards.

Compliance in Crane Operations

Compliance extends to daily crane operations:

- Documentation: Proper record-keeping of maintenance, inspections, and operator certifications.

- Load Limits: Adhering to load limits and warning signs to prevent overloading.

Navigating Regulatory Requirements

Navigating regulatory requirements can be challenging, but it's essential:

- Legal Expertise: Some organizations hire legal experts to ensure full compliance.

- Regular Updates: Staying informed about evolving safety regulations is crucial.

Cost Considerations

Total Cost of Ownership (TCO)

Understanding the total cost of ownership (TCO) is vital in crane procurement. TCO includes:

- Initial Purchase: The cost of acquiring the crane and any necessary attachments.

- Operating Costs: Expenses related to maintenance, repairs, energy consumption, and operator salaries.

- Lifecycle Costs: Considering the crane's expected lifespan and ongoing costs.

Budgeting for Overhead Cranes

Budgeting for overhead cranes involves:

- Long-Term Planning: Consider TCO over the crane's lifespan rather than just initial costs.

- Financial Forecasting: Anticipate maintenance and repair expenses over time.

Cost Efficiency and ROI

Investing in overhead cranes should result in a positive return on investment (ROI):

- Increased Productivity: Efficient crane operations lead to higher productivity and revenue.

- Reduced Downtime: Proper maintenance reduces downtime, minimizing production losses.

- Safety Benefits: Fewer accidents and downtime due to safety incidents contribute to cost efficiency.

Addressing these concerns helps organizations maximize the benefits of overhead cranes while ensuring safe and efficient operations.

Finding the Right Overhead Crane Solution

Evaluating Specific Needs

Selecting the right overhead crane solution for your steel slab handling operations is a critical decision. To make the ideal choice, consider the following:

- Slab Characteristics: Analyze the size, weight, and type of steel slabs you handle. Ensure the crane's specifications match your requirements.

- Work Environment: Evaluate the layout of your facility, including ceiling height and available workspace, to determine the appropriate crane type and configuration.

- Production Volume: Consider your production volume and workflow. Choose a crane that can keep up with demand and optimize efficiency.

- Safety Priorities: Prioritize safety by selecting a crane equipped with the latest safety features and compliance with relevant regulations.

- Budget: Balance your budgetary constraints with the need for a high-quality crane solution. Remember that investing in quality can yield long-term cost savings.

Partnering with the Right Crane Manufacturer and Supplier

Choosing the ideal overhead crane also means selecting the right manufacturer and supplier:

- Reputation: Research the reputation and track record of potential crane suppliers. Look for those with a history of delivering reliable solutions.

- Customization: Partner with a manufacturer that can tailor the crane to your specific needs, including attachments and controls.

- Service and Support: Ensure the supplier offers comprehensive service and support, including maintenance, spare parts availability, and operator training.

- Regulatory Compliance: Verify that the manufacturer adheres to safety and regulatory standards in crane design and production.

Optimizing Steel Slab Handling Efficiency

Ultimately, the goal of selecting the right overhead crane solution is to optimize efficiency in steel slab handling:

- Productivity: An ideal crane should enhance productivity by minimizing downtime, reducing material handling time, and increasing throughput.

- Quality Assurance: Ensure that the crane helps maintain the quality and integrity of steel slabs throughout handling and processing.

- Safety: Prioritize safety for both personnel and materials, investing in safety features and operator training.

- Cost Efficiency: Strive for a solution that offers a favorable return on investment (ROI) by reducing long-term operating costs and maximizing uptime.

In conclusion, finding the right overhead crane solution is a pivotal step in enhancing steel slab handling operations. By carefully evaluating your specific needs, partnering with a reputable manufacturer and supplier, and focusing on efficiency, you can achieve safe, efficient, and cost-effective steel slab handling that supports your industry's demands.

Whether you are a current user of overhead cranes or considering their implementation in steel slab handling applications, this comprehensive guide provides valuable insights and answers to common questions. By understanding the types, features, benefits, and safety considerations, you can make informed decisions to enhance the efficiency and safety of your operations. Choosing the right overhead crane solution tailored to your needs is key to achieving success in the steel manufacturing and processing industry.

Main Projects

Related Products

6.3 ton overhead crane kit for sale Philippines, complete single girder top running overhead crane system, low headroom design for workshop indoor use.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch