Steel Coils Handling :Overhead Cranes & Coil handling Cranes

Overhead crane for steel coil handling. All types of electric cranes for efficient of steel coils handling, ie. overhead cranes & coil handling cranes.

Category: Steel

Your Trusted Overhead Crane Manufacturer & Supplier

Steel Coils Handling :Overhead Cranes & Coil handling Cranes

Overhead crane for steel coil handling. All types of electric cranes for efficient of steel coils handling, ie. overhead cranes & coil handling cranes.

Brief Overview of the Importance of Efficient Steel Coil Handling

Steel coils are the unsung heroes of numerous industries, playing a pivotal role in manufacturing, construction, and more. These cylindrical bundles of steel hold immense potential, but unlocking their true value relies heavily on efficient handling. In this blog, we'll dive deep into the world of steel coil handling and explore how overhead cranes are instrumental in optimizing this critical process.

Introduction to the Role of Overhead Cranes in Steel Coil Handling

Imagine the sheer size and weight of steel coils, often weighing several tons. Moving them efficiently within a manufacturing facility or a construction site is no small feat. This is where overhead cranes step in. These mechanical marvels are designed to lift, transport, and position heavy loads with precision and safety. They are the workhorses that make the handling of steel coils smoother and more productive.

Purpose of the Outline and What the Audience Can Expect to Learn

Our journey through this blog will provide you with a comprehensive understanding of the efficient handling of steel coils, with a specific focus on the indispensable role played by overhead cranes. We will explore the advantages, design considerations, and best practices associated with these cranes. Through case studies, we will see how real-world companies have reaped the benefits of efficient steel coil handling. Additionally, we'll discuss the challenges and future trends in this field, providing you with insights into the evolving landscape of steel coil handling.

Importance of Efficient Steel Coil Handling

Significance of Steel Coils in Various Industries

Steel coils are the unsung backbone of several key industries, playing a pivotal role in the creation of countless products and infrastructure. Here's a glimpse into why steel coils are indispensable:

- 1. Manufacturing: Steel coils are the raw material for manufacturing a wide range of products, from automobiles and appliances to industrial machinery. They are the building blocks of modern production processes.

- 2. Construction: In construction, steel coils are used to create structural components like beams, columns, and reinforcing bars. Their strength and durability make them essential for constructing safe and sturdy buildings and infrastructure.

- 3. Transportation: Steel coils are used in the production of ships, trains, and aircraft. Their strength-to-weight ratio ensures the integrity and safety of these transportation modes.

- 4. Energy Sector: Power plants, both conventional and renewable, rely on steel coils for equipment and infrastructure. Steel's resistance to extreme temperatures and corrosion is crucial in this sector.

- 5. Oil and Gas: Steel coils are employed in pipelines, storage tanks, and drilling equipment, playing a crucial role in the extraction and transportation of oil and gas resources.

Challenges Associated with Inefficient Steel Coil Handling

Inefficient steel coil handling can lead to a cascade of challenges that reverberate through various industries:

- 1. Safety Hazards: Steel coils are heavy and unwieldy, posing significant safety risks to workers during handling. Mishandling can result in accidents, injuries, and even fatalities.

- 2. Production Delays: Inefficient handling can lead to delays in manufacturing processes, construction projects, and transportation operations. This can have a domino effect on project timelines and budgets.

- 3. Material Damage: Rough handling can cause damage to steel coils, leading to product defects and material waste. This not only affects quality but also incurs additional costs.

- 4. Increased Operating Costs: Inefficient handling consumes more time, energy, and labor, driving up operational expenses. It also results in higher maintenance costs for equipment.

The Economic Impact of Improving Steel Coil Handling Efficiency

Efficiency is the linchpin of a thriving economy, and improving steel coil handling efficiency can have a substantial economic impact:

- 1. Cost Savings: Efficient handling reduces labor costs, minimizes material waste, and prolongs equipment life. This translates into significant cost savings for businesses.

- 2. Increased Productivity: Streamlined processes and reduced downtime result in higher production output. This, in turn, boosts revenue and profitability.

- 3. Competitive Advantage: Companies that excel in steel coil handling gain a competitive edge. They can fulfill orders faster, meet customer demands more effectively, and win contracts with more competitive bids.

- 4. Sustainability: Efficient handling practices reduce energy consumption and material waste, contributing to sustainability goals. This can improve a company's image and appeal to environmentally conscious consumers and partners.

As we continue our exploration, we'll delve deeper into how overhead cranes play a pivotal role in addressing these challenges and reaping the economic benefits of efficient steel coil handling.

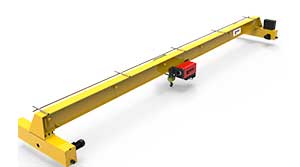

Overhead Cranes: An Overview

Definition and Basic Functionality of Overhead Cranes

Overhead cranes, often referred to as bridge cranes or gantry cranes, are essential material handling equipment widely used in various industries. They operate on an elevated runway system and are equipped with a horizontal bridge that moves back and forth. Here's how they function:

- Lifting: Overhead cranes feature a hoist mechanism that can lift and lower heavy loads vertically.

- Travelling: The horizontal bridge, which carries the hoist and load, can move along the length of the runway. This provides lateral mobility for precise positioning.

- Trolley Movement: A trolley system, attached to the bridge, enables horizontal movement perpendicular to the runway. This trolley is used to position the load accurately.

Main Structures of Overhead Crane for Steel Coil Handling

Overhead Cranes Commonly Used in Steel Coil Handling

Several types of overhead cranes are employed in steel coil handling, each tailored to specific needs and constraints. The most common types include:

When it comes to steel coil handling, several types of cranes are used, each designed to address specific needs and requirements. Special crane designs with below hook devices are also employed to enhance efficiency and safety. Here are some common types of cranes used for steel coil handling, along with their features, benefits, and typical applications:

Coil Handling Cranes (Coil Handling Bridge Cranes):

- Features: Coil handling cranes are typically overhead bridge cranes customized for the specific task of moving steel coils. They often include specialized coil hooks or C-hooks for secure attachment to the coils.

- Benefits: - Designed with a focus on load stability and safety during coil lifting and transport. - Can handle a wide range of coil sizes and weights. - Typically equipped with precision controls for accurate positioning.

- Typical Applications: Steel mills, metal processing facilities, coil distribution centers, and any operation involving the regular movement of steel coils.

Magnet Cranes (Electro-Magnetic Coil Lifters):

- Features: Magnet cranes are equipped with electro-magnetic lifters that can attract and release steel coils. They provide efficient and rapid coil handling capabilities.

- Benefits: - Quick and efficient attachment and detachment of coils. - Reduced risk of damage to the coil's surface compared to traditional hooks. - Suitable for continuous coil handling operations.

- Typical Applications: Steel production facilities, scrap yards, and industries requiring frequent coil manipulation.

C-Hook Cranes for Horizontal Coil Handling :

- Features: C-hook cranes have a specialized C-shaped hook below the crane's hoist. The C-hook design provides a secure grip on steel coils.

- Benefits: - Ideal for handling steel coils without eyelets or special attachments. - Prevents coil distortion and damage during handling. - Suitable for high-temperature environments.

- Typical Applications: Steel coil manufacturing, processing plants, and facilities where coil shape preservation is critical.

Each type of crane and below hook device has its own set of advantages and applications, making them suitable for various aspects of steel coil handling. The choice of crane depends on factors such as the size and weight of the coils, the frequency of handling, and specific safety and efficiency requirements of the operation.

Key Components and Features of Overhead Cranes Relevant to Their Role in Handling Steel Coils

Overhead cranes designed for steel coil handling are equipped with specific components and features to ensure safe and efficient operation:

- 1. Hoist: The hoist is the mechanism responsible for lifting and lowering the load. It includes a hook or other attachments for securing steel coils.

- 2. Runway: The runway consists of a system of rails or beams on which the crane travels. It provides support for the crane's movement.

- 3. Trolley: The trolley is mounted on the bridge and carries the load horizontally. It enables precise positioning of steel coils.

- 4. Control System: Modern overhead cranes are equipped with advanced control systems that can be operated remotely or from a cabin. These systems ensure precise and safe operation.

- 5. Safety Features: Overhead cranes are equipped with safety features such as limit switches, emergency stop buttons, and overload protection to prevent accidents and equipment damage.

- 6. Load-Measuring Devices: Some cranes are equipped with load-measuring devices that provide real-time information about the weight of the load being handled.

Advantages of Using Overhead Cranes for Steel Coil Handling

Steel coil handling is a critical and demanding task, and the utilization of overhead cranes can significantly enhance the overall process. Here are the key advantages of using overhead cranes for steel coil handling:

Improved Safety for Workers

- 1. Reduced Manual Labor: Overhead cranes eliminate the need for manual lifting and positioning of heavy steel coils, reducing the risk of musculoskeletal injuries among workers.

- 2. Enhanced Operator Control: Operators can control the crane's movements and load positioning with precision, reducing the chance of accidents and collisions.

- 3. Safety Features: Modern overhead cranes are equipped with safety features such as overload protection, limit switches, and emergency stop buttons, ensuring a safer working environment.

- 4. Reduced Exposure to Hazards: Workers are less exposed to hazardous environments, such as high-temperature areas or confined spaces, due to the crane's ability to handle coils in diverse conditions.

Increased Efficiency and Productivity

- 1. Faster Handling: Overhead cranes enable swift and precise load handling, reducing downtime and waiting times in manufacturing or processing operations.

- 2. Optimized Workflow: They can be integrated into production lines, ensuring a smooth and continuous workflow, which is particularly important in high-volume operations.

- 3. Multi-Functionality: Overhead cranes can perform a variety of tasks, including lifting, transporting, and positioning, making them versatile tools for various aspects of steel coil handling.

- 4. Remote Operation: Some modern cranes can be operated remotely, allowing operators to control the crane from a safe distance and achieve higher efficiency.

Reduction in Material Damage and Waste

- 1. Gentle Handling: Overhead cranes are designed to handle coils with care, minimizing the risk of surface damage or distortion. This leads to improved product quality and reduced material waste.

- 2. Accurate Placement: Precise control and positioning capabilities of cranes ensure that steel coils are placed exactly where they are needed, reducing the chances of rework or material loss.

- 3. Decreased Product Defects: Reduced material damage translates into fewer product defects, which is crucial in industries where quality control is paramount.

Environmental Benefits

- 1. Energy Efficiency: Overhead cranes are designed for energy efficiency, with features like regenerative braking and variable frequency drives that help reduce power consumption.

- 2. Lower Emissions: The reduced need for forklifts or other heavy equipment for material handling results in lower emissions, contributing to a greener and more sustainable operation.

- 3. Waste Reduction: Minimized material damage and waste, as well as improved load control, align with environmentally friendly practices by reducing the environmental impact of steel coil handling.

Incorporating overhead cranes into steel coil handling operations not only enhances safety and efficiency but also supports sustainability efforts, making them a valuable asset for various industries reliant on steel coil materials. These advantages underscore the crucial role overhead cranes play in modern manufacturing, construction, and logistics.

Design Considerations for Overhead Cranes in Steel Coil Handling

The effective design of overhead cranes for steel coil handling is essential to ensure safe and efficient operations. Here are the key design considerations that should be taken into account:

Load Capacity and Lifting Requirements

- 1. Determine Load Characteristics: Understanding the weight and dimensions of the steel coils to be handled is crucial. This information helps in selecting a crane with the appropriate load capacity and hook or lifting attachment.

- 2. Consider Load Variability: If handling coils of varying sizes and weights, choose a crane with a capacity that accommodates the heaviest loads to be encountered. Variable frequency drives can provide precise control when handling different load sizes.

- 3. Factor in Future Growth: Anticipate potential increases in coil sizes or weights and ensure that the crane's capacity can adapt to future requirements.

Crane Span and Runway Design

- 1. Assess Facility Layout: Evaluate the available space in the facility, including ceiling height and floor layout, to determine the crane span (distance between runways) and runway length required.

- 2. Customized Runway Design: Design the crane runway to accommodate the crane's span and travel path. Ensure proper support structures and runway rails are in place to handle the loads.

- 3. Consider Obstacles: Identify any obstacles or obstructions in the crane's path and design the runway layout to navigate around them safely.

Safety Features and Compliance with Industry Regulations

- 1. Safety Standards: Ensure that the overhead crane design complies with industry safety standards and regulations, such as OSHA (Occupational Safety and Health Administration) in the United States or local safety codes.

- 2. Emergency Features: Include essential safety features such as emergency stop buttons, limit switches, and overload protection systems to safeguard against accidents.

- 3. Operator Training: Design the crane's control interface to be user-friendly, and provide comprehensive training for crane operators to ensure safe operation.

- 4. Collision Prevention: Implement anti-collision systems to prevent collisions between cranes or between cranes and other equipment or structures within the facility.

Maintenance and Upkeep Considerations

- 1. Access for Maintenance: Design the crane and runway system to allow easy access for routine maintenance and inspections. Ensure that maintenance personnel can reach critical components without difficulty.

- 2. Spare Parts Availability: Choose crane models for which spare parts are readily available to minimize downtime in case of repairs.

- 3. Scheduled Inspections: Establish a regular maintenance schedule for the crane, including inspections, lubrication, and component replacement as needed.

- 4. Record-Keeping: Maintain detailed records of maintenance and repair activities, as this can aid in identifying trends and preventing potential issues.

By carefully considering these design factors, you can optimize the performance and safety of overhead cranes used in steel coil handling operations. A well-designed crane system ensures efficient material handling while minimizing the risk of accidents and breakdowns, contributing to a productive and safe work environment.

Best Practices for Efficient Steel Coil Handling with Overhead Cranes

Efficient steel coil handling with overhead cranes requires a combination of best practices to ensure safety, precision, and productivity. Here are the key guidelines for achieving efficient steel coil handling:

Pre-operation Checks and Safety Protocols

- 1. Daily Inspections: Conduct thorough pre-operation inspections of the overhead crane to check for any signs of wear, damage, or malfunction. Address any issues promptly before starting work.

- 2. Safety Checklists: Use comprehensive safety checklists that cover all critical components and safety features of the crane. Ensure operators are trained to follow these checklists diligently.

- 3. Safety Protocols: Implement strict safety protocols, including clear communication among crane operators and ground personnel. Establish and enforce safety procedures to prevent accidents.

- 4. Emergency Procedures: Ensure that all personnel are aware of emergency procedures and know how to respond in case of unexpected situations or equipment failures.

Proper Coil Attachment and Lifting Techniques

- 1. Correct Attachments: Choose the appropriate below-hook attachment for the specific type and size of steel coil. Ensure it is securely attached to the coil to prevent accidents.

- 2. Even Weight Distribution: Distribute the weight of the coil evenly on the crane's lifting equipment. Ensure that the coil is balanced to prevent it from swinging during transport.

- 3. Slow and Smooth Lifts: Lift steel coils slowly and smoothly to minimize the risk of load shifting or instability. Avoid sudden jerks or rapid movements.

- 4. Visual Inspections: Conduct visual inspections of the coil attachment points to verify their integrity before lifting. Look for any signs of wear or damage.

Load Balance and Distribution Strategies

- 1. Consider Load Size: Be aware of the dimensions and weight of the steel coil being handled and ensure that the crane's load capacity is not exceeded.

- 2. Positioning: Use the crane's precise positioning capabilities to accurately place the coil in the desired location, whether it's on a production line, storage rack, or transport vehicle.

- 3. Avoid Overloading: Never overload the crane with more than its rated capacity. Overloading can lead to equipment damage and safety hazards.

- 4. Load Spreader Bars: When handling larger and longer coils, consider the use of load spreader bars to maintain load stability and distribute the weight evenly.

Monitoring and Control Systems

- 1. Remote Operation: If available, use remote control systems to operate the crane from a safe distance, allowing operators to have a clear view of the load and the surrounding area.

- 2. Load Monitoring: Utilize load monitoring systems and load cells to continuously monitor the weight and balance of the coil during handling.

- 3. Collision Avoidance: Implement collision avoidance systems to prevent accidents, especially when multiple cranes are operating in the same area.

- 4. Real-time Feedback: Incorporate real-time feedback systems that provide operators with data on load status, crane conditions, and safety alerts.

By adhering to these best practices, operators and organizations can maximize the efficiency and safety of steel coil handling operations using overhead cranes. Ensuring proper equipment maintenance, operator training, and a strong commitment to safety are essential components of successful steel coil handling practices.

Challenges and Limitations

Efficient steel coil handling with overhead cranes offers numerous advantages, but it also comes with its share of challenges and limitations. Here's a closer look at these aspects:

Common Challenges Faced When Implementing Overhead Cranes for Steel Coil Handling

- 1. Space Constraints: Limited headroom and floor space in facilities can pose challenges when installing overhead crane systems.

- 2. Capital Investment: The initial cost of purchasing and installing overhead cranes can be substantial, especially for small or financially constrained businesses.

- 3. Operator Training: Ensuring that crane operators are properly trained and certified is essential for safety and efficiency, but it can be time-consuming and costly.

- 4. Maintenance Requirements: Overhead cranes require regular maintenance to ensure safe and reliable operation, and maintenance costs can accumulate over time.

- 5. Integration with Existing Processes: Integrating overhead cranes into existing manufacturing or logistics processes may require modifications and adjustments, leading to downtime and disruptions.

Strategies to Mitigate These Challenges

- 1. Space Optimization: Consider compact or customized crane designs that can work within limited space. Collaborate with crane manufacturers to design solutions tailored to your facility.

- 2. Financial Planning: Explore financing options and long-term cost-benefit analyses to justify the capital investment in overhead cranes.

- 3. Operator Training: Invest in comprehensive operator training programs to enhance skills, safety awareness, and productivity. Periodic retraining is essential to keep operators updated.

- 4. Scheduled Maintenance: Develop a proactive maintenance schedule and contract with reliable service providers to minimize downtime and long-term maintenance costs.

- 5. Process Evaluation: Conduct a thorough evaluation of your existing processes to identify areas where overhead cranes can be seamlessly integrated, and plan for necessary process adjustments.

Recognizing the Limitations of Overhead Crane Systems

- 1. Load Limitations: Overhead cranes have specified load capacities, and exceeding these limits can lead to equipment damage and safety hazards.

- 2. Limited Mobility: Overhead cranes are fixed in place, limiting their mobility compared to other material handling equipment.

- 3. Initial Investment: The upfront cost of overhead crane installation can be prohibitive for some businesses, particularly smaller enterprises.

- 4. Skill Dependency: Skilled operators are essential for safe and efficient crane operation. The system's effectiveness depends on operator competence.

- 5. Complexity: Overhead crane systems can be complex to design, install, and maintain, requiring specialized knowledge and resources.

Recognizing these limitations is crucial for making informed decisions about the use of overhead cranes in steel coil handling operations. While they offer numerous benefits, understanding and addressing these challenges is essential for successful implementation.

Future Trends and Innovations

The future of steel coil handling with overhead crane systems holds promise, driven by emerging technologies, sustainability considerations, and the continuous pursuit of efficiency. Here are some key trends and innovations to watch for:

Emerging Technologies and Innovations in Overhead Crane Systems

- 1. Automation and Robotics: Integration of automation and robotics technology is expected to increase, with the development of autonomous overhead cranes that can operate without direct human intervention.

- 2. Advanced Control Systems: Enhanced control systems, including predictive maintenance capabilities and real-time data analytics, will become more prevalent, allowing for smarter, data-driven decision-making.

- 3. IoT Integration: The Internet of Things (IoT) will play a significant role, enabling remote monitoring and control of overhead cranes, as well as facilitating predictive maintenance and performance optimization.

- 4. Energy Efficiency: Improved energy-efficient technologies, such as regenerative braking systems and energy recovery systems, will be integrated into overhead cranes to reduce energy consumption.

- 5. Safety Innovations: Ongoing developments in safety technology, including collision avoidance systems and augmented reality (AR) assistance for operators, will enhance workplace safety.

Potential Advancements in Steel Coil Handling Efficiency

- 1. Smart Load Monitoring: Load monitoring systems will become more sophisticated, providing real-time data on weight, balance, and potential stress points on the coil, leading to even more precise handling.

- 2. Predictive Maintenance: Predictive maintenance algorithms will become more accurate, enabling cranes to detect potential issues before they lead to breakdowns and ensuring maximum uptime.

- 3. Material Tracking: Integration with inventory management and tracking systems will enable seamless tracking and reporting of steel coil movements throughout the supply chain.

- 4. Customization: Overhead crane manufacturers will offer greater customization options, allowing businesses to tailor crane designs to their specific needs and spatial constraints.

Sustainable Practices and Their Role in the Future of Steel Coil Handling

- 1. Energy Efficiency: Sustainable overhead crane designs witl different steel coil lifters will focus on energy-efficient operation, including energy recovery during braking and regenerative systems, reducing the environmental impact.

- 2. Material Handling Optimization: Sustainable practices will involve reducing material waste, improving load stability, and minimizing product defects through precise handling.

- 3. Eco-Friendly Materials: The use of eco-friendly materials in crane construction, such as recyclable and low-impact materials, will become more common.

- 4. Renewable Energy: The adoption of renewable energy sources to power overhead cranes, such as solar or wind power, will contribute to reducing the carbon footprint of steel coil handling.

- 5. Circular Economy: Businesses will increasingly focus on adopting circular economy principles, emphasizing recycling and reusing materials to reduce the need for new steel coils.

The future of steel coil handling with overhead crane systems will be marked by advancements in technology, increased efficiency, and a growing commitment to sustainable practices. By embracing these trends, industries can not only improve their operational efficiency but also reduce their environmental impact and contribute to a more sustainable future.

Conclusion

Recap of Key Points Discussed in the Outline

In this comprehensive exploration of efficient steel coil handling with overhead cranes, we've covered a wide range of topics:

- We began by understanding the importance of steel coils in various industries and the challenges associated with inefficient handling.

- We introduced the concept of overhead cranes and explored their types, components, and functionalities.

- We delved into the advantages of using overhead cranes for steel coil handling, including improved safety, efficiency, and reduced material damage.

- Design considerations for overhead cranes, including load capacity, safety features, and maintenance, were thoroughly examined.

- Best practices for efficient steel coil handling with overhead cranes, such as pre-operation checks, proper attachment techniques, and load balance strategies, were outlined.

- We showcased real-world case studies and success stories to highlight the quantifiable benefits and lessons learned from implementing efficient steel coil handling solutions.

- We acknowledged the challenges and limitations associated with overhead crane systems and discussed strategies to mitigate them.

- Finally, we explored future trends and innovations, including emerging technologies, potential advancements in efficiency, and the role of sustainability in the future of steel coil handling.

Emphasis on the Importance of Efficient Steel Coil Handling and the Role of Overhead Cranes

Efficient steel coil handling is a cornerstone of success for industries relying on these vital materials. Overhead cranes, with their precision, safety features, and versatility, play a pivotal role in optimizing this critical process.

By efficiently handling steel coils, companies can achieve several key objectives:

- Safety: Minimizing workplace accidents and injuries through the use of advanced crane systems.

- Efficiency: Maximizing productivity, reducing downtime, and meeting tight production schedules.

- Quality: Ensuring the preservation of steel coil quality and minimizing material waste.

- Sustainability: Contributing to environmental goals through energy-efficient operations and waste reduction.

Encouragement for Further Research and Adoption of Best Practices

As industries continue to evolve, the adoption of best practices in steel coil handling and the integration of advanced technologies like overhead cranes will be critical for competitiveness, safety, and sustainability. To stay at the forefront of their respective fields, organizations should:

- Invest in Training: Prioritize operator training and certification to ensure safe and efficient crane operation.

- Stay Informed: Keep abreast of emerging technologies and trends in steel coil handling and overhead crane systems.

- Continuously Improve: Regularly evaluate and update processes to optimize efficiency and safety.

- Embrace Sustainability: Incorporate eco-friendly practices and consider the environmental impact of steel coil handling operations.

- Collaborate: Work closely with crane manufacturers and industry experts to design custom solutions that meet specific needs.

In conclusion, efficient steel coil handling with overhead cranes is not merely a matter of convenience but a strategic imperative for industries that rely on steel coils. It is a journey towards safer, more productive, and sustainable operations that will shape the future of manufacturing, construction, and logistics.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch