Gantry Cranes for Raw Material Handling for Steel Industry 5 Ton, 10 Ton

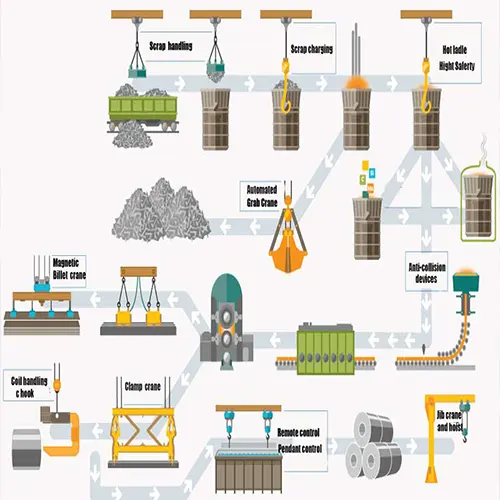

Gantry crane for iron ore, scrap metal & coke handling with single/ double girder gantry, rail / rubber tyred gantry crane, magnet, grab & container device.

Category: Steel

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

Handling Raw Materials with Precision: Gantry Cranes in the Steel Industry

The steel industry stands as one of the cornerstones of modern civilization, providing the sturdy backbone upon which our infrastructure, machinery, and countless other essential elements are built. At the heart of this industrial powerhouse lies the art and science of transforming raw materials into the gleaming steel structures we encounter every day. But before steel can be forged and shaped, it begins as raw materials—iron ore, scrap metal, and coke—each requiring meticulous handling to ensure the quality and precision demanded by modern construction.

In this blog, we delve into the intricate dance of handling raw materials with precision in the steel industry, shining a spotlight on the unsung heroes of this process: gantry cranes. These towering mechanical marvels play a pivotal role in ensuring that the raw materials are delivered with the utmost precision and efficiency to the steel manufacturing process.

Gantry Crane for Raw Materials Handling in the Steel Industry

The steel industry, a powerhouse of manufacturing, relies on a trio of essential raw materials, each playing a unique role in the complex process of steel production:

Iron Ore: The Backbone of Steel

- - Iron ore is the primary source of iron used in steel production.

- - It is typically extracted from mines and is available in various forms, including hematite, magnetite, and taconite.

- - The quality of iron ore directly impacts the quality of the final steel product. High-grade ore results in high-quality steel.

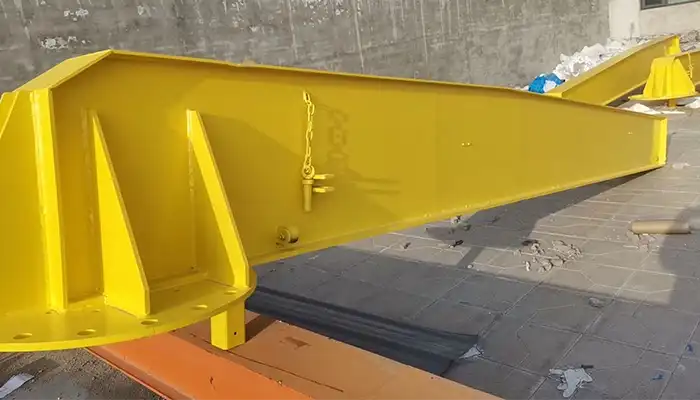

Gantry Crane and below hood devices for Iron Ore Handling

Gantry Crane for Iron Ore Handling

- Gantry Crane Suitable for steel mills and ports, the gantry crane provide precise movement along tracks.

Features:

- - Heavy load capacity to handle large quantities of iron ore.

- - Precision controls for accurate positioning.

- - Safety features, including overload protection.

Below-Hook Device: -

Lifting Magnets: Electromagnetic lifting magnets are commonly used for handling iron ore. They provide a strong, secure grip on ferrous materials and can efficiently load and unload iron ore from railcars, trucks, or ships.

Applications:

- - Loading and unloading iron ore from transportation vehicles.

- - Transferring iron ore to storage or processing areas within steel mills.

- - Ensuring the quality and quantity of iron ore delivered to the blast furnace.

Scrap Metal: The Eco-Friendly Alternative

- Scrap metal is recycled metal material obtained from discarded steel products, construction waste, and industrial leftovers.

- Recycling scrap metal by scrap handling cranes not only conserves natural resources but also reduces the energy required for steel production.

- The cleanliness and composition of scrap metal are critical factors in producing high-quality steel.

Gantry Cranes and Below-Hook Devices for Scrap Metal Handling:

Gantry Crane Types:

- - Grab bucket Gantry Crane : Versatile for outdoor scrap yards.

- - Container Gantry Crane (CGC): Specialized for handling containers filled with scrap metal.

Features:

- - High load capacity and stability to handle heavy scrap metal.

- - Efficient material handling and precise positioning.

- - Safety mechanisms to prevent accidents during handling.

Below-Hook Device:

- Grabs: Mechanical or hydraulic grabs are used to efficiently grasp and lift scrap metal. These grabs have jaws that can close around irregularly shaped scrap pieces, making them versatile for handling various scrap types.

Applications:

- - Loading and unloading scrap metal from trucks, containers, or storage areas.

- - Sorting and segregating different types of scrap metal.

- - Transporting scrap metal to recycling or processing facilities.

Coke: Fueling the Furnaces

- Coke is a high-carbon fuel derived from coal through a process called coking.

- It serves as both a fuel and a reducing agent in the blast furnace, where iron ore is transformed into molten iron.

- The purity and consistency of coke are essential to achieving the desired chemical reactions in the furnace.

Gantry Crane and Below Hook Devices for Coke Handling

Gantry Crane for Coker Handling

- - Rail-Mounted Gantry Crane (RMG): Suitable for coke handling within steel plants.

- - Rubber-Tired Gantry Crane (RTG): Offers mobility for outdoor coke storage yards.

Features:

- - Secure Grasping: The coke grab's jaws are designed to firmly grip coke, ensuring stability during lifting and transportation.

- - High Load Capacity: These grabs are built to handle the heavy weight of coke, making them suitable for the demanding requirements of coke handling.

- - Precision Control: Coke grabs provide precise control over the positioning of coke, allowing for accurate placement in storage bins or containers.

- - Safety Mechanisms: They are equipped with safety features to prevent accidents and ensure safe coke handling operations.

Below-Hook Device for Coke Handling: Coke Grab

- Coke Grab: A coke grab is a specialized below-hook device designed specifically for the efficient handling of coke in the steel industry. It is equipped with mechanical or hydraulic jaws that can securely grasp and lift coke, making it a versatile and efficient solution for coke handling.

Applications:

- - Loading and unloading coke from transportation vehicles, such as trucks or railcars.

- - Transferring coke to storage bins, containers, or designated coke storage areas within steel plants.

- - Ensuring the purity and consistency of coke delivered to the blast furnace for use as a fuel and reducing agent.

Coke grabs are essential equipment in the steel industry, playing a critical role in the efficient and safe handling of coke, a key raw material in the steel production process.

Significance of Quality and Precision in Raw Material Handling

The significance of quality and precision in handling these raw materials cannot be overstated. The steel industry is highly demanding, and deviations in material quality or handling can have far-reaching consequences:

- Quality Assurance: Steel products must meet rigorous quality standards to ensure their strength, durability, and performance. Any impurities or inconsistencies in raw materials can compromise the final product's quality.

- Consistency: To produce uniform steel products, raw materials must be handled with precision. Inconsistent material composition or handling can lead to variations in product properties, which is undesirable in industries such as construction and automotive manufacturing.

- Cost Efficiency: Efficient raw material handling reduces waste and energy consumption, contributing to cost savings in the production process.

- Environmental Impact: Precision handling, particularly in recycling scrap metal, can significantly reduce the environmental footprint of the steel industry. By minimizing waste and energy use, the industry becomes more sustainable.

In summary, the quality and precision with which raw materials are handled form the foundation of the steel industry. From the mines to the recycling facilities, every step in the supply chain must uphold these standards to ensure the steel products we rely on every day meet the highest quality and performance criteria. In the next section, we will explore how gantry cranes play a crucial role in maintaining this precision during the material handling process.

Main Types of Gantry Cranes for Steel Industry : Basics and Types

Definition of Gantry Cranes

Gantry cranes, often referred to as bridge cranes or overhead cranes, are industrial machines designed for the efficient handling and movement of heavy materials within a workspace. They are characterized by their towering structure, which includes vertical legs on either side of the load and a horizontal bridge or girder that spans the gap.

Common Types of Gantry Cranes

There are several types of gantry cranes, each tailored to specific applications within the steel industry:

Gantry cranes are versatile lifting equipment used in various industries, including the steel industry, for raw material handling. The main types of gantry cranes used for raw material handling can be categorized based on different terms, including mobility, structure, and application. Here are the main types:

1. Based on Mobility:

- a. Rail-Mounted Gantry Crane (RMG): These gantry cranes are mounted on rails and are ideal for applications where precise and controlled movement along a straight path is required. They are commonly used in steel mills and port facilities for loading and unloading materials from railcars and ships.

- b. Rubber-Tired Gantry Crane (RTG): RTGs are mobile cranes equipped with rubber tires, allowing them to move freely on solid surfaces. They are versatile and often used in outdoor environments, including scrap yards and storage yards.

2. Based on Structure:

- a. Single Girder Gantry Crane: These gantry cranes have one horizontal beam (girder) on each side and are suitable for lighter loads and lower lifting heights. They are cost-effective and commonly used for material handling in smaller steel facilities.

- b. Double Girder Gantry Crane: Double girder gantry cranes have two horizontal beams (girders) on each side, providing greater load capacity and height. They are used for heavy-duty applications in steel plants, where large and heavy raw materials need to be handled.

3. Based on Application:

- a. Container Gantry Crane (CGC): CGCs are specialized gantry cranes designed for efficiently handling containers, which may contain raw materials or finished steel products. They are commonly used in container terminals at steel ports.

- b. Scrap Yard Gantry Crane: These gantry cranes are designed for handling scrap metal in recycling yards or steel mills. They are equipped with grabs or magnets for efficient scrap handling.

- f. Scrap Charging Gantry Crane: Scrap charging gantry cranes are used in steelmaking processes like electric arc furnaces (EAFs) to charge scrap materials into the furnace. They ensure controlled and efficient scrap feeding.

Scrap yard gantry crane with magnets or grabs

The choice of gantry crane type depends on the specific requirements of the raw material handling task, including the type of raw material, its weight, the required lifting height, and the operational environment. Steel industry facilities often use a combination of these gantry crane types to optimize their material handling processes.

Key Components of a Gantry Crane

Gantry cranes are complex machines with several essential components:

- Trolley: - The trolley is the part of the crane that moves horizontally along the bridge or girder. - It carries the hoist and the load, allowing for precise positioning of materials.

- Hoist: - The hoist is the mechanism responsible for lifting and lowering the load. - It can be equipped with various attachments and hooks to accommodate different types of materials.

- Girders: - The girders are the horizontal beams that support the bridge structure. - They provide the crane with stability and strength to handle heavy loads.

- Controls: - The controls of a gantry crane are the nerve center of the operation. - They include a combination of manual and electronic controls that enable operators to manipulate the crane's movements with precision.

Advantages of Using Gantry Cranes in the Steel Industry

Gantry cranes offer a multitude of advantages that make them indispensable in the steel industry:

- High Load Capacity: Gantry cranes are built to handle heavy loads, making them ideal for lifting and transporting raw materials such as iron ore, scrap metal, and coke.

- Precision Controls: Advanced control systems enable operators to position materials with pinpoint accuracy, ensuring efficient and safe handling.

- Enhanced Safety Features: Gantry cranes are equipped with safety mechanisms, including overload protection and anti-sway technology, reducing the risk of accidents in the workplace.

- Efficient Material Movement: Gantry cranes contribute to streamlined material flow, reducing downtime and increasing productivity in steel production facilities.

In the next section, we will explore how gantry cranes play a crucial role in maintaining precision in the handling of raw materials, ensuring that the quality and consistency of steel products are upheld throughout the manufacturing process.

Precision Handling with Gantry Cranes

Importance of Precision in Raw Material Handling

Precision in raw material handling is a critical factor in the steel industry, where the quality and consistency of the final product are paramount. The following points emphasize the significance of precision:

- Quality Assurance: Precision ensures that raw materials are delivered to the manufacturing process in the right quantity and with the correct specifications, maintaining product quality.

- Consistency: Maintaining precise control over material positioning and movement guarantees uniformity in steel products, which is essential for meeting industry standards and customer expectations.

- Reduced Waste: Precision handling minimizes material wastage, optimizing resource utilization and reducing production costs.

How Gantry Cranes Ensure Precision

Gantry cranes play a pivotal role in ensuring precision in raw material handling. Here's how they achieve this:

Load Capacity and Stability

- Gantry cranes are designed with robust structures and sturdy components to handle heavy loads with stability. This is achieved through:

- Heavy-Duty Girders: The horizontal girders provide the necessary structural support to prevent deformation and maintain load stability.

- Balanced Design: The distribution of weight and load-bearing points ensures that materials are lifted and moved evenly, reducing the risk of tilting or imbalance.

Precision Controls and Automation

Gantry cranes are equipped with advanced control systems that enable precise positioning of materials. Key features include:

- Variable Speed Controls: Operators can adjust the crane's speed for gradual and accurate movements, allowing for delicate material handling.

- Positioning Systems: Gantry cranes often incorporate GPS, laser guidance, or computerized positioning systems to precisely place materials where needed.

- Automation: Some gantry cranes are fully automated, reducing the reliance on human operators and further enhancing precision.

Safety Features

Safety is a top priority in material handling operations, and gantry cranes are equipped with multiple safety features:

- Overload Protection: Gantry cranes have sensors and mechanisms that detect when the load exceeds the crane's capacity, automatically shutting down or alerting operators.

- Anti-Sway Technology: This technology minimizes load swinging during movement, ensuring that materials are positioned accurately and safely.

- Emergency Stop Systems: Gantry cranes have emergency stop buttons that instantly halt all crane movements in case of a safety concern.

Stay tuned for the next part of this blog, where we will explore safety considerations in gantry crane operations, including training and certification for crane operators and industry standards for crane safety.

Safety Considerations

Safety is of paramount importance in gantry crane operations within the steel industry. Here, we delve into the various safety aspects associated with gantry cranes:

Safety Measures in Gantry Crane Operations

- Pre-Operation Checks: Operators must conduct thorough pre-operation checks, examining the crane's components, controls, and safety features to ensure they are in proper working order.

- Load Capacity Awareness: Operators should be well-versed in the crane's load capacity limits and avoid exceeding them, as overloading can lead to accidents.

- Clear Communication: Effective communication between crane operators and ground personnel is crucial to prevent accidents. Hand signals, radios, or other communication tools are used to relay instructions.

- Load Inspection: Before lifting, operators should inspect the load for stability and secure attachment to prevent shifting during transport.

- Avoiding Overhead Obstacles: Operators must be vigilant about overhead obstacles such as power lines, structures, or other equipment that may pose hazards.

- Emergency Procedures: Gantry cranes are equipped with emergency stop systems, and operators should be trained to use them in case of safety concerns.

Training and Certification for Crane Operators

- Operator Training: Crane operators must undergo comprehensive training programs to familiarize themselves with the crane's operation, safety protocols, and emergency procedures.

- Certification: Crane operators should obtain certification from recognized organizations or regulatory bodies. Certification typically involves written tests and practical assessments to ensure operators are qualified.

- Continuing Education: Operators should engage in ongoing training to stay updated on the latest safety procedures, technology advancements, and industry best practices.

OSHA and Industry Standards for Crane Safety

- OSHA Regulations: The Occupational Safety and Health Administration (OSHA) in the United States and similar regulatory bodies in other countries have established strict regulations governing crane safety. These regulations cover areas such as operator training, load limits, and safety inspections.

- Industry Standards: Industry organizations, such as the Crane Manufacturers Association of America (CMAA), publish standards and guidelines for crane safety. These standards help ensure consistency in safety practices across the industry.

Safety Incidents and Lessons Learned

Learning from past incidents is essential for improving safety in gantry crane operations. Real-world examples can provide valuable insights into the consequences of safety lapses and the importance of adherence to safety measures. These incidents often lead to:

- Enhanced Safety Protocols: Incidents prompt companies to review and improve their safety protocols, including additional training and stricter adherence to existing guidelines.

- Technological Advancements: Safety incidents drive the development of new safety technologies, such as anti-sway systems and collision avoidance features, to prevent accidents.

- Regulatory Changes: In response to serious accidents, regulatory authorities may introduce or update safety regulations, making compliance mandatory.

By examining these examples, crane operators and industry stakeholders can gain a better understanding of potential risks and how to mitigate them, ultimately contributing to safer gantry crane operations in the steel industry.

In the next section of this blog, we will explore the critical aspect of maintenance and reliability in gantry cranes, emphasizing the importance of regular maintenance practices to minimize downtime and ensure safe operations.

Maintenance and Reliability

Maintenance plays a pivotal role in ensuring the safety, efficiency, and longevity of gantry cranes in the steel industry. In this section, we will delve into the crucial aspects of maintenance and reliability:

Importance of Regular Maintenance

- Safety Assurance: Regular maintenance is essential to identify and address potential safety hazards, preventing accidents and injuries during crane operations.

- Equipment Longevity: Proper maintenance extends the lifespan of gantry cranes, reducing the need for costly replacements and ensuring a better return on investment.

- Operational Efficiency: Well-maintained cranes operate more efficiently, minimizing downtime and enhancing productivity in steel manufacturing facilities.

Preventive Maintenance Practices for Gantry Cranes

- Scheduled Inspections: Gantry cranes should undergo regular inspections according to a predetermined schedule. These inspections include checks of critical components such as hoists, brakes, and structural elements.

- Lubrication: Adequate lubrication of moving parts is crucial to reduce friction and wear. Lubrication schedules should be followed diligently.

- Electrical System Checks: Inspecting electrical components, wiring, and control systems helps prevent electrical malfunctions and potential fires.

- Load Testing: Periodic load testing ensures that the crane can handle its maximum capacity safely.

- Alignment and Calibration: Aligning the crane's components and calibrating its control systems ensure precise and safe operation.

- Emergency Response Plans: Having well-defined procedures for responding to breakdowns or emergencies is essential to minimize downtime and ensure operator safety.

Ensuring Reliability to Minimize Downtime

- Spare Parts Inventory: Maintaining an inventory of critical spare parts ensures swift replacements in case of component failures, reducing downtime.

- Predictive Maintenance: Utilizing technologies such as vibration analysis and thermal imaging allows for the early detection of potential issues, enabling proactive maintenance before breakdowns occur.

- Operator Training: Well-trained operators can identify early warning signs of equipment issues and report them promptly, contributing to reliability.

- Documentation and Records: Maintaining comprehensive records of maintenance activities, repairs, and inspections provides valuable data for tracking crane performance and identifying trends.

By highlighting these success stories, we emphasize the tangible benefits that regular maintenance and reliability efforts bring to the steel industry and encourage others to adopt similar practices in their crane operations.

In the final part of this blog, we will explore the environmental impact of gantry cranes in the steel industry and examine their role in contributing to sustainability and eco-friendliness.

Environmental Impact

Environmental Concerns in the Steel Industry

The steel industry, while essential, poses several environmental challenges due to its resource-intensive nature:

- Resource Depletion: Steel production consumes vast quantities of iron ore and coal, depleting natural resources.

- Energy Consumption: Steel manufacturing is energy-intensive, leading to significant greenhouse gas emissions.

- Pollution: The industry generates air and water pollution, impacting ecosystems and human health.

How Gantry Cranes Can Contribute to Sustainability

Gantry cranes, when used strategically, can play a role in mitigating the environmental impact of the steel industry:

- Efficient Material Handling: Gantry cranes efficiently move raw materials, reducing energy consumption and emissions associated with transport.

- Recycling Support: Gantry cranes facilitate the handling of scrap metal for recycling, reducing the need for virgin iron ore and decreasing resource depletion.

- Precision Operations: Gantry cranes' precise control systems minimize material waste, optimizing resource use and reducing environmental impact.

- Green Technology Integration: The adoption of eco-friendly technologies, such as electric or hybrid gantry cranes, can reduce greenhouse gas emissions from crane operations.

Eco-Friendly Initiatives Using Gantry Cranes

- Electric Gantry Cranes: Steel plants have transitioned to electric gantry cranes, reducing reliance on diesel fuel and lowering emissions.

- Recycling Excellence: Steel mills using gantry cranes to efficiently handle scrap metal have significantly increased recycling rates, conserving resources.

- Precision Handling: Gantry cranes equipped with advanced automation systems have reduced material waste and improved resource efficiency.

- Solar-Powered Cranes: Some gantry cranes are powered by renewable energy sources like solar panels, further reducing their environmental footprint.

These case studies illustrate that gantry cranes, when employed thoughtfully, can be part of a broader sustainability strategy in the steel industry. By reducing waste, conserving resources, and minimizing emissions, gantry cranes contribute to a more eco-friendly and sustainable steel production process.

In conclusion, gantry cranes are not just heavy lifters in the steel industry; they are also key players in addressing environmental concerns and promoting sustainability. Their efficient and precise material handling capabilities can help the industry reduce its ecological footprint, making steel production more environmentally responsible.

Future Trends and Innovations

Emerging Technologies in Gantry Crane Design and Operation

The world of gantry cranes is continuously evolving, with several emerging technologies and innovations poised to reshape their design and operation:

- Advanced Materials: The use of lightweight yet robust materials, such as carbon fiber-reinforced composites, is expected to make cranes more efficient and durable.

- Telematics and IoT: Gantry cranes are increasingly equipped with sensors and IoT devices that provide real-time data on performance, maintenance needs, and safety, enabling predictive maintenance and smarter operations.

- Energy-Efficient Systems: Energy-efficient motors and regenerative braking systems can reduce power consumption and environmental impact.

- Remote Operation and Augmented Reality: Remote operation capabilities and augmented reality interfaces will enhance operator control and safety.

Integration with Industry 0 and Automation

Gantry cranes are being integrated into the broader framework of Industry 0, where automation, data exchange, and smart technology are transforming industrial processes:

- Autonomous Operation: Gantry cranes are moving towards greater autonomy, with advanced algorithms and AI enabling self-driving and self-optimizing operations.

- Data Analytics: Big data analytics are being applied to crane data, allowing for predictive maintenance, optimization of material flows, and performance improvements.

- Robotics Integration: Collaborative robots (cobots) are working alongside gantry cranes in tasks like loading, unloading, and palletizing, improving efficiency and flexibility.

- Digital Twins: Digital twin technology creates virtual replicas of gantry cranes, allowing for real-time monitoring, testing, and simulations to optimize operations and maintenance.

Potential for Greener and More Efficient Solutions

As environmental concerns become increasingly significant, the future of gantry cranes is likely to prioritize greener and more efficient solutions:

- Electric and Hybrid Cranes: The adoption of electric and hybrid gantry cranes will continue to reduce carbon emissions and reliance on fossil fuels.

- Renewable Energy Integration: Gantry cranes powered by renewable energy sources like wind or solar will become more common, further reducing their carbon footprint.

- Lighter Materials: Continued research into lightweight materials will make cranes more energy-efficient and reduce wear and tear.

- Efficient Scheduling and Planning: Advanced scheduling algorithms and logistics planning will optimize material flows, reducing wait times and energy consumption.

In summary, gantry cranes are on the cusp of a technological revolution. Emerging technologies, increased automation, and a focus on sustainability are driving the future of these critical industrial workhorses. As gantry cranes evolve, they will play an even more integral role in the steel industry's quest for efficiency, precision, and environmental responsibility.

Conclusion

Recap of the Importance of Gantry Cranes in the Steel Industry

In the world of steel production, where raw materials are transformed into the building blocks of modern civilization, gantry cranes stand tall as indispensable workhorses. Their significance cannot be overstated, as they shoulder the responsibility of handling raw materials with precision and efficiency. From iron ore to scrap metal and coke, gantry cranes are the unsung heroes that ensure these materials are delivered to the manufacturing process with the utmost reliability.

Emphasis on Precision, Safety, and Sustainability

Throughout this exploration of gantry cranes in the steel industry, several key themes have emerged:

- Precision: Gantry cranes are instrumental in upholding the precision required in raw material handling, contributing to the quality and uniformity of steel products.

- Safety: Safety is paramount in gantry crane operations, with stringent measures, training, and compliance with regulations to ensure accident-free workplaces.

- Sustainability: Gantry cranes play an increasingly pivotal role in promoting sustainability within the steel industry. They contribute to resource conservation, energy efficiency, and reduced environmental impact, aligning with global efforts to combat climate change.

Outlook for the Continued Evolution of Gantry Crane Technology in the Industry

As we look to the future, the evolution of gantry crane technology within the steel industry is poised for exciting advancements. With emerging technologies, greater automation, and a heightened focus on sustainability, the outlook is promising. Gantry cranes will continue to:

- Incorporate cutting-edge materials and innovative designs for enhanced efficiency and durability.

- Integrate seamlessly into Industry 0 and automation initiatives, improving performance and safety.

- Embrace greener practices, such as electric and renewable energy-powered cranes, to reduce environmental impact.

- Foster a culture of continuous improvement, where safety, precision, and sustainability remain at the forefront of operations.

In conclusion, gantry cranes are not just machines; they are the lifeblood of the steel industry. They embody the industry's commitment to excellence, from the precision required in material handling to the unwavering dedication to safety and sustainability. As they continue to evolve and adapt to the changing landscape of steel production, gantry cranes will remain steadfast in their role as pillars of strength in an ever-advancing industry.

Main Projects

Related Products

6.3 ton overhead crane kit for sale Philippines, complete single girder top running overhead crane system, low headroom design for workshop indoor use.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch