Your Trusted Overhead Wall Crane Manufacturer & Supplier

Wall Crane for Sale, Wall-Mounted Cranes & Wall Travelling Cranes

Wal Mounted Crane 1 Ton to 5 Ton for Sale, Small, Affordable & Space Saving

Small, Affordable & Efficient Space Use Wall Jib Crane for Sale 500kg, 1 Ton, 2Ton, 3 Ton, 4 Ton, 5Ton . Explore the benefits of small, affordable wall-mounted and travelling cranes that maximize efficiency and conserve floor space.

Wall Jib Crane Overview, Types & Applications

Wall-mounted cranes are specialized lifting devices that are securely attached to the walls of a facility. They are designed to maximize vertical space while minimizing floor occupancy, making them ideal for environments where space is at a premium.

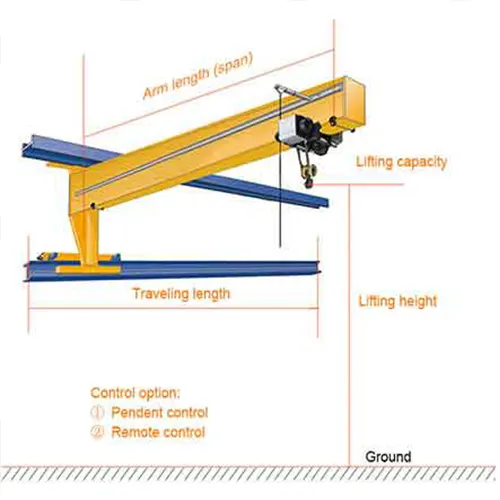

- Components: Typically, these cranes consist of a horizontal arm (or jib) that extends outward from the wall, a lifting mechanism, and sometimes a trolley for lateral movement along the ji

- Functionality: Operators can use these cranes to lift and maneuver loads within a defined workspace, allowing for efficient material handling without the need for expansive floor space.

- Types: Common variations include wall jib cranes, wall-mounted overhead cranes, and wall-mounted gantry cranes, each offering distinct advantages for different applications.

Importance in Industrial Applications

Wall-mounted cranes are integral to various industrial settings, significantly enhancing operational efficiency and safety. Their practical applications include:

- Increased Productivity: By providing a reliable lifting solution, these cranes help reduce downtime associated with manual lifting, allowing workers to focus on other critical tasks.

- Safety Enhancements: They minimize the risk of workplace injuries related to heavy lifting, as operators can handle loads with mechanical assistance rather than relying on physical strength.

- Space Optimization: Wall-mounted cranes free up valuable floor space, enabling better layout configurations for machinery, storage, and work areas.

Wall Jib Cranes for sale :These cranes feature a cantilevered arm that pivots around a fixed point on the wall.

Advantages:

- Ideal for lifting and moving loads within confined areas.

- Flexible operation with a wide range of motion.

- Commonly used in workshops, assembly lines, and maintenance tasks.

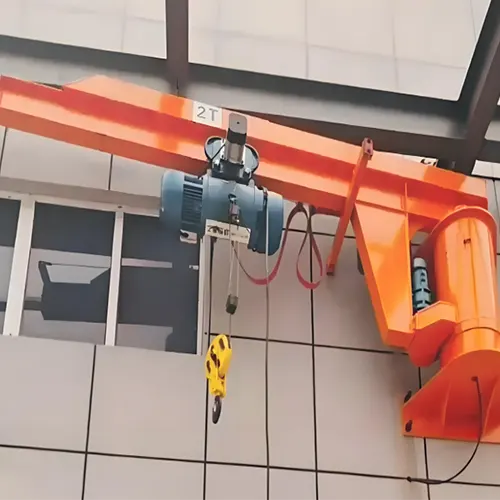

Wall-Mounted Overhead Cranes : These cranes have a runway system attached to the wall, allowing for horizontal movement along the length of the workspace.

Advantages:

- Capable of transporting heavier loads across greater distances.

- Efficient for production lines and large-scale operations.

- Frequently used in manufacturing plants and warehouses where items need to be moved between different stations.

Wall-Mounted Gantry Cranes for Sale: This type combines the features of a gantry crane with wall support, where one side is fixed to the wall and the other is supported by legs.

Advantages

- Provides stability while allowing for lateral movement across a designated area.

- Utilizes wall space effectively for additional support.

- Suitable for loading and unloading materials in areas where space constraints exist.

Wall Jib Cranes: Wall Mounted & Wall Travelling Jib Cranes

Wall-mounted jib cranes are versatile lifting solutions specifically designed to optimize material handling in confined spaces. Their innovative design minimizes floor space usage while enabling a wide range of lifting operations, making them ideal for various industrial applications. The crane consists of a horizontal arm, or jib, that extends from a vertical support mounted securely on a wall, allowing for efficient lifting and maneuvering of loads.

One of the key features of wall jib cranes is their pivoting action. The jib arm typically pivots around a fixed point, facilitating horizontal movement and precise positioning of loads, which enhances productivity in work environments. Additionally, these cranes can integrate various lifting mechanisms, such as manual hoists, chain hoists, or wire rope hoists, to meet specific operational needs.

The compact design of wall-mounted jib cranes maximizes vertical space, ensuring that the floor remains clear for other operations. This efficiency not only streamlines workflow but also contributes to a safer and more organized workspace, making wall jib cranes a valuable asset in any industrial setting.

- Pivoting Action: The jib arm typically pivots around a fixed point, allowing for horizontal movement and positioning of loads.

- Lifting Mechanisms: Various hoists, such as manual hoists, chain hoists, or wire rope hoists, can be integrated into the crane system for lifting capabilities.

- Compact Design: The wall-mounted structure helps maximize vertical space, ensuring that the floor remains clear for other operations.

Wall Mounted/ Wall Bracket Jib Crane

The Wall Bracket Jib Crane is an effective lifting solution designed to be firmly fixed to wall columns or steel structures, providing a stable and reliable lifting point. Its design is particularly advantageous for environments where space is at a premium, making it a popular choice in various industrial applications.

One of the primary benefits of this crane type is its ability to lift lighter loads efficiently in localized areas. This capability enhances productivity, especially in settings that require precise maneuvering and quick access to materials. Additionally, the installation process for wall bracket jib cranes is straightforward, requiring minimal space and resources. This ease of setup allows businesses to integrate the crane into their workflow without significant disruption.

Wall bracket jib cranes are commonly found in workshops, maintenance areas, and assembly lines, where space constraints often dictate the choice of lifting equipment. Their compact design not only maximizes vertical space but also ensures that the floor remains clear for other operations, contributing to a safer and more organized work environment. Overall, the Wall Bracket Jib Crane is a versatile and practical lifting solution for many industrial settings.

Classifications of Wall Bracket Jib Cranes

Wall bracket jib cranes are categorized into several types based on their design and structural features. Each classification serves specific applications and operational requirements. Below are the primary classifications:

The KBK tie rod jib crane features a modular design that incorporates tie rods for enhanced stability. This type is particularly beneficial for dynamic lifting operations in confined spaces.

- Flexibility: Easily customizable for various load handling tasks.

- Ideal Applications: Commonly used in workshops and assembly lines.

H Beam Cantilever Wall Tracked Jib Crane

The H beam wall tracked jib crane is constructed with a robust H-shaped beam, offering excellent load-bearing capacity and durability.

- Strength: Designed for heavier lifting applications.

- Efficiency: Provides smooth and efficient movement of loads, making it suitable for industrial environments.

Box Girder Wall Bracket Jib Crane

The box girder wall bracket jib crane utilizes a box-shaped beam, maximizing load distribution and structural integrity.

- Stability: Ideal for lifting heavy and awkward loads.

- Space Efficiency: The compact design allows for efficient use of vertical space in various operational settings.

Each classification of wall bracket jib cranes offers unique advantages tailored to different lifting needs and space constraints in industrial applications. Understanding these classifications enables businesses to select the most suitable jib crane to enhance their material handling efficiency.

Specific Capacity of Wall Bracket Jib Cranes

Wall bracket jib cranes are specifically designed for handling light loads, making them ideal for various applications in workshops and industrial environments with limited space. These cranes typically have a lifting capacity ranging from 0.5 tons to 5 tons, allowing for efficient management of lighter materials while optimizing floor space. Due to their unique design and functionality, wall bracket jib cranes are often referred to as Small Wall Mounted Jib Cranes or Light Duty Wall Mounted Jib Cranes. Their compact structure enables them to fit seamlessly into tight areas, making them suitable for operations in confined spaces where traditional cranes may not be feasible. This adaptability is crucial for businesses aiming to maximize operational efficiency without sacrificing safety or accessibility.Capacity Options

- 0.5 Ton Wall Bracket Jib Crane:This wall bracket jib crane is designed for the lightest lifting tasks, making it perfect for small workshops or maintenance areas.Ideal for handling tools, small parts, or equipment in confined spaces.

- 1 Ton Wall Bracket Jib Crane:With a capacity of one ton, this wall bracket jib crane provides increased versatility for slightly heavier loads while maintaining a compact footprint.: Commonly used in assembly lines or repair shops for lifting moderate loads.

- 2 Ton Wall Bracket Jib Craneis wall bracket jib crane can handle two tons, offering a balance between capacity and space efficiency.: Suitable for manufacturing facilities where mid-weight components require frequent lifting.

- 3 Ton Wall Bracket Jib Crane:Capable of lifting three tons, this wall bracket jib crane is designed for more demanding tasks while still fitting into tight spaces.: Ideal for larger workshops or warehouses handling various parts and materials.

- 5 Ton Wall Bracket Jib Crane:This is the maximum capacity within the wall bracket jib crane category, allowing for significant load handling.: Used in heavy-duty applications, such as manufacturing plants where substantial materials need to be lifted and moved.

These capacity options for wall bracket jib cranes helps businesses select the appropriate model for their specific needs, ensuring efficient and safe material handling in their operations.

Wall Travelling Jib Cranes

Wall travelling jib cranes are designed to enhance flexibility in material handling by allowing the jib to move along a rail mounted on the wall. This functionality makes them suitable for larger operational areas, offering the ability to transport loads across a wider range compared to fixed jib cranes.

Features

- Increased Mobility: The ability to travel along the wall allows for greater coverage within a workspace, making it easier to lift and move materials over longer distances.

- Space Efficiency: Wall travelling jib cranes save valuable floor space, as the design utilizes vertical space, ideal for environments with limited room.

- Customizable Design: These cranes can be tailored to meet specific operational requirements, including the type of hoist and lifting capacity.

- Durability: Built to withstand industrial conditions, wall travelling jib cranes are made from robust materials ensuring long-term performance.

Applications

Wall travelling jib cranes are particularly effective in linked workshops and facilities, providing flexible material handling solutions in various environments, including:

- Manufacturing Plants: These cranes facilitate the transportation of components and assemblies between interconnected production areas, improving workflow efficiency.

- Assembly Lines: In facilities with multiple assembly stations, wall travelling jib cranes enable the quick movement of parts, reducing downtime and enhancing productivity.

- Warehousing and Distribution Centers: They streamline operations by allowing for the movement of goods between linked storage areas, making inventory management more efficient.

- Maintenance and Repair Shops: Commonly used in facilities where equipment needs to be serviced, these cranes assist in lifting heavy machinery parts from one station to another.

- Construction Sites: Ideal for transporting materials between different areas of a construction site, especially where space is limited and mobility is essential.

By utilizing wall travelling jib cranes in these applications, businesses can maximize efficiency and optimize their material handling processes across linked workshops and facilities.

Classifications of Wall Travelling Jib Cranes

Wall travelling jib cranes can be classified based on their design and hoisting mechanisms, allowing for flexibility and adaptability in various applications. Each classification comes with its own advantages and typical uses.

H Beam Cantilever Rail Travelling Wall Crane :Utilizes an H-shaped beam for structural strength.

Advantages: Provides excellent stability and minimizes deflection under heavy loads, making it suitable for demanding lifting tasks.: Commonly used in manufacturing plants and warehouses where heavy components need to be lifted and transported efficiently.

Box Girder Rail Travelling Wall Crane :Features a box-like structure that enhances rigidity.

Advantages: The enclosed design protects the lifting mechanism from environmental factors, ensuring durability and longevity.: Ideal for applications requiring medium to heavy lifting, such as assembly lines and large industrial facilities.

Tie Rod Cantilever Rail Travelling Wall Crane Design:Incorporates tie rods for additional support and stability.

Advantages: Effective for dynamic lifting applications, this design allows for greater load distribution and reduces the risk of structural failure.: Frequently used in environments with varying load conditions, such as construction sites and maintenance shops.

Crane Hoists

- Manual Hoist:Operated manually for lighter loads.Advantages: Cost-effective and simple to use, making it ideal for occasional lifting tasks.: Suitable for small workshops or maintenance areas where lighter components need to be lifted.

- Chain Hoist:Utilizes a chain mechanism for lifting.Advantages: Reliable for moderate loads and versatile enough to be used in various industrial settings.: Commonly found in assembly lines and warehouses where efficient lifting of mid-weight items is required.

- Wire Rope Hoist :Designed for heavy lifting using a wire rope system.Advantages: Offers high durability and efficiency, suitable for rigorous industrial applications requiring substantial lifting capacity.: Often used in heavy manufacturing, shipping yards, and construction sites where large and heavy materials need to be handled.

- By These classifications, advantages, and applications, businesses can choose the appropriate wall travelling jib crane configuration to meet their specific operational needs and ensure effective material handling.

Capacity Options for Wall Travelling Jib Cranes

Wall travelling jib cranes are available in various capacity options to meet diverse operational needs. Each capacity is designed to handle specific loads efficiently, ensuring safe and effective lifting in industrial environments.

- 0.5 Ton Wall Travelling Jib Crane:Ideal for light-duty applications, this crane can easily handle smaller loads.: Commonly used in workshops, small assembly areas, and maintenance tasks where lighter materials are handled.

- 1 Ton Wall Travelling Jib Crane :Suitable for moderate lifting requirements, providing a good balance of capacity and maneuverability.: Frequently used in manufacturing facilities and warehouses for general material handling and assembly tasks.

- 2 Ton Wall Travelling Jib Crane :Offers increased lifting capacity, making it suitable for handling heavier items efficiently.: Often utilized in industrial settings where medium to heavy loads are moved, such as automotive and metalworking industries.

- 3 Ton Wall Travelling Jib Crane :Designed for heavy-duty applications, this crane is capable of lifting substantial weights safely.Ideal for larger manufacturing plants and warehouses where significant material handling is required, particularly in shipping and receiving operations.

By The various capacity options, businesses can choose the appropriate wall travelling jib crane to enhance their operational efficiency and safety.

Selection Options for Wall Jib Cranes

When selecting wall-mounted cranes, it's essential to consider various factors to ensure optimal performance and safety. The following sections outline key selection options:

Load Capacity

- Weight Requirements:Assess the maximum load that will be lifted regularly. This includes considering both static loads (the weight of materials) and dynamic loads (forces exerted during lifting and movement).It's crucial to account for any additional safety margins, typically recommended to be 20-25% above the expected maximum load.

- Common Capacity Ranges:Wall-mounted cranes typically range from 0.5 tons to 5 tons, with some models offering higher capacities for specialized applications.Choose a crane that not only meets your current needs but also accommodates potential future increases in load requirements.

Reach and Span

- Determining Required Jib Length: Evaluate the distance from the wall to the point where lifting operations will occur. The jib length should be long enough to cover the necessary work area without compromising stability.Consider the lifting height and ensure the jib can operate effectively within the space constraints.

- Considerations for Workspace Layout: Analyze the overall workspace layout to identify potential obstructions and optimize the crane's positioning.Ensure that the crane's reach aligns with workstations, equipment, and storage areas to facilitate efficient material handling.

Mounting Options

- Wall Types and Structural Considerations: Different wall types (concrete, brick, steel) have varying load-bearing capacities. Ensure the wall structure can support the weight and dynamic forces exerted by the crane.Conduct a structural analysis if necessary, potentially consulting a structural engineer to confirm compatibility.

- Installation Requirements: Assess the installation process, including any modifications needed for the wall or surrounding area.Ensure that the installation follows manufacturer guidelines and industry safety standards to promote safe and reliable operation.

By carefully considering these selection options, businesses can choose the most suitable wall-mounted crane to enhance operational efficiency and ensure safe material handling.

Wall Crane Buying Considerations

When purchasing a wall-mounted crane, several key factors should be evaluated to ensure a wise investment. The following sections detail important buying considerations:

Quality and Safety Features

- Compliance with Industry Standards : Ensure the crane meets relevant industry standards and regulations, such as ANSI, OSHA, or ISO. Compliance not only ensures safety but also enhances the crane's reliability.Verify that the equipment has been tested for durability and performance in real-world conditions.

- Safety Mechanisms and Controls: Look for cranes equipped with essential safety features, such as overload protection, emergency stop buttons, and limit switches to prevent overextension.Evaluate the user interface and controls for intuitiveness and ease of operation, which contribute to safer lifting practices.

Manufacturer Reputation

- Researching Suppliers:Investigate various manufacturers to identify those known for producing high-quality cranes. Look for companies with a solid history in the industry and a track record of innovation.Consider manufacturers who provide comprehensive support services, including installation and maintenance.

- Evaluating Customer Reviews and Case Studies:Read customer reviews and testimonials to gauge user satisfaction and common experiences with the crane's performance and reliability.Review case studies that showcase the crane's application in similar industries or environments, providing insight into real-world performance.

Cost and Budgeting

- Total Cost of Ownership:Consider not only the initial purchase price but also the long-term costs associated with maintenance, repairs, and operation. A lower upfront cost may lead to higher expenses over time if the crane is less durable or requires more frequent service.Factor in the costs of installation and any modifications needed for your facility.

- Comparing Prices and Features:Collect quotes from multiple suppliers to compare prices while also evaluating the features offered. Pay attention to the specifications and benefits of each model to ensure you are making a cost-effective decision.Look for bundled packages that may include additional accessories or services at a reduced rate, enhancing overall value.

By taking these buying considerations into account, businesses can make informed decisions when selecting wall-mounted cranes, ensuring they meet operational needs while maintaining safety and budgetary constraints.

How to Select the Right Wall Crane for Your Facility

Choosing the right crane for your facility involves a thorough evaluation of various factors to ensure it meets operational requirements. The following sections outline the key steps in this selection process:

Assessing Your Facility's Layout

- Measuring Space and Headroom:Begin by accurately measuring the available space where the crane will be installed. Take note of the overall dimensions, including length, width, and height, to determine if a wall-mounted crane will fit.Evaluate the headroom, which is the vertical space between the crane's lifting mechanism and the highest point in the workspace. Ensure there is sufficient clearance for lifting operations without obstruction.

- Identifying Workflow Needs:Analyze the specific workflows within your facility. Consider the types of materials being handled, their weights, and how often they need to be lifted or moved.Determine the most efficient routes for material handling, taking into account any potential obstacles that may affect crane operation.

Consulting with Experts

- Engaging with Crane Manufacturers or Suppliers: Reach out to reputable crane manufacturers or suppliers for advice on the best options for your specific requirements. Their expertise can provide valuable insights into suitable models and configurations.Discuss your facility's layout, load requirements, and intended applications to receive tailored recommendations.

- Seeking Professional Recommendations:Consider hiring a consultant or an engineer with experience in material handling systems. Their expertise can help in selecting the right crane that fits your operational needs and complies with safety regulations.Request case studies or examples of similar installations to understand how various options have performed in comparable settings.

Testing and Demonstrating Equipment

- Evaluating Crane Performance:If possible, arrange for a demonstration of the crane in action. This allows you to observe its performance, including lifting speed, stability, and ease of operation.Assess how well the crane handles the expected load and any specific tasks relevant to your operations.

- Ensuring Ease of Use and Maintenance:Evaluate the user interface and controls for intuitiveness. A crane that is easy to operate will improve productivity and reduce the risk of accidents.Inquire about maintenance requirements and check how accessible the components are for routine servicing. A crane that is easier to maintain will lead to lower downtime and better long-term performance.

By following these steps, businesses can effectively select the right crane for their facility, enhancing productivity while ensuring safety and operational efficiency.

Conclusion: Send us an Inquiry to Get Your Wall Crane Design

In summary, selecting the appropriate wall-mounted crane is a critical decision that can significantly impact efficiency and safety in material handling operations. Key considerations include The different types of wall-mounted cranes, such as wall bracket jib cranes and wall travelling jib cranes, along with their classifications and load capacities. Factors like facility layout, workflow needs, and expert consultation play vital roles in making an informed choice. Additionally, evaluating quality, safety features, and total cost of ownership ensures that your investment aligns with operational requirements.

Choosing the right wall-mounted crane requires careful analysis of your specific needs and constraints. By thoroughly assessing your facility's layout, consulting with industry experts, and testing equipment performance, you can make a well-informed decision that enhances operational efficiency. Prioritizing quality, safety, and ease of use will not only improve productivity but also contribute to a safer working environment. Investing time and effort in this selection process will ultimately lead to a more effective material handling solution tailored to your unique requirements.