Your Trusted Overhead Travelling Crane Manufacturer & Supplier

I beam crane & W beam Crane

Economical Low Headroom Beam crane

Beam crane for sale. What are I beam crane or H beam crane? As for beam cranes, it refers to a type of overhead material handling equipment, which takes the steel beams, such as, I beam / W beam or H beam as the main girder of lifting crane , equipped with beam hoists, electric chain hoist or wire rope hoists for various types of loads handling in many industrial sectors. Compared with box girder crane, the beam cranes are usually used for light loads handling. There are types of beam cranes are available based on crane structure designs including i Bean / H beam overhead crane, gantry crane & jib crane design, with beam hoist for light & low headroom material handling.

<

![]()

<

![Gantry beam crane Gantry beam crane]()

Beams for overhead beam crane construction

Beams come in a variety of shapes and sizes. A construction beam is a type of structural element that supports weight by defying gravity's pull. Its horizontal span is significantly greater than its width or depth. Beams are distinguished by their shape, length, and material. The most typical beam types look like a capital I or a capital H. They are commonly used in building, civil engineering, heavy machinery, truck construction, and other heavy duty tasks. Beams are commonly used to support large structures. Aluminum, Stainless Steel, and Hot Rolled Beam are all available for beam crane construction.

H beam or W beam

W or H beams are structural steel beams. It is really strong. Its name refers to the way its cross section resembles a letter H. Compared to an I-beam, the W or H beam has broader flanges, whereas the I-beam has tapered edges. The Web is the height, and the flange is the width. The flange by web ratio is what distinguishes I-beams from H-beams. Because the W or H beam is typically heavier than the I beam, some people claim that it is superior to the I beam. Nevertheless, this claim is debatable because the W beam is typically heavier.

Wide Flange (WF) Beams that have been hot-rolled. as H Beams as well. Wide Flange Beams are frequently used in commercial, industrial, and institutional buildings, bridges, mezzanines and platforms, walers, wallsystems, trailer and truck-bed framing, machine bases, and a variety of other structural steel construction applications.

In the civil construction sector, beams are utilized as foundations or as containing supports for multi-story buildings. In the industrial setting, they are also employed in the construction of warehouses, the structural supports for machinery and equipment, maritime platforms, overhead cranes, and monorails.

<

![H beam H beam]()

<

![I beam I beam]()

An I-beam has tapered edges, but a W-beam does not. Its resemblance to a capital I when viewed from a cross section is how it got its name. With an I-beam, the height of the cross section is higher than the width of its flange. I-beams are preferable for constructions where light weight is required since they are lighter than H-beams.

Overhead i beam crane

The overhead beam crane is a single-beam bridge crane that uses an steel beam as its main girder to support its lifting mechanism, either an electric chain hoist or a wire rope hoist. They are available with top running crane & undehrung crane designs.

A single girder overhead beam crane, sometimes known as an I beam or H beam crane. These are specialized material handling equipment with features like high rigidity, low dead weight, and exceptional design, etc. The best option for you would be to use an overhead crane with an steel beam to reduce your factory's working area requirements and investment costs.

<

![Single beam overhead cranes/ Eot crane with single girder & double girder top running design Single beam overhead cranes/ Eot crane with single girder & double girder top running design]()

Single beam overhead cranes/ Eot crane with single girder & double girder top running design

<

![Under running overhead I beam crane Under running overhead I beam crane]()

<

![Monorail I beam crane Monorail I beam crane]()

<

![Freestanding i beam overhead crane Freestanding i beam overhead crane]()

Freestanding i beam overhead crane

Features of of Overhead Bridge I Beam Crane

- • Design: Small size, light weight, simple to use, simple to maintain.

- • Motors: Depending on the applications, crane duty motors, squirral cage induction motors for hoists and cranes, and slippering induction motors for heavy duty cranes will be offered.

- • Gear boxes: Case-hardened flat helical/spur gear units with high-grade surface treatments, permanent oil/grease lubrication, and light alloy housings.

- • Brakes:Electromagnetic DC single-disc or dual-disc brakes with automated braking in the event of a power outage.

I beam gantry crane

The gantry beam cranes are available in various types. Based on beam crane construction materials, there steel beam gantry & Aluminum beam gantry crane, And based on the mounting types, the are roller travelling or rail travelling i beam gantry crane / w beam gantry cranes. With flexible crane design, the customized I beam gantry crane are available.

<

![Steel i beam gantry crane Steel i beam gantry crane]()

Steel i beam gantry crane

<

![Lightweight alumnium i beam gantry crane Lightweight alumnium i beam gantry crane]()

Lightweight alumnium i beam gantry crane

<

![Rail travelling i beam gantry crane Rail travelling i beam gantry crane]()

Rail travelling i beam gantry crane

<

![Semi i beam gantry crane Semi i beam gantry crane]()

Features of I beam gantry crane

- Various crane types, High flexibility. Due to the various types of gantry cranes, the i beam gantry cranes can be designed into different types to meet your customized needs, portable gantry, rail travelling, steel gantry , and Alum gantry crane, semi gantry and full gantry crane, etc.

- Economical price. Since the free standing gantry crane design, the gantry cranes do not needs the supporting columns and structures, which is very economical. And compared with box girder crane, the H beam and I beam crane is more simple and easy to construction and have cheaper price.

- Wide applications. Indoor and outdoor use for different workshops and yards in vast industrial sectors.

I beam jib crane

I beam jib crane is a type of jib cranes, which takes the steel beam as the cantilever. Compared with tie rod jib crane design, the I beam jib crane provides more lifting height with given specification in a low headroomworkshop or space limited workshops. The I beam jib cranes also can be classified into freestanding jib, wall traveling and wall mounted jib designs.

The I-beam series jibs can be used in assorted places like port, water line, manufacturing line, shop, garage and etc.

<

![Pillar jib crane with I beam design Pillar jib crane with I beam design]()

Pillar jib crane with I beam design

<

![Wall mounted I beam jib crane Wall mounted I beam jib crane]()

Wall mounted I beam jib crane

<

![Wall travelling H/I beam cantilever crane Wall travelling H/I beam cantilever crane]()

Wall travelling H/I beam cantilever crane

<

![I beam hoist I beam hoist]()

I beam hoist & H beam hoist

A beam hoist is a relatively small and lightweight piece of lifting equipment. It is frequently utilized to load and unload materials in factories, warehouses, and production lines. It moves quickly and steadily, making it an essential lifting tool for boosting productivity and enhancing working conditions.

As a well-known famous electric hoist manufacturer, I beam chain hoist and wire rope hoist with general economical style and advanced European style are vailable with excellent quality.

FAQs I beam crane & W beam Crane

What is an H-beam & I beam ?

<

![I beams I beams]()

<

![H beams H beams]()

1. What is an I beam ?

I beams can be used to create columns and support frames for hoists, elevators, trailers, trolleyways, structural steel buildings, and bridges.

Ordinary I-beams, light I-beams, and broad flange I-beams are the three basic categories of I beams. It is split into wide, medium, and narrow wide flange I-beams depending on the height ratio of the flange to the web. The last two produce specifications of 10-60, meaning that the appropriate height is 10-60cm.

Lightweight I-steel features little weight, thin webs, and narrow flanges at the same height. The H-beam is another name for the broad flange I-beam. Two parallel legs and no slope inside the legs define the cross section. It is also known as "universal I-beam" because it is a cost-effective segment of steel that is rolled on a four-high universal rolling mill. National standards have been established for regular and light I-beams.

The I-beam has a cross-section that is "I"-shaped, as its name would imply. The upper and lower flanges' inner surfaces have a slope, often 1: 6, which makes the inside of the flanges thick and thin. The primary plane's cross-sectional characteristics are highly diverse, making it challenging to apply steel's strength properties. The construction of the I-beams has dictated their short-term resistance to torsion, even if thicker I-beams have also been introduced to the market.

2. What is an H-beam ?

H beams come in a number of standard sizes and are frequently used in the construction sector. H-beams can function as columns or as beams. Steel beams known as "H-Beams" are rolled steel structures shaped like the letter "H." They are created in the form of built-up units. The H-section is created by welding the flanges to the web. Wide flange beams is another name for H-beams.

H-Beam has a structural steel profile with an H-shaped cross section. Flanges make up the "I's" vertical element, while the web forms its horizontal element. While the flanges withstand the majority of the beam's bending moment, the web resists shear stresses. The H-shaped section is a very effective form for handling both bending and shear stresses in the plane of the web, according to beam theory.

H-section steel is a cost-effective and effective section with a better distribution of cross-sectional area and a more balanced weight-to-weight ratio. Due of the section's similarity to the English letter "H," it was given that name. The H-shaped steel has been widely utilized because it has the benefits of great bending resistance, simple construction, cost savings, and light weight in all directions because the various elements are organized at right angles.

The inner sides of the H-shaped steel beam's two outer edges are straight and have no slope. This simplifies H-beam welding and splicing compared to I-beam operation and results in better mechanical properties per unit weight, which can save a significant amount of material and construction time. The I-steel beam cross section is well subjected to straight pressure and tensile, but the cross-sectional size is too narrow to withstand torsion. H steel, on the other hand, has its own set of benefits and drawbacks.

3. Which are difference of H-beams or I-beams?

H-beams have a more optimized cross-section than I-beams, which results in a fair strength to weight ratio, or higher strength per unit area. They are stronger because they have a larger cross-sectional surface area.

Difference Between I-Beams and H-Beams

I-Beams | H-Beams |

I-Beams are steel beams formed by milling or rolling steel in the shape of an I. It is constructed entirely of a single piece of metal or aluminum. | H-Beams are steel beams shaped like the letter "H" made of rolled steel. They are made as built-up units. To form the H-section, the flanges are welded to the web. Wide flange beams are another name for H-beams. |

I-beams have a thinner web than H-beams. | When compared to I-beams, H-beams have a thicker web. H-beams gain strength as their thickness increases. |

I-beam flanges are tapered with a 1:10 inclination for greater load-bearing capacity. They have a thinner profile than H-beam flanges. | H-beam flanges are equal in thickness and parallel to one another. They're wider, longer, and heavier than I-beams. |

I-beam cross-sections are typically deeper in height than width, which provides resistance to local buckling. | H-beams have a more optimized cross-section than I-beams, giving them a reasonable strength-to-weight ratio, i.e. more strength per unit area. They have a larger surface area on the cross-section and thus a higher strength. |

I-beams have a lower moment of inertia than H-beams, making them less effective at resisting bending. | H-beams with wider flanges have a higher moment of inertia and lateral stiffness. As a result, they have greater bending resistance than I-beams. |

I-beams are used to span distances ranging from 33 to 100 feet. | H-beams can be built to any size and height and can span up to 330 feet. |

In comparison to H-beams, I-beams are lighter. | I-beams are more lightweight than H-beams. |

I-beams can withstand tensile and direct loads. Due to their smaller cross-sections, they cannot withstand twisting loads. | The H-beam section can withstand both direct and tensile loads. It can withstand twisting loads due to its broad cross-section. |

I-beams can be used to build support frames and columns for elevators, trailers, trolley lines, hoists, structural steel buildings, and bridges. | H-beams are used as load-bearing columns in commercial buildings, platforms, bridges, and other structures. Wide flange beams are commonly used in residential construction. |

H-beams have better mechanical properties than I-beams and are thus considered a more cost-effective option for construction. I-beams are commonly used as beams, while H-beams are used as load-bearing columns.

4. What are the beam crane clamps & trolleys

Hoist trolleys are used to move the hoist horizontally on I-beams and W-beams. This is done by equipping the trolleys with both flat and tapered wheels. This enables the use of the same trolley on both types of I-beams. They can be manually operated with a push trolley, gear operated with a hand chain, or motor driven. Electric or air power can be used to power motorized trolleys. Beam clamps are used to secure a hoist in a fixed position on an I-beam or W-beam in order to provide an anchor point to which a hoist can be attached.

The purpose of trolleys and beam clamps is to lift the load vertically without adding any side loads. From 1 ton to 25 tons, a wide range of lifting beam clamps and hoist trolley sizes are available, with the 2 ton, 3 ton, and 5 ton options being the most popular.

Beam clamps

A beam clamp can be used to suspend a manual, electric, or air hoist from a properly rated beam or gantry; however, for safety reasons, we strongly advise that the beam from which you are suspending is fit for purpose (ie. can handle the weight that the hoist and clamp are rated to).We have a large selection of steel beam clamps for suspending hoisting equipment. All beam clamps come with conformity certificates. Our product line includes capacities ranging from 1000kg (1TON) to 20000kg (20 TON).

Beam travelling trolleys

Install your current hoist on a beam and suspend it from one of our trolleys. Your hoist will be able to move up and down the beam as well as into and out of the way using a beam trolley as needed. We recommend our push travel trolley range for light duty and the geared and electric travel trolleys for heavier duty.There are a diverse range of trolleys to suit a wide range of applications and environments, ranging from standard units to corrosion resistant models for damp/wet applications and ATEX spark proof models for explosive environments.

<

![Push Travel I Beam Trolleys Push Travel I Beam Trolleys]()

Push Travel I Beam Trolleys

Push Travel I Beam Trolleys are made to hang and move a load along a beam using the bottom flange and a set of wheels or rollers that allow for horizontal movement when pushed or dragged by hand.

<

![Geared travel I beam trolleys Geared travel I beam trolleys]()

Geared travel I beam trolleys

Similar to the Push Travel I Beam Trolley, the Geared Travel I Beam Trolley makes quick work of suspending a load with horizontal travel along a "I" beam. When a hand chain is pulled, much like on a Chain Block, this rotates gears that rotate the wheels of the trolley to enable smooth and controlled traverse of the beam while a load is suspended.

Geared Travel I Beam Trolleys are simply bolted, screwed, and tightened to a "I" beam, just like the manual version, and the hoist or lifting equipment is attached to the trolley by hooking it through the designated eye. Custom hand chain lengths are available to suit your drop height, making it ideal for heavier loads that are difficult to push.

<

![Electric travel i beam trolleys Electric travel i beam trolleys]()

Electric travel i beam trolleys

The electric travel trolleys are of high quality and are available with or without low voltage control pendants. Single or dual speed operation to accommodate beam flange widths up to 300mm. Compact and cost-effective for long-distance transport and frequent use.

Single speed electric trolley - Capacity up to 5000kg, beam flange widths up to 300mm. This unit's compact and sturdy design makes it ideal for long-distance transportation.

Dual speed electric trolley-Dual Speed Electric Travel Trolleys offer ultimate load transportation with two speeds of operation for precise movements. The range is sure to meet your needs, with beam flange widths up to 300mm. It is available with or without control gear.

5. How to get your customized Beam hoist and crane ?

If you have any inquiry, please leave us the main parameters of the product you need such as,

<

![]()

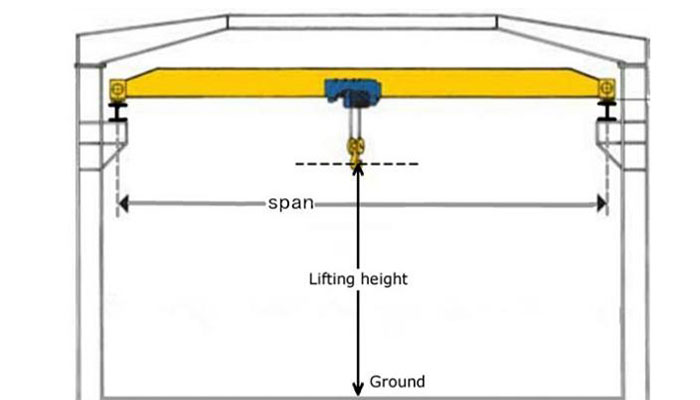

- Main specifications needed for I beam crane and hoist crane inquiry

- Types of beam crane need: ___( Overhead crane, gantry crane, jib crane, or monorail beam crane)

- Lifting capacity ___tons,

- Lifting height ___meters,

- Span length ___meters,

- Voltage ___, etc.

<

![]()

How to measure:Height (A) X Web (B) X Flange Width (C)

- M = Steel Junior Beam or Bantam Beam

- S = Standard Steel I Beam

- W = Standard Wide Flange Beam

- H-Pile = H-Pile Beam

Please leave me your requirements and parameters, and we will respond within 24 working hours. Contact us right away to order your personalized I beam hoist and crane.