Single Girder Gantry Crane Kit & Double Girder Gantry Crane Kit

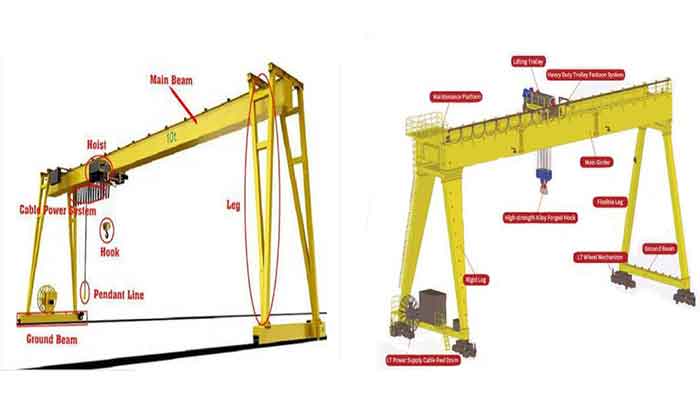

A gantry crane is a type of overhead bridge crane in which the bridge frame is supported by gantry legs running on the ground track at both ends of gantry beam. It consists primarily of a gantry frame (main beam, end beam, leg, lower cross beam, trolley running track, and cab), a hoist trolley, a crane running mechanism, and an electrical control system. Check more on gantry crane kit.

Gantry Steel Structure

The steel frame of gantry cranes are the crane's main force-bearing component. The main beam, end beam, gantry leg, and lower crossbeam are the primary load-bearing components, with trolley tracks, walking platforms, railings, ladders, and other auxiliary metal structures supplementing them.

The main beam

- The main beam is made of Q235-B, and the plate thickness must be at least 6mm.

- The main beam or main girder of the gantry crane can extend out of the legs to one or both sides to form a cantilever, extending the crane's operating range. The cantilever's length is usually less than or equal to one-third of the span length.

The end beam

- The end beam is a box-shaped structure, and the link between it and the main beam is a rigid connection.

- To facilitate transportation, high-strength bolts connect the main beam and end beam, and reamed bolts position each connecting plate.

Support leg

- The leg has a trapezoidal cross-section with a large upper section and a small lower section.

- High-strength bolts connect the upper flange of the leg to the main beam flange support, and high-strength bolts connect the lower flange of the leg to the upper connecting flange of the lower cross beam.

Lower cross beam

- A structural member that bears the weight of the gantry crane and the load is the lower cross beam.

- The lower crossbeam is a box-shaped composite beam formed by welding and splicing steel plates, with a strong bearing capacity and a stable structure.

Trolley track

- The trolley track uses the entire track with joints welded together to ensure the trolley runs smoothly.

The walkway and railing

- The bridge platform tread is made of non-slip patterned steel plate with a thickness of 3mm.

- On the bridge's passages, railings with a height of 1050mm are installed.

Cabin

- The cabin's design takes into account a variety of functional requirements, such as sturdiness, durability, safety, and dependability. It also ensures that the operator has a broad field of vision.

- An alarm is also installed in the driver's cabin to ensure the crane's safe operation.

Gantry crane hoist trolley -lifting mechanism

The hoist trolley is equipped with a lifting mechanism and a trolley running mechanism that runs laterally along the trolley track on the main girder of the crane.

European style electric wire rope hoist for gantry crane as the lifting system

The lifting mechanism, which is the most important and basic mechanism in the gantry crane, is used to lift and lower the load.

- The lifting mechanism consists of the following components: a driving device, a steel wire rope winding system, a lifting device, and a safety protection device.

- Motor, reducer, brake, drum set, and coupling comprise the driving device.

- Steel wire rope winding system consists of steel wire rope, a drum group, a pulley group, and a hook group.

- Hooks, grabs, electromagnetic chucks, hanging beams, spreaders, and other lifting devices are examples.

- Overload limiter, lifting height limiter, overspeed protection switch, and safety brake are all part of the safety protection device.

Features of Lifting mechanism - The hoisting mechanism uses a series resistance speed control system with stable braking, small impact, and accurate hook positioning, which not only improves production efficiency but also greatly extends the service life of the hoisting mechanism's parts.

Working principle of gantry crane lifting mechanism - The lifting mechanism works as follows: after being energized, the electric motor rotates through the reducer to change speed, then drives the drum through the coupling, and finally completes the lifting and lowering operation of the hook through the wire rope winding system.

Trolley running mechanism of gantry cranes

The trolley travelling mechanism is the power device of gantry crane that drives the hoist trolley.The running mechanism is generally faster in order to improve working efficiency of material handling.

To ensure the synchronization of the hoist trolley's driving wheels and to avoid equipment failure, the trolley running mechanism frequently employs concentrated drive with a low-speed shaft.

Gantry crane running mechanism

Gantry crane travelling system

The running mechanism of gantry crane uses two or more independent drive systems to drive the rail travelling crane separately.

The diameter and material of the gantry crane wheels are chosen based on the maximum supporting force of the wheels under the most adverse conditions, ensuring that some wheels are not overloaded.

Electrical Control System

Power supply-Our gantry cranes' standard power supply is three-phase AC, with a rated voltage of 380V and a frequency of 50Hz. It can also be designed to meet the needs of the user.

Mode of power supply

- Cable trolley for trolley feed. Steel rope slides, I-steel slides, and special-shaped steel slides can be used to feed flexible cables and cable trolleys.

- Crane feed: cable reel, safety slide wire.

Electrical protection system

Short-circuit protection, voltage loss protection, an emergency power-off switch, an overload limiter, a travel limit switch, zero position and interlock protection

Protection against phase failure, overvoltage and undervoltage, grounding, and so on.

Methods of gantry crane operation

Cabin control, pendant control, and wireless remote control

Single girder gantry crane kits

Single girder gantry crane parts list for reference

Parts | Specification Model | Quantity | Remarks |

Main beam | 12m | 4 | |

Main beam | 2.77m | 2 | |

Secondary outriggers | 2 | ¢219X12.5m | |

Main outriggers | 4 | ¢325X13.6m | |

Main beam seat | 2 | ||

Sub-beam seat | 1 | ||

Main beam connecting frame | 2 | ||

Crown | 1 | ||

Crown rain shed | 1 | ||

Pulley set | 50XT6 | 1 | |

Electric hoist | 5T | 1 | |

Equalization bar | 1.9m | 4 | |

Stabilizer bar | 5.4m | 2 | |

Control room | 1 | ||

Control room platform | 1 | ||

Control room connecting bars | 0.8m | 2 | |

Control room railing | 3 | ||

Large car motor | ZD1-4 | 2 | |

Crown motor | ZD122-4 | 2 | |

Crown winch | 11KW | 1 | |

Main beam upper chord pin | ¢30X260 | 8 | |

Main beam lower chord pin | ¢30X150 | 1 | |

Main outrigger pin (upper) | ¢60X240 | 1 | |

Main outrigger pin (lower) | ¢80X300 | 1 | |

Secondary outrigger pin (upper) | ¢60X195 | 1 | |

Secondary outrigger pin (lower) | ¢60X195 | 1 | |

Main beam connecting frame pin | ¢40X180 | 1 | |

Equalizer rod pin (upper) | ¢40X215 | 1 | |

Equalizer bar pin (lower) | ¢40X180 | 1 | |

Stabilizer bar pin | ¢60X230 | 1 | |

Beam seat connecting bolts | M24X70 | 75 | |

Reducer fastening bolts | M12X40 | 25 | |

Overhead crane winch cable | 3X6m² | 45 | |

Overhead crane travel motor cable | 3X2.5m² | 100 | |

Electric hoist cable | 3X4m² | 100 | |

Support bar | 1 | Spare parts | |

Base plate | 30cmX48cm | 2 | Spare parts |

Support bar support | 1 | Spare parts |

Double girder gantry crane kits

Double girder gantry crane part list for your reference

Parts | Lifting mechanism | Running mechanism | ||

Main | Sub | Small trolley | crane travelling | |

Motor | YZR315=10/63KW | YZR180L=6/17KW | YZR160M2=6/8.5KW | YZR160L=8/9KW |

Reducer | J500 DQJSD-500-3CA i=56 | ZQ500-I=3CA i=48.57 | ZSC600-III-1 i=46.7 | ZSC(A)-650 i=51.89 |

Brake | YWZ4-500/121 | YWZ4-300/50 | YWZ4-200/23 | YWZ4-200/23 |

Hook | G887(60t) | G883(10t) | ||

Pulley | G863(60t) | G859(10t) | ||

Reel | T1028(Φ800*2000) | T1023(Φ400*1500) | ||

Brake Wheel Coupling | S3409(Φ500) S3408(Φ500) | S3173(Φ300) | S1602-5(Φ200) | |

Gear Coupling | S2233 | S1112 S2429 Φ200 Brake Wheels | ||

Wheelsets | L762 L763 Rail:43kg/m | L784(Φ700) L814(Φ700) Rail:QU80 | ||

Rail Grippers | A380.2 | |||