What Is Free Standing Jib Crane? - Light Duty Free Standing Jib Overview

The free standing jib crane (also known as the pillar jib crane) is a new generation of light lifting equipment that adapts to modern manufacturing. Because of the high reliability of the electric chain hoist, light duty free standing jib cranes are ideal for short distance, frequent use, and intensive lifting operations. Lifting and running back and forth on the beam are just a few of the functions of a free standing jib crane. The arm beam can be driven by a rotary device at the speed of the roller's rotary motion, via an electric control box mounted on the chain hoist.

A free standing jib crane is one of the most versatile pieces of lifting equipment. Free standing jib cranes are widely used by all customers, from small workshops to production lines, ports, and even nuclear power plants, because they are easy to install and have fewer structural limitations than many other material handling equipment.

Light duty free standing jib crane with electric chain hoist - Floor mounted slewing crane with kbk cantilever design

Free standing jib crane application

The free standing jib crane is widely used as infrastructure engineering machinery and equipment in many important industry fields, such as port, electric power, steel, shipbuilding, petrochemical, mining, railway, building, metallurgy, chemical industry, automobile manufacturing, plastics machinery, industrial control, highway, bulk transportation, pipe linings, slope protection, assistance and salvage at sea, tunnel, airport construction, bridges, aviation,etc.

It has advantages such as a reasonable structure, simple operation, flexible rotation, a large working space, and so on. It is a light duty overhead hoisting equipment that saves energy and is efficient.

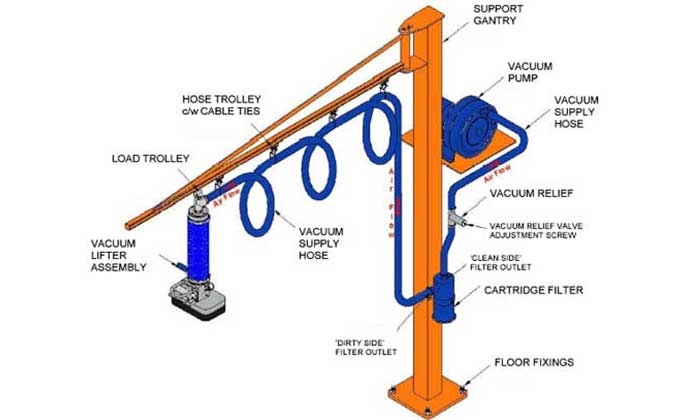

Free standing jib crane component

The free standing jib crane is made up of an upright post device, rotary device, rotary arm device, and chain electric hoist, as well as above column, down column, beams, the girder rod, lifting mechanism (electric chain hoist), slewing mechanism, electrical system, climbing ladder, and maintenance platform. The lower end of the column is fixed to the concrete foundation, and the rotary arm can rotate to meet the needs of the user. Rotary parts are classified as either manual or electric. A chain electric hoist installed on a rotating arm track is used to lift heavy objects.

Parts and Componets of free standing jib crane drawing

Free standing jib crane working

The work intensity of a free standing jib crane is low, and the slewing crane is made up of an upright post device, rotary device, rotary arm device, and chain electric hoist, the lower end of the column by anchor bolts fixed in the concrete foundation, a cycloidal pin wheel speed reducer to drive the rotary cantilever, electric hoist running back and forth on the main beam and lifting heavy objects. Crane boom is a hollow steel structure with a large span and a light weight. It is economical and long-lasting. Because of the use of a special engineer plastic, the built-in type walking mechanism has rolling wheel, low friction, and brisk walking characteristics. Furthermore, the small size structure is especially advantageous for improving the hook stroke.

Free standing jib crane operation notice

When working, no one is not allowed to stand beneath the lifting beam. Overload lifting is prohibited. Examine the lifting equipment on a regular basis. The free standing jib crane is operated by pressing the pendent control or remote control. There are eight buttons, which control the jib crane 's fast lowering and lifting , slow rise, and slow down, as well as the horizontal movement of hoisting along the cantilever.

Free standing jib craneis your ideal choice

Till now, we'have a general understanding about the free-standing jib crane. It is usually recommended to lift indoors. It can also be used for outdoor lifting tasks. However, given the weather conditions, it should be protected by additional protective equipment. A free standing jib crane has many safety features that allow it to adapt to all weather conditions and ensure a long service life and productivity. Furthermore, slewing cranes can be equipped with a variety of attachments to increase flexibility. You can use various hoists to complete various tasks. The operators can easily select the best one for their application.

Jib Crane Terms

- Anchor Bolts: These are large steel bolts that are inserted into the foundation of a base-mounted pillar jib crane.

- The horizontal beam on which the hoist trolley travels is referred to as the boom.

- Fitting Centers: The distance between two support brackets (fittings) on a wall-mounted jib crane, measured from centerline to centerline.

- Capacity: The maximum live weight that the crane can support.

- End Stops: Bolted to the ends of the boom to keep the trolley from falling off the beam.

- The foundation is used for freestanding pillar base mounted jibs. Jib foundations are used to keep the jib from tipping over.

- Gussets are reinforcing plates that are used to stiffen the mast at the base plate.

- The roller is housed in the head, which reduces the crushing forces imposed on the mast.

- H.U.B. (Height Under the Boom): The distance from the finished floor to the underside of the crane boom. To calculate the under-boom, multiply the load's height by the distance it is lifted, as well as the headroom requirements of the hoist/trolley and any attachments.

- Mast: The vertical jib member that supports the crane. The masts of pillar jibs are round pipes.

- Overall Height: The jib crane's highest point (including any hardware). Any overhead obstruction requires a minimum clearance (usually 3").

- Hoist: The actual lifting mechanism (powered by electric, air, or manual movement) that hangs from the trolley that rides on a jib crane's boom.

- The mechanism that travels back and forth on the crane boom (powered by electric, air, or manual movement) from which the hoist hangs.

- Overturning Moment: The force applied to the mounting structure of a self-supporting pillar jib is referred to as the overturning moment. This load is produced by suspending a load from the boom, and it is greatest at full load, at the far end of the boom.

- Span: The span of a pillar base mounted jib crane is the distance between the mast's center and the end of the boom. A column mounted crane's span is measured from the mounting surface to the end of the boom. The span of a mast type jib crane is measured from the vertical mast's center to the end of the boom.

- Thrust and Pull: Thrust and Pull are forces applied to the support structure of a wall/column mounted jib crane. The thrust force is the pushing force exerted on the structure, and the pull force is the tensile, or pulling force. Thrust and pull are equal (but in opposite directions) and are given at full load at the end of the boom.

- Clear Span: The distance between the ends of a crane boom.

- Hook Travel: The distance traveled by the hoist's hook.