Your Trusted Overhead Travelling Crane Manufacturer & Supplier

Steel Coil Handling Equipment, Overhead Crane System

Vertical / Horizontal Steel Coils Lifting Devices 5 Ton, 10 Ton, 20 Ton, 30 Ton, 50 Ton

Steel coil is a finished steel product that has been wound or coiled after rolling; its breadth is substantially greater than its thickness. Steel coil can be Hot Rolled, Cold Rolled, or Galvanized, depending on the manufacturing procedure. For different coil handling, there are various types of coil handling equipment and lifters available to increase steel coil handling safety and efficiency.

Overhead Crane Coil Handling Systems

Overhead crane coil handling systems are specialized material handling systems used largely in the steel and aluminum industries for the effective lifting, transportation, and storage of coils.

Steel coil handling has strict requirements for hot rolling and cold rolling coil rolling mills. For coil loading and unloading, the PLC-controlled coil handling overhead cranes have advanced features and a smart function, which provide safe and accurate control over motor rotation and braking.

The overhead crane coil handling systems are specialized bridge cranes and gantry cranes designed for the handling of steel coils in industrial environments. These industrial overhead cranes are generally utilized in steel mills, coil storage facilities, and other industrial environments in which steel coils must be handled, stored, or transported.

Overhead crane coil handling systems are designed for lifting and transporting steel coils of various sizes and weights.These cranes are often equipped with specific lifting devices such as C-hooks, tongs, or lifting magnets that are designed to grasp and lift steel coils safely.

Electric overhead crane systems are also manufactured to operate in confined places and with great precision, making them optimal for usage in environments with limited space or high precision.

Types of coil handling system based on crane structures

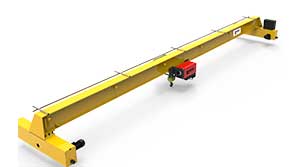

Single girder overhead crane system for steel coil lifting with capacity up to 20 ton

Double girder overhead crane for steel coil handling with capacity of 5 ton and up to 80 ton

Heavy duty open winch overhead crane system with capacity up to 320 ton

Single girder gantry crane coil handling system with capacity up to 20 ton

Double girder overhead crane coil handling system with capacity up to 80 ton

Double girder gantry crane coil handling system with capacity up to 320 ton

For types of steel coils handling

The custom steel electric crane coil handling systems can be customized for different types of steel coil handling with particular lifting capacity form 5 ton, 10 ton, 20 ton, 30 ton, 40 ton, 50 ton and above. Based on the specifications, dimensions, and weights of general steel coils which vary depending on the specific type of steel, the thickness of the coil, and the intended use, the steel coil handling equipment and lifters can be customized. Generally, the overhead crane systems can be used to handling steel coils with the following dimensions and weights:

- Hot-rolled steel coil handling : Hot Rolled coil is produced from semi-finished products that are reduced to certain thicknesses by rolling and annealing and winding into a roll.For hot rolled steel coil handling, the coil handling equipment are typically used to handling rolled steel coils with a thickness range of 1.2mm to 25mm and a width range of 800mm to 2,000mm and with the lifting capacity from a few hundred kilograms to 30 tons.

- Cold-rolled steel coil handling : Cold Rolled coil is produced from hot-rolled steel that is further processed to produce a more highly finished product. Cold Rolled coil has a smoother surface, greater dimensional accuracy, and greater strength than Hot Rolled coil.For coil rolled steel coil handling, the overhead crane systems are typically used for handling coils with a thickness range of 0.4mm to 3.5mm and a width range of 600mm to 2,000mm and with the lifting capaacity range from a few hundred kilograms to 20 tons.

- Galvanized steel coil handling : Galvanized coil has a special zinc coating that has been added to protect the underlying steel from atmospheric exposure. For galvanized coils, the overhead coil lifting equipment and lifting devices are typically used to handle coils with a thickness range of 0.12mm to 4mm, a width range of 600mm to 1,500mm and with capacity for handling steel coils with the weight from a few hundred kilograms to 25 tons.

- Stainless steel coil handling : Stainless steel coils are rolls of steel that are made from a type of steel alloy that contains at least 10.5% chromium. This chromium content gives stainless steel its unique properties, including resistance to corrosion, staining, and rust.For stainless steel coils, the typically used overhead cranes are used to handling steel coils with a thickness range of 0.3mm to 6mm, a width range of 600mm to 2,000mm, and with weight from a few hundred kilograms to 20 tons.

For different industrial uses and applications

To meet different industrial requirements, the steel coils lifting equipment and lifting devices can be customized to meet the specific industrial applications. For example, the industrial overhead crane lifting equipment can be used to improve your operation efficiency and safety.

- Construction: Steel coil handling equipment is used in the construction industry for a variety of applications, including roofing, framing, and structural supports operations, etc.

- Automotive: Steel coil handling equipment used in the automotive industry for the material handlings of car frames, doors, and other components, etc.

- Manufacturing: Steel coil handling overhead cranes are used in the manufacturing industry for the material handling operation of appliances, furniture, and other consumer goods.

- Energy: Steel coil handling equipment is used in the energy industry for the handling operation of pipelines, tanks, and other equipment handling.etc.

- Packaging: Steel coil overhead cranes are used in the packaging industry for the lifting operation of metal containers and other packaging materials.

- Shipbuilding: Steel coil lifting equipment are used in the shipbuilding industry for the lifting and moving of hulls, decks, and other components, etc.

These are just a few examples of the many uses and applications of steel coil handling equipment and coil handling systems. Custom industrial overhead cranes are available for your particular applications. Contact us today to check what we can do to save your steel coils and rolls handling.

For horizontal coil & vertical coil handling

What factors influence the coil handling equipment and device you select? It is determined by the frequency with which coils are moved and whether the orientation of the coil eye—the center hole—changes during the handling operation.

Horizontal coil handling

Coils are commonly stacked with the eye horizontal in steel warehouses and service centers. C-hook-style lifters and two-arm coil grabs are items developed for handling coils in this position. Optional equipment for the coil grab includes urethane padding for further coil protection, a built-in load scale for exact coil weight measurement, and a photo-electric sensor for easier foot alignment.

C hooks cranes: These cranes have a specialized C-shaped hook attachment that is designed to lift and transport steel coils in a horizontal position.

Coil clamp cranes: These cranes use a specialized clamp attachment that is designed to securely grip the coil and lift it in a horizontal position.

Magnetic overhead cranes: These cranes use a magnetic lifting attachment to lift and transport steel coils in a horizontal position or vertical positions.

Vertical coil handling

Vertical eye coil lifters are used to handle vertically stacked coils after they have been slit to size during the production process. Vertical lifters come in a variety of forms, and the optimum one for the job depends on how frequently, how many, and the IDs of the coils you move in a typical workday.

Your Trusted Overhead Crane Manufacturer & Supplier