Your Trusted Overhead Crane Manufacturer & Supplier

Advanced Single Girder Crane & Double Girder Crane European Style

Affordable Euro Hoist & Euro Hoist Crane 3 Ton 5 Ton, 10 Ton, 20 Ton

Overview of European Style Hoists and Cranes

- European style jib crane

- Electric wire rope hoist

- Electric chain hoist

Applications of European Style Overhead Hoist and Cranes

European-style electric wire rope hoists are used in a wide range of industries, including manufacturing, construction, mining, and transportation, Foundry, metallurgy, hydropower, aerospace, shipbuilding, automotive, coal, petrochemical, etc. They are ideal for lifting heavy loads in a safe and efficient manner. Some common applications include:

- Material handling

- Assembly line operations

- Maintenance and repair work

- Warehouse operations

Wire Rope Euro Hoist from China

European-style electric wire rope hoists are a reliable and efficient solution for lifting heavy loads in industrial applications. They are designed to ensure safety and precision during lifting operations. These hoists are renowned for their durability, reliability, and accuracy.

The advanced electric wire rope hoist is the result of years of research, development, and market experience. It is designed and manufactured in compliance with ISO, GB, FEM, DIN, and BS standards to ensure high quality, durability, and cost-effectiveness. The hoist comes in four structural designs and can lift loads ranging from 1 ton to 80 tons. The standard work duty is FEM 2M/ISO M5.

European-style electric wire rope hoists are designed and manufactured according to European standards. They are commonly used to lift and move heavy loads in various industries. The hoist is equipped with a motorized mechanism that utilizes a wire rope to lift and lower loads.

FEM Low Headroom Hoists for Single Girder & Double Girder Crane

European style low headroom wire rope hoist for single girder crane & double girder crane, light weight wire rope hoist, hot sale rope hoist, good price.

Main parameter of euro wire rope hoist

- Standard: FEM

- Working Duty: M5 ~ M7

- Lifting Speed:

- 3 ton , 5ton ,10 ton : 5/0.8 m/min (4/1);

- 16 ton : 3.3/0.5 m/min (6/1); 5/0.8 m/min (4/1);

- 20t ton 4/0.67 m/min (4/1); 5/0.8 m/min (4/1);

- 32 ton : 3/0.5 m/min (6/1); 0.8~5 m/min (8/2);

- 50 ton : 0.5~3.3 m/min (12/2);

- 80 ton : 0.4~2.5 m/min (16/2);

- Traveling Speed: 2.0 ~ 20m/min

- Lifting Height: 6m ~ 24m

The Europ wire rope electric hoist has four structural designs for users to choose from:

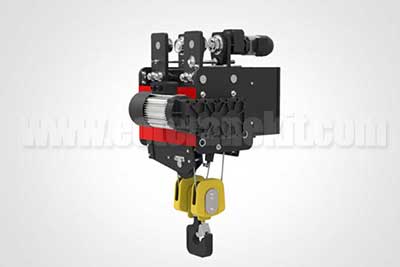

- Model NRL electric hoist is designed for (Low-Headroom single girder crane with capacity of 3 ton, 5 ton, 10 ton, which is used to maximize the value of workshop space.

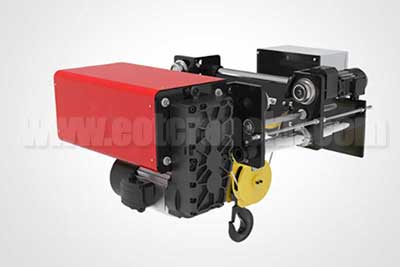

- Model NRS electric rope hoist is the standard-headroom electric wire rope hoist which is generally used for single girder crane with capacity of 3 ~20ton

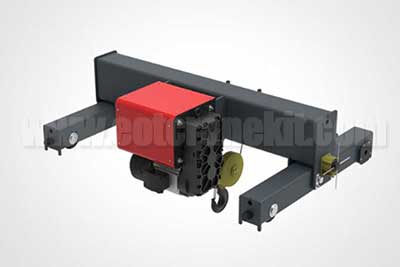

- Model NRT double girder electric wire rope hoist trolley or crab trolley is used for double girder cranes with capacity: 3 ton ~ 80 ton

- Model NRF electric hoist is the Foot-Mounted Hoist, with capacity: 3 ton ~ 80 ton

Model NRL (Low-Headroom Monorail Hoist) Capacity: 3 ton, 5 ton, 10t

Model NRS (Standard-Headroom Monorail Hoist) Capacity: 3 ~ 20 ton

Model NRT (Double-Rail Trolley or Crab) - Capacity / SWL: 3 ton, 5 ton, 10 ton, 16 ton, 20 ton, 32 ton, 50 ton, 80 ton

Model NRF (Foot-Mounted Hoist) - Capacity / SWL: 3 ton, 5 ton, 10 ton, 16 ton, 20 ton, 32 ton, 50 ton, 80 ton

What is a low headroom hoist?What is the headroom of a hoist?What is the difference between European wire rope hoists and cd/md wire rope electric hoist ?Which is better wire rope hoist or chain hoist?

A low headroom hoist is a type of hoist that is designed to operate in areas with limited vertical space. This type of hoist has a shorter headroom dimension than a standard hoist, which allows it to fit into spaces with low ceilings or other height restrictions.

The headroom of a hoist refers to the distance between the underside of the hoist and the floor or other surface below it. This dimension is important because it determines the minimum height required for the hoist to operate safely and effectively.

European wire rope hoists and CD/MD wire rope electric hoists are both types of wire rope hoists, but there are some differences between them. European wire rope hoists are typically designed and manufactured in Europe and are known for their high quality, durability, and advanced features. CD/MD wire rope electric hoists, on the other hand, are a type of wire rope hoist that is commonly used in China and other Asian countries. They are known for their simplicity and affordability.

Whether a wire rope hoist or chain hoist is better depends on the specific needs and requirements of the application. Wire rope hoists are typically better suited for lifting heavier loads over longer distances, while chain hoists are more suitable for lighter loads and shorter lifting distances. The choice between the two also depends on factors such as cost, durability, and ease of maintenance. Click to learn more on European style electric wire rope hoist 5 ton vs. CD/MD electrirc wire rope hoist 5 ton.

Main Parts of European Style Hoist and Cranes

Modular End Carriage

Flexible Design , Easy Assembly, Wide Applications

The various combinations of 2 wheels,4 wheels,8 wheels, and 16 wheels will be satisfied withdifferent wheel pressure.

The various combinations of end carriage and main girder are easily adapted to different workshop space.

Lifting Gear Motor

Traveling Gear Motor

Frequency converter

Inovance brand, Chinese famous brand. Control the travelling motor, change the motor speed.

Overload limiter

Under overload condition, cut off the power of the advaned european style crane

Electric panel

CHINT brand, Chinese famous brand

Main contactors are ABB brand.

Rope guide

High strength nylon rope guide, installed on the winding drum to guide the wire rope to prevent constant winding of steel wire and prolong the life of the drum

The European-style electric hoist has the following features:

- It does not have reverse rollers/wheels.

- It has a bilateral drive where the reducer directly drives the wheels.

- The hoisting mechanism is easy and quick to connect and is also available for the trolley structure.

- The lifting mechanism for 3t and 5t capacities has a fully closed structure, while other capacities have an open gear drive.

- The capacity for 32 ton ~80 ton variable frequency hoisting mechanism has dual drive.

- The lifting mechanism for 3t~16t capacity has a C-type structure, while the lifting mechanism for 20t~80t capacity has a Z-shaped structure.

Some advantages of European-style electric wire rope hoists include:

- High lifting capacity

- Smooth and stable lifting operation

- Advanced safety features

- Low noise and vibration levels

Some disadvantages of European-style electric wire rope hoists include:

- Higher cost compared to CD/MD wire rope hoists

- More complex design

European Style Overhead Cranes

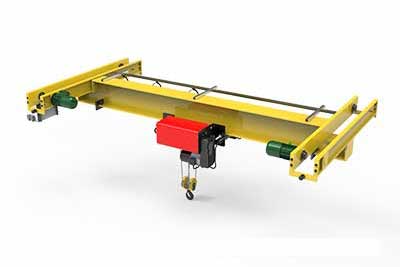

The European style overhead crane is a type of crane that is designed and manufactured in accordance with European standards. It typically features a compact and modular design, advanced safety features, and high efficiency.

10 Ton Overhead Crane & 10 Ton Wire Rope Hoist | Overhead Crane for Sale , Installation & Testing

Features of European Style Overhead Cranes include:

- Modular design: The modular design of European style overhead cranes allows for easy customization and installation.

- Advanced safety features: European style overhead cranes typically come with advanced safety features such as overload protection, emergency stop buttons, and anti-collision systems.

- High efficiency: European style overhead cranes are designed for high efficiency and can help improve productivity in various industries.

- European style overhead cranes are commonly used in industries such as manufacturing, construction, and logistics. They are ideal for lifting and moving heavy loads in a safe and efficient manner.

European style overhead single girder crane - This type of single girder crane has one girder and is suitable for light to medium lifting applications.

- Load capacity: 1-20t

- Span: 7.5-28.5m

- Lifting height: 6-18m

- Lifting speed: 0.8/5m/min

- Hoist running speed: 2-20m/min

- Crane running speed: 3-30m/min

- Work duty: A5

- Custom designs available

Underslung single girder overhead crane: This type of crane is mounted underneath the runway beam and is ideal for low headroom applications.

- Crane capacity: 500kg -10 ton

- Span: 3-22.5m

- Lifting height: 6-30m

- Lifting speed: 0.7-8m/min

- Hoist running speed: 20m/min

- Crane running speed: 20m/min

- Work duty: A4,A5

- Custom designs available

Overhead double girder crane: This type of crane has two girders and is suitable for heavier lifting applications.

Parameters of Euro style NLH Overhead double girder crane

- Load capacity: 5-80t

- Span: 10.5-31.5m

- Lifting height: 6-18m

- Lifting speed: 0.4-5m/min

- Trolley running speed: 2-20m/min

- Crane running speed :3-30m/min

- Work duty: A5

The QDX double girder crane is a European standard overhead crane with the characteristics of light weight, low wheel pressure, small boundary size, reliable performance, and compact structure.

- Load capacity 5-320t

- Span 10.5-31.5m

- Lifting height 6-24m

- Lifting speed 0.2-10.7m/min

- Trolley running speed 2.4-33m/min

- Crane running speed 4.2-68m/min

- Work duty A3-A5

- Custom designs available

Overhead Single Girder vs. Double Girder Crane

Single girder cranes have one girder supporting the hoist and trolley, while double girder cranes have two girders supporting the hoist and trolley. The choice between a single or double girder crane depends on the specific needs and requirements of the application.

Double girder cranes typically have a higher lifting capacity and are more suitable for heavy-duty applications, while single girder cranes are more cost-effective and suitable for lighter loads. Double girder cranes have a wider span and can cover a larger area than single girder cranes. However, single girder cranes are easier to install and maintain than double girder cranes due to their simpler design.

In summary, the main difference between a single girder and double girder crane is the number of girders used to support the hoist and trolley. The choice between the two depends on the specific needs of the application, including load capacity, span, and installation and maintenance requirements. Learn more on types of European style overhead cranes or contact us by leaving a message below or contact WhatsApp: + 86 151 3871 1597.

European Overhead Crane Design Principles

Designed and manufactured according to European FEM advanced standards, the technical level in China has reached the international advanced level. The strength, stiffness and stability conditions are met, and the weight of the steel structure is minimized through finite edge analysis. In the design, the working environment on site and the convenience and possibility of manufacturing, inspection, transportation, installation and maintenance are fully considered.

Structural design

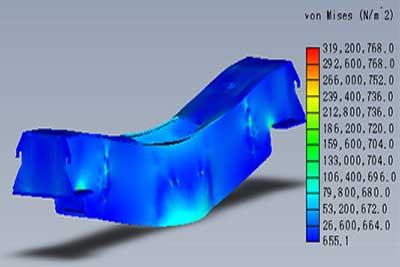

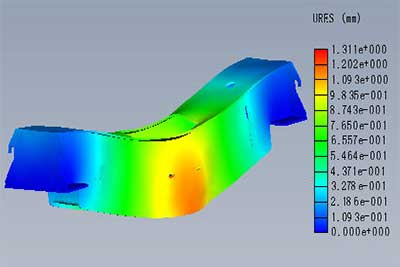

Through the finite element analysis and optimal design of the steel structure, the structure is more reasonable, which can effectively improve the utilization rate of steel and the production efficiency of the crane.

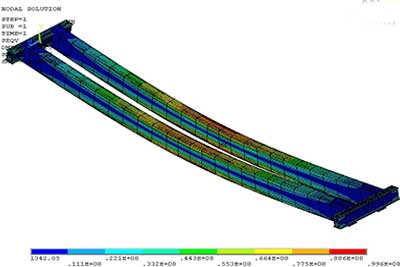

The maximum stress cloud diagram of the connecting beam

(Working condition: full load, 15° cable pull to calculate the strength of the connecting beam)

Connecting beam stiffness contour

(Working condition: full load, cable-stayed at 15° to calculate the stiffness of the connecting beam)

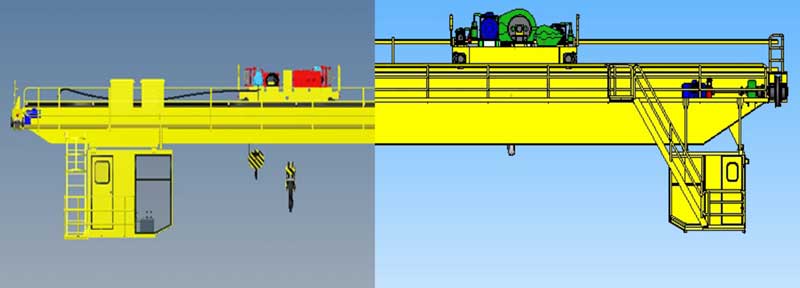

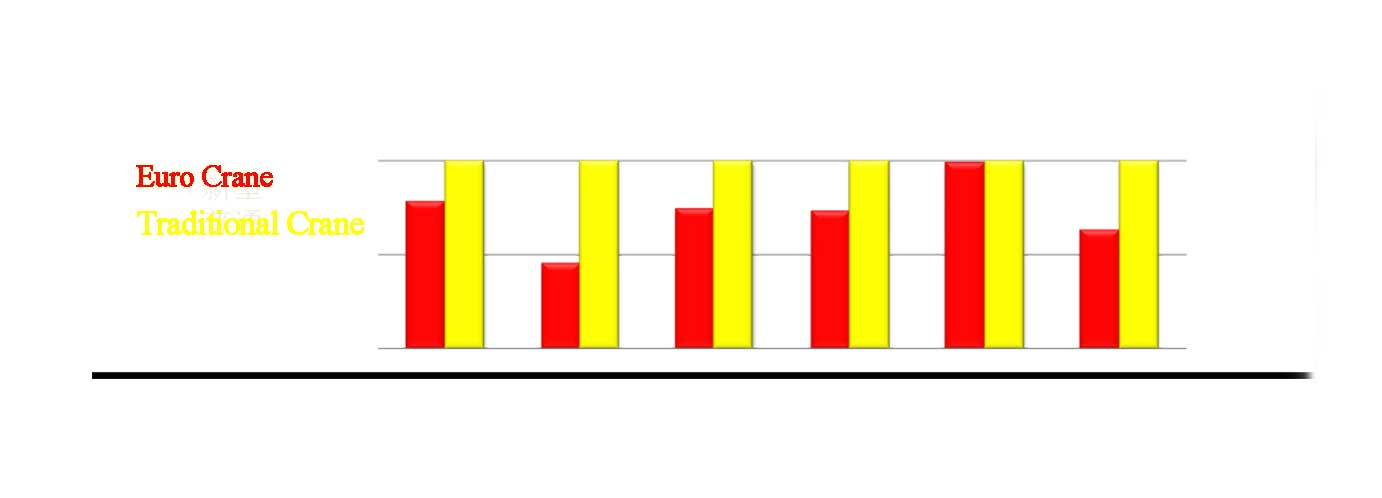

European style double girder crane comparison - qdx type bridge crane with open winch vs qd type bridge crane with open winch the traditional type

European style vs Traditional style overhead crane

European Overhead Crane features

- Low height, light weight, saving construction resources.

- Compared with the traditional overhead bridge cranes, the self-weight can be reduced by 15%~30%, and the wheel pressure can be reduced by 15%~30%.

- Its own height is also reduced by 20~30%.

Item | Self weight(kg) | Max. Wheel Pressure KN | Lifting height | Effective lifting height | Width of crane | Crane Power KW | |

QD50/10t -22.5m | European style | 39241 | 184 | 2041 | 2750 | 6792 | 72.5 |

General type | 50137 | 404 | 2752 | 3766 | 6858 | 115.5 | |

Main beam design

The main girder is an automatically welded box girder, the web has no butt welds, the trolley track is made of Q345B square steel, and the off-track structure design, the contact area between the wheel and the track is large, and the operation is more stable. There are safety stoppers at both ends of the track.

There is a retaining hook frame on the side of the sliding line of the cart to prevent the hook from colliding with the safety sliding line and causing electric shock accidents. At the same time, there is a simple maintenance cage on the side of the trolley sliding line, which is convenient for daily inspection and maintenance of the trolley sliding line

End Beam / End Carriages Design

The end carriage adopts a rectangular square tube structure, and the material is Q235B or Q345B. The formed end carriage is positioned and processed in a CNC machining center at one time to ensure dimensional accuracy and fit tolerance. The end beams are equipped with double-rim wheels, buffers and anti-derailment protection.

The main beam and end beam adopt 10.9 grade high-strength bolts, which have good safety and high strength, ensuring the accuracy and stable operation of the whole machine.

Electrical System Design

- Schneider electric components

- Inovance Inverter

- Electrical box aviation plug

- The trolley can be powered with flat cables, busbar, etc.

- Cross paddle limit switch

European Style Gantry Crane

The European style gantry crane is a type of crane that is designed and manufactured in accordance with European standards. It is typically used for lifting and moving heavy loads in applications where overhead cranes are not suitable. There are several types of European style gantry cranes, including:

25 Ton Double Girder Gantry Crane for Precast Concrete Yard Poland | Gantry Crane for Sale

Some features of European style gantry cranes include:

- Modular design: The modular design of European style gantry cranes allows for easy customization and installation.

- Advanced safety features: European style gantry cranes typically come with advanced safety features such as overload protection, emergency stop buttons, and anti-collision systems.

- High efficiency: European style gantry cranes are designed for high efficiency and can help improve productivity in various industries.

European style gantry cranes are commonly used in industries such as manufacturing, construction, and logistics. They are ideal for lifting and moving heavy loads in a safe and efficient manner where there is no overhead support available.

Single girder gantry crane

This type of crane has one girder and is suitable for light to medium lifting applications.

- Load capacity: 3.2-20t

- Span: 8-35m

- Lifting height: 6-12m

- Lifting speed: 0.66-5m/min

- Hoist running speed: 2-20m/min

- Crane running speed: 3-30m/min

- Work duty :A5

Double girder gantry crane: This type of crane has two girders and is suitable for heavier lifting applications.

- Load capacity: 5-500t

- Span: 18-35m

- Lifting height: 6-18m

- Lifting speed :1.5-11.5m/min

- Trolley running speed: 10-40.1m/min

- Crane running speed: 16-50m/min

- Work duty: A3-A7

- Custom designs available

Semi-gantry crane: This type of crane has one end supported by a building structure or column and the other end supported by a runway beam.

- Load capacity: 5-32t

- Span :12-30m

- Lifting height: 6-12m

- Lifting speed: 6-11.5m/min

- Trolley running speed: 37-40.1m/min

- Crane running speed: 37.7-40.1m/min

- Work duty: A3-A6

What are the similarity and differences of single girder goliath crane and double girder goliath crane ?

The main similarity between a single girder goliath crane and a double girder goliath crane is that they are both types of gantry cranes that operate on a runway system. They are both used to lift and move heavy loads in various industrial applications.

The main difference between the two is that a single girder goliath crane has one girder supporting the hoist and trolley, while a double girder goliath crane has two girders supporting the hoist and trolley. Double girder cranes typically have a higher lifting capacity and are more suitable for heavy-duty applications, while single girder cranes are more cost-effective and suitable for lighter loads.

In addition, double girder cranes have a wider span and can cover a larger area than single girder cranes. However, single girder cranes are easier to install and maintain than double girder cranes due to their simpler design.

Full Gantry vs. Semi Gantry Cranes

The main similarity between a full gantry crane and a semi-goliath crane is that they are both types of gantry cranes that operate on a runway system and are used to lift and move heavy loads in various industrial applications.

The main difference between the two is the way they are supported. A full gantry crane is supported by a pair of legs that run along the length of the runway on either side, while a semi-goliath crane is supported on one side by a leg that runs along the runway, and on the other side by a structure such as a building column or wall.

Another difference is the span they can cover. Full gantry cranes can span a larger area than semi-goliath cranes, as they are supported on both sides by legs. However, semi-goliath cranes are more flexible in terms of their positioning and can be used in areas where a full gantry crane cannot be installed due to space constraints or other limitations.

Finally, full gantry cranes are typically more expensive than semi-goliath cranes due to their larger size and more complex design.

European Style Jib Cranes

European-style jib cranes are a type of jib crane that are designed and manufactured in Europe. They are known for their high quality, durability, and advanced features.

There are several types of European-style jib cranes available, including:

- Pillar-mounted jib cranes: These cranes are mounted to a pillar or column and can rotate up to 360 degrees.

- Wall-mounted jib cranes: These cranes are mounted to a wall or column and can rotate up to 300 degrees.

- Portable jib cranes: These cranes are designed to be moved around a workspace and can be easily disassembled for transportation.

Some of the key features of European-style jib cranes include:

- High-quality construction materials: European-style jib cranes are typically made from high-quality steel or aluminum, which makes them strong and durable.

- Advanced control systems: Many European-style jib cranes come with advanced control systems that allow for precise movement and positioning of loads.

- Customizable options: European-style jib cranes can be customized to meet specific customer needs, including load capacity, reach, and rotation angle.

Safety features: European-style jib cranes come with a range of safety features, including overload protection, emergency stop buttons, and anti-collision systems.

Overall, European-style jib cranes are a reliable and efficient solution for lifting and moving heavy loads in industrial applications.

FEM Standard Light Electric Chain Hoist

European-style electric chain hoists are a type of hoist that are designed and manufactured in Europe. They are known for their high quality, durability, and advanced features. There are several types of European-style electric chain hoists available, including:

- Single-speed hoists: These hoists have a single speed for lifting and lowering loads.

- Dual-speed hoists: These hoists have two speeds for lifting and lowering loads, which allows for greater control and precision.

- Low-headroom hoists: These hoists are designed for use in spaces with low headroom, such as workshops or factories with low ceilings.

- Explosion-proof hoists: These hoists are designed for use in hazardous environments where there is a risk of explosion.

Some of the key features of European-style electric chain hoists include:

- High-quality construction materials: European-style electric chain hoists are typically made from high-quality steel or aluminum, which makes them strong and durable.

- Advanced control systems: Many European-style electric chain hoists come with advanced control systems that allow for precise movement and positioning of loads.

- Customization options: European-style electric chain hoists can be customized to meet specific customer needs, including load capacity, lifting height, and speed.

- Safety features: European-style electric chain hoists come with a range of safety features, including overload protection, emergency stop buttons, and anti-collision systems.

Overall, European-style electric chain hoists are a reliable and efficient solution for lifting and moving heavy loads in industrial applications.

Your Trusted European Style Overhead Crane Manufacturer & Supplier