RMG Crane- Rail mounted gantry crane, Your Container Crane, Good priced

RMG crane is a rail mounted gantry crane for ISO standard container handling. Wide specifications of rail mounted gantry cranes meet your container crane requirements. Get RMG crane price now!

| Crane Type | Rail mounted gantry crane, container crane |

| Crane Capacity | 30 ton -50 ton |

| Crane Span | 18-35m |

| Lifting Height | 12.3-21m |

| Working Class | A6-A8 |

Category: Gantry Crane

Your Trusted Gantry Crane Manufacturer & Supplier

30 Ton- 50 Ton Rail Mounted Gantry Cranes

Heavy Duty Gantry Cranes

Rail Mounted Gantry Crane, shorten as RMG crane is a type of container cranes for lifting the international ISO standard containers. Adopting U frame supporting legs , the rail mounted gantry crane has wider clear space than the regular gantry crane, which enables containers move to sides easily. The whole RMG crane is designed to run quickly and steadily on the fixed gantry rails on ground for efficient container handling in outdoor workplaces, such as, port and dock, etc. With high operating speed and working level, the rail mounted gantry cranes is aimed to offer you the efficient container handling solution and to boost your business productivity.

rail mounted gantry crane for container handling

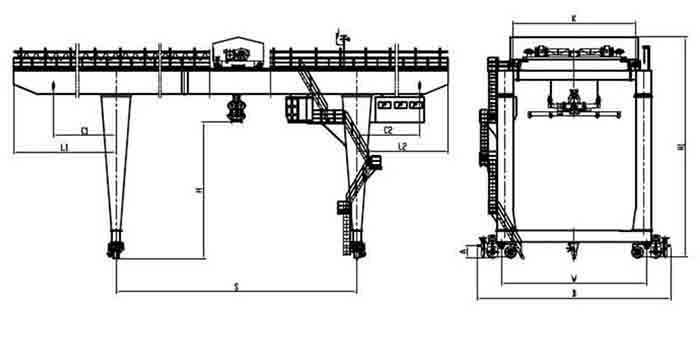

rail mounted gantry crane with container spreader drawing for your reference

The Rail-Mounted Gantry (RMG) crane is a highly efficient and robust solution designed specifically for container handling in various locations, including ports, wharves, railway yards, and logistics stations. These cranes are engineered to provide seamless loading, unloading, and stacking of ISO containers and railway-wide containers. Their ability to move across long distances on steel tracks allows them to cover large container yards, making them an ideal choice for high-volume container terminals.

Unlike traditional cranes, the RMG crane operates on multiple steel wheels, which enables it to traverse across tracks in a smooth, stable manner. This rail-based system offers increased stability compared to wheeled or rubber-tired cranes, making it suitable for heavy-duty operations, even under the most demanding conditions.

Key Features

- Electric-Powered Operation: RMG cranes are powered by electricity, making them energy-efficient and environmentally friendly. The electric drive system ensures smooth operation with precise control over speed and movement.

- Efficient Steel Wheel Support: Supported by steel wheels running on tracks, these cranes can handle heavy loads with minimal maintenance and wear, extending their service life and reliability. The steel wheels provide stability and allow for high load capacities without sacrificing performance.

Primary Applications

- Ports and Wharves: RMG cranes are essential at ports where they handle large volumes of containerized cargo. They are used to unload containers from ships, move them to storage areas, or transfer them to other transport systems such as trucks or trains.

- Railway Yards: These cranes are also critical in railway yards where they assist in transferring containers between trains and trucks. By using RMG cranes, yards can operate more efficiently and reduce the time needed to load and unload freight.

- Logistics Stations: In logistics hubs, RMG cranes are used to facilitate the transfer of containers across different modes of transportation. They are commonly found in large logistics stations where efficient container handling is crucial to meeting tight schedules and delivery deadlines.

In summary, the Rail-Mounted Gantry Crane (RMG) is the backbone of modern container handling in transportation hubs, offering a safe, efficient, and reliable solution for the loading and unloading of containers in a variety of settings. Its ability to handle heavy loads with precision and speed makes it indispensable in the fast-paced world of logistics and freight management.

Parameters of Rail Mounted Gantry Crane for Container Handling

The main parameters and specifications of the Rail mounted gantry cranes are presented for your reference. And If your container crane requirements needs custom design, please feel free to contact us.

Rail mounted gantry crane parameters:

- Load capacity of Rail mounted Gantry : 30 ton -50 ton

- Span of Rail mounted Gantry : 18-35m

- Lifting height of Rail mounted Gantry : 12.3-21m

- Lifting speed of Rail mounted Gantry : 9.2-12.5m/min

- Trolley running speed of Rail mounted Gantry : 45-56m/min

- Crane running speed of Rail mounted Gantry : 42-50m/min

- Work duty of Rail mounted Gantry : A6-A8

- Power supply of RMG crane : 3P 50HZ, 380V

- Application temperature of RMG crane : -25~+40 centigrade

- Relative humidity of working environment : No more than 50% when the temperature is +40 centigrade

Main Technical Parameters | ||||

Lifting Capacity Under Spreader(t) | 35 | 41 | 70 | |

| 10/16 | |||

| 30/35/40 | |||

| 12.5/15.3/18.3 | |||

|

| |||

| 20', 40' , 45' | 20', 40' , 45' | 双20', 20', 40' ,45' | |

|

| 13/20 | 13/20 | 20/40 |

| 45 | 45 | 45 | |

| 70 | 70 | 70 | |

| 16/20 | 16/20 | 24 | |

| 250 | 280 | 300 | |

|

| |||

- Lifting height vs. Lifting speed -The hoisting height of rail mounted crane is determined by the requirements of container handling yard, according to "heap three over four" or "heap four over five". and due to the lifting height is not so high, and correspondingly the hoisting speed of containers is relatively slow.

- Crane travelling length vs crane travelling speed-The travelling length of the container gantry crane is generally long running along in the direction of crane track in container yard. To improve the productivity, , the rail mounted gantry crane is able to achieve a higher travelling speed.

- Crane Span and cantilever length vs Hoisting trolley speed -The hoisting trolley running speed of the rail gantry crane can be determined according to the length of crane span and the extended cantilevers. The shorter the length of crane span and cantilever is, the slower the running speed of crane trolley will be and the longer the length is, the higher the speed will be.

Main Structure & Components of Rail Mounted Gantry Cranes

The main structure of the rail mounted gantry crane is a cantilever double girder gantry crane, supported on U frame legs, running on the fixed crane rail on ground.

The main crane parts and components of the RMG cranes are including gantry frame, eclectic hoisting mechanism, trolley traveling mechanism, gantry crane traveling mechanism, and supply system, i.e. cable reel, trolley power supply system and other components,etc. And also the RMG crane are equipped with the accessories such as anchoring device, wind cable device, lightning protection device, anemometers and other, etc.

The main structures and crane parts of the rail mounted gantry crane are presented in the above picture for your reference. Please contact us to get detailed customized CAD RMG crane drawing.

Click to learn more on main parts and components of rail mounted gantry crane for container handling

rotary trolley for container handling rmg gantry crane

rmg gantry crane's driver's cabin

rail mounted gantry crane travelling system

container handling

customized container handling spreader

simple container handling spreader

Key Features

High Efficiency and Versatility

Rail-Mounted Gantry (RMG) cranes are known for their impressive versatility and high efficiency, making them ideal for handling a wide range of container types and sizes. Whether it's standard ISO containers or wider railway containers, these cranes are designed to meet the varied demands of busy container terminals, ports, and logistics stations. Their ability to manage different container dimensions and weights, coupled with quick lifting and repositioning capabilities, ensures that operations run smoothly and efficiently, reducing downtime and increasing overall throughput.

- Multiple Functions: RMG cranes are equipped to handle various tasks including loading, unloading, stacking, and transferring containers, providing a complete solution for container logistics.

- Efficiency: With optimized operations, RMG cranes minimize idle time, speed up container handling, and maintain consistent performance even during high-volume operations.

Safety and Protection

Safety is a top priority in any industrial setting, and RMG cranes are designed to provide maximum protection for both operators and equipment. These cranes come with built-in safety features, including safety indication systems and overload protection devices.

- Overload Protection: The crane is equipped with systems that automatically monitor load weights, ensuring that the crane does not exceed its lifting capacity. If an overload is detected, the system will halt operations to prevent damage.

- Safety Indications: Clear indicators and alarms are used to alert operators of any safety issues, ensuring that the crane operates within safe parameters at all times. This is especially crucial in high-traffic environments like ports or railway yards.

Advanced Control System

RMG cranes are equipped with advanced control systems, providing operators with precision and flexibility during operations. These systems ensure that the crane operates smoothly and efficiently, even under complex handling conditions.

- Digital AC Variable Frequency: The electric drive system uses fully digital AC variable frequency technology, which allows for smooth speed control and high accuracy in crane movements. This feature provides better control over the crane's lifting and traveling functions, ensuring precise operations.

- PLC Speed Control: The Programmable Logic Controller (PLC) offers a high level of control by adjusting the crane's speed and movement dynamically. This not only improves operational flexibility but also enhances overall performance by ensuring that the crane responds precisely to the needs of the operation.

Quality Components

To ensure reliability and durability, RMG cranes are built using high-quality components from reputable brands, both domestically and internationally. These components meet rigorous standards for performance, safety, and durability, ensuring that the crane remains reliable even in the harshest operating conditions.

- Reputable Brands: The use of trusted brands for key components such as motors, sensors, and control systems guarantees a high level of quality and performance, reducing the likelihood of equipment failure and minimizing maintenance costs.

- Long-Lasting Performance: High-quality components also contribute to the overall longevity of the crane, making it a cost-effective solution over its service life.

In summary, the Rail-Mounted Gantry Crane combines high efficiency, robust safety features, advanced control systems, and high-quality components to deliver an exceptional product for container handling. Whether used in ports, railway yards, or logistics stations, these cranes are designed to optimize operations, enhance safety, and ensure long-term reliability.

Various Types of Rail Mounted Gantry Cranes Offering

We provide a range of Rail-Mounted Gantry (RMG) Cranes, each designed to meet specific container handling requirements in various environments like ports, railway yards, and logistics stations. Our RMG cranes offer versatile options with rotating and non-rotating designs, as well as customizable features tailored to the needs of different industries.

Rotating RMG Cranes

Upper Rotating (Trolley Rotation)

- Design: The trolley rotates along the top of the crane structure.

- Ideal For: High maneuverability and efficient stacking in container yards.

- Key Benefit: Allows for precise container positioning across various sections of the yard, especially in busy port environments.

Lower Rotating (Spreader Rotation)

- Design: The spreader rotates at the base of the crane.

- Ideal For: Handling larger or heavier containers with enhanced stability.

- Key Benefit: Reduces horizontal movement, making it ideal for confined spaces and heavy-duty lifts.

Upper Rotating (Trolley Rotation)

Lower Rotating (Spreader Rotation)

Cantilevered and Non-Cantilevered RMG Cranes

Cantilevered RMG Cranes

- Design: Features an extended frame that allows the crane to reach beyond its standard footprint.

- Ideal For: Handling oversized cargo and reaching containers stacked in hard-to-access locations.

- Key Benefit: Increased flexibility and extended reach, making it ideal for complex container handling in port terminals.

Non-Cantilevered RMG Cranes

- Design: A more compact design without the extended frame.

- Ideal For: Operations with limited space, such as densely packed container yards.

- Key Benefit: Higher stability in confined areas, making it perfect for high-density stacking and container transfer.

cantilevered RMG gantry cranes

Non cantilevered container gantry cranes

Railway-Specific RMG Cranes

Tailored for Rail Container Handling

- Design: Customized to handle the unique dimensions and loading requirements of railway containers.

- Ideal For: Intermodal transport hubs and rail yards, where containers need to be transferred between trains and trucks.

- Key Benefit: Enhanced efficiency in rail container terminals, designed with features such as wider spans and specialized lifting mechanisms to ensure safe and fast handling of railway containers.

rail mounted gantry crane for railway and rail road container handling

40.5 ton rail mounted gantry crane for railway container handling

Each of these RMG crane models is engineered to offer maximum efficiency, stability, and flexibility in container handling. Whether you're dealing with high-volume port operations or specialized rail transport needs, our cranes provide the right solution for your specific challenges.

Rmg Crane Applications: RMG Crane with Hook vs RMG Crane with Spreader

As rail mounted gantry crane manufacturers, we are devoted to provide cost-effective and efficient material handling solution. Through years study and development, two main types of Rail mounted gantry cranes are presented for various material handling.

- Regular Rail mounted gantry cranes for general material handling - The rail mounted gantry crane with hook is for general material handling in stock , yard, and stack and when it is hook with sling, the RMG crane will also can be used for containers handling, which is a cost-effective solution in therm of equipment budget cost and crane applications.

- Specialized Rail mounted gantry crane for container handling - The RMG crane is designed for container handling with specialized container handling spreader, only used for lifting containers, and the lifting capacity under spreader up to 50 ton.

Rail mounted gantry crane for large and heavy concrete pipe handling

Rail mounted gantry crane for large and heavy loads handling

rail mounted gantry crane with customized spreader for slag soil handling

rail mounted gantry crane with hook and slings for concrete slab handling

rail mounted gantry crane for long rebar bundles handling

Performance Features

Our Rail-Mounted Gantry (RMG) Cranes are designed with a wide range of advanced features to enhance performance, safety, and efficiency. Below are some key performance features that make these cranes a reliable choice for container handling operations:

Anti-Swing System

Standard System: Equipped with a two-way flexible resistance system to reduce container swing during lifting and movement.

Optional Upgrades:

- Multi-function Frequency Control: Allows for finer control of container movements and improved anti-swing response.

- Electronic Anti-Swing System: Provides enhanced stability and smooth operation, especially when handling large or heavy containers.

These systems work together to significantly reduce sway, improve container safety, and ensure smoother crane movements, even in challenging working environments.

Smart Monitoring with CMS

- Real-Time Monitoring: The CMS (Crane Management System) provides continuous, real-time tracking of crane operations, including performance, load status, and mechanical health.

- Proactive Maintenance: Alerts and notifications for performance issues enable operators and maintenance teams to respond quickly, reducing downtime and preventing costly repairs.

This intelligent monitoring system enhances crane performance by ensuring all components are operating efficiently and helps identify potential issues before they lead to failures.

Energy Efficiency

- Vector Frequency Conversion: Ensures smooth and efficient operation by adjusting crane movements to match load conditions, reducing energy consumption.

- Electric Energy Feedback: Captures excess energy generated during operations and feeds it back into the system, minimizing energy waste.

- Torque Balance Control: Ensures that the crane operates efficiently, reducing the energy required for lifting and transportation, while improving overall system balance.

These energy-saving technologies help reduce operating costs, minimize environmental impact, and increase overall efficiency, making the RMG cranes a sustainable choice for container handling.

Fault Detection and Data Display

- Automatic Fault Detection: Continuous monitoring of crane components ensures that any issues, such as mechanical failures or system malfunctions, are quickly detected.

- Real-Time Data Display: Vital operational data is displayed in real time, giving operators immediate access to key metrics, such as load weight, speed, and performance status.

This system enhances crane reliability and safety by preventing unexpected failures and optimizing operations based on up-to-date data.

Flexible Operation Modes

- Manual Operation: Operators have full control over crane movements, allowing for precise adjustments during container handling.

- Semi-Automatic Operation: The crane automatically performs some functions, with operators overseeing critical tasks for greater efficiency.

- Remote Automatic Operation: The crane can be operated from a distance using remote controls, providing flexibility and improving safety in busy environments.

These operation modes give crane operators the flexibility to choose the best method of operation based on the situation, improving efficiency and safety.

Advanced Safety Features

- Automatic Running Positioning: The crane can automatically adjust its position, ensuring accurate alignment when lifting and placing containers.

- Flexible Landing on Containers: The spreader adjusts to ensure containers are positioned correctly and securely during the lifting and placement process.

- Trajectory Intelligent Control: Monitors the crane's movements to ensure it follows the most efficient and safe path, avoiding potential obstacles.

- Intelligent Tilting Anti-Snag Protection: Prevents the spreader from tilting too far, avoiding damage to the container and ensuring smooth handling.

These advanced safety features enhance operational reliability and prevent accidents, ensuring the crane's effective operation even in challenging conditions.

Additional Safety Measures

- Strong Wind Alarms: The crane is equipped with alarms that alert operators to high wind conditions, ensuring safety when working in adverse weather.

- Safety Dynamic Scanning: Continuously scans the environment for potential hazards, such as obstacles or nearby personnel, automatically adjusting the crane's movement to avoid collisions.

These additional safety features provide an extra layer of protection for both the equipment and the operators, ensuring a secure and smooth working environment.

These performance features combined create a highly efficient, safe, and reliable RMG crane system, optimized for modern container handling operations in ports, logistics centers, and rail yards.

Application of Rail-Mounted Gantry Cranes for Container Handling

Rail mounted gantry crane is your optimal container crane solution and general material handling crane solution.

The rail mounted gantry cranes is a special container crane, designed for loading and unloading the international ISO standard containers in terminal, container yard , cargo yards, port, outside stores railway freight station, etc. The rail mounted gantry crane with hook is not only for container handling but also can be used for general material handling in stock , yard, and stack, etc.

The rail mounted gantry crane is a good choice when a cost-effective lifting solution is need for container handling and general material handling.

Port Container Terminals

- Handling Containers from Ships:RMG cranes are commonly used in port container terminals to unload containers from ships as they dock. These cranes efficiently move containers from the vessel to the quay, where they are either stored or transferred to other transport systems.

- Transfer to Other Transport Systems:After unloading, the RMG crane transports containers to storage yards or directly to trucks and railcars for onward shipment. The crane's ability to operate on tracks allows it to cover large areas, ensuring smooth and fast transitions between sea, land, and rail transport.

Benefits:

- Speeds up cargo turnover.

- Enhances port efficiency and reduces container dwell times.

Intermodal Rail Yards

- Transferring Containers Between Trains and Trucks:In intermodal rail yards, RMG cranes are used to transfer containers from trains to trucks and vice versa. This seamless movement optimizes the flow of cargo, connecting different transportation modes and ensuring faster and more efficient container handling.

- Optimizing Rail Transport:By placing containers onto trucks for further transportation or moving containers to other trains, RMG cranes play a vital role in maintaining the flow of goods, minimizing downtime, and enhancing the overall efficiency of the rail transport system.

Benefits:

- Increases efficiency in intermodal transport.

- Ensures quick container swaps between trains and trucks, improving overall throughput.

Container Storage Yards and Freight Terminals

- Maximizing Storage Capacity:RMG cranes are ideal for use in container storage yards and freight terminals, where they are responsible for stacking containers efficiently. The cranes' high-precision movements allow for optimal use of available space, ensuring that containers are stored in an organized and accessible manner.

- Efficient Retrieval of Containers:When containers need to be retrieved for shipment, RMG cranes can quickly and accurately position the required containers for loading onto trucks or trains, minimizing retrieval times and keeping operations running smoothly.

Benefits:

- Maximizes space utilization within storage yards.

- Reduces turnaround time for containers, speeding up both storage and retrieval processes.

RMG cranes are integral to port terminals, rail yards, and container storage yards due to their ability to handle large volumes of containers efficiently. Their high mobility, coupled with precise control and advanced safety features, makes them essential for improving container throughput, optimizing transport systems, and maximizing storage capacity. Whether transferring containers between ships, trains, and trucks, or managing storage operations, RMG cranes play a critical role in the global supply chain.

Container Handling: Rail Mounted Gantry Crane vs. Rubber-tired Gantry Crane

As for Container Handling, how to select from the rail mounted gantry crane and rubber tyred gantry crane ? Rail mounted gantry crane and rubber tired gantry cranes are two types of specialized gantry cranes used for container loading and unloading. Both of the rmg crane and rtg cranes are widely used in yards and ports and other applications. What is the difference between the two types of container cranes? Let's compare the two container gantry cranes in term of travelling, lifting capacity and adaptability briefly for your reference.

Rail mounted gantry crane for container handling

- RMG rail mounted gantry crane runs on and along the gantry rails fixed on ground, with the working area of rmg crane limited by the coverage of the gantry rail. The RMG crane is powered by electricity.

- RTG rubber tired gantry crane is running on rubber tires, which enable the rtg crane able to move in 9 directions with more flexibility in lifting and transport. The RTG crane is powered by diesel engine, electricity power, or combination drive.

Lifting Capacity

- RMG crane are used for handling both containers and other long and large piece loads with , lifting capacity up to 600 ton.

- RTG crane are mainly used for containers handling, with the average lifting capacity of 35 ton, 40 ton and 45 ton.

Adaptability

- Both RMG crane and RTG crane are mainly used for lifting containers in freight yard and stock yard.

- RMG crane are used for handling both containers and other long and large piece loads but the working space are limited;

RTG crane is specially designed container crane, which are mainly used for busy container yard where container loading crane is required with high working efficiency.Click to learn more on rail mounted container crane vs rubber typred container cranes.

Advantages of Rail Mounted Gantry Crane

For heavy loads handling, the rail mounted gantry crane is designed to reduce heavy loads lifting and transferring times and promote efficiency. The RMG crane is widely used in many industrial application with the following advantages:

- With strong adaptability, the rail gantry crane is suitable for many different working site conditions.

- The RMG crane has a long service life and a low maintenance requirement.

- The performance of rail mounted gantry crane is outstanding, with smooth and stable movement, and no swing during operation.

- Accurate positioning and minimal positioning time makes your rail gantry crane handling safe and efficient.

- The energy consumption of rmg crane is low which reduces the operation cost largely.

Customization Options for Your RMG Crane

Rail-Mounted Gantry (RMG) cranes are highly versatile and can be customized to meet the specific demands of your operations. Whether you're working in a port terminal, rail yard, or container storage facility, we offer tailored solutions to optimize performance and efficiency.

Tailored Solutions for Your Needs

Customization allows you to configure your RMG crane to fit your operational requirements, including:

- Crane Span:Choose the appropriate span width to suit the layout of your container yard or port. A wider span allows for greater flexibility in handling larger container stacks and optimizing space usage.

- Lifting Height:Adjust the crane's lifting height to accommodate different container types and sizes. Whether you need to handle standard ISO containers or taller, oversized containers, our cranes can be configured to meet your height requirements.

- Load Capacity:Select the load capacity that aligns with your typical container weights. From light-duty to heavy-duty cranes, we provide options to handle varying load demands efficiently and safely.

- Special Features:Customize additional features such as anti-sway systems, advanced control systems, or safety mechanisms to enhance crane performance, safety, and operational reliability.

Benefits:

- Maximizes efficiency for your specific application.

- Increases operational flexibility and scalability.

Consultation and Engineering Support

Our engineering team works closely with clients to ensure that every RMG crane is designed to meet their unique needs:

- Consultation:We begin with an in-depth consultation to understand your operational challenges and specific requirements. This helps us to offer the best crane design and configuration tailored to your business.

- Design and Customization:Our experienced engineers collaborate with you throughout the design process to ensure the crane meets your specifications. Whether it's optimizing crane span or lifting height or integrating advanced features, we ensure that every aspect of the crane aligns with your operational goals.

- Ongoing Support:After designing the perfect crane, we provide installation, training, and maintenance support to ensure that your RMG crane operates at peak efficiency for years to come.

Benefits:

- Expert guidance in designing a crane that fits your exact needs.

- Continued support throughout the crane's lifecycle, from design to maintenance.

Customization options for Rail-Mounted Gantry cranes are extensive, allowing businesses to design the ideal crane based on operational needs. With tailored solutions in crane span, lifting height, load capacity, and advanced features, our cranes can be optimized to suit any environment. Additionally, our team offers expert consultation and engineering support to guide you through the process, ensuring your crane meets all requirements for maximum efficiency and safety.

Customized 41 Ton RMG container gantry cranes project

In the following, it is one of our typical rail mounted gantry crane with container speader for an autombile company in Uzibekistan. Rail mounted gantry crane for sale Uzbekistan for container handling, capacity 41 ton, 4+1 containers. Check rmg container gantry crane specifications now.

- Types of Cranes: Rail Mounted Container Gantry Crane

- Date of Placing Order: 2021-06-24

- Date of delivery : 2021.12.22

- Transportation :Railway

- Payment: 30% TT prepaid, 35% TT completed main steel structure production, 30% TT before delivery, 5% TT installation completed

- Destination port: CIP Pitnak

- Destination country:Uzbekistan

- First contact:2015-3-21

- Click to check production of 41 ton double girder rail mounted gantry crane, please feel free to contact us to learn more or get your customized rmg crane design for free. WhatsApp: + 86 151 3871 1597.

How to Buy an RMG Crane

Buying a Rail-Mounted Gantry (RMG) crane involves a straightforward process to ensure that the crane meets your specific operational requirements. From requesting a quote to ongoing support after installation, we provide a seamless experience. Here's how the process works:

Request a Quote

Steps to Request a Quote:

Initial Consultation: To ensure we meet your needs, we will have an initial conversation to discuss your operational requirements. This helps us understand factors like your container types, handling capacity, and facility layout.

Provide Key Information: During the consultation, we will ask you to provide essential details such as:

- Load Capacity: The weight of containers you will be handling.

- Crane Span: The distance between the crane's legs, which affects its ability to cover the entire container yard.

- Lifting Height: The required lifting height to ensure the crane can handle containers of various sizes.

Customization Preferences: You can also specify any custom features, such as anti-swing systems, power supply needs, and safety features.

Receive Your Quote: Once we have all the necessary details, we will provide you with a detailed quote, including the price, lead time, and any additional options.

Delivery and Installation

Overview of the Delivery Timeline, Installation Process, and Commissioning:

Delivery Timeline: After confirming your order, the delivery time typically ranges from a few weeks to several months, depending on the level of customization and manufacturing time required.

Installation Process: Our team will manage the complete installation of the crane. This process includes:

- On-site Assembly: Assembling the crane structure, lifting components, and installing the power system.

- Safety Checks: Ensuring all components are safely integrated and functional.

Commissioning: After installation, we will perform a full system test to ensure that the crane operates as expected, including:

- Load Testing: To verify the crane's lifting capacity.

- Operational Testing: Checking all functions, from hoisting to safety systems.

- Training: Providing training for your operators to ensure they can use the crane efficiently and safely.

After-Sales Support and Maintenance

Ongoing Support for Long-Term Crane Performance:

Service Agreements: We offer tailored service agreements that include:

- Regular Inspections: To ensure the crane remains in optimal working condition.

- Scheduled Maintenance: Periodic checks and maintenance to prolong the life of your crane and prevent unexpected downtime.

- Emergency Support: 24/7 support in case of unexpected issues or emergencies.

Maintenance Options:

- Preventive Maintenance: Ensures that all components are functioning well and reduces the risk of breakdowns.

- Repairs and Replacements: In case of any parts wearing down, we provide efficient repair or replacement services to keep your crane running smoothly.

Spare Parts Availability: We ensure the availability of spare parts for quick replacements to minimize downtime and maintain performance.

By choosing our RMG crane, you not only receive a high-quality product but also ongoing support to ensure the longevity and efficiency of your operations.

Purchasing an RMG crane from us is a well-supported and efficient process, from requesting a quote to full installation and after-sales support. Our team is here to guide you every step of the way, ensuring you get a crane that fits your exact needs and operates reliably for years to come.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch