Grab crane- Overhead crane with crane grab bucket- Grab overhead crane

5 ton 10 ton 16 ton 20 ton Grab Overhead Cranes with orange peeler grabs or clamshell grab buckets for scattered material handling in power station, steel mill, port, cement plant,storage & waste recycling station, etc

| Crane Type | QZ overhead crane with grab bucket |

| Crane Capacity | 5 ton ~20 ton |

| Crane Span | 10.5~34.5m |

| Working Class | A6, A7. |

| Ambient Temperature | -20~40℃ |

Category: Overhead Crane

Your Trusted Grab Overhead Crane Manufacturer & Supplier

Grab Crane & Grab Overhead Crane

Single Girder & Double Girder Overhead Crane with Grab Bucket

5 ton 10 ton 16 ton 20 ton Grab Overhead Cranes with orange peeler grabs or clamshell grab buckets for scattered material handling in power station, steel mill, port, cement plant,storage & waste recycling station, etc

Grab Overhead Crane

Overhead grab crane / grabbing crane is a heavy duty overhead travelling bridge crane , which can be equipped with different types of crane grabs/ grab buckets for bulk and granular materials handling, such as, bulk cargo, minerals, sand, coals, logs and gravel materials for examples,earth and stone, etc. The grab overhead crane can be used indoors or outdoors with a rain proof cover devices. It is widely used in applications such as power plants, freight yards, workshops, wharf, docks, station yards, and mines, etc.

Single Girder Grab Overhead Crane

This single girder overhead crane with grab is commonly used to grab and lift common materials with a work duty of less than A4. The crane can handle almost any type of loose or bulk material, including garbage, industrial materials, and sand. This crane should not be used in a flammable, explosive, or corrosive environment.

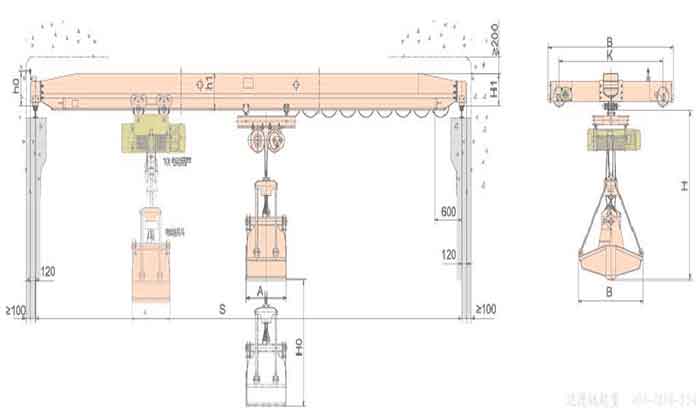

single girder grab overhead crane drawing

- Lifting capacity of single girder grab overhead crane:1ton, 2ton, 3ton, 5ton, 10 ton ;

- Span of single girder grab overhead crane: 7.5m ~ 22.5m;

- Lifting height of single girder grab overhead crane: 6m, 9m, 12m, 18m, 24m, 30m

- Power sources of single girder grab overhead crane: 380V 50HZ 3Phases, can be customized

- Working temperature of single girder grab overhead crane: -20℃ ~ 40℃;

- Relative humidity of single girder grab overhead crane:≦ 85%.

- Working materiel density of single girder grab overhead crane: 0.6 ~ 2.9 t/m³

- Volume of grab bucket:0.75m³, 1m³, 1.5m³and 2.5m³.

Customized single girder grab overhead crane are available. More infomation about grab bucket single girder overhead crane, please feel free to contact us.

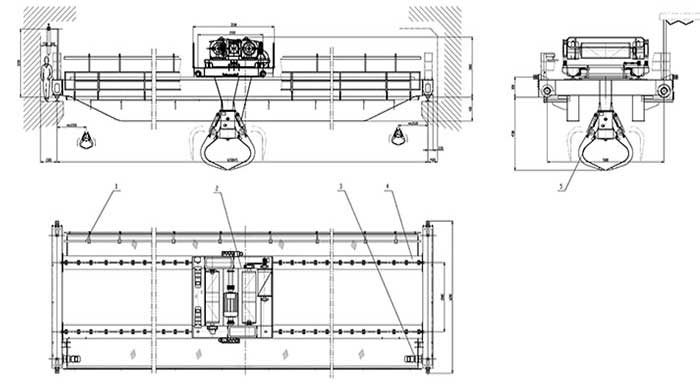

Double Girder Grab Overhead Crane

Double girder grab overhead cranes is widely used for material handling with capacity of 5 ton to 20 ton and the working duty of grab overhead crane is A6, A7, working environment 20 ° C ~ +40 ° C. QZ grab overhead crane is not allowed to be used in the hazardous environment such as explosive, acid, and others, etc.

Double girder overhead crane with grab bucket drawing

Main Parameters of Double Girder Grab Cranes:

- Product Type of Grab Overhead Crane: QZ type double girder grab overhead crane

- Lifting Capacity of Grab Overhead Crane: 5 ton ~20 ton (5 ton , 10 ton, 16 ton, 20ton, etc. )

- Span Length of Grab Overhead Crane: 10.5~34.5m, ( 0.5m, 13.5m, 16.5m, 19.5m, 22.5m, 25.5m, 28.5m, 31.5m, etc. )

- Working Class of Grab Overhead Crane:A6, A7.

- Ambient Temperature of Grab Overhead Crane:-20~40℃

If you have any special need about the grab crane or grab bucket crane, please feel free to contact us to get your custom designed grab bridge crane. More on double girder grab overhead cranes.

Crane Component & Structure of Grab Bucket EOT Cranes

QZ type grab bridge crane is mainly consisted of the crane parts and components such as box-shaped crane bridge, grab car/ trolley, truck operating mechanism, crane driver;s cab and electrical control system, and the crane / grab bucket as the lifting devices for bulk material handling.

Main girder of grab overhead cranes

The grab overhead cranes are heavy duty material handling crane systems, and the working level is A6, A7. All the operation of the overhead grab crane is conducted in the driver's cab / cabins, offering closed cabin & un-closed types , which can be accessed in three directions,- end entry, side entry, and top entry. The rated lifting capacity of grab crane includes the grab weight.

Overview of QZ Grab Bucket Overhead Crane Double Girder Design

The QZ Grab Bucket Overhead Crane is a specialized type of overhead crane designed primarily for handling bulk materials. Unlike traditional cranes, the QZ crane is equipped with a grab bucket attachment, which makes it particularly well-suited for lifting and moving loose, granular, and bulk materials. These materials include substances such as coal, cement, grains, ore, and sand, which are often stored in large quantities and require specialized equipment for efficient loading and unloading.

This crane typically uses a dual girder design, providing extra strength and stability to handle the heavy and often irregular loads associated with bulk materials. The grab bucket is the key component of the crane, which can automatically open and close to securely hold large amounts of loose material, ensuring smooth and efficient operations. The system is designed to grab and release materials quickly, making it a highly efficient tool for industries that require frequent and rapid material handling.

Importance in Industries Handling Loose and Granular Materials

The QZ Grab Bucket Overhead Crane plays a vital role in various industrial sectors that deal with large volumes of bulk or granular materials. Its design and functionality make it particularly important in industries such as:

- Mining: In mining operations, the crane is used to handle minerals and ores, which are typically stored and transported in bulk. The grab bucket can easily lift and transfer heavy, irregular loads like coal, iron ore, or gravel, helping streamline loading and unloading processes.

- Cement Industry: Cement production requires the handling of large quantities of raw materials, including limestone, clay, and coal. The QZ crane's grab bucket is ideal for efficiently loading or unloading these materials, making the crane essential in both quarries and cement plants.

- Ports and Harbors: Bulk cargo like grains, coal, and iron ore are common in port operations. The QZ Grab Bucket Overhead Crane is widely used in these environments due to its ability to handle different kinds of bulk materials safely and efficiently. It helps reduce the time spent on loading and unloading, improving the overall turnaround time for ships.

- Power Plants: Power stations, especially those burning coal or other bulk fuels, rely on the QZ crane for efficient material handling. The crane is used for moving bulk coal and ash, as well as other materials used in the operation of power plants.

Overall, the QZ Grab Bucket Overhead Crane is crucial for improving productivity and reducing manual labor in industries that handle large quantities of bulk materials. By automating the process of loading and unloading, it ensures a faster and safer workflow, while also minimizing material loss and environmental impact. This makes it an essential piece of equipment for operations that require speed, efficiency, and precision in material handling.

Typical Features of QZ Grab Bucket Overhead Crane

Design and Structure

- Bridge Design: Dual Girder Configuration for Stability: The QZ Grab Bucket Overhead Crane utilizes a dual girder configuration to provide enhanced stability and greater load-bearing capacity. This robust design ensures that the crane can support the weight of bulk materials efficiently, with smooth and stable movements of the grab bucket.

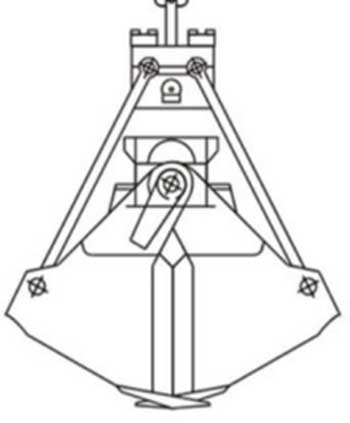

- Grab Bucket Mechanism: Four-Rope Grab Bucket for Efficient Material Handling: The crane is equipped with a four-rope grab bucket, a feature that provides superior stability and balance when handling loose and granular materials. This design allows the bucket to open and close smoothly, ensuring precision when lifting materials such as coal, ore, and cement.

- Control Systems: PLC-Based Control System for High Automation and Easy Operation: The crane features a PLC-based control system for advanced automation. This system simplifies crane operation, enhancing safety and operational efficiency. It enables precise control of the crane's movements, reducing the risk of human error and improving overall productivity.

- Hoisting System: High Capacity Hoisting Mechanism for Bulk Material Handling: The high-capacity hoisting system is designed to handle heavy bulk materials. The hoisting mechanism allows for the lifting and lowering of materials efficiently, even under high loads, ensuring that operations run smoothly in heavy-duty industrial environments.

- Durability and Strength: Heavy-Duty Structural Components for Long-Term Reliability: Built with heavy-duty structural components, the QZ crane is engineered for long-term reliability. The use of high-quality materials in its construction ensures that the crane can withstand the wear and tear of demanding industrial environments, reducing the frequency of maintenance and extending the crane's service life.

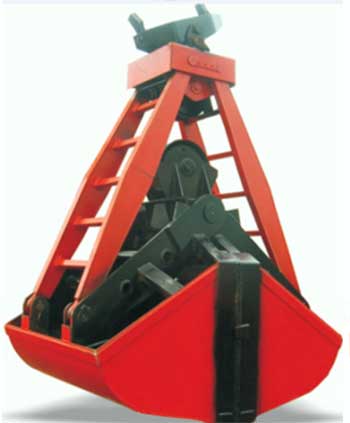

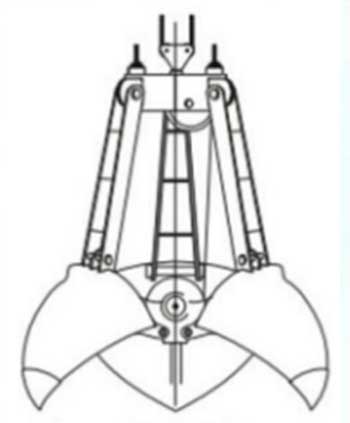

Crane Grab Buckets

As a widely used material handling lifting devices, crane grabs or grab buckets are designed to handle powder and fine bulk objects such as, grain, fertilizer, chemicals, coal, coal cinder, coke, slag, iron ore, other fine minerals, sand, particle construction materials and small rock and stones, etc.

Crane buckets and grab buckets including Mechanical rope grabs, hydraulic grabs & electric motor grabs, with clamshell grab design, cactus grab design and orange peel grab design and other customized crane bucket designs for various types of material handling of powder and fine bulk materials such as chemicals, fertilizer, grain, steel scrap, waste, coal, coke, iron ore, sand, particle construction materials and mashed rock, etc. Crane buckets and grab buckets equipped on various types of industrial cranes are widely used in ports, steel plants, scrapyard, power stations, ships and garbage& waste treatment plant,etc.

Clamshell grab for grab overhead crane

Clamshell grab for grab overhead crane

Orange peel grab for grab overhead crane

Orange peel grab for grab overhead crane

Cactus grab for grab overhead crane

Cactus grab for grab overhead crane

Grab Bucket Operation

Automatic Opening and Closing: Features for Easy Handling of Materials: The automatic opening and closing mechanism of the grab bucket allows for easy and efficient handling of materials, especially those with varying shapes and sizes. This feature helps in efficiently grabbing materials like coal, grains, and scrap metal, reducing the need for manual intervention and increasing operational speed.

Two Working Modes: Overhead Mode and Non-Overhead Mode: The QZ Grab Bucket Overhead Crane offers two working modes for optimal flexibility:

- Overhead Mode: The grab bucket moves through the centerline of the crane, ideal for larger lifting operations where materials need to be centrally positioned.

- Non-Overhead Mode: The grab bucket operates within a confined space and does not pass through the crane's centerline, ideal for more compact or specialized lifting needs where precision is important.

Electrical and Safety Features

Electrical Equipment: Power Supply Options and Control Features: The crane's electrical equipment includes a 3-phase AC power supply (380V) and advanced control features. This setup ensures stable and efficient operation, compatible with a variety of industrial power systems. The electrical components are designed for durability, optimizing the crane's performance across different environments.

Safety Mechanisms: Overload Protection, Limit Switches, and Emergency Stop Functions: Safety is prioritized with a range of mechanisms:

- Overload Protection: Prevents the crane from lifting loads beyond its rated capacity, ensuring safe operation and avoiding mechanical failure.

- Limit Switches: These switches help ensure that the crane operates within its designated range, avoiding any over-travel or mechanical strain.

- Emergency Stop Functions: In case of an emergency, the crane can be immediately halted using the emergency stop button, ensuring quick intervention to prevent accidents and material loss.

These electrical and safety features combine to enhance the crane's overall reliability, safety, and efficiency in handling bulk materials.

Features of Grab Bridge Crane

Grab bucket cranes is specially designed double girder overhead cranes for bulk material handling which has the features as the following:

- Different grab crane configurations are are available.

- There are two types of parallel and vertical main beams in the direction of opening and closing of the grab;

- Types of conductive angled steel and safety sliding line are available for your selection.

- Two types of standard crane trolleys and weighing trolleys are available for the grab bucket cranes.

- The lifting capacity of the grab crane should include the weight of the crane grab or crane grab bucket.

Advantage of Grab Bucket Crane

The grab crane with special designs are having the following advantages:

- Optimal designed overhead grab cranes can be operated with automatic, semiautomatic and manual control, which is easy and convenient.

- Equipped with Laser-assisted Height Measurement and Double Speed Mechanism, overhead grab cranes is able to get high precision and better working performance.

- Safety protection devices such as limit switches , Low voltage protection, phase sequence protection and emergency stop device and overload protection device and other devices are equipped to grab cranes to increase the security of grab crane and crane operation.

- Flashing lights and warning sound are installed to indicate warning efficiently.

- The heavy duty grab bridge cranes is able to work continuously all around clock.

Offering of Grab Overhead Cranes

Grab overhead cranes can be grouped into different types based on crane girder designs, types of crane grabs and grab buckets, crane driving powers, operation characteristics, and types of handling objects / loads, etc. In the following, the general types of grab bucket cranes are presented for your reference to get your best suitable grab cranes .

Single Girder Grab Crane & Double Girder Grab Cranes

According to the girder designs, the grab overhead cranes can be grouped in to Single girder grab crane & double girder grab crane,both of which can be equipped with different crane grabs for light duty and heavy duty material handling in various applications.

Clamshell grab crane & Multi-petal orange peel grab cranes

Clamshell grab crane is used for loading various bulk loads or cargo, such as minerals, coal, sand and gravel materials, etc. It is widely used in ports, docks, station yards, mines, etc.

Multi-petal orange peel grab cranes are widely used for scrap steel handling andgarbage handling in garbage station or biomass handling station with the crane driver's control.

Hydraulic grab, Mechanical grab & Motor grab cranes

- According to the driving method, it can be divided into types: hydraulic grab, mechanical grab and motor grab cranes.

- Hydraulic grab crane is equipped a hydraulic grab equipped with an opening and closing structure, driven by a hydraulic cylinder.

- Mechanical grab crane is used a mechanical grab which does not have an opening and closing structure, but driven by a rope or a connecting rod.The mechanical grab cranes can be grouped in single rope grab crane & double rope grab crane.

- Motor grabs crane refers to the grab crane equipped with the motor driven grab which has an electric motor equipped on the grab bucket. The motor grab crane is not able to handle loads underwater

Hydraulic grab crane

Mechanical grab crane

Motor grabs crane

Applications of Grab Bucket overhead Cranes

Grab bridge crane is widely used in various applications such as steel plants, ports, cement plants, waste recycling stations, smelting workshop power stations for bulk material handling, such as,ore, limestone, slag, coke, coal, sand and other bulk materials in fixed spans indoors and other industrial application outdoors. Besides, the grab bucket cranes have higher requirements for hazardous application such as hot, dusty and corrosive environment .

According to the loading and unloading object, it is divided into round wood grab crane, sugar cane handling grab crane and so on. However, the multi-purpose grab cranes have been developed for different loads handling.

- Wastes handling grab crane is applied for handling bulk waste, waste refining, handling and handling at work, garbage disposal sites and construction sites, car recycling yards for car dismantling, refining and recycling, tooth replacement, and high hardness wear-resistant steel to ensure the long service life.

- Steel scrap handling grab crane is used in steel mill and factory for steel scrap handling or other material handling.

- Coal, ore, mineral handling grab crane is the main dry bulk handling tool for handling mineral, coal, ore and others.

- Grab cranes for construction industries for cement, sand, and small stones handling

If you need grab crane to handle special load, please leave us your requirement to get your custom grab crane.

Orange peal grab overhead cranes

Industrial Applications of Grab Bucket Eot Crane

- Mining: Handling Ores, Minerals, and Coal: The QZ Grab Bucket Overhead Crane is widely used in the mining industry for handling ores, minerals, and coal. Its efficient grab bucket system allows for quick and precise loading and unloading of bulk materials from mining sites. The crane is designed to withstand harsh mining conditions, including exposure to dust and heavy loads, making it a critical tool for material handling in mines.

- Cement Plants: Moving Cement, Limestone, and Other Bulk Materials: In cement plants, the QZ crane is essential for moving cement, limestone, and other bulk materials required for cement production. The crane's ability to handle large volumes of material makes it ideal for loading and unloading storage silos, transport vehicles, and processing equipment. Its grab bucket system ensures that even heavy and dusty materials are handled efficiently without spillage or waste.

- Ports and Harbors: Loading and Unloading Bulk Goods like Grains, Coal, and Sand: Ports and harbors rely on the QZ Grab Bucket Overhead Crane for loading and unloading bulk goods such as grains, coal, and sand. The crane's ability to handle loose and granular materials with ease makes it an invaluable piece of equipment in port operations, helping to streamline the transportation of materials from ships to storage areas or vice versa. Its fast operation increases turnover rates at docks, improving the efficiency of port logistics.

- Power Stations: Handling Coal, Ash, and Other Bulk Materials: In power stations, the crane is used to move materials like coal, ash, and other bulk materials essential for energy generation. Its robust design allows it to handle the heavy demands of power plants, ensuring a continuous supply of coal to the furnace and managing ash disposal efficiently. The crane is designed to meet the demanding safety standards of power stations, ensuring that operations are uninterrupted.

Material Types Handled

- Granular Materials: Sand, Coal, Ore, and Grains: The QZ Grab Bucket Overhead Crane is ideal for handling granular materials such as sand, coal, ore, and grains. The crane's four-rope grab bucket is specifically designed to handle these materials without causing spillage. The grab can securely hold the materials and transport them efficiently, reducing waste and optimizing material handling.

- Loose and Bulk Materials: Cement, Chemicals, and Aggregates: This crane is also suitable for moving loose and bulk materials such as cement, chemicals, and aggregates. The versatility of the grab bucket allows it to handle a wide range of materials, from light and fine powders to heavy and coarse aggregates. Whether the material is abrasive, corrosive, or hazardous, the crane can be configured with the necessary equipment to handle it safely and efficiently.

Operating Environment

- Indoor and Outdoor Environments: The QZ Grab Bucket Overhead Crane is designed for both indoor and outdoor operations, providing flexibility in various industrial settings. Whether it's in a warehouse, cement plant, or port, the crane can be installed to meet the demands of the specific environment.

- Weatherproofing for Harsh Environments: When used in outdoor environments such as ports or mining operations, the crane is equipped with weatherproofing features to ensure it operates reliably even under harsh conditions. This includes corrosion-resistant materials and protective coatings that allow the crane to function efficiently despite exposure to moisture, temperature extremes, and heavy-duty use. In coastal areas or regions with high humidity, special corrosion-resistant treatments may be applied to protect the crane's components.

The QZ Grab Bucket Overhead Crane's design and adaptability make it ideal for a range of industrial applications, particularly where large volumes of bulk materials need to be handled quickly and efficiently. Its robust build ensures it can operate smoothly in various environments, contributing to high productivity and safety across multiple industries.

Single Rope Grab Buceket Crane , Single Girder Overhead Crane with Grab Bucket

Four Rope Grab Bucket Overhead Crane

Biomass Crane, Biomass Strewbale Handling Crane

Capacity of QZ Grab Bucket Overhead Crane

Load Capacity

- Standard Load Capacity: The QZ Grab Bucket Overhead Crane typically has a load capacity that ranges from 5 tons to 20 tons. This range is suitable for most industrial applications where bulk material handling is required, such as in cement plants, ports, and mining operations. The crane is capable of lifting and transporting large volumes of material efficiently.

- Heavy-Duty Configurations: For more demanding applications, heavy-duty configurations of the QZ crane can handle loads of up to 50 tons, depending on the specific design and requirements. These configurations are often used in larger-scale industrial operations, such as power stations or large mining sites, where significantly heavier materials need to be moved.

Span and Lifting Height

- Span: The span of the QZ Grab Bucket Overhead Crane typically ranges from 7.5 meters to 30 meters, which defines the horizontal distance between the two rails on which the crane travels. The span is a key factor in determining the crane's ability to cover wide areas, such as warehouses, loading docks, and port terminals. Customization options may be available based on the facility's layout and material handling needs.

- Lifting Height: The typical lifting height for the QZ Grab Bucket Overhead Crane is between 6 meters to 30 meters. The lifting height refers to the vertical distance the crane can raise the load, from the ground level to the highest point of the hook or grab bucket. This flexibility ensures that the crane can handle various material handling tasks, whether it's loading or unloading from storage piles or moving materials from ground level to higher platforms.

Speed and Efficiency

- Hoisting Speed: The hoisting speed of the crane is adjustable based on the type of material being handled. For example, lighter and more granular materials such as grains or coal may require a faster hoisting speed, while heavier, denser materials like cement or ore may need a slower, more controlled lifting operation. The ability to adjust hoisting speed helps optimize efficiency and prevent damage to both the crane and the material.

- Traveling Speed: The traveling speed of the QZ Grab Bucket Overhead Crane can also be tailored to meet the specific needs of the operation. In some applications, high-speed travel is necessary to quickly transport materials across large areas, such as in busy ports or during emergency situations. In contrast, in more controlled environments like cement plants, slower speeds may be preferred to allow for precise material handling.

Work Classification

Work Classification: The QZ Grab Bucket Overhead Crane is generally classified under work classifications A5 to A7, depending on the intensity and frequency of use.

- A5: Light-duty use, where the crane is operated for a few hours a day and with minimal load variations.

- A6 and A7: More frequent and heavier-duty operations, such as those encountered in mining, cement plants, and ports, where the crane operates for extended hours, often with more demanding lifting tasks.

The classification ensures that the crane is designed to handle the specific workload expected in its environment, providing long-term durability and safe operation.

The difference between the QZ Grab Bucket Overhead Crane and the QD Double Girder Overhead Crane with Grab Bucket lies primarily in their design focus, intended use, and structural features. Both cranes utilize a grab bucket for material handling, but they are configured differently based on the types of tasks and industries they are intended to serve.

Key Differences Between QZ Grab Bucket Overhead Crane vs QD Double Girder Overhead Crane with Grab Bucket

QZ Grab Bucket Overhead Crane:

QD Double Girder Overhead Crane with Hook and Below Hook Devices, Grab Bucket or Magnetic Spreader

QZ Grab Bucket Overhead Crane:

- Specialized Crane: Designed specifically for handling bulk materials such as coal, ore, grain, and sand. The crane's entire system is optimized for grab bucket operations, with specialized controls and mechanisms tailored for handling granular and loose materials.

- Components: Equipped with four-rope grab buckets, a PLC-based control system, and hoisting and grab-opening mechanisms designed to ensure efficient bulk material handling.

QD Double Girder Overhead Crane with Grab Bucket:

- Versatile Crane: A more general-purpose crane, capable of handling a variety of lifting tools, including grab buckets, hooks, magnets, and other attachments. Though it can handle bulk materials, it is suited for more diverse applications and industries.

- Components: Can be used with various lifting devices, making it adaptable to a wide range of materials and lifting tasks, from steel to machinery and bulk materials.

Load Handling and Capacity:

QZ Grab Bucket Overhead Crane:

- Load Capacity: Typically ranges from 5 tons to 20 tons, though configurations can be made for larger capacities as needed.

- Bulk Material Focus: The crane's design and functionality are optimized for bulk material handling, focusing on industries like mining, cement, and power generation where materials are loose and granular.

QD Double Girder Overhead Crane with Grab Bucket:

- Load Capacity: Can handle much heavier loads, from 5 tons to 450 tons, making it suitable for large-scale industrial applications.

- Greater Flexibility: While it can be equipped with a grab bucket, the QD crane is versatile enough to handle a wide variety of lifting tasks, from heavy machinery to steel and bulk materials.

Structure and Design:

QZ Grab Bucket Overhead Crane:

- Bridge Design: The QZ crane features a rigid, stable frame with optimized structural elements for grab bucket operations. It is designed to support precise and efficient bulk material handling.

- Grab Mechanism: Utilizes a four-rope grab bucket mechanism to handle bulk materials with automatic opening and closing for improved material handling.

QD Double Girder Overhead Crane with Grab Bucket:

- Double Girder Structure: This crane uses a double girder design that offers greater stability and strength for heavier lifting applications. The design supports a wide range of tasks, making it adaptable to different lifting requirements.

- Customizable Lifting Mechanism: While equipped with a grab bucket, the QD crane is also compatible with other lifting tools, such as hooks, clamps, and electromagnetic devices, allowing for more flexibility in different industrial settings.

Application and Industry Use:

QZ Grab Bucket Overhead Crane:

- Specialized Applications: Primarily used in industries where bulk materials need to be efficiently handled, such as ports, mines, cement plants, and power stations.

- Ideal for Irregular Materials: The crane is especially suited for materials that are granular or irregularly shaped, such as coal, cement, and grains, which require efficient handling and transport.

QD Double Girder Overhead Crane with Grab Bucket:

- Wider Industry Use: The QD crane is suitable for a broader range of industries, including steel mills, manufacturing plants, construction sites, and warehouses.

- Multiple Applications: The QD crane's versatility extends beyond bulk material handling. It can be used for heavier lifting tasks (e.g., machinery, metal products, and construction materials) and can handle various lifting attachments depending on the application.

Operating and Work Levels:

QZ Grab Bucket Overhead Crane:

- Work Levels: Typically operates within a lower work level range (A6 to A7), as it is primarily designed for handling bulk materials rather than heavy-duty lifting of large, solid objects.

- Usage: Optimized for efficient bulk material handling, where precision is required for grab bucket operations, including opening and closing mechanisms.

QD Double Girder Overhead Crane with Grab Bucket:

- Work Levels: The QD crane offers a wider work level range (A5 to A7), allowing for more flexibility in lifting different types of loads.

- Usage: Designed for heavier and more continuous lifting operations, the QD crane can be customized for specific load handling capacities based on the environment and operational requirements.

Special Features and Functionality:

QZ Grab Bucket Overhead Crane:

Grab Bucket: Features a four-rope grab bucket that is highly efficient for bulk material handling, with automatic opening and closing mechanisms for smoother operations.

Two Working Modes: The crane can operate in two modes:

- Overhead Mode: The grab bucket moves across the centerline of the main girder.

- Non-Overhead Mode: The grab bucket operates within a confined space for more precise handling in tighter spaces.

QD Double Girder Overhead Crane with Grab Bucket:

- Greater Customization: The QD crane can be equipped with multiple lifting tools beyond the grab bucket, including hooks, magnets, and clamps, which makes it suitable for a range of lifting tasks and materials.

- Heavy Duty Lifting: While it can be fitted with a grab bucket, the QD crane is built for more demanding lifting tasks, offering greater load capacities and a broader range of applications compared to the QZ crane.

Summary Table of Key Differences:

QZ Grab Bucket Overhead Crane

The QZ Grab Bucket Overhead Crane is designed specifically for bulk material handling, making it ideal for industries such as mining, cement plants, and ports. This crane excels in handling granular and irregular materials like coal, ore, and sand. Its primary focus is on efficient, precise lifting and unloading of bulk goods, which require specialized grab bucket mechanisms for optimal material handling.

QD Double Girder Overhead Crane with Grab Bucket

The QD Double Girder Overhead Crane with a grab bucket is a versatile, general-purpose crane. It is suitable for a wide range of materials and applications, from heavy lifting tasks in steel mills and manufacturing plants to construction site operations. The crane's flexibility allows it to be fitted with various lifting tools, making it adaptable for different lifting needs, whether it's for bulk material handling or more complex lifting tasks.

| Feature | QZ Grab Bucket Overhead Crane | QD Double Girder Overhead Crane with Grab Bucket |

|---|---|---|

| Design Focus | Specialized for bulk material handling | General-purpose crane, adaptable to many lifting tasks |

| Load Capacity | 5 to 20 tons (typically) | 5 to 450 tons (high flexibility) |

| Primary Application | Bulk materials (coal, ore, sand, etc.) | Variety of materials (metal, machinery, bulk materials) |

| Structure | Designed for bulk material lifting with grab bucket | Double girder design, adaptable to various lifting tools |

| Flexibility in Lifting Tools | Limited to grab bucket for bulk materials | Highly versatile (grab bucket, hook, clamp, magnet) |

| Work Levels | A6 to A7 | A5 to A7 |

| Special Features | Grab bucket with automatic opening/closing | Customizable with various attachments for heavy loads |

Conclusion

The QZ Grab Bucket Overhead Crane is a specialized crane designed primarily for handling bulk materials, particularly loose and granular items. It is widely used in industries like mining, cement production, and ports, where efficient handling of materials like coal, cement, ore, and sand is essential.

- Capacity: The QZ crane typically offers capacities ranging from 5 to 20 tons, making it ideal for medium-duty bulk material handling operations.

- Operational Features: It is equipped with automatic grab bucket control, ensuring easy handling of materials with varying shapes and sizes. The crane also offers two working modes (overhead and non-overhead), enhancing its flexibility for different handling scenarios.

When to Choose QZ Crane Over QD Crane

The QZ Grab Bucket Overhead Crane is an excellent choice when the primary need is to handle granular or bulk materials. Industries such as mining, cement production, and port operations where bulk goods need to be efficiently moved will benefit from the QZ crane's specialized design and focused features.

If your operation primarily deals with loose, granular materials or requires the use of grab buckets for bulk material handling, the QZ crane provides a cost-effective, high-efficiency solution.On the other hand, the QD Double Girder Overhead Crane is better suited for more diverse applications, especially in industries requiring heavier loads or the use of various lifting tools such as hooks, magnets, and grabs. The QD crane's versatility allows it to adapt to a broader range of industrial needs, making it ideal for operations that require multi-purpose lifting capabilities.

Main Projects

Related Products

Latest project

32/5 Ton Overhead Crane Sale in India: Case Study

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch