Construction and Infrastructure

Reliable and cost-effective industrial material lift for construction and infrastructure. Types of industrial travelling crane systems including goliath crane, single girder goliath & double girder goliath crane, overhead cranes and underhung bridge crane, jib cranes, are used in construction sites for handling the prefabrication building materials and architectural elements,etc. The construction site material lifting equipment are all reliable and durable with high safety. And also the customized industrial cranes are also required for material handling in specialized infrastructure constructions such as, high rise building, bridge erection, rail way construction, tunnel construction, and subway construction, etc.

Various types of industrial cranes for construction industries

On the construction site, there are various building elements needed to be lifted and transported such as, steel, lime or wood, cement, glass and concretes, etc. With high precision, our material lift equipment can be pickup and place the concrete pillars or laminated wooden beams effectively and precisely. At the tunnel and pipe line constructing site, low-headroom Electric hoists and specialized portable gantry cranes are used to ensure the efficient lifting in the limited space.

Small portable gantry crane Roof gantry crane for high rising building material handling

Truss gantry crane Truss crane for material handling in windy bridge construction site

A frame gantry crane Box girder gantry crane for road construction site

Gantry crane Tunnel gantry crane for limited space application

Rubber tyred gantry crane 30 ton for Tunnel construction at Changyi Airport Singapore

Subway crane & Tunnel construction gantry crane

Industrial cranes for construction and infrastructure

Industrial material lift for construction and infrastructure are required to be reliable and durable. With our own research and development team, our industrial crane and industrial crane services with made-to-order design can meet the specific needs of every phase in construction and infrastructure industry.

Roof gantry crane& rooftop portable gantry crane for high rise building material handling- The rooftop material lift gantry crane is a portable gantry crane are featured as Light dead weight, compact structure, small size and small wheel load, easy operation and rapid assembly and dis-assembly, etc. The rooftop gantry cranes can be widely used for light and small loads handling in the outdoor construction site and in the indoor workshop, warehouse and garage, etc.

Industrial gantry crane with truss crane design for windy construction sites- The industrial gantry crane with truss gantry crane design is featured as light weight, small wheel pressure and reliable performance, and high wind resistance, widely used for material handling in the windy outdoor material handling, such as, bridge construction, etc.

Industrial cranes for road construction of road- Heavy duty industry gantry crane are widely used for heavy material handling in construction site of rail or road construction, and other industrial applications such as, Precast yards, Marble / Granite Industry, Stock yards, Scrap yards, Railway yards, etc.

Industrial cranes for construction of subway, tunnel & others limited space - With advanced technology, based on FEM (Europe), DIN (Germany), ISO(International) crane standards, with the features of Strong rigidity, light dead weight, low power, outstanding structure design etc. The European standard industrial gantry cranes can be used in the underground rail construction site, and construction site of well or tunnel or shaft in the subway building.

Industrial crane for bridge construction & erection - The industrial cranes are also need in the bridge construction and erection for heavy duty loads handling , especially for the transporting and delivery of prefabricated beams, with the features of good stability, high efficiency, safety and reliability, variable span convenient adjustment and convenient operation and etc.

Hoist & Cranes for General Use

0.25 ton to 550 ton overhead cranes for wide industrial applications. Types of overhead cranes with different crane configuration, ie, Top running overhead cranes , Under hung or overhead cranes, and free standing overhead KBK cranes, with various crane bridge girder designs, including single girder, double girder ,box girder, Beam girder, monorails, etc., are manufactured and supplied for industrial material handling in various workshops and workstations, etc.

Single girder overhead crane

Single girder overhead crane designs, various single girder crane hoists, economical single girder overhead crane price, ideal overhead travelling crane solution.

Double girder overhead crane

Double girder overhead cranes -overhead travelling hoist crane & open winch crane - with below the hook lifting devices, grab, magnet, spreader,C hook, etc.

FEN standard open winch crane

FEM/ DIN open winch bridge crane-European standard double girder overhead crane with open winch trolley, your heavy duty winch crane up to 320 ton.

European style single girder overhead crane

European standard overhead hoist crane,single girder overhead cranes, compact FEM hoist crane design, small & light overhead hoist crane.

Suspension Crane & Underhung Overhead crane

Double/ single girder suspension cranes, ceiling mounted crane system, economical underslung bridge crane solution. Get free Suspension crane design for your ceiling now.

Light duty KBK crane & Workstation Crane

kbk light crane systems, flexible kbk crane & rigid kbk crane, modular crane design, cost-effective workstation crane solution, tailored light duty bridge crane.

Electric chain hoist

Electric chain hoists mounted on hook, lug, manual or electric hoist trolley for types of electric chain hoist cranes with capacity of 500kg, 5 ton, 10 ton, 32 ton.

Electric wire rope hoist

Types of wire rope hoists designs for overhead hoist cranes- explosion-proof cable hoist, low profile wire hoist & single & double girder hoists for your hoist cranes.

Air Hoist & Pneumatic Hoist

Safe & fast air operated hoists. Air hoist & pneumatic hoist is a compressed air powered hoist & air operated hoists,wide specification, good price.

Double girder gantry crane

Double girder gantry crane specifications: Capacity: 5 ton - 500 ton, Span Length: 12~35m, Working Class: A5, A6.Ask for double girder gantry crane price.

Single girder gantry crane

Single girder gantry crane specifications: Capacity: 1ton-20ton, Span Length: 8~30m, Working Class: A3, A4. Ask for single girder gantry crane price.

Singl Leg Semi Gantry Crane

Semi gantry crane designs, single leg gantry cranes, save half gantry crane cost with existing workshop.Semi gantry cranes & semi goliath cranes for sale.

Floor mounted slewing jib crane

Free standing jib crane-Pillar mounted jib crane is a free standing jib crane with pillar jib mounted on floor, for short & crowded lifting, capacity up to 16 ton.

Wall mounted jib crane

Wall mounted jib crane & wall bracket jib crane with I beam & tie rod design for light duty handling with capacity up 2 ton. or less building structure changes.

Wall travelling jib crane

Wall travelling jib crane, a perfect & economical cantilever wall travelling crane for light & long distance lifting. Wall travelling jib crane, your efficient light duty crane!

Movable & Portable Jib Crane

Portable jib crane on wheels/ rollers, self-supportive jib mobile crane design, no foundation, wide application. Mobile jib crane & Movable jib crane for sale, economical & profitable.

Aluminium gantry cranes

500kg -10 ton fixed gantry crane, a type of aluminum gantry crane with stationary design, with no rail & castors. Light, Foldable, Easy use & Assembly.

Light Crane or Small Crane

Light Crane System Small, Portable & Economical,i.e.,lightweight overhead crane system,lightweight gantry crane,light duty jib crane for all you needs.

For metro construction, what is the concerns of contractor and how to solve ?

For contractors working on metro construction projects, there are several key concerns related to lifting equipment. Here are some of the most common concerns:

Safety:

- Safety is the primary concern for contractors working with lifting equipment in metro construction. Workers must be properly trained on how to operate the equipment safely, and safety procedures must be followed at all times to prevent accidents and injuries.

- Contractors should prioritize safety by ensuring that workers are properly trained on how to operate lifting equipment safely, and that safety procedures are followed at all times. This may include providing personal protective equipment (PPE), conducting regular safety inspections, and implementing emergency procedures.

Cost:

- Lifting equipment can be expensive to purchase or rent, and contractors must carefully consider the cost of equipment when planning and budgeting for a project. They must also consider the cost of maintenance, repairs, and replacement parts.

- Contractors can manage costs by carefully planning and budgeting for lifting equipment, including the cost of rental or purchase, maintenance, repairs, and replacement parts. They can also consider sharing equipment with other contractors or renting equipment as needed to reduce costs.

Availability:

- Lifting equipment may not always be available when it is needed, particularly for large or complex projects. Contractors must plan ahead to ensure that the necessary equipment is available when it is needed, and may need to make arrangements with equipment rental companies or other contractors to obtain the required equipment.

- Contractors can ensure that the necessary lifting equipment is available when it is needed by planning ahead and making arrangements with equipment rental companies or other contractors. They can also consider using alternative equipment or methods if the required lifting equipment is not available.

Productivity:

- The productivity of lifting equipment is an important concern for contractors, as it can affect the overall timeline and success of a project. Contractors must ensure that the equipment they use is capable of handling the required loads and that it is used efficiently to avoid delays and downtime.

- Contractors can maximize the productivity of lifting equipment by ensuring that it is properly maintained and used efficiently. This may include scheduling regular maintenance and repairs, optimizing load placement and movement, and using the appropriate type of lifting equipment for the job.

Compliance:

- Contractors must comply with all relevant regulations and standards related to lifting equipment in metro construction. This includes OSHA regulations, ANSI standards, and other guidelines related to safety, load capacity, and environmental factors.

- Contractors can ensure compliance with relevant regulations and standards by staying up-to-date on changes to regulations and guidelines, conducting regular inspections and audits, and providing training on compliance requirements.

By addressing these concerns, contractors can ensure that they are able to work safely and efficiently with lifting equipment in metro construction and complete projects on time and within budget.

For metro construction, what are the lifting cranes used on construction sites?

For metro construction, several types of cranes are commonly used on construction sites. Here are some of the most common types of cranes used in metro construction:

- Tower cranes: Tower cranes are commonly used in metro construction for lifting heavy loads to great heights. They are typically mounted on a concrete foundation and can reach up to several hundred feet in height. Tower cranes are ideal for lifting large precast concrete segments, steel beams, and other heavy materials.

- Mobile cranes: Mobile cranes are another type of crane commonly used in metro construction. They are mounted on a truck or crawler and can be easily moved around the job site. Mobile cranes are ideal for lifting heavy loads to moderate heights and can be used for a variety of tasks including material handling and equipment installation.

- Gantry cranes: Gantry cranes are a type of crane that is supported by a gantry system, which consists of two uprights and a horizontal beam. They are commonly used in metro construction for lifting heavy loads over a large area. Gantry cranes can be easily moved around the job site and can be used for a variety of tasks including material handling and equipment installation.

- Crawler cranes: Crawler cranes are a type of mobile crane that is mounted on a set of tracks or crawlers. They are commonly used in metro construction for lifting heavy loads to great heights and can be easily moved around the job site. Crawler cranes are ideal for working on soft or uneven ground where other types of cranes may not be able to operate.

By using the appropriate type of crane for the job, workers can ensure that material handling and lifting operations in metro construction are conducted safely and efficiently.

What are the types of gantry cranes used in the metro construction sites?

There are several types of gantry cranes that are commonly used in metro construction sites. Here are some of the most common types:

- Rubber-tired gantry cranes (RTGs): RTGs are mobile gantry cranes that are mounted on rubber tires. They are commonly used in metro construction sites because they can be easily moved around the job site and do not require a permanent foundation. RTGs are ideal for lifting heavy loads to moderate heights.

- Rail-mounted gantry cranes (RMGs): RMGs are gantry cranes that are mounted on rails. They are commonly used in metro construction sites because they can be easily moved along the rail system and can lift heavy loads to great heights. RMGs are ideal for lifting large precast concrete segments, steel beams, and other heavy materials.

- Portable gantry cranes: Portable gantry cranes are lightweight and easy to move, making them ideal for smaller metro construction sites or for use in areas with limited space. They can be used to lift and move loads vertically or horizontally, and are available in a variety of weight capacities and configurations.

- Container gantry cranes: Container gantry cranes are a type of gantry crane that is specifically designed for lifting shipping containers. They are commonly used in metro construction sites where large amounts of materials or equipment need to be moved quickly and efficiently.

- Semi-gantry cranes: Semi-gantry cranes are a type of gantry crane that is supported by one leg and a runway system. They are commonly used in metro construction sites where space is limited, and can be easily moved along the runway system to lift and move loads.

Rubber tired gantry cranes and rail mounted gantry cranes

Rubber-tired gantry cranes (RTGs) and rail-mounted gantry cranes (RMGs) are mentioned in metro construction because they are both commonly used types of gantry cranes in this type of construction project.

- RTGs are mobile gantry cranes that are mounted on rubber tires, which allows them to move around the job site easily without requiring a permanent foundation. They are ideal for lifting heavy loads to moderate heights and can be used for material handling and transportation of equipment or materials around the job site. In metro construction projects, RTGs may be used to lift and move precast concrete segments, steel beams, or other heavy materials.

- RMGs, on the other hand, are gantry cranes that are mounted on rails. They are commonly used in metro construction projects because they can be easily moved along the rail system and can lift heavy loads to great heights. RMGs are ideal for lifting large precast concrete segments, steel beams, and other heavy materials.

Both RTGs and RMGs offer advantages in terms of mobility and lifting capacity that make them well-suited for use in metro construction projects. By using the appropriate type of gantry crane for the job, workers can ensure that material handling and lifting operations in metro construction sites are conducted safely and efficiently

The choice between a rubber-tired gantry crane and a rail-mounted gantry crane for your metro construction project will depend on factors such as the available space on the job site, the terrain of the job site, and the weight and size of the materials or equipment being lifted. A professional engineer or crane manufacturer can help you determine which type of crane is best suited for your specific project.

Semi gantry crane

Semi-gantry cranes are mentioned in metro construction because they can be a useful type of gantry crane for use in areas where space is limited or where the terrain is uneven. In some metro construction projects, the job site may be located in an area where it is difficult to install a full gantry crane system due to space constraints or other factors. In these situations, a semi-gantry crane can be a practical solution.

Semi-gantry cranes are supported by one leg and a runway system, which allows them to move along the runway to lift and move loads. Because they only require one leg for support, they can be used in areas where a full gantry crane system would not fit or where there are obstacles that would prevent the use of a full gantry crane.

In metro construction projects, semi-gantry cranes may be used to lift and move precast concrete segments, steel beams, or other heavy materials. They can also be used for material handling and transportation of equipment or materials around the job site.

Overall, semi-gantry cranes can be a useful type of gantry crane for use in metro construction projects where space is limited or where a full gantry crane system is not practical.

Container crane

Container cranes are mentioned in metro construction because they can be used to lift and move shipping containers that are used to transport construction materials and equipment to and from the job site. In some cases, metro construction projects may involve the use of large shipping containers to store materials or equipment on site, and container cranes can be used to move these containers as needed.

Container cranes are designed to lift and move heavy loads quickly and efficiently, making them ideal for use in metro construction projects where large amounts of materials or equipment need to be moved quickly. They are typically mounted on rails or other support systems and can be easily moved along the rail system to reach different areas of the job site.

While container cranes are not typically used for lifting and moving precast concrete segments or other heavy materials that are commonly used in metro construction, they can be a valuable tool for moving materials and equipment to and from the job site.

Can a gantry crane used for a metro construction project be used for another ?

Yes, a gantry crane that is used for a metro construction project can be used for another project, provided that it meets the requirements of the new project. Gantry cranes are versatile pieces of equipment that can be adapted to meet the specific needs of different projects.

However, it is important to ensure that the gantry crane is properly maintained and serviced between projects to ensure that it remains in good working condition. This may involve inspecting the crane for wear and tear, replacing any worn or damaged parts, and conducting any necessary repairs or maintenance.

Additionally, it is important to ensure that the gantry crane is properly certified and meets any regulatory requirements for the new project. This may involve obtaining new certifications or permits, or ensuring that the crane meets any local or national regulations for construction equipment.

Overall, while a gantry crane can be used for multiple projects, it is important to ensure that it is properly maintained, serviced, and certified to ensure that it can be used safely and effectively on each new project.

Can gantry cranes be used in underground material handling of metro construction projects?

Yes, gantry cranes can be used in underground metro construction projects, but they need to be designed to fit the specific requirements and limitations of the underground space.

Things to consider for underground material handling

When the lifting height of a crane covers the depth of an underground area, there are several things that should be noticed to ensure safety:

- Check for underground utilities: Before beginning any excavation work, it is important to check for underground utilities such as gas lines, water pipes, and electrical cables. This will help to prevent accidents and avoid damage to the utilities.

- Ensure proper ventilation: When working in an underground area, it is important to ensure proper ventilation to prevent the buildup of toxic gases. This can be achieved by using ventilation fans or natural ventilation.

- Use proper lighting: Proper lighting is essential when working in an underground area. It is important to use bright, high-quality lighting that illuminates the entire work area.

- Ensure stability of the crane: When using a crane in an underground area, it is important to ensure that the crane is stable and secure. This can be achieved by using outriggers or stabilizers to prevent the crane from tipping over.

- Use proper lifting equipment: When lifting heavy loads in an underground area, it is important to use proper lifting equipment such as slings, chains, and shackles. This will help to ensure that the load is secure and prevent accidents.

- Follow safety guidelines: It is important to follow all safety guidelines and regulations when working in an underground area. This includes wearing appropriate personal protective equipment (PPE) such as hard hats, safety glasses, and gloves, and following safe work practices at all times.

How to confirm the lifting height when your material handling involving above and underground operations?

When material handling involves both above and underground operations, it is important to confirm the lifting height to ensure safety and avoid accidents. Here are some steps to confirm the lifting height:

- Measure the distance: The first step is to measure the distance between the above and underground areas. This can be done using a measuring tape or other measuring tools.

- Determine the maximum lifting height: Once the distance is measured, you can determine the maximum lifting height required for the job. This will depend on the height of the upper area, the depth of the underground area, and any other factors that may affect the lifting height.

- Check for obstructions: Before lifting any materials, it is important to check for any obstructions that may interfere with the lifting process. This includes overhead power lines, tree branches, and other obstacles that may be in the way.

- Use proper lifting equipment: When lifting materials between above and underground areas, it is important to use proper lifting equipment such as cranes, hoists, and slings. This will help to ensure that the materials are lifted safely and securely.

- Follow safety guidelines: It is important to follow all safety guidelines and regulations when working with lifting equipment. This includes wearing appropriate personal protective equipment (PPE), following safe work practices, and ensuring that all equipment is properly maintained and inspected before use.

By following these steps, you can confirm the lifting height and ensure that your material handling operations involving above and underground areas are conducted safely and efficiently.

Factors affect underground material handling

- Safety procedures: Establishing safety procedures for material handling operations involving above and underground areas is critical to prevent accidents and injuries. This may include procedures for inspecting equipment before use, securing loads, and properly positioning workers during lifting operations.

- Communication: Communication between workers on the ground and those operating lifting equipment is essential to ensure that lifting operations are conducted safely and efficiently. Workers on the ground should be able to communicate with equipment operators to provide guidance on load positioning and movement.

- Equipment maintenance: Proper maintenance of lifting equipment is essential to ensure that it is functioning properly and can safely handle loads. Regular inspections, repairs, and replacements of worn or damaged parts can help to prevent accidents and extend the life of the equipment.

- Load capacity: Lifting equipment should only be used to lift loads that are within its capacity. Overloading equipment can result in accidents and damage to the equipment. Workers should be trained to properly assess load weight and ensure that it does not exceed the equipment's capacity.

- Environmental factors: Environmental factors such as weather conditions, temperature, and humidity can affect material handling operations in above and underground areas. For example, high winds can make lifting operations more dangerous, while extreme temperatures can affect the performance of equipment. Workers should be trained to take these factors into account when planning and executing material handling operations.

- Emergency procedures: In the event of an emergency, workers should be trained on procedures for shutting down equipment, evacuating workers, and responding to accidents or injuries. Having clear emergency procedures in place can help to prevent injuries and minimize damage to equipment.

What are the typical lifting equipment used for above and underground material handling and lifting ?

There are several types of lifting equipment that are commonly used for material handling and lifting in above and underground areas. Here are some of the most typical types of lifting equipment:

- Cranes: Cranes are a type of lifting equipment that use a hoist and wire ropes or chains to lift and move heavy loads. They are commonly used for material handling in above and underground areas, and come in a variety of types including tower cranes, mobile cranes, and overhead cranes.

- Hoists: Hoists are a type of lifting equipment that use a chain or wire rope to lift and move loads vertically. They are commonly used in underground areas where space is limited, and are available in electric, hydraulic, and manual models.

- Slings: Slings are a type of lifting equipment that are used to support and lift loads. They are typically made of wire rope, chain, or synthetic materials, and come in a variety of configurations including flat, round, and wire rope slings.

- Aerial lifts: Aerial lifts are a type of lifting equipment that are used to lift workers to elevated work areas. They are commonly used in construction and maintenance settings, and come in a variety of types including scissor lifts, boom lifts, and personnel lifts.

By using the appropriate type of lifting equipment for the job, workers can ensure that material handling and lifting operations in above and underground areas are conducted safely and efficiently.

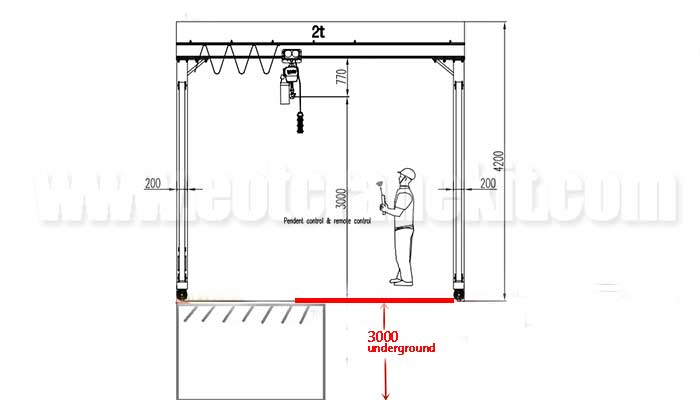

2000KG Mobile Gantry Crane for Sale, Economical Gantry Crane for Subway Construction

2 ton mobile gantry crane vs. 2000kg portable Jib crane. Economical gantry crane meets material handling needs for subway construction, 7m W & 3 + 3m H.Turnkey services for material lift for construction and infrastructure industry

Customized industrial material lift for construction and infrastructure material handling for your specific applications. And one stop industrial crane services are available which includes industrial crane design, industrial crane processing, installation and maintenance. Contact us to get more information on the turn-key project service for the industrial cranes and other material lift for construction and infrastructure industry now.