500kg -10 Ton Single Girder Underhung Bridge Crane with FEM Hoist

Underhung bridge crane, a ceilling mounted single girder overhead crane, with European style rope hoist for light duty loads handling, 500 kg to 10 ton.

Category: Single Girder Overhead Crane

Your Trusted Overhead Crane Manufacturer & Supplier

Single Girder Underhung Bridge Crane + FEM Hoist

Single Girder Underslung Crane, Ceilling Mounted Overhead Crane 0.5 to 10 Ton

Motorized single girder underhung bridge crane or under running bridge crane are the same type of single girder overhead crane. With the underhung bridge cranes design, the end trucks / end carriages move on the bottom flange of the runway beam unlike the top running overhead travelling cranes. With anunderhung bridge crane, the runway beam is often attached and supported by the roof supporting structure, without the requirement of extra floor columns to support the runway. In this way, the underhung bridge crane can be advantageous if floor space and the requirement to reduce floor obstructions is a concern in the factory workshop or warehouse. An single girder underhung bridge crane may also be a good solution for workshops with sloped ceilings or with multiple crane systems.

Single girder underhung bridge cranes are typically adopted for lighter duty material handling with capacity to 10 ton or less. Our overhead Underhung cranes are designed to improve crane safety and reduce load cycle times during production in your workshops.

Parameters & specifications of NLX series Single Girder Underslung Crane

The NlX series single girder underhung bridge crane is a type of single girder European overhead cranes, developed based on the European standards, FEM, DIN & ISO to meet the requirements of European customers. The lifting capacity of European single girder underslung crane is a type of overhead crane with lifting capacity from 1 to 10 ton and the working class is A5. The main parameters of European single girder underslung crane is shown for your reference in the following table. Customized underslung overhead crane is available.

- Lifting capacity of single girder underhung bridge crane:1ton, 2 ton, 3 ton, 5 ton, 10 ton

- Span of single girder underhung bridge crane:3-15 m

- Lifting height of single girder underhung bridge crane:3-100 m

- Working class of single girder underhung bridge crane:A3

- Supplied with European wire rope electric hoist or chain electric hoist

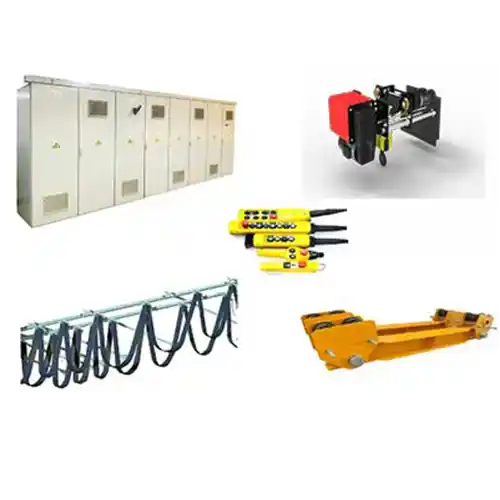

Main Structure & Complements of Single Girder Underslung Crane

The single girder underhung bridge crane is single girder overhead crane with underhung bridge cranes design that the end trucks / end carriages move on the bottom flange of the runway beam unlike the top running overhead travelling cranes. The single girder underhung bridge crane components and parts are mainly including the main girder, end carriage, hoisting system, electric systems, crane controls and other safety devices and measurements, etc.

Electric Cabinet of underhung bridge crane single girder design

The main underhung bridge crane components are presented for your reference. More underhung bridge crane details, please feel free to contact us.

Design Features of Single Girder Underslung Crane

European under running single girder crane is a light duty material handling craneswhich are attached to the roof of the workplace without floor columns, saving space and lowering cost. The general features of single girder overhead crane with under slung crane design are as following:

- Consistent quality , reliable and stable performance with benefits of overhead traveling crane design

- End truck / end carriage are designed with optimized structure.

- Rigid beam girders or welded box structure crane girders make load distribution optimal.

- Loads can be handled closely near the building walls with process crane design tailored to your applications,

- Attached to the roof structure without requirements of columns maximizing floor space

- Light duty single girder overhead crane designs with capacity around 10 ton or less.

Smart and Optional Features of Single Girder Underslung Cranes

Modular and Compact Design

- Optimal Performance in Tight Spaces: Single girder underslung cranes are designed for use in complex buildings where space is limited. These cranes attach directly to the existing roof structure, eliminating the need for floor-supporting columns, which saves time and costs.

- Efficient Use of Building Width: With small side approach dimensions and bespoke main girder cantilevers, these underhung bridge cranes maximize available building width. The highest hook position can be optimized by raising the main girder between end carriages.

- Robust Construction: Designed with torsion-resistant welded box girders, the single girder underslung crane can also use I beams or H beams, combined with our NL series electric chain hoists for light-duty applications.

- High-Quality Modular Design: Utilizing a combination of high-quality components and standardized modules, these cranes ensure product quality and shorten manufacturing periods while facilitating easy transportation and installation.

- Compact and Lightweight: The use of compact hoists and high-strength materials results in smaller sizes, reduced wheel loads, and lower overall weight, allowing for lower building heights and reduced plant construction costs.

- Enhanced Production Efficiency: The compact structure and low clearance of single girder underslung cranes provide a larger work scope, improving production efficiency.

Advanced Manufacturing Technology

- Steel Plate Preparation: Our advanced production line features shot blasting with a Sa2.5 grade and surface roughness of 40–80μm, followed by prompt primer spraying to prevent rust.

- Precision Welding: The main girder, end carriages, and trolley frame employ robot automatic welding technology, ensuring high-quality welds through various advanced techniques like submerged arc welding.

- Modular Interchangeability: Industry-leading technology allows for the modular interchangeability of crane main girders and end beams, enhancing versatility and repairability.

- Post-Welding Processing: The processing technology for crane frames and trolley frames after welding ensures high efficiency and stable accuracy in overall crane processing.

- Eco-Friendly Production: The automatic spraying production line operates across sandblasting, painting, and drying workshops, ensuring safety and environmental reliability.

High Safety, Reliability, Efficiency, and Maintenance-Free Operation

- Reliable Hoisting Motor: The single girder underslung crane features a Germany ABM hoist lifting motor with a dual-speed system for stable and reliable operation, requiring no maintenance.

- Advanced Safety Systems: Safety monitoring systems for hoisting and traveling mechanisms include overload, zero, and limit protection, ensuring safe operation.

- PLC Automatic Detection: Advanced PLC functions monitor performance, safety, and working conditions, providing safer and more reliable item transportation.

- Service Durability: The standard working duty is FEM 2M/ISO M5, equipped with our ND or NR series electric rope hoists designed for 1,600 hours of full-load service.

- Dual-Speed Control: The crane offers standard dual-speed hoisting and variable frequency drive (VFD) control for smooth cross and long travel, improving load handling and reducing sway.

Optional Functions

- Anti-Collision Protection: For multiple cranes operating on the same rail, anti-collision devices are installed to prevent impacts, with non-contact infrared sensors providing an additional layer of safety.

- Tandem Operation Capability: Loads can be transported safely by two ND(S) rope hoists through a single control unit, allowing synchronization of up to four hoists across two crane systems.

- Smart Anti-Sway Control Technology: This feature minimizes mechanical and electrical damage from load shaking, allowing for precise control and safer transportation of loads to designated positions. The operator can focus on the load, enhancing accuracy and efficiency throughout the process.

By incorporating these smart features, single girder underslung cranes and single girder underhung bridge cranes deliver exceptional performance, safety, and efficiency tailored to various industrial applications.

Why Choose the European Style Single Girder Underhung Bridge Crane Over the Traditional Type

When selecting an underhung bridge crane, many industries are increasingly opting for the European style single girder underslung cranes over the traditional Chinese designs. Here are several reasons for this preference:

European standard single girder underhung bridge crane

Compact Design

- Space Efficiency: The European style underslung cranes are designed to occupy minimal space, making them ideal for facilities with limited overhead clearance. Their compact structure allows for better maneuverability and operation in tight spaces.

- Enhanced Customization: This design facilitates bespoke configurations tailored to specific operational requirements, ensuring that the crane fits seamlessly into the existing workspace.

Lighter Deadweight

- Reduced Structural Load: European-style cranes typically have a lighter construction, which places less stress on the supporting structure (like the roof). This allows for easier installation without the need for extensive reinforcements.

- Lower Energy Consumption: The lighter weight translates to lower energy costs during operation, as less power is required to lift and move loads.

Larger Lifting Height

- Increased Vertical Capacity: The design of European single girder underslung cranes maximizes lifting height, allowing for handling taller loads. This is particularly beneficial in industries where vertical space is at a premium.

- Enhanced Operational Flexibility: With greater lifting heights, operators can perform a wider range of tasks without worrying about height restrictions.

Elegant Appearance

- Modern Aesthetic: European-style cranes often feature sleek and modern designs, which can enhance the overall appearance of the facility. This aesthetic quality can reflect positively on the business's image and professionalism.

- Improved Safety and Accessibility: The elegant design often includes thoughtful engineering to minimize hazards and improve operator safety during crane operation.

Advanced Technology and Engineering

- Superior Manufacturing Standards: European cranes are typically manufactured to higher quality standards, incorporating advanced technology and materials that enhance reliability and performance.

- Enhanced Safety Features: These cranes often come equipped with the latest safety features, including overload protection, emergency stop functions, and advanced control systems to ensure safe operation.

Hot Sale Options and Custom Designs

- Diverse Capacity Range: Available models include popular capacities such as 1 ton, 2 tons, 3 tons, 5 tons, and 10 tons, catering to various industrial needs.

- Customized Solutions: Process designs can be tailored to meet specific applications and lifting requirements, ensuring that each crane is fit for its intended purpose.

In summary, choosing the European style single girder underslung bridge crane offers significant advantages over traditional types. Its compact design, lighter deadweight, larger lifting heights, elegant appearance, and advanced engineering make it a superior choice for modern industrial applications. Investing in a European-style crane not only enhances operational efficiency but also contributes to a safer and more productive work environment.

Single girder underlsung cranes for sale at good overhead crane price. Hot sale single girder underhung bridge cranes includes 1 ton underhung bridge crane, 2 ton underhung bridge crane,3 ton underhung bridge crane,5 ton underhung bridge crane, 10 ton underhung bridge crane, etc.Process single girder underslung bridge cranes designs are available to meet your specific applications and lifting requirements. click to learn more on the types of European style hoists and cranes.

Applications of 1 Ton to 10 Ton Single Girder Underslung Cranes with European Style

Single girder underslung cranes, particularly in the 1 ton to 10 ton capacity range, are designed for efficient light load handling in various industrial environments. Their compact design and ceiling-mounted configuration make them ideal for applications where floor space is limited.

Applicaiton Advantages & Limitations of Single Girder Underslung Cranes

Single girder underslung cranes offer a distinct set of advantages and limitations, influenced by their design and intended applications.

Advantages

Maximized Floor Space:

- No Floor Columns: Single girder underslung cranes are mounted directly to the roof structure, freeing up valuable floor space, which is crucial in environments with limited room.

- Enhanced Workflow: Increased floor space facilitates easier movement of personnel and materials, improving overall operational efficiency.

Optimized Load Handling:

- Closer End Approaches: The design of single girder underslung cranes allows the monorail hoist to operate nearer to the end truck, maximizing reach.

- Wall Proximity: Loads can be handled close to walls, enabling better use of facility space for storage and operations.

Safety and Productivity:

- Reduced Hazards: The elimination of floor columns minimizes tripping hazards and improves safety for workers navigating the workspace.

- Increased Efficiency: The ability to utilize available space effectively can lead to quicker operations and higher productivity levels.

Customizable Features:

- Tailored Solutions: Single girder underslung cranes can be customized with various hoist types, control systems, and safety features to suit specific operational needs.

Limitations

Restricted Lifting Capacity:

- Weight Limitations: Typical lifting capacities for single girder underslung cranes range from 1 ton to 10 tons, which may not be sufficient for heavier applications.

- Special Considerations: Industries requiring higher lifting capacities may need to consider alternative crane types or configurations.

Structural Evaluation Required:

- Roof Strength Assessment: Before installation, it is essential to evaluate the structural integrity of the building's roof to ensure it can support the crane and the intended loads.

- Reinforcements May Be Necessary: If the roof structure is deemed inadequate, additional supporting beams or reinforcements may need to be installed, adding to project costs and complexity.

Installation Complexity:

- Potential for Higher Costs: Depending on the structural evaluation outcomes, installation costs for single girder underslung cranes may increase due to the need for additional supports or reinforcements.

- Specialized Installation Requirements: Ensuring proper alignment and securing the crane to the roof may require specialized skills and equipment.

Theseadvantages and limitations of single girder underslung cranes helps businesses make informed decisions when considering their integration into operations. Proper planning and assessment can lead to optimized lifting solutions that enhance productivity while ensuring safety and compliance.

Optimal Design Conditions for Ceiling-Mounted Underslung Cranes

- Limited Floor Space: When workshop layouts require maximizing available floor space, ceiling-mounted underslung cranes provide an effective solution by eliminating the need for floor-supporting columns.

- Low Headroom Requirements: In facilities with low ceiling heights, underslung cranes can be installed to operate within the available space without compromising lifting capabilities.

- Enhanced Maneuverability: The ability to operate close to walls and in tight corners allows for improved workflow and productivity in confined areas.

Typical Industrial Workshops for Underhung Single Girder Overhead Cranes

- Manufacturing Plants: Ideal for assembly lines where light components are handled, such as electronics or small machinery parts. Typical underslung crane capacities used in this sector range from 1 ton to 5 tons.

- Automotive Workshops: Commonly used for tasks like parts assembly, maintenance, and inspections of lighter automotive components. Underslung cranes in this environment typically have capacities of 1 ton to 3 tons.

- Maintenance Facilities: Effective for servicing equipment and machinery, where light loads need to be moved for repairs and upkeep. Typical capacities range from 1 ton to 5 tons.

- Warehouses: Frequently utilized for loading and unloading light materials, optimizing storage space, and facilitating efficient inventory management. Capacities used here generally range from 2 tons to 10 tons.

- Textile and Apparel Manufacturing: Useful in moving lighter fabrics and garments during various stages of production, with typical crane capacities ranging from 1 ton to 3 tons.

- Food Processing Plants: Employed in handling light food products and packaging materials, ensuring compliance with hygiene standards. Typical capacities used in this sector are between 1 ton and 5 tons.

- Aerospace Workshops: Suitable for assembly and maintenance tasks involving lighter components and parts in aircraft manufacturing and servicing, with typical capacities of 1 ton to 3 tons.

- Electronics and Electrical Equipment Production: Commonly used for assembling and moving lightweight electronic components, optimizing workspace and workflow. Crane capacities in this sector often range from 1 ton to 5 tons.

In summary, single girder underslung cranes are an excellent choice for light load handling in a variety of industrial workshops. Their design is particularly beneficial in environments where space is at a premium, enabling efficient operations while ensuring safety and productivity.

Exploring Underhung Single Girder Overhead Crane Types and Options

Underhung single girder overhead cranes are essential in various industrial applications due to their compact design and ability to save vertical space. These cranes are suspended from the building's roof structure, providing efficient lifting solutions for facilities with limited headroom. This article will explore the types and options available for underhung single girder overhead cranes.

- Standard Electric Underhung Single Girder Cranes:These cranes feature a single girder that runs along the top of the supporting structure, allowing for flexible movement. They are ideal for lighter loads and are commonly used in warehouses and assembly areas.

- Uner Running Single Girder Overhead Crane with Fixed Cantilever:The under running single girder overhead crane with a fixed cantilever is designed to extend its reach beyond the main girder, allowing for enhanced load handling capabilities. This configuration is ideal for applications requiring precise positioning of loads at the edges of the workspace. The fixed cantilever provides stability and support, making it suitable for operations in tight spaces or where traditional cranes cannot operate efficiently.

- Uner Running Single Girder Overhead Crane with Telescoping Sliding Cantilever: The under running single girder overhead crane with a telescoping sliding cantilever offers greater flexibility and adaptability. The cantilever can extend and retract, allowing for variable reach depending on the load requirements. This design is particularly beneficial in dynamic environments where load positioning varies frequently. Its compact nature ensures optimal space utilization while maintaining high lifting efficiency and safety standards.

- Explosion-Proof Electric Underhung Single Girder Overhead Cranes: Explosion-proof underhung single girder cranes are designed for hazardous environments where flammable materials are present. These cranes feature specialized safety designs and materials that prevent ignition, making them ideal for industries like oil and gas and chemical processing. Their compact design allows for efficient operation in tight spaces while ensuring compliance with safety regulations.

- Manual Underhung Single Girder Overhead Cranes:These cranes rely on manual operation for lifting and moving loads. While they require more physical effort, they are often more economical and suitable for smaller operations.

- Custom Underhung Single Girder Cranes:Tailored to meet specific operational needs, custom cranes can be designed with various features, including specialized hoists, safety systems, and controls. They are ideal for unique industrial environments.Check more on types of underhung bridge crane designs and customized projects

Contact to Get CustomizedUnderhung Single Girder Overhead Cranes

- Load Capacity Options:Underhung single girder cranes are available in various load capacities, typically ranging from 1 ton to 10 tons. Selecting the appropriate capacity is crucial for ensuring safe and efficient operation.

- Span Lengths:These cranes can be customized with different span lengths to fit the workspace's layout. Standard spans range from 10 feet to over 40 feet, allowing for flexibility in design.

- Control Options:Operators can choose between various control systems, including pendant controls, radio remote controls, and cabin controls. Each option provides different levels of convenience and operational efficiency.

- Hoist Types:Different hoist configurations, such as electric chain hoists and wire rope hoists, can be integrated into underhung single girder cranes. The choice depends on the specific lifting requirements and the nature of the loads.

- Safety Features:Modern underhung single girder cranes often come equipped with safety features such as overload protection, emergency stop buttons, and limit switches. These enhancements help ensure safe operations.

Underhung single girder overhead cranes are versatile and effective lifting solutions suitable for various industrial applications. By understanding the different types and options available, businesses can select the right crane to enhance their operational efficiency and safety. Whether opting for standard models or customized solutions, these cranes play a crucial role in optimizing material handling in confined spaces.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch