Multi-Pivot Underhung Crane for Large-Span Industrial Workshop

1 to 10 ton multi-pivot underhung bridge crane for large-span workshops in industrial plants. Custom underhung bridge crane, 6 mounted point up to 68 m.

Category: Underhung Bridge Crane

Your Trusted Underhung Overhead Crane Manufacturer & Supplier

1 Ton to 10 Ton Multi-Pivot Underhung Bridge Crane for Large-Span Workshops in Industrial Plants

Efficient, durable underhung bridge cranes designed for large-span workshops, offering customized lifting solutions for industrial plants with capacities from 1 to 10 tons.

Overview of the Multi-Pivot Underhung Bridge Crane

Multi-Pivot Underhung Bridge Crane

The Multi-pivot underhung bridge crane is a specialized type of crane designed to provide efficient and flexible lifting solutions in large-span workshops and industrial plants. It is distinct in its ability to operate with multiple pivot points, allowing for greater maneuverability and precise control over heavy loads. This design ensures that the crane can handle complex lifting tasks, especially in environments where space and precision are critical.

The crane is typically installed in facilities with expansive floor space, such as manufacturing plants, assembly lines, and large warehouses. Its underhung configuration, where the bridge crane runs along the top of the supporting structure, maximizes the available overhead space, making it ideal for areas with limited headroom.

Overview of its Role in Large-Span Workshops and Industrial Plants

In large-span workshops and industrial plants, the multi-pivot underhung bridge crane serves as a key tool for efficiently moving heavy materials and components across a wide area. Its design enables it to navigate complex layouts and cover extensive distances, offering excellent flexibility in operations.

This type of crane plays a vital role in industries that require precise material handling, such as automotive manufacturing, aerospace, shipbuilding, and heavy machinery production. It allows for synchronized lifting of large, heavy parts, ensuring that materials are transported safely and efficiently without the risk of damage.

Key Benefits

- Efficient Material Handling in Spacious Environments: The multi-pivot design makes it easy for the crane to cover large areas, improving productivity by enabling fast and safe transport of materials across the workshop. This is especially beneficial in industries where time-sensitive tasks are common.

- Optimized for Flexibility and High Lift Capacities: With the ability to lift heavy loads with precision, the multi-pivot underhung bridge crane excels in settings where both flexibility and high lifting capacities are required. It can be tailored to handle different types of loads, including bulky components and sensitive materials that need careful handling.

This crane system is also built to withstand the demands of busy industrial environments, ensuring long-term durability and minimal downtime due to its efficient design.

large span underhung bridge crane for large industrial workshop

multi-pivot overhead underhung crane with large span design for industrial plant

Design and Features

Advanced Multi-Pivot Technology

The multi-pivot design is a standout feature of this crane, offering superior stability and maneuverability. This technology utilizes multiple pivot points along the crane’s structure, allowing for enhanced control over load movement and minimizing the risk of tipping or sway during operation. The system enables the crane to navigate through large, open spaces with greater flexibility, making it ideal for complex workflows where precise movements are essential.

Additionally, the multi-pivot system helps distribute weight more evenly across the crane, improving its ability to handle heavy loads without straining the structure. This provides greater operational safety, especially when lifting delicate or large items.

Benefits of Underhung Bridge System

The underhung bridge system offers significant advantages in terms of headroom and workspace optimization. Because the crane is mounted under the support structure, there’s more room available for other machinery or personnel, making it ideal for environments with limited overhead space. This design maximizes the usable space within the workshop or industrial facility, offering greater flexibility for operators and other equipment. It also allows the crane to lift loads higher than traditional overhead cranes, which can be a crucial factor in certain applications.

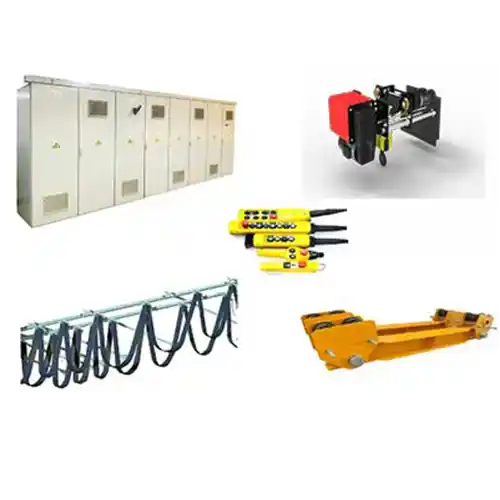

Crane Structure and Components

- Frame Construction: The crane frame is made from high-strength steel, providing a durable and robust structure capable of withstanding heavy loads and frequent use. The construction is designed to endure the stresses of lifting operations while maintaining stability and safety.

- Traveling Mechanism: The crane features a smooth traveling mechanism, designed to minimize friction and ensure easy movement along the tracks. This feature enhances operational efficiency by reducing wear and tear on both the crane and the tracks, leading to longer lifespan and less maintenance.

- Hoist System: The hoist system is built to handle heavy loads with precision. With adjustable speeds and fine-tuned controls, the hoist allows operators to lift loads accurately, reducing the risk of accidents and improving overall operational efficiency.

Customizable Design

The multi-pivot underhung bridge crane is highly customizable, offering adjustable features to suit specific needs:

- Load Capacities: Available in capacities ranging from 1 ton to 10 tons, this crane can be tailored to handle a variety of material handling requirements across different industries.

- Lifting Height, Span, and Travel Length: Users can specify the lifting height, span, and travel length based on the unique needs of their workshop or industrial facility. These adjustable features ensure that the crane fits seamlessly into a range of operational environments.

This adaptability makes the multi-pivot underhung bridge crane an ideal solution for diverse industries, from manufacturing to aerospace, providing the necessary flexibility to optimize operations and productivity.

Underhung Crane Specifications

| Model | LXD |

| Load capacity | 0.5-10t |

| Span | 3-22.5m, Customized up to 68 meters |

| Lifting height | 6-30m |

| Lifting speed | 0.7-8m/min |

| Hoist running speed | 20m/min |

| Crane running speed | 20m/min |

| Work duty | A3, A4 |

Load Capacity and Handling

Load Handling Capabilities

The multi-pivot design significantly improves load handling by distributing the weight across multiple pivots. This ensures balanced lifting and minimizes the risk of tipping or sway, especially when handling heavy or uneven loads. The load distribution system allows the crane to lift and move heavy items smoothly, even when operating at maximum capacity. This feature is essential in environments where precision is key, such as in machinery assembly lines or delicate material handling tasks.

The crane’s design helps maintain the structural integrity of both the crane and the load, ensuring smooth operation throughout the lifting process. By reducing stress on individual components, it also extends the crane’s lifespan and minimizes wear and tear.

Different Weight Ranges Suitable for Industrial Applications

The multi-pivot underhung bridge crane is highly adaptable and can be configured to handle different weight ranges, typically from 1 ton to 10 tons. This range provides flexibility for a variety of industrial applications:

- Lightweight materials like small machinery parts or components can be easily lifted at lower capacities (1-2 tons).

- Heavy industrial parts, such as large metal sheets, machine components, or bulk materials, can be efficiently handled with capacities up to 10 tons.

This versatility makes the crane ideal for industries such as manufacturing, automotive, aerospace, and general construction, where different load sizes are frequently handled in the same workspace.

Typical Loads Handled

The multi-pivot underhung bridge crane is designed to handle a wide range of loads commonly found in industrial settings:

- Heavy Machinery Components: Lifting large parts such as engines, gears, and heavy-duty machine tools.

- Bulk Materials and Large Industrial Parts: Moving items such as steel beams, machinery casings, or large containers in warehouses or assembly plants.

The crane’s precise load handling capabilities ensure these items are lifted safely and efficiently, preventing potential damage to both the load and the facility.

Safety Features

Safety is a top priority with the multi-pivot underhung bridge crane. Several key safety features are integrated to ensure safe operation in demanding environments:

- Overload Protection Systems: These systems automatically detect when the crane is lifting beyond its capacity, triggering a safety shutdown or warning to prevent accidents.

- Emergency Stop: The crane is equipped with emergency stop buttons that immediately halt operations in case of unexpected issues or hazards.

- Limit Switches: These switches prevent the crane from traveling beyond its designated range, reducing the risk of accidents caused by overextension or collisions.

Together, these safety features ensure the crane operates within safe parameters, protecting both operators and the equipment from potential hazards.

customized suspension underrunning bridge crane with multiple mounted points

workshop underhung bridge crane with large span

Application in Large-Span Workshops

Ideal Work Environments

The multi-pivot underhung bridge crane excels in large-span workshops and industrial environments where there is a need to cover long distances with precision and efficiency. Its underhung design is perfect for these expansive spaces, as it allows the crane to travel smoothly across wide areas without taking up valuable floor space, making the most out of the available overhead room.

In facilities with high-clearance areas, where maximizing headroom is essential, this crane is particularly beneficial. The underhung structure ensures that the crane’s components don’t obstruct overhead space, which is a crucial consideration for environments requiring the lifting of tall or bulky items. The design also minimizes the need for excessive structural reinforcement, thus reducing both construction costs and space consumption.

Industries and Sectors

The versatility of the multi-pivot underhung bridge crane makes it well-suited for a variety of industries that rely on large-span workshops and high-clearance spaces. Some of the most common sectors include:

- Automotive Manufacturing Plants: The crane is ideal for lifting heavy automotive components, assembly parts, and large machinery with precision, particularly in large-scale assembly lines and production areas.

- Aerospace and Shipbuilding Workshops: These industries require precision lifting for delicate parts such as fuselages, wings, and ship components. The crane’s ability to handle heavy loads with fine control makes it indispensable for these sectors.

- Steel and Metal Fabrication Facilities: In environments where large metal sheets, beams, and heavy-duty equipment are common, this crane can efficiently move materials across wide spans, optimizing production flows and minimizing downtime.

These industries benefit from the crane’s ability to handle large and heavy components in expansive facilities, improving both safety and productivity.

Operational Efficiency

One of the key advantages of the multi-pivot underhung bridge crane is its ability to maximize space usage in large workshops. By utilizing an underhung design, the crane operates in the air, freeing up valuable floor space that would otherwise be occupied by traditional cranes. This feature is especially important in constrained factory layouts, where space optimization is critical.

Moreover, the crane’s robust build and high-speed performance help minimize operational downtime. With smooth and efficient traveling mechanisms, the crane can operate continuously, even in demanding environments, ensuring that production processes remain uninterrupted. Its quick response times and high-speed lifting capabilities also ensure that large components are moved with minimal delays, further enhancing overall operational efficiency.

Customization and Flexibility

Tailored to Specific Needs

The multi-pivot underhung bridge crane is highly customizable to meet the diverse needs of different production lines and industrial environments. Key adjustable features include:

- Adjustable Span: The span of the crane can be tailored to fit the specific dimensions of your workshop or factory, ensuring it can cover long distances as required.

- Lift Height: The lift height can be customized to accommodate the lifting of various sized components, from smaller items to large, heavy machinery, ensuring optimal flexibility for your operations.

- Speed Adjustments: The speed of the crane can be modified to match the demands of specific tasks. Whether slow and precise movements are needed for delicate tasks, or faster speeds for high-volume operations, this crane can be easily adjusted for optimal performance.

These flexible configurations enable seamless integration with existing plant layouts and workflow processes, making it easier to incorporate the crane into any production environment without the need for extensive modifications.

Integration with Existing Plant Layouts and Workflow Processes

This crane is designed with versatility in mind, ensuring it integrates smoothly with your existing plant layouts and workflow processes. Whether you have a new facility or an established one, the crane’s customizable features allow it to be adapted to different industrial settings, enhancing your existing operations.

Its modular design ensures that it can be easily incorporated into both small and large-scale plants, minimizing disruption during installation. By aligning with your factory’s operational flow, the crane boosts efficiency by reducing bottlenecks and streamlining material handling tasks.

Specialized Features

The multi-pivot underhung bridge crane also offers a range of specialized features, ensuring that it can operate in even the most demanding environments. These options include:

- Anti-Corrosion Options: For use in harsh industrial environments, such as outdoor locations or areas exposed to moisture, the crane can be equipped with anti-corrosion coatings and materials. This ensures long-lasting durability, reducing the need for maintenance and extending the lifespan of the crane in challenging conditions.

- Explosion-Proof or Spark-Resistant Configurations: In industries where there is a risk of explosion or fire, such as chemical processing or oil and gas facilities, the crane can be configured with explosion-proof or spark-resistant components. This safety feature is crucial for ensuring safe operation in hazardous environments where sparks or electrical malfunctions could lead to dangerous situations.

By offering these customizable and specialized features, the multi-pivot underhung bridge crane ensures both flexibility and safety in a wide range of industrial applications.

Installation and Maintenance

Easy Installation

The installation of the multi-pivot underhung bridge crane is designed to be straightforward and efficient, with a step-by-step process that ensures minimal disruption to your operations. Key features include:

- Seamless Installation Process: The crane is engineered for quick and easy installation in large-span workshops and factory spaces. The system is designed to be assembled with minimal downtime, allowing for fast setup and operation.

- Compatibility with Existing Infrastructure: The crane is built to integrate seamlessly with your existing infrastructure. It is adaptable to various building layouts, reducing the need for significant modifications to your building structure, which helps to shorten the installation timeline and lower costs.

Maintenance Best Practices

Regular maintenance is key to ensuring the crane continues to operate at peak efficiency and with maximum safety. Best practices for maintenance include:

- Regular Inspections: Routine inspections should be conducted to check for wear and tear, structural integrity, and any potential issues with the moving components. These inspections help identify problems before they become costly repairs or safety hazards.

- Lubrication and Cleaning: Ensuring that the crane's components are properly lubricated and cleaned will help prevent friction and wear, prolonging the life of the crane and reducing maintenance costs. Regular attention to hoists, drives, and cables will keep the crane functioning optimally.

- Preventative Maintenance: Scheduled maintenance checks, such as verifying the condition of the load-bearing components and electrical systems, will prevent unexpected breakdowns and prolong the crane’s lifespan. Regular updates to the crane’s software and control systems also help to maintain performance.

- Long-lasting Components: The crane is built with high-quality, durable components that minimize the need for frequent repairs. The use of robust materials, such as high-strength steel and corrosion-resistant coatings, reduces wear and enhances the overall longevity of the crane.

Troubleshooting and Support

Should any issues arise, troubleshooting is made simple thanks to the crane's design and available customer support services:

Common Issues and Solutions:

- Uneven Load Distribution: Ensure that the load is balanced across all pivots. Check for any obstructions or misalignments in the tracks or crane components.

- Electrical Failures: Inspect power connections and control systems for potential malfunctions. Ensure that electrical components are clean and free of damage.

- Wear on Moving Parts: Check for wear on wheels, hoists, and rails, and lubricate where necessary to maintain smooth operation.

Available Customer Support: Our support team is available for troubleshooting and technical assistance. Should any issue arise, our experts can quickly provide step-by-step solutions. Additionally, we offer maintenance and support packages to ensure that your crane operates at peak performance for years to come.

Why Choose Our Multi-Pivot Underhung Bridge Crane

Quality and Reliability

Our Multi-Pivot Underhung Bridge Cranes are designed with premium materials and advanced craftsmanship to ensure exceptional durability and optimal performance. Each crane is built to meet rigorous quality standards, offering a reliable solution for demanding industrial environments. With precision engineering and attention to detail, these cranes are designed to handle heavy loads and continuous operations without compromising on safety or efficiency. Whether you're in automotive manufacturing, heavy-duty assembly lines, or high-demand production environments, our cranes provide the robustness required to keep operations running smoothly and efficiently for years to come.

- High-Quality Materials: We use only the best materials, including corrosion-resistant steels, heavy-duty components, and advanced bearings to ensure longevity and superior performance in tough industrial settings.

- Craftsmanship: Every crane is crafted by experienced professionals with years of expertise, ensuring that each unit meets the highest standards of quality and reliability.

- Designed for Demanding Environments: Whether subjected to extreme temperatures, high humidity, or constant use, our cranes are designed to withstand these challenges, offering reliable performance in even the harshest conditions.

Cost-Effectiveness

Investing in our Multi-Pivot Underhung Bridge Crane brings long-term value to your business by offering energy-efficient systems and reducing operational costs. We prioritize sustainability and affordability without sacrificing performance.

- Energy-Efficient Systems: Our cranes are engineered with energy-saving features, such as optimized motors and variable speed drives, which reduce electricity consumption while maintaining powerful lifting capabilities.

- Reduced Operating Costs: With fewer components exposed to wear and tear and advanced control systems that enhance efficiency, these cranes significantly lower energy and maintenance expenses over time.

- Low Maintenance Requirements: Designed for minimal upkeep, our cranes have fewer moving parts that require servicing, reducing downtime and minimizing repair costs. Their robust construction ensures they can go longer between scheduled maintenance sessions, making them a reliable and cost-effective long-term investment for your plant.

Client Testimonials

We have received glowing feedback from clients in various industries who have successfully integrated our Multi-Pivot Underhung Bridge Cranes into their operations. Here are just a few success stories from our satisfied customers:

- Automotive Industry: "The crane has revolutionized our production line. It handles heavy components with ease and has significantly reduced our operational downtime. We couldn't be happier with its performance." – Automotive Manufacturer

- Manufacturing Plant: "We chose the Multi-Pivot Underhung Bridge Crane for its reliability and cost-effectiveness. It's been in operation for years, and it has proven to be one of the most valuable investments we've made." – Plant Manager

- Steel Manufacturing: "The energy-saving features of this crane are incredible. We've noticed a significant reduction in electricity costs, and the crane's ability to handle our heaviest loads has made our processes more efficient." – Steel Plant Operations Director

Get a Quote and Contact Us

Request a Custom Quote

At our factory, we understand that each industrial operation has its unique needs. That's why we offer customized quotes to ensure that our Multi-Pivot Underhung Bridge Cranes are perfectly tailored to your specific requirements. Requesting a quote is simple and straightforward—just follow the steps below:

- Provide Your Specifications: Fill out our online form or reach out via email with the details of your project, such as load capacity, operational environment, and crane dimensions. Our team will assess your needs based on your provided information.

- Customization Options: Indicate any special features you need, such as corrosion-resistant coatings, specific control systems, or advanced safety features. We offer a range of customization to ensure the crane fits seamlessly into your facility.

- Receive Your Quote: Once we have all the necessary information, we’ll provide a comprehensive quote that includes pricing, lead times, and any optional features that may benefit your operations.

We pride ourselves on offering competitive pricing and a transparent process, ensuring you receive the best value for your investment.

Conclusion

The Multi-Pivot Underhung Bridge Crane offers a comprehensive solution for demanding industrial applications, providing you with unmatched performance, energy efficiency, and reliability. Here’s a recap of its key benefits:

- High-Quality Construction: Built to withstand harsh industrial environments with corrosion-resistant materials and precision engineering.

- Energy Efficiency: Optimized for low energy consumption, helping to reduce operating costs and enhance long-term sustainability.

- Customization Options: Tailored solutions to meet specific operational needs, from load capacity to special environmental conditions.

- Low Maintenance: Designed for ease of maintenance, reducing downtime and long-term maintenance costs.

- Proven Success Across Industries: Trusted by a diverse range of industries, including automotive, steel manufacturing, and more, with excellent client feedback.

Ready to elevate your operations with a Multi-Pivot Underhung Bridge Crane? Contact us today for more information or to request a tailored quote based on your unique needs. Our team is here to assist you with all the details, from selecting the right crane to delivery and installation. Don’t hesitate—reach out now and experience the difference our cranes can make for your facility’s productivity and efficiency.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch