Arched Girder Bridge Crane 5-Ton Maximizing Vertical Clearance

5 ton overhead bridge crane for sale. Optimize headroom & lifting capacity in low-ceiling gable roof workshops with arched main beam 5 ton bridge cranes.

Category: 5 Ton Overhead Crane

Your Trusted Overhead Crane Manufacturer & Supplier

5 Ton Bridge Crane for Sale Bolivia, Arched Girder Bridge Crane

Customized Double Girder Overhead Crane 5 Ton for Low-Ceiling Gable Roof Workshops Maximizing Vertical Clearance

Focus: The benefits of arched main beam designs in overcoming ceiling height limitations. Key Difference: Arched main beam cranes have a distinctive curved design that provides higher lifting capacities and greater clearance under the main beam, even in facilities with restricted headroom. This topic would delve into how the arched design increases the usable space while maintaining the strength and stability of the crane. Unique Feature: The arched beam design that optimizes lifting height without sacrificing crane strength, making it ideal for tight or low-ceiling spaces.

Maximizing Vertical Clearance: Arched Main Beam 5-Ton Bridge Cranes for Low-Ceiling Gable Roof Workshops in Bolivia

Overview of Low-Ceiling Gable Roof Workshops in Bolivia

Low-ceiling gable roof workshops are common in Bolivia due to the region's architectural constraints and limited vertical clearance. These types of workshops present several challenges for businesses that rely on overhead lifting systems. The most significant issue is the limited headroom, which restricts the installation and operation of traditional overhead cranes. This can create a bottleneck in material handling, reduce efficiency, and increase the risk of safety hazards.

Common challenges faced in low-ceiling gable roof workshops include:

- Limited vertical clearance for installing standard cranes.

- Difficulty in lifting heavy loads without compromising available space.

- Limited flexibility for placing equipment and materials due to restricted headroom.

- Increased risk of accidents or unsafe lifting practices in tight spaces.

To overcome these challenges, it is essential to maximize the available vertical space while ensuring that lifting equipment operates efficiently and safely.

Importance of Maximizing Available Space Without Compromising Lifting Capacity

In workshops with limited ceiling height, maximizing available vertical space is critical to maintaining efficient operations. A crane system that can provide maximum lifting height without requiring excessive clearance is essential. In many low-ceiling environments, traditional cranes may occupy too much headroom, rendering them ineffective for heavy lifting tasks.

Key benefits of maximizing space in low-ceiling workshops include:

- Optimized lifting height without compromising capacity.

- Improved space utilization, allowing for more efficient workflow and storage.

- Enhanced safety by reducing the risk of accidents caused by improper lifting in cramped spaces.

- Cost-effective operations by minimizing the need for costly building modifications.

Using a crane that is specifically designed for low-ceiling environments allows businesses to take full advantage of their available space while maintaining the lifting capacity required for heavy-duty tasks.

The Role of Arched Main Beam 5-Ton Bridge Cranes

Introduction to the Arched Main Beam Design and Its Relevance for Low-Ceiling Environments

The arched main beam design provides an innovative solution to the challenges of low-ceiling workshops. Unlike traditional flat beam cranes, the arched main beam crane features a curved structure that maximizes available headroom. This design allows for greater clearance beneath the crane's main beam, enabling it to lift heavy loads while occupying less vertical space.

Benefits of the arched main beam design include:

- Increased headroom beneath the crane, allowing for better lifting height in low-ceiling spaces.

- Curved beam structure that offers more clearance without taking up additional space.

- Efficient use of vertical space, making it ideal for environments with height restrictions.

This unique design is particularly suitable for workshops in Bolivia where limited ceiling height can otherwise restrict crane operations.

How Arched Designs Solve Clearance Issues While Providing Stability and Strength

The arched design addresses clearance issues by providing more vertical space beneath the crane, enabling the lifting of larger and heavier loads without requiring additional ceiling height. Despite the curvature of the beam, the design does not compromise the crane's structural strength. In fact, the arched beam distributes the load more evenly, providing better stability and performance.

Key advantages of the arched main beam in overcoming clearance limitations:

- Maximized lifting height without the need for building modifications.

- Increased crane stability due to the even distribution of load across the arched beam.

- High lifting capacity maintained even in facilities with low ceilings.

The arched main beam crane ensures that businesses can lift heavy loads safely and efficiently, even in tight spaces. It offers an ideal solution for facilities in Bolivia, where traditional crane systems may not be suitable due to ceiling height restrictions.

Key Specifications of the 5-Ton Arched Main Beam Bridge Crane for Sale in Bolivia

Main Specifications of the Overhead Crane for Sale in Bolivia:

- Crane Type: LH Series Double Girder Top Running Bridge Crane with CD/MD Electric Hoist

- Crane Capacity: 5 ton

- Crane Span: 28.11m

- Crane Lifting Height: 6m

- Crane Power: 380V 50HZ 3P

- Project Location: Bolivia

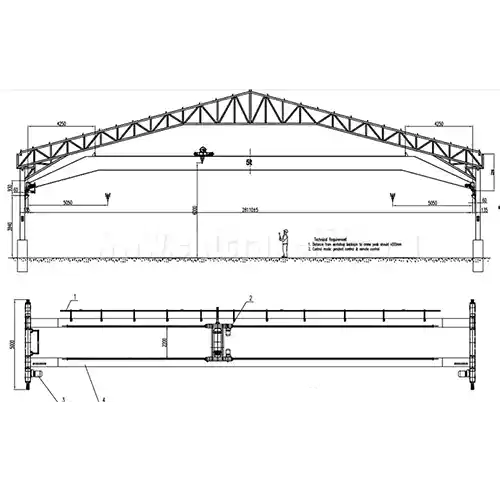

Design Blueprint for the Arched Girder 5-Ton Bridge Crane: Engineering Precision for Low-Ceiling Spaces

The detailed design drawings of the 5-ton arched girder bridge crane, engineered specifically to optimize headroom and lifting height in low-ceiling workshops. The design features a curved main beam structure that maximizes vertical space while maintaining strength and stability. Whether you're building a new facility or upgrading an existing one, this section provides the essential design insights necessary for integrating the crane into your workshop.

Crane Type: LH Series Double Girder Top Running Bridge Crane

The LH Series Double Girder Top Running Bridge Crane is a robust and reliable crane system designed for efficient material handling in a variety of industrial applications, especially in facilities with limited vertical space. The double girder configuration, where two parallel girders support the crane's hoisting mechanism, is particularly suitable for tight spaces because it allows for a higher lifting capacity and more stable operations than single girder cranes.

Key features and benefits of the LH Series double girder configuration:

- Increased stability: The double girder design ensures a more stable crane, which is essential for heavy lifting and precise movements in confined spaces.

- Higher load capacity: Unlike single girder cranes, the double girder design can support heavier loads, making it ideal for 5-ton lifting applications in industrial environments.

- Compact design for tight spaces: While the double girder design increases strength, it still allows for an efficient use of space by supporting the crane's hoist and trolley from above, reducing the footprint of the crane on the ground.

Advantages of top running design for maximum headroom and stable operation:

- Maximized headroom: The top running design means that the crane's track is mounted on the ceiling or upper portion of the facility, leaving the full height of the building's interior free for operations. This design maximizes vertical space and ensures that the hoist can reach its full lifting height without interference from the building structure.

- Stable operation: The top running design provides a stable, smooth motion along the runway, ensuring that the crane can handle loads with minimal sway and more precise positioning.

- Reduced building modifications: With the tracks mounted above the facility, there is less need for extensive modifications to the building structure, making it a more cost-effective solution.

In workshops with low ceilings, the LH Series double girder top running bridge crane is the ideal choice for lifting heavy loads while maintaining operational stability.

Crane Span and Lifting Height

The crane span of the 5-ton arched main beam bridge crane is 28.11 meters, and its lifting height is 6 meters. These specifications are designed to provide optimal functionality and efficiency in facilities with limited vertical space, such as low-ceiling gable roof workshops.

How these dimensions optimize space and functionality:

- Crane Span (28.11m): The span of the crane refers to the horizontal distance between the two support points of the crane's girders. A span of 28.11 meters is ideal for covering large areas of a workshop, allowing the crane to move materials or equipment across the entire space. This span ensures that the crane can serve multiple workstations or storage areas without requiring additional cranes.

- Lifting Height (6m): The lifting height refers to the maximum distance the crane can raise a load. In low-ceiling environments, having a 6-meter lifting height is valuable because it makes full use of the available space. The arched design of the main beam creates additional clearance beneath the crane, which maximizes this lifting height within the restricted vertical space.

These dimensions work together to ensure that the crane is not only capable of lifting loads up to 5 tons but also has the ability to cover large areas and reach necessary heights, even in a low-ceiling workshop.

Crane Power and Operating Conditions

The 5-ton arched main beam bridge crane is powered by a 380V 50HZ 3P electrical system, which is standard for industrial cranes in Bolivia. This power system is designed to meet the operational demands of workshops and factories while ensuring reliable and efficient performance.

Key aspects of the power system:

- 380V 50HZ 3P system: This power supply provides three-phase electrical power, which is common for industrial operations in Bolivia. It ensures that the crane operates smoothly, with consistent power output to support the lifting of heavy loads.

- Efficiency and compatibility: The 380V system is compatible with the majority of industrial equipment used in Bolivia, making it easier to integrate the crane into existing operations and infrastructure.

Environmental factors that may influence crane operation in local conditions:

- Temperature and humidity: Bolivia's climate can vary significantly depending on the region, with some areas experiencing high humidity or temperature fluctuations. These factors may affect the crane's mechanical components and its performance over time. However, the crane is designed to handle a range of environmental conditions, and optional anti-corrosion coatings can be applied to protect the crane from environmental wear and tear.

- Altitude considerations: Bolivia's high-altitude regions can affect the performance of machinery due to lower oxygen levels. The crane's design accounts for these factors, ensuring reliable operation even in higher-altitude facilities where machinery may need adjustments for optimal performance.

Project Location: Bolivia

Choosing the right crane design for facilities in Bolivia requires understanding the unique challenges posed by local building structures, climate, and space limitations. In Bolivia, many workshops are housed in gable roof structures, which, while offering structural strength, often come with limitations in vertical space.

The importance of choosing the right crane design for Bolivia's building structures:

- Space constraints in gable roof workshops: Gable roof workshops are common in Bolivia, especially in industrial zones. These roofs often have steep angles, which reduce the available vertical space for overhead cranes. The arched main beam design addresses this by offering more clearance without the need for significant building modifications.

- Customization to fit local conditions: Cranes in Bolivia often need to be customized to accommodate the specific dimensions and load requirements of local workshops. The 5-ton arched main beam bridge crane is designed with Bolivia's unique building structures in mind, ensuring that it fits seamlessly into workshops with low or restricted ceilings.

Challenges of working with gable roof workshops in Bolivia's climate:

- Temperature extremes: Bolivia's varied climate can present challenges for crane operation. Workshops in higher altitudes or colder regions may experience more extreme temperatures, which can affect crane components. The crane is designed to operate in such conditions, with materials and coatings chosen to withstand Bolivia's climate.

- Environmental resilience: The crane's durable design and optional environmental protections make it suitable for Bolivia's diverse environments, from industrial zones in lowland areas to those located at higher altitudes.

By selecting the 5-ton arched main beam bridge crane, businesses in Bolivia can ensure reliable operation in their low-ceiling workshops while addressing local challenges such as restricted vertical space and climate variability.

Production of the Arched 5-Ton Bridge Crane: From Concept to Completion

In the following, the production pictures of 5-ton arched girder bridge crane are presented for your reference. Our bridge cranes can ensure top-quality craftsmanship and precision in manufacturing. With accompanying pictures, we showcase the key stages of production, from initial assembly to final testing. Discover how the crane's robust structure and advanced engineering come together to provide a reliable, efficient solution for low-ceiling facilities.

ariched girder of the 5 ton overhead crane for sale Bolivia

arched girder, customized designed for client's workshop

double girder hoist trolley for the arched beam girder bridge crane

What is an Arched Main Beam Bridge Crane?

Design Features of the Arched Main Beam

An arched main beam bridge crane features a distinctive curved design that sets it apart from traditional flat beam cranes. The main beam of the crane is shaped with an arc, rather than remaining straight across the span. This curved structure allows the crane to increase headroom beneath the main beam, thereby optimizing the available vertical space in a workshop or facility. Unlike conventional cranes, which have a flat beam that extends across the full height of the crane, the arched beam design elevates the center portion of the crane, creating additional clearance for lifting operations.

Key features of the arched design:

- Curved beam structure: The main beam is designed with a gentle arc that raises the center of the beam, allowing for more headroom.

- Optimized load distribution: The curve in the beam helps distribute the weight more evenly, increasing the crane's stability and performance.

- Compact design: Despite the increased lifting height, the arched beam crane remains compact, occupying less vertical space compared to traditional designs.

This design provides a powerful solution for facilities where ceiling height is limited but heavy lifting is still required. The arched main beam crane is ideal for applications that demand both vertical space and lifting capacity.

Benefits of the Arched Design in Optimizing Headroom and Lifting Height

The primary benefit of the arched main beam design is its ability to optimize available headroom in low-ceiling spaces. By utilizing a curved structure, this crane design allows for greater clearance under the beam, thus maximizing the usable lifting height within the same vertical space.

Advantages of the arched design:

- Increased lifting height: The curved beam creates additional space beneath the crane, allowing the hoist to be positioned higher, which increases the maximum lifting height.

- Efficient use of available space: The design enables more usable headroom without the need for extensive building modifications or lowering the ceiling.

- Improved lifting capacity: The increased headroom allows the crane to handle larger loads while remaining within the confines of the facility's height limitations.

In facilities with low ceilings, every inch of vertical space is valuable, and the arched main beam design ensures that these precious inches are fully utilized without compromising the crane's performance.

Why Arched Main Beam Cranes Are Ideal for Low-Ceiling Spaces

The arched main beam crane design is particularly beneficial for low-ceiling spaces because it provides more clearance beneath the crane's beam. This added space is crucial for lifting heavy loads without the crane interfering with the building's structure or other equipment. In environments where vertical clearance is at a premium, the arched beam design can significantly improve operational efficiency by increasing usable headroom.

Key benefits for low-ceiling environments:

- Higher clearance: The arched design provides more space directly under the crane, enabling it to operate efficiently in workshops with limited ceiling height.

- Better headroom utilization: The arc of the beam effectively utilizes the available headroom, increasing the crane's lifting height while preserving overall stability and strength.

Comparison with Other Crane Types in Terms of Vertical Space Optimization

When compared to other types of cranes, such as flat beam or double girder cranes, the arched main beam crane excels in vertical space optimization. Traditional flat beam cranes occupy a larger portion of the available vertical space, limiting the usable headroom. Similarly, double girder cranes, although strong, have a higher profile and require more clearance to function properly.

Arched beam cranes vs. other crane types:

- Flat beam cranes: These cranes typically have a large profile, requiring more vertical space for operation and offering less headroom for lifting tasks.

- Double girder cranes: While they offer excellent load capacity, double girder cranes often demand more space, both vertically and horizontally, to install and operate effectively.

- Arched main beam cranes: The arched design allows for better clearance under the beam and more efficient use of available height, making them the best choice for facilities with limited ceiling height.

In terms of vertical space optimization, the arched main beam crane stands out by providing greater lifting height while keeping the crane's profile lower than both flat and double girder alternatives. This makes it ideal for businesses operating in low-ceiling environments where every inch of headroom counts.

Benefits of Arched Main Beam 5-Ton Cranes for Low-Ceiling Gable Roof Workshops

Maximizing Lifting Capacity in Tight Spaces

One of the standout benefits of the arched main beam design is its ability to maximize lifting capacity without requiring additional ceiling clearance. In workshops or facilities with low-ceiling gable roofs, there is often a limited amount of vertical space to install traditional overhead cranes. However, the unique curved structure of the arched main beam crane elevates the center of the beam, increasing the usable headroom beneath the crane while still maintaining its lifting capabilities.

How the arched beam increases lifting height:

- Elevated beam design: The curvature of the beam allows the hoist to be positioned higher without the need for structural modifications to the ceiling, increasing the lifting height within the existing headroom.

- Greater lifting capacity: With the added clearance beneath the beam, the crane can lift heavier loads without sacrificing operational efficiency.

This is especially beneficial in applications where the lifting height is crucial but the available vertical space is minimal, such as in manufacturing, assembly, or material handling tasks in low-clearance workshops.

Suitable applications for 5-ton capacity cranes in low-clearance spaces:

- Manufacturing facilities: Lifting heavy equipment or parts in tight spaces where headroom is restricted.

- Material handling: Moving heavy materials or stock within confined storage areas.

- Assembly lines: Lifting components onto or off of assembly lines where the ceiling height may be insufficient for traditional cranes.

By utilizing the arched main beam design, a 5-ton crane can efficiently perform these tasks in spaces that would otherwise not be suitable for overhead lifting equipment.

Improved Space Utilization

The arched beam design not only maximizes lifting capacity but also enhances overall space utilization within the workshop. In low-ceiling environments, every inch of available space matters. The arched main beam crane optimizes this space by allowing more room for other operations beneath the crane.

How the arched design increases usable headroom:

- Maximized vertical space: The curve of the beam elevates the central portion, freeing up valuable headroom and enabling better access to taller objects or equipment beneath the crane.

- Efficient layout design: With more vertical space available, the layout of the workshop can be optimized to improve workflow, reduce congestion, and streamline operations.

By improving space utilization, the crane design contributes to a more organized and efficient work environment.

Benefits of maximizing space in gable roof workshops:

- Improved workflow: More usable headroom allows for smoother movement of materials and equipment, reducing the time and effort required to move loads.

- Better equipment placement: With more space beneath the crane, other machinery or tools can be arranged in a way that maximizes operational efficiency.

- Increased storage capacity: The additional space beneath the crane can be used for storage, further enhancing the overall capacity of the facility.

In a gable roof workshop where space is limited, the arched main beam design makes it possible to fully utilize the available vertical and horizontal space, increasing the overall efficiency of the facility.

Enhanced Safety and Stability

Safety and stability are critical concerns in any material handling operation, especially in workshops with restricted vertical clearance. The arched main beam crane offers several structural advantages that enhance both safety and long-term stability, ensuring reliable performance even in tight spaces.

Structural advantages of the arched design:

- Even load distribution: The curved structure of the beam helps evenly distribute the load, reducing the stress placed on any single point of the crane's structure. This improves the crane's stability and ensures better handling of heavy loads.

- Increased rigidity: The arched design provides enhanced rigidity, reducing the likelihood of beam deflection and maintaining the crane's stability during lifting operations.

These structural benefits ensure that the crane can safely handle the lifting of heavy loads, even in environments where space constraints may otherwise pose a risk.

Safety features integrated into the design for low-clearance environments:

- Anti-sway mechanisms: To prevent swinging or unstable movement of heavy loads, arched main beam cranes are often equipped with anti-sway systems that ensure smooth and controlled lifting.

- Overload protection: Safety systems built into the crane, such as overload sensors and limit switches, prevent excessive load from being lifted, minimizing the risk of damage or injury.

- Precision controls: The crane's control system allows for precise positioning and movement of the load, enhancing safety in tight and confined spaces where accurate positioning is crucial.

With these built-in safety features, the arched main beam crane ensures that lifting operations in low-clearance gable roof workshops are both safe and efficient, contributing to a safer work environment and a more reliable crane system.

The 5-ton arched main beam bridge crane stands out as an ideal solution for low-ceiling gable roof workshops, offering a range of benefits including maximized lifting capacity, improved space utilization, and enhanced safety and stability. By optimizing headroom and maintaining a compact design, this crane ensures that even facilities with height restrictions can operate efficiently and safely.

Cost-Effective Pricing for 5-Ton Arched Main Beam Cranes

Affordability and Value for Money

The 5-ton arched main beam bridge crane provides excellent value for money, especially for businesses in Bolivia operating within low-ceiling gable roof workshops. While the initial investment in a custom-designed crane may appear higher compared to standard solutions, the long-term benefits in terms of space optimization, safety, and efficiency make it a wise investment.

Key benefits of investing in the 5-ton arched main beam crane:

- Tailored Solution for Low-Ceiling Workshops: The crane's arched design specifically addresses the challenges posed by low-clearance environments. By maximizing lifting height without requiring significant alterations to the facility, it helps businesses save on costly structural modifications. This custom approach ensures that the crane fits perfectly within the available space, reducing the need for additional equipment or solutions.

- Cost-Effective Operation: With its optimized headroom and efficient lifting system, the crane reduces the need for additional cranes or lifting equipment in the workshop. This makes it a more cost-effective choice for businesses looking to streamline their operations without sacrificing performance.

- Affordable Initial Investment: The price of a 5-ton arched main beam crane is competitive compared to other custom-designed cranes for similar applications. For businesses in Bolivia, the upfront cost is justified by the crane's ability to optimize space and increase operational efficiency, ensuring long-term returns on investment.

Comparisons of pricing for standard vs. custom-designed cranes for low-clearance environments:

- Standard Cranes: Traditional bridge cranes, such as single girder designs, may initially appear cheaper than custom solutions. However, their design limitations in low-ceiling workshops often result in the need for additional adjustments or modifications to the building, such as raising the ceiling or altering structural supports. These extra costs can quickly add up, making the overall investment much higher.

- Custom-designed Arched Main Beam Cranes: The 5-ton arched main beam crane, though slightly more expensive initially, offers a much more effective solution for low-clearance workshops. Its unique design reduces the need for structural changes, offering a better fit for the facility and eliminating the cost of unnecessary renovations. The crane's customized nature ensures it provides maximum lifting height while utilizing all available space, which ultimately saves on future costs.

Conclusion: Although the upfront cost of the 5-ton arched main beam crane may be higher than standard cranes, it offers a better long-term value due to the reduction in additional costs associated with building modifications and operational inefficiencies. For businesses in Bolivia, this crane provides a tailored solution that offers both immediate savings and long-term benefits.

Long-Term Savings

Investing in a 5-ton arched main beam bridge crane offers significant long-term savings, making it a smart financial decision for workshops with limited vertical clearance. The design of the crane helps reduce operational and maintenance costs over time, while also improving overall efficiency.

How the design contributes to long-term savings:

- Reduced Maintenance Costs: The arched main beam design is built with durability in mind, meaning fewer repairs and replacements over the years. Its robust structure and smooth operation reduce wear and tear on both the crane and the building infrastructure. Furthermore, the crane's design minimizes stress on the hoist and lifting mechanism, reducing the frequency and cost of maintenance checks and repairs.

- Lower Energy Consumption: The efficient design of the 5-ton arched main beam crane allows it to operate with reduced power consumption compared to less optimized cranes. With energy costs becoming a significant factor for businesses, the crane's efficiency ensures ongoing cost savings.

- Increased Productivity and Efficiency: By offering maximum lifting height and smoother operations, the crane increases operational efficiency within the workshop. The optimized space and lifting capabilities ensure faster and more precise handling of loads, which translates into more efficient workflows. In high-demand environments, this increased productivity directly impacts revenue generation, offering a return on investment that extends far beyond the initial purchase.

Reduction in the need for expensive building modifications:

- No Need for Ceiling Adjustments: One of the major expenses businesses face when installing a crane in a low-ceiling workshop is the need for building modifications to accommodate a standard crane design. The arched beam crane, however, does not require these costly adjustments. Its design allows it to fit neatly into spaces with limited vertical clearance, utilizing the available headroom without requiring structural alterations to the facility.

- Minimized Construction Costs: Instead of raising the ceiling, adding height to the building, or installing complex support structures, the arched crane provides a cost-effective solution by optimizing the existing space. This reduces the need for heavy construction work and keeps overall project costs within budget.

Conclusion: The 5-ton arched main beam bridge crane is a wise investment for businesses seeking to optimize their operational costs. By reducing maintenance and energy costs, as well as eliminating the need for expensive building modifications, this crane ensures substantial savings over the years, making it an excellent value proposition for workshops with limited vertical clearance.

Maximizing Workshop Space with the 5-Ton Arched Bridge Crane

Optimizing Layout and Workflow in Low-Ceiling Gable Roof Workshops

When working in a low-ceiling gable roof workshop, maximizing available space is essential for efficient operation and ensuring smooth workflow. The 5-ton arched main beam bridge crane can significantly contribute to improving workspace layout by providing higher clearance and more usable vertical space. To make the most of the available space, here are some useful tips for optimizing your workshop layout around the crane system:

- Strategic Placement of Workstations: Arrange workstations and machinery in areas where the crane can provide the most benefit. Ideally, workstations should be placed under the arched crane beam to take advantage of the increased lifting height. This ensures that heavy loads are handled with ease, and workers can operate equipment without worrying about low-clearance restrictions.

- Workflow Design: Design your workflow so that materials can be moved quickly and easily with minimal obstruction. Since the 5-ton arched crane provides a clear path for lifting, try to arrange materials and tools in a way that minimizes travel time and maximizes productivity. You can also use the crane's full span of 28.11 meters to cover wide areas of the workshop, eliminating bottlenecks in operations.

- Flexible Use of Floor Space: The crane's ability to lift vertically with maximum headroom allows for more flexibility in organizing the floor space. For example, materials or equipment can be stacked higher without obstructing the crane's movement, which helps free up valuable floor space for other operations.

Case Studies of Successful Installations in Similar Environments:

- Example 1 – Manufacturing Facility in Bolivia: A local manufacturing facility in Bolivia faced challenges with low ceiling heights and a need for efficient material handling. By installing a 5-ton arched main beam crane, the company was able to optimize its existing space without modifying the building structure. The crane's high lifting capacity and compact design allowed for greater flexibility in the layout, ultimately increasing production throughput.

- Example 2 – Automotive Workshop: An automotive workshop operating in a low-clearance building was able to install the 5-ton arched crane and rearrange its workstations to make better use of the available space. With the arched design allowing more headroom, the workshop was able to fit larger components without risking interference with the overhead crane system. The result was improved workflow, faster turnaround times, and a more efficient use of the workshop floor.

These case studies demonstrate how the 5-ton arched bridge crane can be a game-changer for businesses with low-ceiling gable roof workshops, offering an optimized layout and streamlined operations.

Recessed Crane Runways and Installation Tips

One of the most effective ways to maximize headroom and space efficiency in low-ceiling workshops is by installing recessed crane runways. This design consideration enables the crane to sit closer to the ceiling, effectively utilizing the full height of the building. Below are some recommendations for recessed crane tracks and installation tips that can enhance space efficiency without compromising crane operation:

- Recessed Crane Tracks for Maximum Headroom: Installing the crane tracks recessed into the building's ceiling structure frees up additional height. This allows the 5-ton arched main beam crane to run closer to the ceiling, optimizing the available headroom. By positioning the rails as high as possible, the crane system can operate without wasting valuable vertical clearance, which is crucial in low-ceiling environments.

- Ensuring Structural Integrity: Recessing the crane tracks requires careful planning and installation to ensure the building's ceiling structure remains stable. It's essential to work with engineers and crane specialists to ensure the tracks are securely mounted and that the ceiling can bear the weight of the crane system and its load without compromising safety.

- Minimize Modifications to the Building: While recessed tracks help optimize headroom, it's important to keep building modifications to a minimum. The 5-ton arched bridge crane is designed to fit within existing structures without the need for extensive renovations. Recessed tracks should be installed with minimal disruption to the building's integrity and should work in harmony with the crane's overall design to provide maximum lifting height.

Installation Best Practices for Maximizing Space Without Compromising Crane Operation:

- Professional Installation Services: Ensure the installation process is carried out by qualified professionals with experience in working with low-clearance spaces. Proper installation ensures that the crane operates safely, with minimal risk of damage or malfunction. A well-installed crane will have a longer operational life and require fewer repairs.

- Maximize Rail and Hoist Efficiency: Position the crane rails and hoist mechanisms strategically to avoid unnecessary obstructions. In some cases, lowering the rails slightly can help improve the usable lifting height without affecting the crane's operation. The hoist itself should be configured to run efficiently with minimal clearance, providing optimal lifting distance.

- Ongoing Maintenance Considerations: After installation, it's important to maintain both the crane and the recessed track system to ensure continued safe operation. Regular maintenance checks can prevent issues such as rail misalignment or damage to the crane's lifting mechanism, ensuring that the crane continues to function smoothly within the available space.

By implementing these tips, businesses can achieve maximum space efficiency and crane functionality, ensuring that the 5-ton arched main beam crane operates optimally in low-ceiling environments.

Maximizing workshop space in low-ceiling gable roof environments requires thoughtful planning and design considerations. The 5-ton arched main beam bridge crane offers a unique solution to these challenges by optimizing headroom, improving workflow, and increasing the overall efficiency of the space. Whether through strategic layout design, recessed crane runways, or expert installation practices, businesses in Bolivia can make the most of their available vertical clearance and ensure smooth, efficient operations in their workshops.

Why Choose Arched Main Beam Cranes for Your Facility in Bolivia?

Tailored Solution for Bolivia's Low-Ceiling Facilities

In Bolivia, many industrial and manufacturing facilities face significant challenges due to limited vertical clearance, especially in low-ceiling gable roof workshops. These constraints can make it difficult to install traditional overhead cranes without sacrificing valuable space. The 5-ton arched main beam crane is designed to address these challenges, providing an ideal solution for facilities where maximizing headroom is essential.

- Customized Design for Low-Ceiling Environments: The arched main beam crane is engineered specifically to fit within the unique structural constraints of Bolivia's low-ceiling buildings. The crane's curved beam design allows it to provide greater lifting height while maintaining a compact structure, making it perfect for environments where headroom is limited.

- Optimized for Vertical Clearance: Unlike traditional flat beam cranes, the arched main beam maximizes available headroom, offering higher lifting capacities without requiring additional building modifications. This makes it a perfect match for Bolivia's facilities, where the need to optimize space and ensure efficient operations is critical.

- Local Expertise in Design and Installation: By choosing a local supplier with expertise in Bolivia's specific building standards, you can ensure that the crane system is customized to meet both structural and environmental requirements. A supplier who understands local regulations, climate conditions, and logistical challenges will provide better design, installation, and ongoing support services.

Benefits of Choosing a Local Supplier Who Understands the Unique Structural and Environmental Requirements

- Tailored Recommendations for Your Facility: A local supplier has an in-depth understanding of Bolivia's building designs and environmental conditions, ensuring that the crane system is perfectly suited to your specific facility. They can provide expert advice on optimizing space and layout while recommending the most suitable crane features for your operations.

- Compliance with Local Regulations: Local suppliers are well-versed in Bolivia's regulations regarding safety, building codes, and environmental factors, ensuring that the crane is installed and operated in full compliance with local laws. This minimizes the risk of delays or costly modifications.

- Ongoing Support and Maintenance: Working with a local supplier ensures that you have access to ongoing technical support, maintenance, and spare parts. This reduces the downtime associated with crane repairs and helps maintain smooth operations in your facility.

Potential for Scalability and Upgrades as Business Requirements Evolve

- Upgradable Capacity and Features: As your lifting needs increase, the crane system can be easily upgraded to handle larger loads or different operational requirements. For example, if you need to increase your lifting capacity beyond 5 tons, the crane's design can be scaled up to accommodate higher loads.

- Integrating New Technologies: The crane system can also be updated with the latest technologies in automation, remote control, and safety features, making it easier to adapt to the evolving needs of your business.

- Enhanced Flexibility: The arched main beam design is versatile and can be adapted for different types of operations, from manufacturing to assembly lines, making it an ideal choice for businesses that anticipate future changes in their lifting needs.

Choosing the 5-ton arched main beam bridge crane for your low-ceiling facility in Bolivia is a strategic decision that provides numerous benefits, including optimized vertical clearance, cost-effectiveness, and the ability to scale as your business grows. By working with a local supplier who understands the unique challenges of Bolivia's building structures and environmental conditions, you can ensure that your crane system is tailored to meet your specific needs. This investment will not only improve the efficiency and safety of your operations today but also help future-proof your business for years to come.

Summing Up the Benefits of Arched Main Beam 5-Ton Cranes in Low-Ceiling Gable Roof Workshops

The 5-ton arched main beam bridge crane offers an ideal solution for workshops with limited vertical clearance, such as those in low-ceiling gable roof environments. By incorporating a curved beam design, this crane maximizes headroom and lifting height without requiring significant building modifications.

Key advantages include:

- Optimized Vertical Clearance: The arched design increases the clearance beneath the crane's beam, allowing for higher lifting capacities while maintaining a compact structure.

- Space Efficiency: The design allows for better space utilization in tight areas, making it possible to arrange workstations and improve overall workflow.

- Cost-Effectiveness: The crane system's durability and minimal need for additional building modifications make it a cost-efficient solution.

- Safety and Stability: The arched main beam enhances load stability and safety, reducing operational risks in low-clearance environments.

Choosing the 5-ton arched main beam crane ensures not only optimal space use and lifting capacity but also long-term value and efficiency.

If you're looking to maximize the lifting height in your low-ceiling gable roof workshop while maintaining the strength and stability of your crane system, contact us today for a customized quote or to discuss the best crane solution tailored for your facility in Bolivia. Our team is ready to help you improve your operations with a crane system designed for your unique space and needs.

Additional Resources:

FAQs on Arched Main Beam Cranes

What are the key differences between an arched main beam crane and a traditional flat beam crane?

- The arched beam crane features a curved design that increases headroom under the crane, making it ideal for low-ceiling environments. Unlike flat beam cranes, which may require more vertical space, the arched design maximizes clearance and lifting height.

What kind of maintenance does an arched main beam crane require?

- Regular inspections, lubrication of moving parts, and checks on structural integrity are essential for long-term operation. Since these cranes are designed for durability, they require minimal maintenance compared to traditional systems, reducing overall operating costs.

Can I install an arched main beam crane in an existing facility with limited space?

- Yes! The arched main beam crane is specifically designed for environments with low ceilings and limited vertical clearance. It fits well in existing structures without the need for major modifications, providing an efficient and cost-effective lifting solution. Check more on flat vs arched girder overhead crane 5 ton design.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch