Download a company brochure

Crane pdf dowload: Overhead Crane pdf, Gantry Crane Pdf & Jib Crane pdf free download.

Download PDFCrane Manufacturing & Crane Quality Control

As of crane engineer's factory, each and every crane manufacturing process are strictly supevised to ensure the quality of our overhead travelling cranes, gantry crane, slewing jib cranes, hoists, winches, and other related parts and components.

Crane quality and crane safety is and always will be top concern during crane design and processing. To ensure crane quality and safety , we have developed a strict quality control system with the core of crane control which have implemented the philosophy of crane safety and crane quality control into crane design, fabrication, assembly, testing, installation & commissioning and future maintenance and refurbishment,etc.

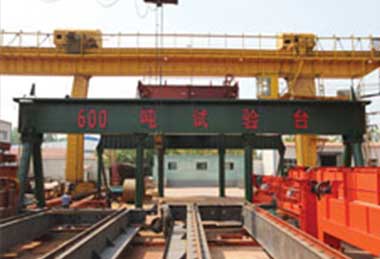

Hoisting Testing Center- All of our hoists and cranes will be tested before delivery to ensure quality.

With advanced crane technology, intelligent production equipment, effective inspection and testing equipment, well trained processing workers and QC supervisors, and the scientific and strict crane quality managing systems, we can ensure and supervise every and each procedure of the crane fabrication and assembly to guarantee the quality of each parts and components of overhead travelling cranes we produced and supplied.

Crane Enginer's Factory, Strict Crane Quality Control

Strict Crane Quality Control

Best Fit Crane Design For You

Crane quality control starts from the crane design, advanced crane design concept, process crane design based on thorough consideration, best fit crane design,cost-effective material handling solution for you!

As a hi-tech and innovation oriented enterprise, we have splendid capability on crane design and processing which has enable us to obtain more than 300 patents of cranes, expanded crane types to more than 80 varieties in seven series, standardized more than 20 high-class processes in the crane production, etc. With increased research and development, we have developed our featured container bridge cranes, large-tonnage large-span cranes and high-intelligent remote monitoring cranes, etc.

All the designs and drawings of our hoist and crane are developed on the base of the latest international standards and optimized with more reasonable features to meet your lifting requirements and application conditions to ensure your crane safety and quality at very beginning.

Crane tech research

Best fit overhead travelling crane design

Accurate and efficient crane fabrication by well trained staffs wit advanced processing equipment

Crane Enginer's Factory, Strict Crane Quality Control

Intelligent Fabrication Equipment

High Quality & Exactness Cranes

With investment of 120 million RMB, Dongqi Cranes has built an intelligent finishing workshop, with a complete digital management system, Siemens CNC system,high-precision detection system, robot automatic feeding and other cutting-edge equipment. With introduced advanced equipment like soldering robot we have developed an internationally advanced digital crane factory with intelligent production lines, etc.

Six-axis articulated robot for automatic gear processing production line

Fully automatic robot welding line

Crane Girder Intelligent Welding Line

Crane Manufacturing Workshop

Constant Temperature CNC Workshop

Heat Treatment Workshop

Machining Workshop

LD Wheel Finishing

Forged Wheel Line

Single Girder Welding Line

End Girder Production Line

Single Beam Flexible Production Line

Side Plate Molding Production Line

U Shaped Groove Molding Production Line

U Shaped Groove Molding Production Line

Overhead Crane Testing Platform

Electric Hoist Testing Platform

Large Floor Boring and Milling Machine

Crane Enginer's Factory, Strict Crane Quality Control

Complete & Thorough Quality Control

Quality Material & Strict Procetures

Crane quality is the life of a crane manufacturer and supplier company, and the pursuing of superior overhead travelling crane quality is the foundation of our development. In order to ensure the quality of all of our hoist and cranes, we have adopted a serious and scientific crane control system and supervising system which are implemented through every procedure of crane manufacturing and issue ex-work qualifications to every qualified hoist and crane.

- Crane control of crane steel structure :The quality control of crane steel structure is vital which mainly concerns the steel quality and welding quality.

- Crane quality control on steel quality:All the incoming steel plates or other steel materials will be inspected and checked in compliance with national standard of GB/T 700-2006, GB/T 709-2006, GB/T3274-2007, and GB/T 1591-2008 by the designated professionals and specialists on steel material, size, configuration, weight and allowable deviation, etc.

- Crane quality control on welding quality:To ensure welding quality, all of our welders are well trained and certified to ensure the weld groove form, size, and welding materials strictly abiding to the welding procedures, welding specification and blueprint requirements.All welding quality inspections,conducted in compliance with national standard GB/T 3323-2005, JB/T 10559£ 2006,JB/T 6062-2007 are mainly consisted of appearance detection, nondestructive testing, radiographic testing, ultrasonic testing, penetrate testing, magnetic particle testing, etc.

Crane quality control measures during crane steel structure processing

- Crane control for the incoming material inspection: All the incoming materials such as steel plates and welding parts will be inspected to ensure its quality in terms of chemical composition, mechanical strength, etc.

- Pre - treatment of steel surface to remove the rust by shot blasting and ball blasting to ensure steel plates are in compliance with the national standards.

- Primer Painting to protect steel from rust to ensure after shot blasting and ball blasting

- Precision marking of steel plate with sample plate,diagram or handrail to ensure the accuracy

- Accurate steel plate-cutting by CNC cutting, semi-automatic cutting, shearing and sawing to ensure the dimension exactly as required.

- Plate welding by semi-automatic cutter and automatic submerged-arc welding to ensure quality of welding part.

- Flaw detection by ray and ultrasonic to detect the flaw of weld seams to ensure seam quality

- Leveling: Level the steel plate after connecting.

- Secondary marking & cutting: To mark and cut the steel plate with the required shape and size

- Assemble: All the assembly should be serious conducted according to the general crane drawing with exact specifications and configurations.

- Flaw detection to detect the weld seams of main parts to ensure quality of welding

- Assembly (assemblage)to assemble each part as required with high accuracy and right operation.

Advanced crane testing equipment in our hoist and crane factory

Advanced crane testing equipment in our hoist and crane factory

Advanced crane testing equipment in our hoist and crane factory

Advanced crane testing equipment in our hoist and crane factory

Advanced crane testing equipment in our hoist and crane factory

Advanced crane testing equipment in our hoist and crane factory

Advanced crane testing equipment in our hoist and crane factory

Advanced crane testing equipment in our hoist and crane factory

Quality control measures on crane parts and crane assembly

- Machining parts are made into qualified one by changing the shape, size, or surface roughness through milling, planning, grinding, boring, drilling, insertion, etc.

- Quality control on bought out crane parts such as motor, reducer, bearing, standard fastener, electrics and other standard parts are purchased exactly as the required configuration table prepared by crane designing department and will be assembled according the crane drawing.

- Quality control on cooperation crane parts: referring cast steel, iron casting, forging and overall spare parts which are designed by our crane engineer but fabricated by cooperated crane spare parts manufacturers, which will be inspected when arriving in our crane factory.

- Quality control on on General assembly of Crane: To assemble cranes part and components as the request of general crane drawing. After trial crane erection, some of the crane parts will be removed for the convenience of transportation, which will be assembled again at crane installation site.

- General inspection to ensure crane quality are in compliance with relative standard and technical requirements, and ex-work certificate will be issued to the qualified one.

- Crane loading tests by doing static loading tests and dynamic loading test to ensure the bearing capacity and crane mechanism function,etc.

- Right crane painting selection to ensure quality and assistance in the fitted application such as wet, corrosive or chemical,etc.

- Paint inspection to check crane paint quality in terms of film thickness, sag and crinkle, etc.

- Crane Delivery: To delivery the overhead travelling crane to user as request

- Site erection & crane commissioning to ensure the crane operation at its best condition and to ensure operation safety

- Acceptance

Beside, we offer full set of after-sale services to ensure a long working life to make the best of your crane investment which concludes crane inspection, maintenance, part supply and crane refurbishment, etc.

Crane Enginer's Factory, Strict Crane Quality Control

Complete, Scientific & Advanced

Crane Inspection Ensures Quality

With the top-level quality assurance system,comprehensive strict management system,strong production capacity and advanced inspection technology, we can not only ensure high quality products and outputs but also can provide versatile of overhead travelling crane solutions with various of crane designs and crane configurations to meet different lifting requirements and industrial applications.

Crane inspection checklist and testing methods

- Radiographic Testing(RT).- to detect the inside defect and discontinuity of materials by X ray, Y ray or neutron ray

- Ultrasonic Testing (UT)-to detect the internal defects of the metals such as, pipe, plate, bar, and welding

- Penetration Testing (PT). To detect the internal defects of metals together with ultrasonic testing to provide absolute quality assurance.

- Magnetic Testing(MT) . To find the discontinuity on specimen surface and near surface.

- Coating testing.To inspect crane paint with coating thickness tester, adhesion tester, and film girding instrument in terms of film performance and mechanical properties, such as thickness, adhesion, gloss, etc, and special properties,such as, corrosion resistance, oil resistance, and acid resistance, etc ,

- Metal hardness testing and resistance ability testing. by static testing methods such as HB, HRC, HV, and HL for detecting the resistance ability of metal materials.

Crane Enginer's Factory, Strict Crane Quality Control

Well Trained Staff, Strict Supervision

High Quality Processing & Assembly

Our production team are consisted of experienced craftsmen and skilled workers who work on welding, machining, electrical, steel fabrication, painting and shipping . Particularly, the fabrication employees from welders to electricians are certified and professional.The honest, experienced and skillful working staff are our greatest treasure who are the foundation of crane manufacturing and ensure the crane quality and output.Dongqi Cranes,together with our honest and lovely employees, are ready to provide high standard overhead travelling cranes to improve your working efficiency, safety and productivity.

Experienced working staff to ensure the quality of your overhead cranes, gantry crane, jib cranes, and various electric hoists, winch and other crane parts and components, etc.

Serious working and advanced crane processing equipment to ensure the production precision and to offer you high quality lifting hoists and cranes for your applications.

All of our welders are trained, certified and experiences to ensure working efficiency and quality to ensure your delivery time and quality requirements.

As a crane factory, we are capable of fabricating the key crane parts and componenents to ensure the quality and delivery time to ensure all the products we produced and offered with

During every procedure, we have very strict quality supervision and strict testing to ensure overhead travelling crane quality and prevent the occurance of any problems.

We are a team with strict working pricipals and managment systems to ensure the overhead travelling crane and gantry crane production quality, safety and efficiency.

Crane designing team and R & D team are devoted to providing the best fit crane solution for your application with process designs to lift your loads and save your crane cost.

Our sales teams helps you to find out the right crane design for your application and help to provide one stop crane solution services to free you from trouble to provide economical crane solution.

Crane services team to help you solve all your problem from crane consulation before crane buying to after sale crane services including future crane maintainence, etc.

Certificates of hoists and cranes

All of types of our overhead travelling cranes, gantry cranes, jib cranes, hoists cranes and process cranes , crane parts and components are certified with the qualifications and certifications including Crane manufacture licenses,Crane Installation,alteration,repair&maintenance license, Crane Modeling Test Certificates, ISO Certificates and CE certificates and other qualifications,etc. The . quality of our hoist and cranes are the name card of Dongqi Crane who is your honest and trustworthy crane manufacturer and provider in China.

We have various types of certificates such as, Crane Quality Management System Certificate, Crane Environment Management System Certificate, Crane Safety Management System Certificate,etc. In the following, the most frequently asked CE certificates are presented for your reference.

Third-Party Certification

To build reliability and to show our confidence on product quality, we are offering third party certifications services. At present, the international export certification mainly includes ISO9000, CCC mark, TüV certification, UL certification, CE certification, RoHS order, and SGS commodity inspection,etc. If you want to get the third part certifications concerning our overhead crane, gantry crane, jib crane, electric hoist, electric winch, and aerial working platform , etc., please feel free to contact us.

Various types of overhead crane, gantry crane, jib crane and hoist certificates are provided if required.

Various types of overhead crane, gantry crane, jib crane and hoist certificates are provided if required.

Various types of overhead crane, gantry crane, jib crane and hoist certificates are provided if required.

Various types of overhead crane, gantry crane, jib crane and hoist certificates are provided if required.

Various types of overhead crane, gantry crane, jib crane and hoist certificates are provided if required.

Various types of overhead crane, gantry crane, jib crane and hoist certificates are provided if required.