Your Trusted Single Girder Overhead Crane Manufacturer & Supplier

0.5 Ton to 32 Ton Single Girder Overhead Crane

Top Running & Underhung Single Girder Crane Designs

What is an single girder overhead crane? Single girder overhead cranes are an very important type of overhead cranes, an ideal solution for light duty and medium duty material handling. The single girder overhead cranes are mainly consisted of one main crane girder, supported on each side by an end truck, with monorail trolley hoist suspended on the beam girder. The single girder overhead cranes are usually designed either in top running single girder overhead crane configuration or under running single girder overhead crane configuration , equipped with manual or electric monorail hoists to meet various workshop or warehouse applications with the features of simple structure, light deadweight, lower shipping cost, and good crane price, etc.

Single girder overhead cranes are often the most cost-effective overhead bridge crane solution for various workshops and industrial applications.. Single girder overhead cranes use less steel material, with more compact crane structure and lighter dead weight than double girder overhead cranes, which results in a significant cost-savings in steel material purchasing , transportation, and crane installation. Also, due to the one girder design, these overhead cranes usually have less deadweight, which enable them to utilize lighter runway systems and attach to the existing support structure of the building .

Crane Specifications of Single Girder Overhead Cranes

With single girder overhead crane designs, the single girder overhead cranes are designed for light and medium duty material handling. The rated lifting capacity of single girder eot crane are from 1 ton, 2 ton, 3 ton, 5 ton, 10 ton, up to 20 ton . The single girder overhead crane specifications and parameters are mainly presented for your reference.

HD series of European style single girder overhead crane video

Single girder overhead crane specifications

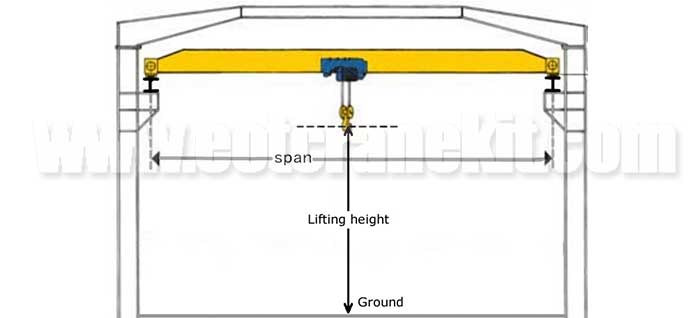

- Lifting capacity of single girder overhead crane: 1ton ~16 ton,

- Span of single girder overhead crane: 7.5m~35m,

- Lifting height of single girder overhead crane : As your request,

- Working Class of Overhead Crane: A5,A6

- Crane hoist Supply: Wire rope electric hoist or chain Electric hoist, European standard FEM hoists

- Customized single girder overhead crane can be up to 35 ton.

Various single girder overhead crane designs are available. Contact us to get process single girder overhead crane designs and specific crane specifications and crane dimensions or to download free single girder overhead crane pdf brochure.

Top Running & Under Running Single Girder Overhead Crane Designs

Single girder overhead cranes can be designed either in top running overhead crane configuration or under running overhead crane configuration. The main girder of single girder overhead cranes can optionally adopt I beam girder design,box girder design or a combination section of formed steel with steel plate. The single girder overhead crane hoisting systems are usually assemblies of manual or electric trolley with manual hoist, electric monorail hoist, including monorail electric wire rope hoists and monorail electric chain hoists, etc.

Top Running Single Girder Overhead Crane

Lifting Capacity of Single Girder Overhead Crane: 3.2t to 16t

Span of Single Girder Overhead Crane: 7.5m to 28.5m

Lifting Height of Single Girder Overhead Crane:6m to 18m

Working Class of Single Girder Overhead Crane: A5

Under Running Single Girder Overhead Crane

Lifting capacity of single girder overhead crane: 1ton- 10 ton

Span of single girder overhead crane: 3-15 m

Lifting height of single girder overhead crane: 3-100 m

Working Class of Overhead Crane: A3

Top Running Crane -A top running single girder overhead crane is the most frequently used overhead bridge crane system for the top running crane configuration typically meets the needs of lifting requirements and facility space requirements for most customers.

Under Running Cranes -Under running overhead cranes are the suspension overhead crane system which are usually supported and attached to the existing structure in the facility,usually the building roof structure with no requirement of columns, free up floor space efficiently, a very cost-effective crane solution. Crane bridge of under running overhead crane travels along the bottom flange of the runway beam.

Lifting Hoists for Single Girder Overhead Cranes

For the various single girder overhead travelling crane designs, there are diverse types of single girder overhead crane hoists and hoist trolleys available to meet the different lifting requirements and applications such as Manual single girder overhead crane hoists and Electric single girder overhead crane hoists. For the electric single girder overhead crane hoists, there are various type of electric monorail hoists available, including the following :

European Style Electric Hoist for Single Girder Overhead Crane

The single girder crane hoists are applicable for various types of single girder overhead travelling crane, single beam crane, H beam crane, I beam crane, monorail crane, and other types of single girder overhead cranes, etc.

Chinese Style Electric Wire Rope Hoist for Single Girder Overhead Crane

The Chinese type single girder crane hoists are applicable for various types of single girder overhead travelling crane, single beam crane, H beam crane, I beam crane, monorail crane, and other types of single girder overhead cranes, etc.

Explosion Proof Electric Wire Rope Hoist for Single Girder Overhead Crane

The explosion proof single girder crane hoists are applicable for various types of single girder overhead travelling crane, single beam crane, H beam crane, I beam crane, monorail crane, and other types of single girder overhead cranes, etc.

Low Headroom Electric Wire Rope Hoist for Single Girder Overhead Crane

The low headroom single girder crane hoists are applicable for various types of single girder overhead travelling crane, single beam crane, H beam crane, I beam crane, monorail crane, and other types of single girder overhead cranes, etc.

Ladle Handling Electric Wire Rope Hoist for Single Girder Overhead Crane

Single girder overhead hoist crane system for hot metal & ladle handling in steel & metallurgic industries. 2 ton, 3 ton, 5 ton & 10 ton ladle hoist crane for sale.

Electric Trolley Electric Chain Hoist for Single Girder Overhead Crane

Types of process crane hoist designs are available for your single girder overhead travelling crane. Contact us to get your overhead crane design and good overhead crane price.

Manual Trolley Electric Chain Hoist for Single Girder Overhead Crane

Types of process crane hoist designs are available for your single girder overhead travelling crane. Contact us to get your overhead crane design and good overhead crane price.

Low Headroom Electric Chain Hoist for Single Girder Overhead Crane

Types of process crane hoist designs are available for your single girder overhead travelling crane. Contact us to get your overhead crane design and good overhead crane price.

Advantages of Single girder overhead cranes

If you are in the market for an overhead crane, you may be debating between a single girder crane and a double girder crane. Despite the fact that each style has advantages and disadvantages, you might want to consider a single girder overhead crane. Here are just a few of the benefits they provide:

A lower cost.

It should go without saying that single girder overhead cranes are less expensive than double girder cranes. It makes sense when you think about it. After all, by removing one of the girders, the design requires far fewer materials. Furthermore, trolleys designed for single girder cranes are much simpler than those designed for double girder cranes. Again, this can help lower the overall purchase price, making these cranes a cost-effective option.

Less weight. Single girder cranes are much lighter weight because they lack the second girder and much of the support structure required for a double girder crane. This can help to reduce your building's structural support requirements.

Lower installation costs.

Single girder cranes are far less expensive to install due to their light weight and minimalistic design. Adding additional structural support to the building to support the weight of the crane is not always necessary. The same cannot be said for double-girder cranes, which are often extremely heavy and require additional support. With a single girder crane, you not only save money on the crane itself, but also on the cost of installation. That is why these cranes are such an excellent choice for businesses with limited resources.

Main types of Single Girder Overhead Crane

Single girder overhead cranes are a popular type of crane used in industrial settings. They are designed to lift and move heavy loads with ease and precision. These cranes are commonly used in manufacturing plants, warehouses, and other industrial facilities where heavy lifting is required. In this article, we will explore the components of a single girder overhead crane, the different types available, their advantages and disadvantages, factors to consider when selecting one, installation and safety guidelines, maintenance and inspection requirements, troubleshooting common issues, and frequently asked questions about these cranes.

HD single girder top running overhead crane with European style 1, 2 ton, 3 ton, 5 ton 10 ton

Top running cranes: Top running cranes are designed to run on rails mounted on top of the building structure. They are ideal for facilities with high ceilings and heavy loads.

Nlx single girder underhung bridge crane 500kg, 1 ton, 2 ton, 3 ton, 5 ton, up to 10 ton

Underhung cranes: Underhung cranes run on rails mounted underneath the building structure. They are ideal for facilities with low ceilings and limited space.

Freestanding single girder bridge cranes

Freestanding single girder overhead cranes for workshop or warehouse with floor mounted crane columns for loads handling

Monorail hoist cranes

Monorail hoist cranes with straight & curved, freestanding & ceiling mounted design for your selection. They are ideal for moving loads along a fixed path.

Processed single girder cranes for different industrial sectors

Industrial single girder overhead cranes are used in a variety of sectors, including manufacturing, construction, mining, transportation, and logistics. They are commonly used for lifting and moving heavy loads in industrial settings such as factories, warehouses, and assembly lines. These cranes are ideal for handling materials such as steel, concrete, and machinery components. They are also used in maintenance and repair operations, as well as in the construction of buildings and infrastructure. The specific type of single girder overhead crane used will depend on the requirements of the particular industry or sector.

The main types and molds of single girder bridge cranes in China are marked with the following:

- HD - single girder overhead crane with European style monorail hoist with capacity up to 1 ton -16 ton

- LD / LDA - electric single beam crane with economical cd/md wire rope hoist with capacity up ton 20 ton .

- NLX - single girder electric overhead crane with underhung crane design with capacity from 1 ton to 10 ton.

- LX— electric single girder suspension crane with capacity from 1 ton to 10 ton.

- LB— Explosion-proof electric single beam crane for hazardous environment to ensure safety.

- LDY—Metallurgical Electric Single Girder Crane for hot ladle handling for small steel mill with capacity form 1 ton to 10 ton.

- SL— Manual Single Beam Crane & SLX—Manual Single Girder Suspension Crane

Components of a Single Girder Overhead Crane

Single girder overhead cranes consist of several components that work together to lift and move heavy loads. These components include:

- Bridge: The bridge is the main component of the crane and consists of a single girder that spans the width of the workspace. The girder is supported by two end trucks that move along rails mounted on the building structure.

- Hoist: The hoist is the component that lifts and lowers the load. It consists of a motor, gearbox, brake, drum, wire rope, hook, and block. The hoist is mounted on the bridge girder and moves along it.

- Controls: The controls are used to operate the crane and include a pendant or radio remote control.

- Electrification: The electrification system provides power to the crane and includes a power cable or festoon system.

- End trucks: The end trucks support the bridge girder and move along rails mounted on the building structure.

Advantages and Disadvantages of Single Girder Overhead Cranes

Single girder overhead cranes offer several advantages over other types of cranes. These advantages include:

- Cost-effective: Single girder overhead cranes are less expensive than double girder overhead cranes.

- Easy to install: Single girder overhead cranes are easy to install and require less space than other types of cranes.

- Versatile: Single girder overhead cranes can be used in a variety of industries and applications.

- However, there are also some disadvantages to using single girder overhead cranes, including:

- Limited lifting capacity: Single girder overhead cranes have a lower lifting capacity than double girder overhead cranes.

- Limited span: Single girder overhead cranes have a limited span compared to double girder overhead cranes.

Factors to Consider When Selecting a Single Girder Overhead Crane

When selecting a single girder overhead crane, there are several factors to consider, including:

- Lifting capacity: The lifting capacity of the crane should be sufficient for the heaviest load that will be lifted.

- Span: The span of the crane should be appropriate for the workspace.

- Duty cycle: The duty cycle of the crane should be appropriate for the application.

- Speed: The speed of the crane should be appropriate for the application.

- Environment: The environment in which the crane will be used should be considered when selecting a crane.

Installation and Safety Guidelines for Single Girder Overhead Cranes

Proper single girder crane installation and safety guidelines should be followed when installing and operating a single girder overhead crane. Some important guidelines include:

- The crane should be installed by qualified personnel.

- The crane should be inspected regularly for any signs of wear or damage.

- The crane should be operated by trained personnel only.

- Load limits should be strictly adhered to.

- Safety devices such as limit switches and overload protection should be installed on the crane.

Single girder overhead cranes offer many benefits over other types of cranes, including cost-effectiveness, ease of installation, and versatility. However, they also have some limitations that should be considered when selecting a crane for an application. Proper installation, operation, maintenance, and inspection are essential for ensuring the safe and efficient operation of a single girder overhead crane. By following these guidelines, users can take full advantage of the benefits offered by these cranes while minimizing their limitations.

0.5 to 32 ton Single Girder Overhead Cranes Offering