How Your Hoisting Requirements Shape Crane Duty & Affect Crane Price

Your hoisting requirements dictate crane duty, influencing design complexity, material quality, safety features, and ultimately affecting overall crane pricing.

Category: Overhead Crane Prices

Your Trusted Overhead Crane Manufacturer & Supplier

How Your Hoisting Requirements Shape Crane Duty & Affect Crane Price

Your hoisting requirements dictate crane duty, influencing design complexity, material quality, safety features, and ultimately affecting overall crane pricing.

Deciphering Crane Efficiency: Understanding Hoisting Needs

In today's industrial landscape, where operational efficiency is paramount, the selection of the right crane for load movement is crucial. Whether you're managing a factory, overseeing a warehouse, or working on a construction site, understanding your hoisting requirements lays the foundation for effective crane selection. Before exploring the wide array of available cranes, it's essential to assess the specific needs of your operations, including load types, lifting heights, and frequency of use.

Relationship Between Crane Duty and Price

As you embark on your search for the ideal crane, one critical concept will emerge: crane duty. This term refers to the crane's capacity and the frequency with which it will be used, both of which are pivotal in determining its suitability for your operational requirements.

Why does this matter? The relationship between crane duty and price is straightforward yet significant. Generally, the more robust and capable the crane, the higher the price point. While the temptation to choose a less expensive option is understandable, it often leads to inadequate lifting capabilities, which can result in increased costs over time due to inefficiencies or potential downtime.

How your hoisting needs directly influence crane duty empowers you to make informed decisions, ensuring you achieve an optimal balance between functionality, affordability, and performance. Let’s explore this complex interplay further.

Basics on Crane Duty

Definition of Crane Duty

Crane duty defines the workload that a crane can manage over a specified perioThis encompasses key elements such as load capacity, frequency of operation, and environmental conditions—all essential for determining a crane's classification and capabilities.

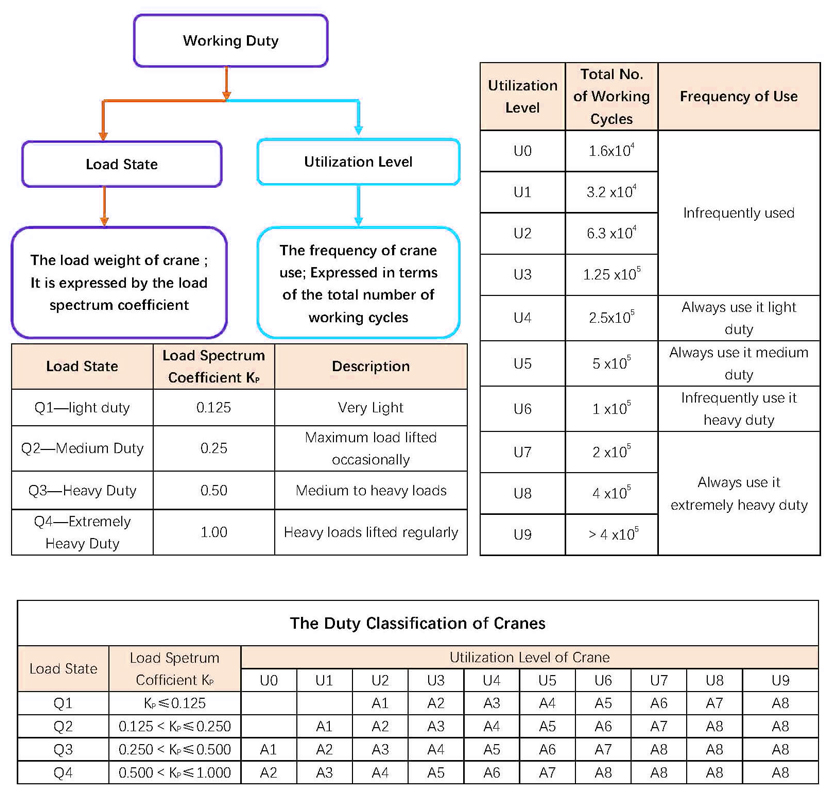

Factors Influencing Crane Duty Classification

- Frequency of Use: The operational frequency of a crane significantly impacts its design and construction. Cranes that will see continuous operation require a higher duty classification and a sturdier build to withstand the demands of regular lifting and lowering activities. Understanding your operational schedule can guide you in selecting the appropriate duty rating.

- Load Capacity: The maximum weight that a crane can safely lift is a fundamental aspect of its classification. Lighter-duty cranes are ideal for handling smaller loads, while heavy-duty cranes are engineered to lift larger and more cumbersome items efficiently. This distinction not only influences initial costs but also affects long-term operational efficiency.

- Environment and Operating Conditions: The environment in which a crane operates plays a crucial role in determining its duty classification. Cranes exposed to extreme temperatures, corrosive substances, or outdoor elements must be designed with enhanced durability and protective features. This often involves additional costs but is essential for ensuring safety and longevity.

- Service Classifications (e.g., CMAA, FEM, ISO): Various organizations, including the Crane Manufacturers Association of America (CMAA), the European Materials Handling Federation (FEM), and the International Organization for Standardization (ISO), provide frameworks for crane duty classifications. These standards categorize cranes based on their intended use, load-handling capacity, and operational requirements, serving as valuable tools in the crane selection process.

Navigating the complexities of crane selection requires a thorough understanding of how your hoisting requirements influence crane duty and, consequently, crane pricing. By carefully assessing your operational needs, including frequency of use, load capacity, environmental conditions, and adherence to established service classifications, you can make informed decisions that optimize both performance and cost-effectiveness. Ultimately, this strategic approach ensures that your chosen crane meets both current and future demands, providing reliability and efficiency in your industrial operations. Click to check how to select proper crane duty.

Impact of Hoisting Requirements on Crane Duty

Matching Crane Duty to Hoisting Needs

Selecting the appropriate crane duty classification is crucial for ensuring optimal performance, safety, and longevity of the equipment. When the crane's duty aligns with specific hoisting requirements, it maximizes efficiency and minimizes the risk of mechanical failure.

- Enhanced Operational Productivity: Cranes designed for their intended load capacities operate more smoothly, increasing workflow and reducing delays.

- Safety Assurance: Properly matched cranes are less likely to experience performance issues, lowering the risk of accidents and ensuring a safer working environment.

- Long-Term Cost Efficiency: Choosing the right duty classification can prevent premature wear and tear, ultimately leading to lower maintenance and replacement costs over time.

Assessing Workload Frequency and Intensity

Understanding the frequency and intensity of crane utilization is critical for determining the right duty classification.

- High-Demand Settings: Cranes in environments with continuous lifting operations require heavier duty classifications to endure rigorous use.Example: Manufacturing facilities where cranes lift heavy components multiple times a day benefit from robust designs that prevent breakdowns.

- Infrequent Use: For operations with lighter or sporadic lifting tasks, lighter-duty cranes can be a more cost-effective solution without sacrificing necessary functionality.Example: A warehouse that handles occasional shipments might opt for a lighter-duty crane, achieving significant savings while meeting operational needs.

Considering Load Variability and Weight Ranges

Variability in the loads being handled is another vital consideration when selecting crane duty classifications.

- Adaptability to Load Fluctuations: Operations that involve lifting objects of varying sizes and weights need cranes capable of accommodating these differences.Example: Construction sites often deal with materials ranging from lightweight framing to heavy steel beams, necessitating cranes with flexible duty classifications.

- Performance Consistency: A crane that can handle a range of load capacities ensures continuous workflow and reduces downtime due to equipment inadequacies.Benefit: This adaptability helps prevent bottlenecks in operations caused by equipment limitations.

Evaluating Environmental Factors and Safety Regulations

Environmental conditions significantly influence crane performance and durability, making this evaluation crucial in duty classification selection.

- Harsh Operating Conditions: Cranes exposed to extreme temperatures, high humidity, or corrosive environments require specialized designs and materials.Example: Cranes in coastal areas may need enhanced corrosion resistance to withstand saltwater exposure.

- Safety Compliance: Adhering to safety regulations is paramount, as compliance mitigates risks to personnel and equipment.Regulatory Standards: Cranes must meet local and international safety standards, which can dictate specific design and engineering requirements.

How hoisting requirements impact crane duty is vital for selecting the right equipment for your operational needs. By carefully considering factors such as workload frequency, load variability, environmental conditions, and safety regulations, you can ensure that your crane performs optimally.

- Informed Decision-Making: Making decisions based on these criteria leads to improved performance, reduced downtime, and long-term reliability of your crane system.

- Enhanced Efficiency and Safety: Ultimately, aligning crane duty with hoisting requirements results in a more efficient operation, contributing to overall business success.

This structured rewrite provides clear and practical information about the factors that impact crane duty selection, making it easier to understand and apply in real-world scenarios.

Relationship Between Crane Duty and Price

Cost Factors Associated with Crane Duty

Design and Engineering Complexity

The design complexity of a crane is heavily influenced by its duty classification. Higher-duty cranes must be engineered to handle greater stress, requiring more sophisticated design solutions.

- Structural Components: More robust materials and engineering techniques are necessary to ensure safety and functionality.

- Weight Distribution: Advanced calculations are needed to ensure that load distribution is managed effectively under heavy loads.

- Customization Needs: Custom features may be required to meet specific operational demands, increasing design complexity.

Material Quality and Durability

The choice of materials directly affects the price of the crane, particularly for higher-duty models.

- High-Strength Steel: Used for heavy-duty cranes to withstand extreme loads and stresses.

- Corrosion Resistance: Additional coatings and treatments for cranes operating in harsh environments, adding to material costs.

- Longevity Considerations: Investing in quality materials reduces the need for frequent replacements or repairs.

Safety Features and Compliance

Higher-duty cranes often come with enhanced safety features to meet stringent industry standards, impacting overall costs.

- Overload Protection Systems: Essential for preventing accidents during lifting operations.

- Emergency Stop Mechanisms: Mandatory for safety compliance, particularly in high-capacity cranes.

- Regular Compliance Testing: Ensures that all safety features function correctly, contributing to the crane’s total cost.

Installation and Maintenance Requirements

The installation and ongoing maintenance needs vary significantly based on the crane's duty classification.

- Specialized Installation: Higher-duty cranes may require specific foundation designs or additional structural support.

- Maintenance Intervals: Heavy-duty cranes often need more frequent inspections and repairs to ensure they operate safely and efficiently.

- Operational Training: Staff training may be necessary to handle more complex systems, adding to overall costs.

How Crane Duty Affects Pricing Structure

Higher Duty Classifications vs. Increased Costs

There is a clear correlation between crane duty classifications and their pricing structure.

- Material and Engineering Costs: Increased investment in materials and engineering for higher-duty cranes directly influences their pricing.

- Market Trends: As demand for heavy-duty cranes grows, so does their price, reflecting the costs of innovation and compliance.

- Long-term Value: Although higher upfront costs are common, these cranes often provide superior performance and lower operational costs over time.

Cost-Benefit Analysis of Crane Duty Selection

Conducting a cost-benefit analysis is essential when selecting the appropriate crane duty classification.

- Upfront vs. Long-term Costs: Higher-duty cranes may be more expensive initially but often result in reduced maintenance and downtime costs.

- Operational Requirements: Analyze whether the higher capacity is necessary for your tasks or if a lighter-duty option suffices.

- ROI Considerations: Assess potential return on investment by evaluating efficiency gains and productivity improvements from the right crane selection.

Case Studies and Examples

Examples of Crane Duty Selection for Different Hoisting Requirements

Real-world scenarios demonstrate the importance of selecting the right crane duty classification.

- Construction Industry: A heavy-duty crane used for lifting steel beams in a construction site can manage the demands of continuous operation.

- Automotive Workshop: A lighter-duty crane sufficient for intermittent engine lifts showcases how needs vary across industries.

Comparison of Crane Prices Based on Duty Classifications

Understanding price variations among different crane duty classifications helps in budget planning.

- Light-Duty Cranes: Typically range from $10,000 to $20,000, suitable for lighter, less frequent lifting tasks.

- Moderate-Duty Cranes: Cost between $20,000 and $50,000, balancing capability and affordability.

- Heavy-Duty Cranes: Prices can exceed $50,000, reflecting their advanced engineering and safety features.

Real-Life Scenarios Highlighting Impact of Hoisting Requirements on Crane Duty and Price

Analyzing case studies reveals how inadequate crane duty selection can lead to operational inefficiencies.

- Oil and Gas Sector: A company faced increased costs due to mechanical failures from underestimating crane duty needs.

- Logistics Firm: A well-chosen crane for diverse load demands led to reduced downtime and higher operational efficiency.

Factors to Consider When Determining Crane Duty and Price

Working with Qualified Crane Suppliers and Engineers

Engaging experienced professionals is crucial for informed decision-making.

- Expert Guidance: Suppliers and engineers can provide insights on the best crane duty for your specific applications.

- Recommendations: Seek advice based on industry best practices and past experiences.

Conducting Site Assessments and Load Analysis

A comprehensive understanding of your operational environment is vital.

- Site Conditions: Assess the physical space, including overhead clearance and floor conditions.

- Load Analysis: Identify the types, weights, and frequencies of loads to accurately determine crane requirements.

Budgetary Considerations and Long-Term Cost Analysis

Evaluate both immediate and future financial implications.

- Short-term vs. Long-term Costs: Consider installation, maintenance, and operational costs over the crane's lifecycle.

- Cost-Benefit Assessments: Conduct thorough analyses to understand the overall value of different duty classifications.

Future Expansion and Adaptability Needs

Plan for future growth when selecting crane solutions.

- Scalability: Choose cranes that can adapt to changing operational demands without necessitating significant additional investment.

- Trends and Innovations: Stay informed about industry trends that may influence future hoisting requirements.

This rewrite provides detailed, practical information in a clear format, making it easy to understand the relationship between crane duty and pricing while offering actionable insights.

Conclusion

- Key Points: Crane duty is essential for defining a crane's capacity and suitability for specific tasks. It is influenced by factors such as workload frequency, load variability, environmental conditions, and safety regulations. Generally, higher duty classifications lead to increased costs due to the need for stronger materials and additional safety features, which are critical for reliable performance.

- Importance of Alignment: Aligning hoisting requirements with the appropriate crane duty is vital for ensuring optimal performance and safety. Proper alignment minimizes the risks of mechanical failures and accidents, creating a safer working environment. Additionally, selecting the right crane maximizes operational efficiency, ultimately leading to reduced long-term costs and improved productivity.

- Final Considerations: To make informed decisions in the crane selection process, it’s crucial to thoroughly evaluate your hoisting requirements. Collaborating with experienced crane suppliers and engineers can provide valuable insights tailored to your specific needs. Finally, investing in cranes that support future growth and adaptability ensures that your operations remain efficient and effective as demands change.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch