Gantry Crane Price Inquiries: Essential Terms and Considerations

Crucial terms for gantry crane pricing, including load capacity, span, lifting height, mobility options, installation requirements, to get accurate quotes.

Category: Overhead Crane Prices

Your Trusted Gantry Crane Manufacturer & Supplier

Mastering Gantry Crane Price Inquiries: Essential Terms & Considerations

Gantry crane pricing involves a myriad of technical and financial terms that can be daunting to navigate without proper understanding. From lifting capacity to delivery terms, each term carries weight in determining the final cost and functionality of the crane. Without clarity on these terms, misunderstandings can arise, leading to inaccurate quotes and potential budgetary issues down the line. Therefore, taking the time to familiarize yourself with these terms ensures that you can communicate effectively with suppliers, ask the right questions, and ultimately, make well-informed decisions.

Overview of Key Aspects to Consider When Requesting Gantry Crane Prices

Requesting gantry crane prices goes beyond simply asking for a quote. It involves a comprehensive assessment of your operational needs, budgetary constraints, and project timelines. Key aspects to consider include:

- Basic crane specifications such as lifting capacity, span, and lifting height.

- Operational requirements like power source, control method, and duty cycle.

- Environmental and installation details including location and site conditions.

- Additional features and customization options tailored to your specific needs.

- Financial and legal terms encompassing pricing, payment terms, and contractual obligations.

- Logistics and delivery considerations to ensure timely deployment and minimal disruption to operations.

- Maintenance and support agreements to safeguard your investment and ensure long-term performance.

These key aspects and considering them thoughtfully when requesting gantry crane prices, you can streamline the procurement process, mitigate risks, and maximize the value of your investment in material handling equipment.

Basic Crane Specifications

The basic specifications of a gantry crane lays the foundation for selecting the right equipment to meet your operational needs efficiently.

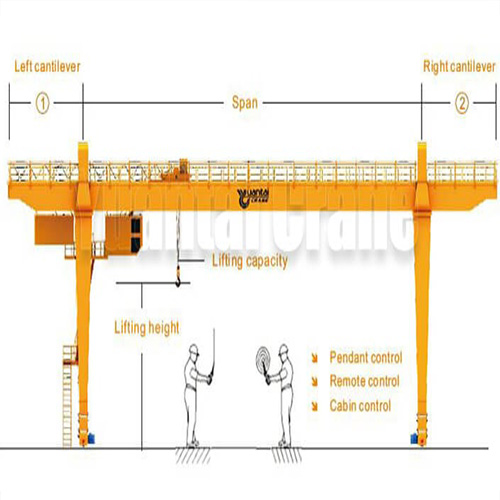

Lifting Capacity

The lifting capacity of a gantry crane refers to the maximum weight it can safely lift and move. It is essential to assess your lifting requirements accurately to ensure that the crane's capacity aligns with your workload. Overestimating or underestimating the lifting capacity can lead to safety hazards or inefficiencies in operations. Factors such as the weight of the heaviest loads to be handled and any potential future growth in workload should be taken into account when determining the required lifting capacity.

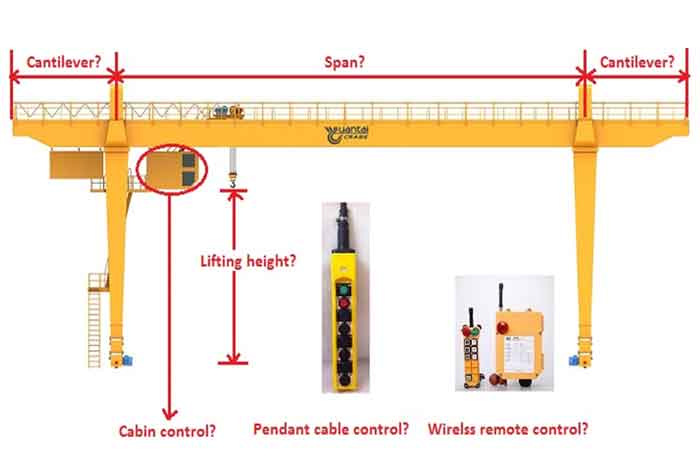

Span

The span of a gantry crane is the horizontal distance between the two legs of the crane. It determines the coverage area or width that the crane can effectively serve. Assessing the span requirement involves considering factors such as the layout of the workspace, the width of aisles or work zones, and the positioning of materials or equipment to be lifted. A gantry crane with an appropriate span ensures optimal utilization of space and efficient material handling operations.

Lifting Height

Lifting height refers to the vertical distance from the ground to the highest point that the crane's hook or lifting device can reach. It is crucial to determine the lifting height based on the height of the tallest objects to be lifted and the clearance required to maneuver them safely. Factors such as building height, overhead obstructions, and stacking requirements should be considered when specifying the lifting height of the gantry crane. A gantry crane with sufficient lifting height ensures that it can handle materials efficiently without risking damage to the crane or surrounding structures.

Cantilever (if required)

In some applications, a cantilevered extension may be required on one or both sides of the gantry crane to provide additional reach beyond the legs. Cantilevers are typically used to access materials or work areas that are not directly accessible from the main span of the crane. When specifying a cantilever, factors such as the length of the extension, the weight of the loads to be supported, and the stability of the crane should be carefully considered. Integrating a cantilever into the design of the gantry crane expands its versatility and enhances its effectiveness in handling materials across a wider area.

By paying careful attention to these basic crane specifications, you can ensure that the gantry crane you select is well-suited to meet the demands of your operations efficiently and safely.

Operational Requirements

Efficient operation of a gantry crane relies on meeting specific operational requirements tailored to your unique work environment and workflow. Let's explore these crucial operational considerations in detail:

Power Source

Determining the appropriate power source for your gantry crane is essential for seamless and reliable operation. Common power sources include electric, hydraulic, and diesel. Each has its advantages and suitability for different applications. Electric gantry cranes are environmentally friendly and cost-effective for indoor use, while hydraulic cranes offer robust performance for heavy-duty outdoor applications. Diesel-powered cranes provide flexibility and mobility for remote or temporary job sites. Understanding your power source requirements ensures that your gantry crane operates efficiently and safely within your facility.

Control Method

The control method of a gantry crane dictates how operators maneuver the crane's movements, including lifting, lowering, and traversing. Common control methods include pendant control, radio remote control, cabin control, and automated systems. The choice of control method depends on factors such as operator preference, operational complexity, and safety considerations. Pendant control offers simplicity and direct operator feedback, while radio remote control provides flexibility and mobility. Cabin control is suitable for long-duration operations requiring operator comfort and visibility. Automated control systems optimize efficiency and precision for repetitive tasks. Selecting the right control method ensures smooth and intuitive operation of your gantry crane.

Crane Travelling Length / Runway Length

The travelling length, also known as the runway length, defines the distance along which the gantry crane can move horizontally. It is determined by the layout of your facility and the required coverage area for material handling operations. Assessing the crane travelling length involves considering factors such as aisle width, obstacle clearance, and material flow patterns. Optimal runway length ensures that the gantry crane can access all work areas efficiently without obstruction or interference.

Duty Cycle

The duty cycle of a gantry crane refers to the frequency and intensity of its operation over a given period. Duty cycles are typically categorized as light, moderate, or heavy-duty based on the crane's workload and operating conditions. Understanding the duty cycle requirement is crucial for selecting a gantry crane that can withstand the demands of your operation without compromising performance or safety. Factors such as load capacity, operating environment, and operational hours influence the duty cycle rating of the crane. Matching the duty cycle to your operational requirements ensures reliable and efficient performance while maximizing the lifespan of the gantry crane.

By addressing these operational requirements in your gantry crane specifications, you can ensure that the crane meets the demands of your operation effectively and delivers optimal performance for years to come.

Environmental and Installation Details

Ensuring that your gantry crane is installed in the right environment and location is essential for its optimal performance and longevity. Let's delve into the critical aspects of environmental and installation details:

Installation Location (Indoor or Outdoor)

Determining whether your gantry crane will be installed indoors or outdoors is the first step in ensuring its suitability for the intended environment. Indoor installations are typically characterized by controlled conditions, such as stable temperatures, limited exposure to weather elements, and minimal dust or debris. Outdoor installations, on the other hand, face a broader range of environmental challenges, including exposure to sunlight, rain, wind, and temperature fluctuations. Selecting the appropriate installation location ensures that the gantry crane is equipped to withstand the environmental conditions it will encounter, thereby maximizing its durability and performance.

Environmental Conditions

The specific environmental conditions in which your gantry crane will operate is crucial for selecting the right equipment and implementing appropriate measures to mitigate potential risks. Factors to consider include:

- Temperature: Extreme temperatures, both hot and cold, can affect the performance of crane components such as motors, lubricants, and structural materials. Selecting equipment rated for the expected temperature range ensures reliable operation in challenging conditions.

- Humidity: High humidity levels can accelerate corrosion and rust formation, particularly in outdoor installations or facilities near water bodies. Implementing protective measures such as corrosion-resistant coatings and regular maintenance schedules can help mitigate the impact of humidity on crane components.

- Wind Load: Outdoor gantry cranes are susceptible to wind forces, which can affect stability and safety during operation. Assessing the wind load requirements and implementing structural reinforcements or wind protection measures ensures safe and stable crane operation in windy conditions.

- Dust and Debris: Facilities with high levels of dust, debris, or airborne contaminants pose challenges for gantry crane maintenance and performance. Installing protective enclosures, air filtration systems, and regular cleaning protocols can help minimize the impact of dust and debris on crane components and ensure smooth operation.

By carefully evaluating the installation location and environmental conditions, you can select a gantry crane that is well-suited to withstand the challenges of its operating environment and deliver reliable performance over its service life. Additionally, implementing appropriate maintenance and protective measures helps extend the lifespan of the crane and maximize its return on investment.

Additional Features and Customization

Beyond the standard specifications, gantry cranes offer a range of additional features and customization options to enhance their functionality and adaptability to specific operational needs. Let's explore these options in detail:

Additional Features

Gantry cranes can be equipped with various additional features to optimize performance, improve safety, and streamline operations. Some common additional features include:

- Anti-Sway Systems: These systems minimize load sway during lifting and positioning, enhancing safety and efficiency.

- Variable Speed Controls: Adjustable speed settings allow operators to control crane movements with precision, facilitating delicate handling tasks.

- Collision Avoidance Systems: Sensors and alarms alert operators to potential collisions with obstacles or other equipment, reducing the risk of accidents and damage.

- Remote Monitoring and Diagnostics: Advanced systems enable remote monitoring of crane performance and condition, allowing for proactive maintenance and troubleshooting.

- Load Monitoring and Weighing: Integrated load cells or sensors provide real-time feedback on load weight, ensuring safe lifting and preventing overloading.

- Environmental Protection: Protective coatings, seals, and covers shield crane components from environmental factors such as corrosion, moisture, and dust, prolonging their lifespan.

Selecting the right combination of additional features depends on your specific operational requirements, safety considerations, and budget constraints. Integrating these features enhances the functionality and safety of the gantry crane while optimizing productivity and reliability.

Customization Requirements

In addition to off-the-shelf features, gantry cranes can be customized to meet unique operational challenges and requirements. Customization options may include:

- Specialized Lifting Attachments: Tailored attachments such as grabs, magnets, or spreader bars enable the crane to handle specific types of loads or materials with precision.

- Extended Reach or Height: Modifications to the crane's structure or components allow for increased lifting height or reach, accommodating unique workspace layouts or handling requirements.

- Integration with Existing Systems: Custom engineering solutions enable seamless integration of the gantry crane with existing infrastructure, such as conveyor systems, storage racks, or production lines.

- Control and Automation Upgrades: Customized control systems, automation software, or operator interfaces can be developed to meet specific workflow requirements or safety standards.

Identifying your customization requirements involves assessing your operational challenges, workflow constraints, and performance goals. Working closely with experienced crane manufacturers or integrators ensures that your customized gantry crane solution meets your exact specifications and delivers optimal performance in your unique operating environment.

By exploring additional features and customization options, you can tailor your gantry crane to suit your specific operational needs, enhance productivity and safety, and achieve maximum efficiency and reliability in your material handling operations.

Cost and Pricing Terms

The various cost and pricing terms associated with gantry crane procurement is essential for accurate budgeting and effective negotiation. Let's explore these terms in detail:

Ex Works (EXW) Price

The Ex Works (EXW) price represents the cost of the goods at the manufacturer's facility or production site. In this pricing arrangement, the buyer is responsible for all transportation costs, insurance, and risks from the point of origin. EXW pricing is often used for domestic transactions or when the buyer arranges their own shipping and logistics.

Free On Board (FOB)

Free On Board (FOB) pricing includes the cost of delivering the goods onto a vessel at a specified port. Once the goods are loaded onto the ship, the buyer assumes responsibility for transportation, insurance, and any additional costs associated with shipping to the final destination. FOB pricing is commonly used for international transactions involving ocean freight.

Cost, Insurance, and Freight (CIF)

Cost, Insurance, and Freight (CIF) pricing covers the cost of goods, insurance, and freight to bring the goods to a specified port of destination. Under CIF terms, the seller is responsible for arranging and paying for transportation and insurance until the goods reach the designated port. Once the goods are delivered to the port, the buyer assumes responsibility for any further transportation or costs.

Delivery Duty Paid (DDP)

Delivery Duty Paid (DDP) pricing includes all costs associated with delivering the goods to the buyer's specified location, including transportation, insurance, and import duties. Under DDP terms, the seller is responsible for arranging and paying for all aspects of the delivery process, ensuring that the goods are delivered to the buyer's premises ready for use.

Price Breakdown

A price breakdown provides a detailed itemization of the costs associated with purchasing the gantry crane. It includes the base price of the crane, additional features or customizations, installation, delivery, taxes, and any other applicable charges. A comprehensive price breakdown helps buyers understand the total cost of ownership and compare quotes from different suppliers effectively.

Budget

Establishing a budget is essential for gantry crane procurement to ensure that the project remains financially viable and within predetermined constraints. Factors to consider when setting a budget include the total cost of the crane, installation costs, ongoing maintenance expenses, and any additional costs such as training or infrastructure upgrades. By defining a clear budget upfront, buyers can prioritize features and options to align with their financial goals and project requirements.

By understanding these cost and pricing terms, buyers can navigate gantry crane procurement effectively, negotiate favorable terms, and make informed decisions that align with their budgetary constraints and operational needs.

Logistics and Delivery

Efficient logistics and timely delivery are critical aspects of gantry crane procurement to ensure that the equipment is available when needed and that project timelines are met. Let's explore the key considerations in logistics and delivery:

Lead Time

Lead time refers to the period between placing an order for the gantry crane and its delivery or installation. The lead time can vary depending on factors such as crane specifications, customization requirements, production capacity, and supplier availability. Understanding the lead time allows buyers to plan their procurement timeline effectively, ensuring that the crane is delivered in time to meet project deadlines and operational requirements.

Project Timeline

The project timeline encompasses the entire duration of the gantry crane procurement process, from initial planning and specification to installation and commissioning. It includes milestones such as site preparation, equipment fabrication, shipping, and assembly. Developing a realistic project timeline involves coordinating various stakeholders, including suppliers, contractors, and internal teams, to ensure that each phase of the project progresses smoothly and according to schedule. By closely monitoring the project timeline and addressing any delays or obstacles promptly, buyers can minimize disruptions and ensure that the gantry crane is ready for operation when needed.

Effective management of logistics and delivery is essential for successful gantry crane procurement, ensuring that the equipment is delivered on time and within budget. By understanding lead times, coordinating project timelines, and working closely with suppliers and contractors, buyers can streamline the procurement process and achieve their project objectives efficiently.

Maintenance and Support

Proper maintenance and reliable support are crucial for ensuring the longevity, safety, and efficiency of your gantry crane. Let's explore the key components of maintenance and support:

Maintenance and Service Agreements

Maintenance and service agreements outline the terms and conditions for ongoing maintenance, inspections, and repair services provided by the crane manufacturer or authorized service provider. These agreements typically include scheduled maintenance visits, emergency repair services, replacement parts availability, and performance guarantees. By entering into a maintenance agreement, buyers can ensure that their gantry crane receives regular upkeep and remains in optimal working condition, minimizing downtime and extending its lifespan.

Warranty

The warranty provided by the crane manufacturer covers defects in materials and workmanship for a specified period after the crane's installation or commissioning. Warranties may vary in duration and coverage, so it's essential to review the terms carefully. Common warranty provisions include parts replacement, labor costs, and limitations or exclusions. Understanding the warranty coverage ensures that buyers are protected against unexpected failures or malfunctions and can seek timely repairs or replacements if necessary.

Compliance and Certification

Compliance with industry standards and regulatory requirements is essential for ensuring the safety and legal compliance of your gantry crane. Cranes should meet applicable standards such as OSHA (Occupational Safety and Health Administration), ANSI (American National Standards Institute), and CMAA (Crane Manufacturers Association of America) guidelines. Additionally, gantry cranes may require certification from regulatory authorities or third-party inspection agencies to verify their compliance with safety and performance standards. Ensuring compliance and certification demonstrates a commitment to safety and quality and mitigates the risk of accidents or regulatory penalties.

By prioritizing maintenance and support, including service agreements, warranties, and compliance certifications, buyers can safeguard their investment in the gantry crane and ensure its continued reliability and performance throughout its service life. Working closely with reputable manufacturers and service providers ensures access to quality maintenance services and support resources, enhancing the overall value and longevity of the gantry crane.

Financial and Legal Terms

Navigating the financial and legal aspects of gantry crane procurement involves understanding key terms and agreements that govern the transaction. Let's explore these terms in detail:

Terms of Payment

The terms of payment outline the agreed-upon schedule and method for making payments for the gantry crane. Common payment terms include:

- Advance Payment: A portion of the total amount is paid upfront before the crane is manufactured or delivered.

- Progress Payments: Payments are made at predetermined milestones or stages of the project, such as completion of fabrication, delivery, or installation.

- Final Payment: The remaining balance is paid upon successful delivery, installation, and acceptance of the crane.

The terms of payment is essential for managing cash flow, budgeting, and ensuring timely payment to suppliers and contractors.

Incoterms

Incoterms, or International Commercial Terms, are a set of standardized rules established by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international trade transactions. Common Incoterms used in gantry crane procurement include:

- Ex Works (EXW): The seller is responsible for making the goods available at their premises, and the buyer assumes all risks and costs from that point onwards.

- Free On Board (FOB): The seller is responsible for delivering the goods onto a vessel at a specified port, and the buyer assumes responsibility once the goods are loaded onto the ship.

- Cost, Insurance, and Freight (CIF): The seller is responsible for delivering the goods to a specified port of destination, including transportation and insurance costs, up to the point of arrival at the port.

- Delivery Duty Paid (DDP): The seller is responsible for delivering the goods to the buyer's premises, including all costs and duties associated with importation.

Selecting the appropriate Incoterms clarifies the responsibilities and liabilities of both parties regarding transportation, insurance, and customs clearance, reducing the risk of disputes and misunderstandings.

By understanding and adhering to financial and legal terms such as payment terms and Incoterms, buyers can ensure smooth and transparent transactions, mitigate risks, and protect their interests throughout the gantry crane procurement process. Collaborating with legal and financial advisors or consultants can provide additional guidance and expertise in navigating these complex terms effectively.

Evaluating Proposals

When soliciting proposals for gantry crane procurement, careful evaluation is essential to ensure that you select the right supplier and solution for your needs. Let's explore key strategies for evaluating proposals effectively:

Comparing Quotes from Multiple Suppliers

Obtaining quotes from multiple suppliers allows you to compare pricing, terms, and offerings to identify the most competitive and suitable option. When comparing quotes, consider factors such as total cost, delivery timelines, warranty terms, and included services or features. By evaluating multiple proposals, you can leverage competition to negotiate better terms and ensure that you receive the best value for your investment.

Verifying Supplier Reputation and Experience

Researching the reputation and experience of potential suppliers provides insights into their reliability, quality of service, and track record of delivering successful projects. Look for reviews, testimonials, and case studies from previous clients to gauge the supplier's performance and customer satisfaction. Additionally, verify the supplier's credentials, certifications, and industry affiliations to ensure compliance with standards and regulations. Choosing a reputable and experienced supplier minimizes the risk of delays, quality issues, and project failures, providing peace of mind throughout the procurement process.

Requesting Detailed Cost and Specification Breakdowns

Requesting detailed breakdowns of costs and specifications from suppliers allows you to understand the components and factors contributing to the overall price of the gantry crane. Ask for itemized lists of equipment, materials, labor, and other expenses involved in the project. Additionally, seek clarification on technical specifications, performance guarantees, and customization options to ensure that the proposed solution meets your requirements accurately. Analyzing detailed cost and specification breakdowns enables you to make informed comparisons between proposals and identify any discrepancies or areas for negotiation.

By following these strategies for evaluating proposals, you can make confident and well-informed decisions when selecting a supplier and gantry crane solution. Prioritizing thorough research, comparison, and verification ensures that you choose a partner who can deliver the quality, reliability, and value you need to achieve your material handling goals effectively.

Conclusion

As we conclude our comprehensive guide on soliciting proposals and evaluating options for gantry crane procurement, it's essential to recap the key insights and empower buyers with the knowledge needed for informed decision-making:

Recap of Key Terms and Their Significance

Throughout this guide, we've explored a wide range of terms and considerations crucial to the gantry crane procurement process. From understanding basic crane specifications to navigating financial and legal terms, each aspect plays a vital role in ensuring successful project outcomes. By familiarizing yourself with these terms and their significance, you can confidently engage in discussions with suppliers, negotiate favorable terms, and make decisions aligned with your operational needs and budgetary constraints.

Empowering Buyers with Knowledge for Informed Decision-Making

Knowledge is power, especially when it comes to making significant investments like gantry crane procurement. By equipping buyers with a comprehensive understanding of the factors influencing pricing, logistical considerations, and evaluation criteria for proposals, we aim to empower you to make informed decisions that drive value and efficiency for your organization. Whether you're a seasoned procurement professional or navigating gantry crane procurement for the first time, the insights shared in this guide serve as a valuable resource to guide your decision-making process effectively.

Encouraging Thorough Research and Careful Evaluation for Optimal Investment

In the competitive landscape of gantry crane procurement, thorough research and careful evaluation are essential for securing optimal investment returns. We encourage buyers to take the time to explore multiple options, compare proposals, and verify supplier credentials to ensure that their chosen solution aligns with their unique requirements and delivers long-term value. By investing time and effort into the procurement process upfront, you can mitigate risks, maximize efficiency, and achieve success in your material handling operations.

As you embark on your gantry crane procurement journey, we hope this guide serves as a valuable resource to guide your decision-making process effectively. By applying the insights and strategies outlined herein, you can navigate the complexities of gantry crane procurement with confidence and achieve your operational objectives efficiently. Thank you for entrusting us with your procurement journey, and we wish you success in your endeavors.Click to learn more on gantry crane price and goliath crane price range for your refernce, and for customized gantry crane, please contact us to get your price.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

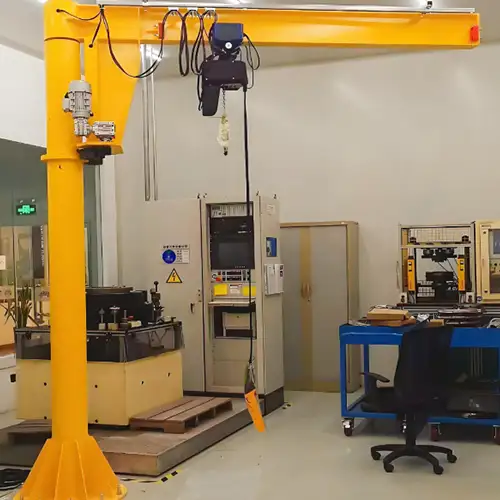

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch