Everything You Need to Know Before Requesting Gantry Crane Prices

Key points to consider before asking for gantry crane prices: required lifting capacity, span, height, mobility needs, and installation constraints & others.

Category: Overhead Crane Prices

Your Trusted Gantry Crane Manufacturer & Supplier

Everything You Need to Know Before Requesting Gantry Crane Prices

Key points to consider before asking for gantry crane prices: required lifting capacity, span, height, mobility needs, and installation constraints & others.

Gantry cranes are indispensable assets in various industries, offering efficient material handling solutions. Whether you're planning to invest in a new gantry crane or upgrade an existing one, understanding gantry crane pricing is paramount. In this guide, we'll delve into the nuances of gantry crane pricing, helping you navigate the process with confidence.

Gantry cranes come in different types, capacities, and configurations, each tailored to specific applications. Pricing can vary significantly based on these factors, making it crucial to obtain accurate and relevant pricing information. Understanding gantry crane pricing ensures you make informed decisions aligned with your budget and requirements.

Before diving into the process of requesting gantry crane prices, there are essential considerations to keep in mind. Providing suppliers with the right information is key to receiving accurate quotes tailored to your needs. Be prepared to provide details such as lifting capacity, span and height requirements, power source preferences, and any additional features or customization options desired. This information helps suppliers create custom quotes that meet your specific project needs, ensuring you get the most value for your investment.

Now that we've highlighted the importance of gantry crane pricing and the key considerations before requesting prices, let's delve deeper into understanding gantry cranes and the factors influencing their prices.

Overview of Gantry Cranes

Gantry cranes are versatile lifting machines that play a crucial role in material handling across various industries. Gantry cranes, also known as overhead cranes or bridge cranes, are lifting devices characterized by a horizontal beam (or gantry) supported by two or more legs that run along rails or tracks. This design allows for horizontal movement, enabling the crane to lift and transport heavy loads with precision and efficiency. There are several types of gantry cranes, including single girder, double girder, and portable gantry cranes, each with its own set of features and applications.

Gantry cranes find applications in a wide range of industries and settings, including manufacturing, construction, warehousing, logistics, shipping ports, and more. In manufacturing facilities, gantry cranes are used to lift and move materials, components, and finished products along assembly lines. In construction, they aid in lifting heavy equipment and materials to elevated heights, facilitating building construction and infrastructure projects. Warehouses and distribution centers utilize gantry cranes for loading and unloading goods from trucks and shipping containers, maximizing efficiency and throughput. Gantry cranes are also prevalent in shipping ports, where they are employed for loading and unloading cargo ships with containers.

Benefits of Gantry Cranes:

The use of gantry cranes offers several benefits in material handling operations:

- Versatility: Gantry cranes can be customized to meet specific lifting requirements, with options for different capacities, spans, and heights to accommodate various loads and work environments.

- Flexibility: Gantry cranes can be easily moved and positioned as needed, allowing for efficient use of space and adaptability to changing workflow demands.

- Safety: Gantry cranes are equipped with safety features such as overload protection, emergency stop buttons, and limit switches to ensure safe operation and protect both workers and equipment.

- Efficiency: By streamlining lifting and moving tasks, gantry cranes help improve productivity and reduce manual labor, leading to faster turnaround times and cost savings.

In summary, gantry cranes are essential tools in material handling operations, offering versatility, flexibility, safety, and efficiency across diverse industries and applications.

3 D presentation of all types of gantry cranes and overhead crane operation and applications

What to Know Before Asking for Gantry Crane Prices

When inquiring about gantry crane prices, having a comprehensive understanding of your project requirements and the various factors influencing costs is essential. Here are key considerations and parameters you need to be aware of before requesting gantry crane prices:

Key Considerations

Project Specifications

Lifting Capacity: Define the maximum weight the crane needs to lift. This could range from 1 ton to over 100 tons depending on your specific needs.

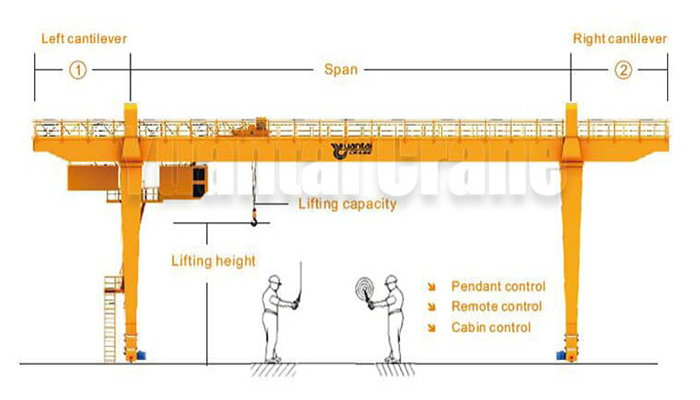

Span: Determine the distance between the runway rails or the width of the area the crane needs to cover.

Lifting Height: Specify the maximum height the crane needs to lift the load.

Environmental and Installation Conditions

Installation Location: Specify whether the crane will be used indoors or outdoors, as this affects design and material requirements.

Environmental Conditions: Consider factors such as temperature, humidity, and potential exposure to corrosive substances, which might necessitate special coatings or materials.

Operational Requirements

Power Source: Decide whether you need an electric, hydraulic, or manual crane.

Control Method: Determine if the crane will be operated via a pendant, remote control, or a ca

Usage Frequency: Estimate how often the crane will be used, which influences the design and durability requirements.

Additional Features and Customization

Additional Features: Identify any extra features you may need, such as anti-sway mechanisms, automated controls, or specialized lifting attachments.

Customization Requirements: Be clear about any specific customization you might need for your operation.

Factors Influencing Gantry Crane Prices

Gantry crane prices can vary widely depending on several key factors. Let's explore these factors in detail:

Capacity Requirements:

The lifting capacity of a gantry crane is one of the primary factors influencing its price. Gantry cranes are available in a wide range of capacities, from smaller models capable of lifting 1 ton to heavy-duty options with capacities of up to 100 tons or more. As the lifting capacity increases, so does the complexity of the crane's design and the materials required for construction, resulting in higher pricing.

The capacity of a gantry crane significantly influences its price. Here's how:

- Structural Requirements: Higher capacity gantry cranes require stronger and more robust structures to support heavier loads. This necessitates the use of stronger materials and more complex engineering, which can increase the overall cost of the crane.

- Components and Materials: Larger capacity gantry cranes often require heavier-duty components and materials to ensure safe and efficient operation under increased loads. These specialized components and materials come at a higher cost, contributing to the overall price of the crane.

- Engineering and Design: Designing a gantry crane with higher capacity requires more detailed engineering and design work to ensure structural integrity, stability, and safety. This increased engineering effort adds to the overall cost of the crane.

- Safety Features: Gantry cranes with higher capacity typically require additional safety features and systems to manage heavier loads safely. These may include advanced control systems, overload protection mechanisms, and redundant safety measures, all of which can add to the cost of the crane.

- Transportation and Installation: Larger capacity gantry cranes are often larger and heavier, requiring specialized transportation and installation procedures. The logistics involved in transporting and installing these cranes can add significant costs to the overall project.

- Customization: In some cases, higher capacity gantry cranes may require customization to meet specific application requirements. Customization adds to the engineering and manufacturing costs, further increasing the price of the crane.

Overall, as the capacity of a gantry crane increases, so do the requirements for structural integrity, specialized components, engineering effort, safety features, transportation, and customization, all of which contribute to higher pricing.

The capacity of a gantry crane significantly influences its price. Here's how:

- Structural Requirements: Higher capacity gantry cranes require stronger and more robust structures to support heavier loads. This necessitates the use of stronger materials and more complex engineering, which can increase the overall cost of the crane.

- Components and Materials: Larger capacity gantry cranes often require heavier-duty components and materials to ensure safe and efficient operation under increased loads. These specialized components and materials come at a higher cost, contributing to the overall price of the crane.

- Engineering and Design: Designing a gantry crane with higher capacity requires more detailed engineering and design work to ensure structural integrity, stability, and safety. This increased engineering effort adds to the overall cost of the crane.

- Safety Features: Gantry cranes with higher capacity typically require additional safety features and systems to manage heavier loads safely. These may include advanced control systems, overload protection mechanisms, and redundant safety measures, all of which can add to the cost of the crane.

- Transportation and Installation: Larger capacity gantry cranes are often larger and heavier, requiring specialized transportation and installation procedures. The logistics involved in transporting and installing these cranes can add significant costs to the overall project.

- Customization: In some cases, higher capacity gantry cranes may require customization to meet specific application requirements. Customization adds to the engineering and manufacturing costs, further increasing the price of the crane.

Overall, as the capacity of a gantry crane increases, so do the requirements for structural integrity, specialized components, engineering effort, safety features, transportation, and customization, all of which contribute to higher pricing.

- 1 Ton Gantry Crane Price: Suitable for light-duty applications such as workshops, small factories, and maintenance tasks.

Price Factors: Minimal structural demands and simple design, basic safety features, and very low transportation and installation costs. - 2 Ton Gantry Crane Price: Used in light industrial applications including small warehouses and maintenance areas.

Price Factors: Very basic structural and design requirements, essential safety and control features, and very low transportation and installation costs. - 3 Ton Gantry Crane Price: Ideal for smaller workshops, repair shops, and light manufacturing applications.

Price Factors: Light construction materials and simpler design, basic operational and safety features, and minimal transportation and installation costs. - 5 Ton Gantry Crane Price: Frequently used in small to medium-sized manufacturing units, workshops, and maintenance operations.

Price Factors: Simpler design and construction, basic safety and control features, and lower transportation and installation costs. - 10 Ton Gantry Crane Price: Suitable for medium-scale operations in warehouses, factories, and construction sites.

Price Factors: Balanced design with moderate structural requirements, standard safety features and control systems, and easier and less costly transportation and installation compared to higher capacity cranes. - 50 Ton Gantry Crane Price: Commonly used in manufacturing, assembly, and logistics for handling substantial loads.

Price Factors: Durable materials and construction, intermediate level of engineering and safety features, and moderate transportation and installation costs. - 100 Ton Gantry Crane Price: Heavy-duty cranes designed for large-scale industrial operations such as shipbuilding, heavy manufacturing, and large construction projects.

Price Factors: High structural strength and advanced engineering required, use of robust materials and components, additional safety features and advanced control systems, and higher transportation and installation costs due to size and weight.

How Capacity Affects Gantry Crane Price

When it comes to gantry cranes, the lifting capacity is a crucial determinant of price. Here's a breakdown of how different capacities impact the pricing, based on suppliers from China:

| Capacity (Tons) | Description | Price Factors |

|---|---|---|

| 1 Ton | Suitable for light-duty applications such as workshops, small factories, and maintenance tasks. | Minimal structural demands and simple design Basic safety features Very low transportation and installation costs |

| 2 Tons | Used in light industrial applications like small warehouses and maintenance areas. | Very basic structural and design requirements Essential safety and control features Very low transportation and installation costs |

| 3 Tons | Ideal for smaller workshops, repair shops, and light manufacturing applications. | Light construction materials and simpler design Basic operational and safety features Minimal transportation and installation costs |

| 5 Tons | Frequently used in small to medium-sized manufacturing units, workshops, and maintenance operations. | Simpler design and construction Basic safety and control features Lower transportation and installation costs |

| 10 Tons | Suitable for medium-scale operations in warehouses, factories, and construction sites. | Balanced design with moderate structural requirements Standard safety features and control systems Easier and less costly transportation and installation |

| 50 Tons | Commonly used in manufacturing, assembly, and logistics for handling substantial loads. | Durable materials and construction Intermediate level of engineering and safety features Moderate transportation and installation costs |

| 100 Tons | Heavy-duty cranes for large-scale industrial operations like shipbuilding, heavy manufacturing, and large construction projects. | High structural strength and advanced engineering Use of robust materials and components Additional safety features and advanced control systems Higher transportation and installation costs |

This table provides a clear overview of the different capacities of gantry cranes, along with their descriptions and key price factors, without specifying the price ranges.Click to check the gantry crane price ranges for your reference or contact us to leave your required main parameters to confirm the specific gantry crane price for your needs.

Span and Height Specifications:

The span and height requirements of a gantry crane play a significant role in determining its price. The span refers to the distance between the legs or supports of the crane, while the height refers to the clearance or lifting height required for your specific application. Longer spans and higher lifting heights may require additional structural support and specialized components, leading to increased pricing.

How crane span and height affect gantry crane price ?

The span and height of a gantry crane are crucial factors that significantly influence its price. Here's how:

Span:

Structural Requirements: The span of a gantry crane refers to the distance between the legs or support structures. A longer span requires a sturdier and more substantial frame to maintain stability and support the load, leading to increased material and construction costs.

Engineering and Design: Designing a gantry crane with a longer span requires more complex engineering and design considerations to ensure structural integrity and stability. This may involve additional reinforcement, bracing, or other structural enhancements, which can increase the overall cost of the crane.

Customization: Gantry cranes with longer spans may require customization to accommodate specific application requirements or site constraints. Customization adds to the engineering and manufacturing costs, further impacting the price of the crane.

Transportation and Installation: Longer-span gantry cranes may require specialized transportation and installation procedures due to their size and weight. The logistics involved in transporting and installing these cranes can add significant costs to the overall project.

Height:

Structural Requirements: The height of a gantry crane refers to the distance from the ground to the hook or lifting mechanism. A taller crane requires a taller support structure and may need additional bracing or reinforcement to withstand the increased vertical forces, leading to higher material and construction costs.

Engineering and Design: Designing a gantry crane with greater height involves additional engineering and design considerations to ensure stability and safety, especially under heavy loads or adverse weather conditions. This may require specialized components or systems to mitigate sway or vibration, which can add to the overall cost of the crane.

Customization: Gantry cranes with greater height may require customization to accommodate specific lifting requirements or workspace constraints. Customization can increase the engineering and manufacturing costs, impacting the price of the crane.

Transportation and Installation: Taller gantry cranes may pose challenges during transportation and installation due to height restrictions or clearance issues. Specialized equipment or procedures may be needed, adding to the overall project costs.

In summary, both span and height are critical factors that affect the structural requirements, engineering complexity, customization needs, and logistics involved in the manufacturing, transportation, and installation of a gantry crane, all of which contribute to its overall price.

- Power Sources: The choice of power source for a gantry crane, whether electric, hydraulic, or manual, can also impact its price. Electric gantry cranes are commonly used in industrial settings for their efficiency and reliability but typically come with higher upfront costs compared to manual options. Hydraulic gantry cranes offer excellent lifting capabilities but may have higher maintenance costs associated with hydraulic systems. Manual gantry cranes are more cost-effective upfront but may require more labor-intensive operation.

- Additional Features and Customization Options: Gantry cranes can be customized with various features and options to meet specific requirements. These may include remote control operation, variable speed controls, specialized lifting attachments, and advanced safety systems. While these upgrades can enhance productivity and safety, they also add to the overall cost of the crane.

- Installation, Delivery, and Site Preparation Costs: In addition to the cost of the crane itself, there are often additional expenses associated with installation, delivery, and site preparation. This may include crane assembly, transportation logistics, and any necessary site modifications to accommodate the crane's footprint. These costs can vary depending on factors such as the complexity of the installation, the distance of transportation, and site-specific requirements.

- Maintenance and Service Agreements: The long-term maintenance and service requirements of a gantry crane should also be considered when evaluating pricing. Investing in a comprehensive maintenance plan or service agreement can help ensure optimal performance, reliability, and safety over the lifespan of the crane. While these agreements may add to the upfront cost of the crane, they can ultimately save money by reducing downtime and prolonging the life of the equipment.

In summary, several factors influence gantry crane prices, including capacity requirements, span and height specifications, power sources, additional features and customization options, installation and delivery costs, and maintenance and service agreements. Understanding these factors is essential for making informed decisions and maximizing the value of your investment in a gantry crane. If you want to know more on how to buy Gantry Cranes and Goliath Crane, please check Gantry Crane Buyer Guide: How to Buy Gantry Crane for Your Use ?

Main Parameters Needed to Request Gantry Crane Prices

When requesting prices, providing detailed specifications helps suppliers give accurate quotes. Here are the main parameters you should include:

- Lifting Capacity: Specify the maximum load capacity required (e.g., 1 ton, 10 tons, 50 tons).

- Span: Indicate the span of the crane (distance between the supports).

- Cantilever Length (if required): Specify the length of any cantilevers (extensions beyond the runway support).

- Crane Lifting Height : Define the maximum height the crane needs to lift loads.

- Power Source : Indicate the type of power source (electric, hydraulic, manual).

- Control Method : Specify the preferred control method (pendant control, remote control, cab control).

- Crane Travelling Length / Runway Length : State the length of the path along which the crane will travel.

- Additional Features: List any additional features or special requirements (e.g., anti-sway, automated controls).

- Installation Location : Specify if the crane will be used indoors or outdoors.

- Usage Frequency : Estimate how often and intensively the crane will be used.

- Budget : Provide a budget range to help suppliers propose suitable options.

Special Considerations

- Compliance and Certification: Ensure the crane meets relevant industry standards and safety certifications, such as OSHA, ANSI, and ISO.

- Maintenance and Support: Consider the availability of maintenance services and the terms of service agreements.

- Warranty: Review warranty terms to understand what is covered and for how long.

- Delivery and Installation Costs : Account for costs related to the delivery, installation, and any necessary site preparation.

- Supplier Reputation: Research the supplier's reputation, customer reviews, and track record to ensure reliability and quality.

Your Trusted Gantry Crane Manufacturer & Supplier

Pricing Variations for Different Gantry Crane Types

Gantry cranes come in various types, each tailored to specific applications and industries. Let's delve into the pricing variations across different types of gantry cranes:

Standard Gantry Cranes:

Standard gantry cranes are versatile lifting machines used in a wide range of industries and applications. Pricing for standard gantry cranes can vary significantly depending on factors such as lifting capacity, span, height, and additional features. Smaller capacity cranes may have lower price points compared to larger capacity cranes due to differences in materials, engineering, and construction. Factors such as power source, customization options, and maintenance agreements also influence pricing.

To request pricing for a single girder or double girder gantry crane, provide the following main parameters:

Main Parameters for Single Girder & Double Girder Gantry Crane Pricing

- Lifting Capacity: The maximum weight the crane will need to lift.

- Span: The horizontal distance between the runway rail on the ground and the runway rail on the building structure.

- Cantilever Length (if required):Left Cantilever:_____ - Right Cantilever: _____

- Crane Lifting Height: The height the crane needs to lift loads, measured from the ground to the highest point the crane hook will reach.

- Power Source: Specify whether the crane will be electric, hydraulic, or manual.

- Control Method: Pendant control, radio remote control, or cabin control.

- Crane Travelling Length / Runway Length: The length of the track the crane will travel along.

- Additional Features: Any additional requirements such as variable speed control, safety features, or specialized lifting attachments.

- Installation Location: Indoor use or outdoor use, and any environmental conditions (e.g., corrosive environment, extreme temperatures).

- Usage Frequency: How often the crane will be used (e.g., daily, weekly).

- Budget: Your budget range for the project.

Semi Gantry Cranes

When inquiring about a semi gantry crane, you need to provide specific parameters to ensure accurate pricing and suitability for your application. Additionally, there are special considerations unique to semi gantry cranes.

Single girder semi gantry crane

Double girder semi gantry cranes

Here are the main parameters required for requesting the single girder and double girder semi gantry crane price, along with any special notes:

Main Parameters for Semi Gantry Crane Pricing

- Lifting Capacity: The maximum weight the crane will need to lift.

- Span: The horizontal distance between the runway rail on the ground and the runway rail on the building structure.

- Cantilever Length (if required):Left Cantilever:_____ - Right Cantilever: _____

- Crane Lifting Height: The height the crane needs to lift loads, measured from the ground to the highest point the crane hook will reach.

- Power Source: Specify whether the crane will be electric, hydraulic, or manual.

- Control Method: Pendant control, radio remote control, or cabin control.

- Crane Travelling Length / Runway Length: The length of the track the crane will travel along.

- Additional Features: Any additional requirements such as variable speed control, safety features, or specialized lifting attachments.

- Installation Location: Indoor use or outdoor use, and any environmental conditions (e.g., corrosive environment, extreme temperatures).

- Usage Frequency: How often the crane will be used (e.g., daily, weekly).

- Budget: Your budget range for the project.

Special Considerations When Requestiong Semi Gantry Cranes Price

- Building Structure: Semi gantry cranes are typically supported on one side by a ground rail and on the other side by a structure (such as a building column). Ensure that the building structure can support the load and crane movements.

- Ground Rail Installation: Details about the existing floor and any requirements for ground rail installation.

- Runway Alignment: Ensure precise alignment between the ground rail and the elevated rail on the building structure for smooth crane operation.

- Environmental Factors: Consider any environmental factors that may affect crane operation, such as exposure to elements, dust, moisture, or chemicals.

- Obstructions: Identify any potential obstructions in the crane's travel path, both at ground level and along the building structure.

By providing these parameters and considering these special notes, you can ensure that suppliers have all the necessary information to give you an accurate quote and a crane that fits your needs perfectly.

RTG (Rubber-Tired Gantry) Cranes:

RTG cranes are commonly used in container terminals and ports for loading and unloading shipping containers from trucks and ships. Pricing for RTG cranes tends to be higher compared to standard gantry cranes due to their specialized design and capabilities. RTG crane prices can vary depending on factors such as lifting capacity, span, height, and automation level. While RTG cranes offer advantages such as mobility and flexibility, they come with higher upfront costs compared to standard gantry cranes.

When inquiring about an RTG (Rubber-Tired Gantry) Crane, it's crucial to provide detailed parameters to get accurate pricing and ensure the crane meets your specific needs. Additionally, there are special considerations unique to RTG cranes. Here are the main parameters required, along with special notes:

Main Parameters for RTG (Rubber-Tired Gantry) Crane Pricing

- Lifting Capacity: The maximum weight the crane will need to lift.

- Span: The horizontal distance the crane needs to cover between the legs.

- Cantilever Length (if required):Left Cantilever:_____ - Right Cantilever: _____

- Crane Lifting Height: The height the crane needs to lift loads, measured from the ground to the highest point the crane hook will reach.

- Power Source: Specify whether the crane will be powered by diesel, electric, or a hybrid power system.

- Control Method: Options include cabin control, radio remote control, or automated control systems.

- Crane Travelling Length: The distance the crane will travel along the ground on its rubber tires.

- Additional Features: Any additional requirements such as automatic stacking systems, anti-sway systems, or advanced safety features.

- Operation Location: Indoor use or outdoor use, and any specific environmental conditions (e.g., exposure to saltwater, extreme temperatures).

- Usage Frequency: How often the crane will be used (e.g., daily, weekly).

- Budget: Your budget range for the project.

Special Considerations for Requseting Price of RTG (Rubber-Tired Gantry) Cranes

- Mobility Requirements: RTG cranes are designed for mobility, moving on rubber tires rather than fixed rails. Ensure your site layout allows for the necessary maneuverability and turning radius of the crane.

- Ground Surface: The condition and type of ground surface where the RTG will operate. It should be stable and able to support the weight and movement of the crane.

- Power Supply: For electric or hybrid RTGs, ensure there is an adequate power supply and charging infrastructure available on-site. Diesel RTGs will require fuel storage and refueling facilities.

- Operational Environment: Consider environmental conditions such as dust, moisture, and temperature extremes that could impact the crane's operation and maintenance requirements.

- Load Characteristics: Detailed information about the types of loads the crane will handle, including dimensions, weight distribution, and any special handling requirements.

- Regulatory Compliance: Ensure the RTG crane complies with local safety and environmental regulations, which may affect the choice of power source and operational practices.

- Maintenance and Service: Plan for regular maintenance and have a service agreement in place. Consider the availability of spare parts and technical support from the supplier.

- Operator Training: Adequate training for crane operators on the specific type of RTG crane, including safety procedures and efficient operational practices.

By providing these parameters and considering these special notes, you can ensure that suppliers have all the necessary information to give you an accurate quote and a crane that fits your operational needs perfectly.

Rail Mounted Gantry Cranes (RMGs):

RMGs are gantry cranes that are mounted on rails for lateral movement along a track. Pricing considerations for RMGs include factors such as rail length, number of rails, lifting capacity, span, height, and automation level. RMGs are commonly used in container yards and intermodal terminals for stacking and retrieving shipping containers. While RMGs offer advantages such as high stacking density and efficient use of space, they also come with higher upfront costs compared to standard gantry cranes due to the need for rail infrastructure and specialized components.

Rail mounted gantry crane for subway construction

Rail mounted gantry crane for container handling

When inquiring about a Rail Mounted Gantry Crane (RMG), it's crucial to provide detailed parameters to obtain accurate pricing and ensure the crane meets your specific requirements. Additionally, there are special considerations unique to RMG cranes. Here are the main parameters required, along with special notes:

Main Parameters for Rail Mounted Gantry Crane (RMG) Pricing

- Lifting Capacity: The maximum weight the crane will need to lift.

- Span: The horizontal distance between the rails on which the crane will operate.

- Cantilever Length (if required):Left Cantilever:_____ - Right Cantilever: _____

- Crane Lifting Height: The height the crane needs to lift loads, measured from the ground to the highest point the crane hook will reach.

- Power Source: Typically electric; specify any particular requirements such as power supply voltage.

- Control Method: Options include cabin control, radio remote control, or automated control systems.

- Crane Travelling Length / Runway Length: The total length of the rails along which the crane will travel.

- Additional Features: Any additional requirements such as automatic positioning systems, anti-sway systems, or advanced safety features.

- Installation Location: Indoor use or outdoor use, and any specific environmental conditions (e.g., exposure to saltwater, extreme temperatures).

- Usage Frequency: How often the crane will be used (e.g., daily, weekly).

- Budget: Your budget range for the project.

Special Considerations for Buying Rail Mounted Gantry Cranes (RMGs)

- Rail Infrastructure: Ensure that the site has the necessary rail infrastructure or can accommodate the installation of rails. The condition and alignment of the rails are crucial for smooth crane operation.

- Site Preparation: Detailed information about the site preparation required for the rail installation, including ground leveling and reinforcement.

- Power Supply: Ensure there is an adequate and stable power supply to support the crane's operations. This includes considerations for cable management and power distribution along the crane's travel path.

- Operational Environment: Consider environmental conditions such as dust, moisture, and temperature extremes that could impact the crane's operation and maintenance requirements.

- Load Characteristics: Detailed information about the types of loads the crane will handle, including dimensions, weight distribution, and any special handling requirements.

- Regulatory Compliance: Ensure the RMG crane complies with local safety and environmental regulations, which may affect the design and operational practices.

- Maintenance and Service: Plan for regular maintenance and have a service agreement in place. Consider the availability of spare parts and technical support from the supplier.

- Operator Training: Adequate training for crane operators on the specific type of RMG crane, including safety procedures and efficient operational practices.

- Automation and Integration: Consider any automation requirements, such as integration with terminal operating systems or warehouse management systems for improved efficiency.

By providing these parameters and considering these special notes, you can ensure that suppliers have all the necessary information to give you an accurate quote and a crane that fits your operational needs perfectly.

Container Gantry Cranes:

Container gantry cranes, also known as ship-to-shore cranes, are specifically designed for loading and unloading shipping containers from cargo ships. Pricing factors for container gantry cranes include lifting capacity, outreach (distance between the crane and the ship), height, and automation level. Container gantry cranes are among the most expensive types of gantry cranes due to their specialized design and capabilities. However, they are essential for container handling operations in ports and shipping terminals, where efficiency and productivity are paramount.

Container handling gantry crane, railroad container handling gantry cranes

When inquiring about a Container Gantry Crane, it's essential to provide detailed parameters to obtain accurate pricing and ensure the crane meets your specific needs. Additionally, there are special considerations unique to container gantry cranes. Here are the main parameters required, along with special notes:

Main Parameters for Container Gantry Crane Pricing

- Lifting Capacity: The maximum weight the crane will need to lift, typically measured in tons or in terms of container sizes (e.g., 20-foot, 40-foot containers).

- Span: The horizontal distance between the legs of the crane, covering the number of container rows plus any additional width for walkways or vehicle lanes.

- Cantilever Length (if required): Left Cantilever: ___ - Right Cantilever: ____

- Crane Lifting Height: The height needed to stack containers, including the number of containers stacked high (e.g., 5 high, 7 high).

- Power Source: Typically electric; specify any particular requirements such as power supply voltage and connection type.

- Control Method: Options include cabin control, radio remote control, or automated control systems.

- Crane Travelling Length / Runway Length: The total length of the crane's travel path, often covering the length of the container yard.

- Additional Features: Any additional requirements such as automatic positioning systems, anti-sway systems, container identification systems, or advanced safety features.

- Installation Location: Indoor use or outdoor use, and any specific environmental conditions (e.g., exposure to saltwater, high winds, extreme temperatures).

- Usage Frequency: How often the crane will be used (e.g., daily, continuously).

- Budget: Your budget range for the project.

Special Considerations for Asking Crane Price of Container Gantry Cranes

- Port or Terminal Layout: Detailed information about the layout of the port or terminal, including the arrangement of container rows, access points, and any existing infrastructure that the crane will integrate with.

- Ground Conditions: Information about the ground conditions where the crane will operate, ensuring it can support the heavy loads and constant movement of containers.

- Power Supply: Ensure there is an adequate and stable power supply to support the crane's operations. This includes considerations for cable management, power distribution, and potential requirements for backup power systems.

- Operational Environment: Consider environmental conditions such as dust, moisture, temperature extremes, and potential exposure to saltwater that could impact the crane's operation and maintenance requirements.

- Load Characteristics: Detailed information about the types of containers the crane will handle, including their sizes, weights, and any special handling requirements such as hazardous materials.

- Regulatory Compliance: Ensure the container gantry crane complies with local safety, environmental, and port authority regulations, which may affect the design and operational practices.

- Maintenance and Service: Plan for regular maintenance and have a service agreement in place. Consider the availability of spare parts and technical support from the supplier.

- Operator Training: Adequate training for crane operators on the specific type of container gantry crane, including safety procedures and efficient operational practices.

- Automation and Integration: Consider any automation requirements, such as integration with terminal operating systems, container tracking systems, or other logistics management systems for improved efficiency.

- Environmental Impact: Assess and mitigate the environmental impact of the crane's operation, considering factors such as noise, emissions (for diesel-powered cranes), and energy consumption.

By providing these parameters and considering these special notes, you can ensure that suppliers have all the necessary information to give you an accurate quote and a crane that fits your operational needs perfectly.

In summary, pricing for different types of gantry cranes varies based on factors such as lifting capacity, span, height, power source, customization options, and application-specific requirements. Understanding these pricing variations is essential for selecting the most suitable gantry crane for your specific needs while maximizing value for your investment.

Tips for Evaluating Gantry Crane Proposals

Once you've gathered gantry crane proposals from various suppliers, it's essential to evaluate them carefully to make an informed decision. Here are some tips to help you navigate the evaluation process effectively:

- Compare Quotes from Multiple Suppliers: Don't settle for the first proposal you receive. Instead, gather quotes from multiple suppliers to ensure competitive pricing. By comparing quotes side by side, you can identify any discrepancies in pricing and negotiate for the best deal.

- Verify Supplier Reputation and Experience: Before committing to a supplier, take the time to research their reputation and experience in the industry. Look for reviews and testimonials from past customers to gauge their reliability and service quality. Choosing a reputable supplier ensures a smoother transaction and a higher likelihood of satisfaction with your purchase.

- Request Detailed Breakdowns of Costs and Specifications: Ask suppliers to provide detailed breakdowns of costs and specifications for their gantry crane proposals. This allows you to understand exactly what you're paying for and compare features and pricing across different proposals. Pay close attention to any hidden fees or additional charges that may affect the overall cost.

- Consider Long-Term Costs vs. Upfront Investment: While upfront cost is an important factor, don't overlook the long-term costs associated with owning and operating a gantry crane. Consider factors such as maintenance, repairs, and energy consumption over the lifespan of the crane. Investing in a higher-quality crane with lower long-term costs may ultimately save you money in the long run.

- Negotiate for the Best Deal: Don't be afraid to negotiate with suppliers to secure the best deal possible. Use the information gathered from your research and comparison of quotes to leverage negotiations. Focus on achieving a balance between cost-effectiveness and quality to ensure you get the most value for your investment. Be open to compromises, but always prioritize quality and reliability in your negotiations.

By following these tips, you can effectively evaluate gantry crane proposals and make a confident decision that meets your requirements and budget while ensuring quality and reliability.

Exploring Different Terms for Gantry Crane Procurement

When considering the pricing of gantry cranes, it's vital to understand the diverse pricing terms that can apply based on delivery locations and responsibilities. Here's an overview of the primary types of gantry crane prices and what they typically cover:

Main Types of Gantry Crane Pricing

Ex-Works (EXW) Price

Ex-Works (EXW) price refers to the cost of the gantry crane at the manufacturer's facility. The buyer is responsible for all costs and risks associated with transporting the crane from the factory to the final destination.

Coverage:

Price of the gantry crane at the point of origin.

The buyer arranges and pays for all transportation, insurance, and any export or import duties.

Key Points:

Suitable for buyers who have their own logistics and transportation arrangements.

Provides maximum control over shipping and handling.

Free on Board (FOB) Price

Free on Board (FOB) price includes the cost of delivering the gantry crane onto a vessel at a specified port. The seller is responsible for the crane until it is loaded onto the shipping vessel.

Coverage:

Price of the gantry crane.

Loading onto the shipping vessel.

Risk and responsibility transfer to the buyer once the crane is onboard the vessel.

Key Points:

Commonly used for international shipments.

Buyers take responsibility for shipping, insurance, and handling from the port of departure.

Cost and Freight (CFR) Price

Cost and Freight (CFR) price covers the cost of the gantry crane and the transportation to the destination port. However, insurance is not included and must be arranged by the buyer.

Coverage:

Price of the gantry crane.

Transportation to the destination port.

Excludes insurance, which is the buyer's responsibility.

Key Points:

Suitable for buyers who want to manage their own insurance.

Risk transfers to the buyer once the crane is loaded onto the shipping vessel.

Cost, Insurance, and Freight (CIF) Price

Cost, Insurance, and Freight (CIF) price includes the cost of the gantry crane, transportation to the destination port, and insurance during transit.

Coverage:

Price of the gantry crane.

Transportation to the destination port.

Insurance coverage for the crane during transit.

Key Points:

Provides a more comprehensive pricing option, covering major risks.

Buyers are responsible for unloading and subsequent transportation costs.

Delivered at Place (DAP) Price

Delivered at Place (DAP) price includes all costs to deliver the gantry crane to a specified location, excluding import duties and taxes.

Coverage:

Price of the gantry crane.

Transportation to the specified delivery location.

Excludes import duties and taxes, which are the buyer's responsibility.

Key Points:

Offers convenience as the seller handles most of the logistics.

Buyers must handle customs clearance and associated costs.

Delivered Duty Paid (DDP) Price

Delivered Duty Paid (DDP) price includes all costs to deliver the gantry crane to the buyer's specified location, including import duties and taxes.

Coverage:

Price of the gantry crane.

Transportation to the buyer's location.

Import duties and taxes.

Customs clearance.

Key Points:

The most comprehensive pricing option, covering all delivery costs and risks.

Minimizes buyer's involvement in logistics and customs processes.

These pricing terms helps buyers select the most suitable option based on their logistical capabilities, risk preferences, and project requirements. Each term shifts different levels of responsibility and risk between the buyer and seller, allowing for flexibility in procurement strategies.

Send Your Quoation and Ask for Your Gantry Crane Price Now

Ready to find the perfect gantry crane for your operation? Don't wait any longer! Gather your specifications, understand your pricing options, and reach out to us today. By providing detailed information about your project needs, you'll receive an accurate and tailored quote that meets your budget and operational requirements. Contact us now to start the process and secure the best gantry crane solution for your business!

Effectively navigating the process of asking for gantry crane prices involves several critical steps. It's essential to provide detailed parameters such as lifting capacity, span, lifting height, power source, control method, and additional features. Custom quotes require precise information about your specific needs, including installation location, usage frequency, and budget. By offering clear and comprehensive details, you ensure suppliers can provide accurate and relevant pricing tailored to your requirements.

Thorough research and a deep understanding of your project requirements are fundamental to making informed decisions. This includes assessing the operational environment, understanding the various types of gantry cranes available, and knowing how different factors influence pricing. By thoroughly understanding your needs and the market offerings, you can select the right gantry crane that not only meets your operational demands but also offers the best value for your investment.

With the knowledge and tools provided, you are now empowered to navigate the process of requesting gantry crane prices effectively. By comparing quotes from multiple suppliers, verifying their reputation and experience, and considering both upfront costs and long-term investments, you can secure the best deal without compromising on quality and reliability. This approach ensures you maximize the value of your investment, leading to improved operational efficiency and cost-effectiveness in your material handling operations.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch