China's Gantry Crane Empire, 3 to 550 Ton Gantry Crane Supplier

Gantry crane manufactured in China and for sale around world market. Check typical cost-effective goliath gantry crane & Advanced gantry crane in China.

Category: China

Your Trusted Gantry Crane Manufacturer & Supplier in China

China's Gantry Crane Empire, 3 to 550 Ton Gantry Crane Supplier

Cost-effective Goliath Gantry Crane & Advanced Gantry Crane in China For Sale Around Word

Gantry crane manufactured in China and for sale around world market. Check typical cost-effective goliath gantry crane & Advanced gantry crane in China.

Export of Gantry Cranes from China Worldwide

In industrial sectors of construction, one industry stands tall, shaping skylines and powering progress - China's gantry crane industry. This blog embarks on a journey through the heart of this thriving sector, delving into its significance, global impact, and strategic export endeavors.

China's gantry crane industry epitomizes innovation, efficiency, and reliability. With a robust manufacturing infrastructure and a legacy of craftsmanship, Chinese gantry cranes have earned a reputation for excellence worldwide. From towering structures to precision engineering, these cranes embody the ingenuity and dedication of China's manufacturing prowess.

The export of gantry cranes from China isn't merely a commercial endeavor; it's a testament to the nation's technological prowess and global influence. As construction projects proliferate across continents, Chinese gantry cranes play a pivotal role in fueling urban development, infrastructure growth, and economic prosperity worldwide. Their reliability, cost-effectiveness, and adaptability have made them sought-after assets in construction projects of all scales and complexities.

China's gantry crane industry has forged a formidable presence in global markets, with a strategic focus on expansion and innovation. Through a combination of market intelligence, customer-centric approaches, and strategic partnerships, Chinese gantry crane manufacturers have penetrated diverse markets, from the United States and Europe to emerging economies in Asia and Latin America. Their export strategies prioritize quality, customization, and customer satisfaction, ensuring that Chinese gantry cranes remain at the forefront of global construction projects.

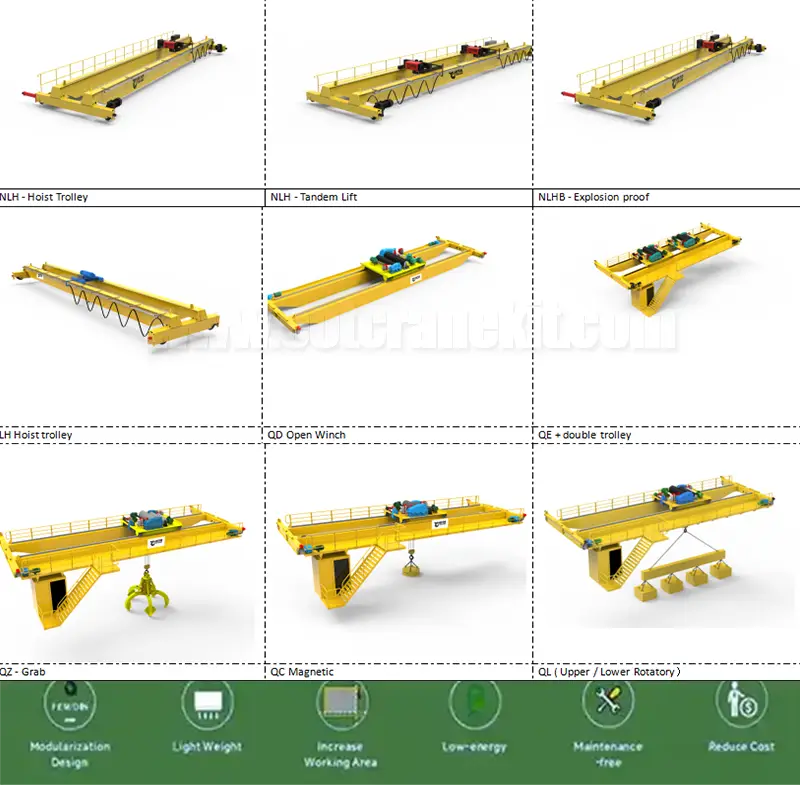

Types of Gantry Cranes and Goliath Gantry Cranes for Sale In China

In China, gantry cranes and goliath gantry cranes are available for sale in various classifications, each tailored to specific applications and operational requirements. Here are the main types based on different classifications:

Classification Based on Structure:

Single Girder Gantry Cranes:

Single girder gantry cranes are characterized by a single horizontal beam (girder) that supports the hoist and trolley mechanism. These cranes are designed for light to moderate lifting capacities and are commonly used in a variety of industrial settings, including workshops, warehouses, assembly lines, and small-scale construction sites.

Single girder gantry crane with cost-effective electric wire rope hoist

Advanced gantry crane with low headroom wire rope hoists

Here are some key features and applications of single girder gantry cranes:

Versatility: Single girder gantry cranes are versatile and adaptable to different work environments, making them suitable for a wide range of lifting applications.

Compact Design: The single girder design results in a more compact and lightweight crane structure compared to double girder gantry cranes, allowing for easier installation and maneuverability.

Cost-Effectiveness: Single girder gantry cranes are often more cost-effective than their double girder counterparts, making them an attractive option for budget-conscious customers.

Suitable for Light to Moderate Loads: These cranes are designed to handle light to moderate loads, typically ranging from a few hundred kilograms to several tons, depending on the specific model and configuration.

Single girder gantry cranes are commonly used for tasks such as material handling, equipment maintenance, loading and unloading of goods, and assembly operations. They offer efficient and reliable lifting solutions for businesses across various industries.

Double Girder Gantry Cranes:

Double girder gantry cranes feature two horizontal beams (girders) mounted on vertical support legs, providing enhanced stability, lifting capacity, and durability. These cranes are designed for heavy-duty lifting applications in industries such as shipbuilding, steel manufacturing, automotive production, and container terminals.

Double girder gantry crane with crab hoist trolley

Double girder goliath crane with main hoist and auxiliary hoist

Here are some key features and applications of double girder gantry cranes:

High Lifting Capacity: Double girder gantry cranes are capable of lifting heavier loads compared to single girder cranes, making them ideal for handling large and bulky materials or equipment.

Increased Stability: The dual girder design offers greater stability and resistance to deflection, ensuring safe and reliable lifting operations even under heavy loads.

Longer Span Capability: Double girder gantry cranes can span larger distances between support legs, allowing for greater coverage and flexibility in material handling applications.

Suitable for Heavy-Duty Industries: These cranes are well-suited for heavy-duty industries where robust lifting equipment is required to handle demanding tasks and harsh operating conditions.

Double girder gantry cranes are commonly used for tasks such as loading and unloading cargo ships, moving heavy machinery and components, lifting steel coils and plates, and assembling large structures. Their superior lifting capacity and durability make them indispensable assets in industries that rely on efficient and reliable material handling solutions.

In summary, single girder gantry cranes and double girder gantry cranes offer distinct advantages and are tailored to meet different lifting requirements and operational demands. By understanding the features and applications of each type of gantry crane, customers can select the most suitable option to optimize their material handling processes and achieve greater efficiency and productivity.

Classification Based on Mobility:

Rubber-Tired Gantry Cranes (RTG):

Rubber-Tired Gantry Cranes, abbreviated as RTG cranes, are a type of gantry crane that is mounted on rubber tires, enabling easy mobility and flexibility in operation. These cranes are widely utilized in port terminals for the handling and storage of shipping containers, offering efficient material handling capabilities.

RTG gantry crane for sale

Here are some key features and applications of RTG cranes:

Mobility: RTG cranes can move freely along the ground within the port terminal, allowing for quick relocation and efficient container handling operations.

Flexibility: The rubber tires of RTG cranes provide flexibility in maneuvering and positioning containers in tight spaces, maximizing storage capacity and operational efficiency.

High Productivity: RTG cranes are known for their high productivity levels, with fast lifting and stacking capabilities that enable rapid container handling and turnaround times in busy port environments.

Remote Control Operation: Many RTG cranes are equipped with remote control systems that allow operators to control crane movements from a safe distance, improving operational safety and efficiency.

RTG cranes play a crucial role in the container handling process at port terminals, contributing to the efficient transfer of cargo between ships, trucks, and storage yards.

Rail-Mounted Gantry Cranes (RMG):

Rail-Mounted Gantry Cranes, often referred to as RMG cranes, are gantry cranes that travel along rails installed on the ground, providing precise and stable movement during lifting and transportation operations. These cranes are preferred for container terminals, intermodal yards, and rail freight depots due to their high lifting capacities and operational efficiency.

Here are some key features and applications of RMG cranes:

Stability: RMG cranes travel along fixed rails, offering stable and precise movement during lifting and transportation operations, even when handling heavy loads.

High Lifting Capacities: RMG cranes are capable of lifting and stacking multiple containers vertically, maximizing storage density and operational efficiency in container terminals.

Automated Operation: Many RMG cranes are equipped with automation technology, such as laser-guided or GPS-controlled systems, allowing for autonomous operation and precise container positioning.

Optimized Yard Layout: RMG cranes are designed to operate in dedicated container yards with optimized layouts, facilitating efficient container handling and storage processes.

RMG cranes are integral to the efficient operation of container terminals and intermodal facilities, playing a critical role in the movement and management of shipping containers within the global logistics network.

In summary, Rubber-Tired Gantry Cranes (RTG) and Rail-Mounted Gantry Cranes (RMG) are two distinct types of gantry cranes classified based on their mobility characteristics. While RTG cranes offer flexibility and maneuverability for container handling in port terminals, RMG cranes provide stability and precision in intermodal yards and rail freight depots. Both types of cranes contribute to the efficient movement and management of cargo in the global supply chain, supporting the smooth flow of goods between ships, trains, and trucks.

Classification Based on Span and Reach:

Fixed Height Portable Gantry Cranes:

Fixed height portable gantry cranes feature a fixed vertical clearance between the ground and the underside of the crossbeam. These cranes are designed for applications where the lifting requirements remain consistent, and there is no need for vertical adjustment during operation.

Fixed height portable gantry cranes offer several benefits, including:

Portability: Despite their fixed height, these gantry cranes are portable and can be easily transported between different work areas using a forklift or overhead crane.

Quick Setup: Fixed height portable gantry cranes typically require minimal assembly and setup time, allowing for rapid deployment in temporary or remote locations.

Cost-Effectiveness: Compared to adjustable gantry cranes, fixed height models are often more cost-effective, making them an attractive option for budget-conscious customers.

Fixed height portable gantry cranes are commonly used in workshops, maintenance facilities, loading docks, and construction sites for lifting and moving loads within a predefined height range.

Adjustable Gantry Cranes:

Adjustable gantry cranes, also known as height-adjustable or telescopic gantry cranes, feature adjustable vertical clearance between the ground and the underside of the crossbeam. These cranes offer the flexibility to adjust the lifting height to accommodate different load sizes, work environments, or overhead obstructions.

Adjustable gantry cranes offer several advantages, including:

Versatility: With adjustable height capabilities, these gantry cranes can accommodate a wide range of load sizes and configurations, providing greater versatility in lifting applications.

Optimized Clearance: Adjustable gantry cranes allow operators to optimize the vertical clearance to avoid overhead obstacles or obstructions, ensuring safe and efficient lifting operations.

Enhanced Flexibility: The ability to adjust the crane's height enables it to adapt to varying work environments and operational requirements, maximizing productivity and efficiency.

Adjustable gantry cranes are commonly used in manufacturing facilities, warehouses, assembly lines, and construction sites where the lifting height may vary or overhead clearance is limited. They are available in manual or powered configurations, with hydraulic or screw-type mechanisms for height adjustment.

Both fixed height portable gantry cranes and adjustable gantry cranes offer unique advantages and applications based on the specific lifting requirements and operational constraints of the job site or facility. By selecting the appropriate type of gantry crane, customers can optimize their material handling processes and achieve efficient and safe lifting operations.

Classification Based on Power Source:

Electric Gantry Cranes:

Electric gantry cranes are powered by electricity, making them environmentally friendly and suitable for indoor applications where emissions, noise, and pollution must be minimized. These cranes utilize electric motors to drive hoisting, trolley, and crane movements, providing smooth and precise operation.

Single girder electric gantry crane

Double girder electric gantry

Semi gantry or single leg electric gantry cranes

Electric gantry cranes offer several advantages, including:

Quiet Operation: Electric gantry cranes operate quietly, making them suitable for noise-sensitive environments such as manufacturing facilities, warehouses, and assembly lines.

Reduced Maintenance: Electric motors require less maintenance compared to other power sources, resulting in lower operating costs and extended crane lifespan.

Precise Control: Electric gantry cranes offer precise control over lifting, lowering, and positioning operations, enhancing safety and productivity.

Environmentally Friendly: With zero emissions during operation, electric gantry cranes contribute to a cleaner and healthier working environment.

Electric gantry cranes are available in various configurations, including single girder, double girder, rubber-tired, and rail-mounted options, catering to a wide range of lifting capacities and operational requirements.

Manual Gantry Cranes:

Manual gantry cranes, also known as hand-operated or push-pull gantry cranes, rely on manual force for lifting, moving, and positioning loads. These cranes feature hand-operated chain hoists or lever mechanisms for lifting and lowering operations, as well as manual push or pull movement for horizontal travel along the runway beams. Manual gantry cranes are commonly used in applications where electricity is unavailable or impractical, such as outdoor construction sites, remote locations, or temporary work areas.

Small gantry crane with manual travelling

Manual gantry crane

While manual gantry cranes offer simplicity and versatility, they have some limitations compared to electric gantry cranes, including:

Lower Lifting Capacities: Manual gantry cranes typically have lower lifting capacities compared to electric gantry cranes, limiting their suitability for heavy-duty lifting operations.

Manual Labor Requirement: Operating manual gantry cranes requires physical effort from operators, which may result in fatigue and reduced productivity over time.

Limited Control: Manual gantry cranes offer limited control over lifting and movement operations compared to electric cranes, potentially impacting precision and efficiency.

Despite these limitations, manual gantry cranes remain a cost-effective and practical solution for certain applications, providing flexibility and mobility in environments where power sources are limited or inaccessible.

Both electric and manual gantry cranes play important roles in material handling and lifting operations, offering distinct advantages and applications based on the specific requirements of the job site or facility. By understanding the differences between these types of gantry cranes, customers can select the most suitable option to meet their lifting needs effectively and efficiently.

These are some of the main types of gantry cranes and goliath gantry cranes for sale in China, categorized based on different classifications to meet diverse industrial and commercial needs. Each type offers unique features, capabilities, and advantages, allowing customers to select the most suitable crane for their specific applications and operational requirements.

Classification Based on Application:

Industrial gantry cranes, also known as goliath cranes, are versatile lifting systems used across various industrial applications to handle heavy loads and streamline material handling processes. The main types of industrial gantry cranes or goliath cranes based on different industrial applications include:

Container Gantry Cranes:

Container gantry cranes are specifically designed for container handling operations in ports and container terminals. These cranes are equipped with specialized spreader attachments to lift and stack standard shipping containers, facilitating the efficient movement of cargo between ships, trucks, and storage yards.

Design: Container gantry cranes typically feature a large span and height to accommodate multiple rows of shipping containers. They are equipped with a specialized spreader attachment that can lift and stack standard ISO shipping containers.

Applications: These cranes are primarily used in ports and container terminals for loading and unloading containers from ships, transferring them to trucks or railcars, and stacking them in storage yards.

Functions: The main function of container gantry cranes is to efficiently handle shipping containers, ensuring timely and organized movement of cargo within the port terminal.

Typical Loads Handling: Container gantry cranes are designed to handle standard ISO shipping containers of various sizes and weights, ranging from 20-foot to 40-foot containers, as well as oversized or specialized containers used for specific cargo types.

Shipbuilding Gantry Cranes:

Shipbuilding gantry cranes are used in shipyards for the construction, assembly, and maintenance of ships and vessels. These cranes are characterized by their high lifting capacities and wide spans, allowing for the handling of large ship components and sections during the shipbuilding process.

Design: Shipbuilding gantry cranes have a high lifting capacity and wide span to accommodate large ship components and sections. They are often equipped with specialized lifting attachments tailored to the unique shapes and sizes of shipbuilding materials.

Applications: These cranes are used in shipyards for assembling ship hulls, lifting and positioning prefabricated sections, and transporting ship components during the construction and maintenance of ships and vessels.

Functions: Shipbuilding gantry cranes facilitate the efficient handling of heavy shipbuilding materials, ensuring precise assembly and construction processes in shipyard facilities.

Typical Loads Handling: Shipbuilding gantry cranes handle a wide range of shipbuilding materials, including steel plates, sections, modules, and ship components such as hulls, decks, and superstructures.

Steel Mill Gantry Cranes:

Steel mill gantry cranes are employed in steel manufacturing plants for the handling of heavy steel coils, plates, and structural components. These cranes are designed to withstand harsh operating conditions and high temperatures commonly found in steel mills, providing reliable material handling solutions for steel production processes.

Design: Steel mill gantry cranes are robust and durable, designed to withstand harsh operating conditions and high temperatures found in steel manufacturing plants. They are often equipped with specialized lifting attachments for handling heavy steel coils, plates, and structural components.

Applications: These cranes are used in steel mills for material handling tasks such as lifting and transporting steel coils from storage yards to processing areas, loading and unloading materials from trucks or railcars, and positioning steel components for processing.

Functions: Steel mill gantry cranes play a critical role in the steel production process by facilitating the efficient movement of raw materials, semi-finished products, and finished steel products within the manufacturing facility.

Typical Loads Handling: Steel mill gantry cranes handle heavy steel coils, plates, billets, ingots, and other steel products commonly used in steel manufacturing processes.

Automotive Industry Gantry Cranes:

Gantry cranes used in the automotive industry are utilized for various tasks such as loading and unloading vehicles from assembly lines, transporting car bodies and components within manufacturing facilities, and handling heavy machinery and equipment in automotive plants. These cranes play a crucial role in the production and assembly of automobiles.

Design: Gantry cranes used in the automotive industry are designed with versatility and flexibility to handle various tasks within manufacturing facilities. They may be equipped with specialized lifting attachments or fixtures tailored to specific automotive components or assemblies.

Applications: These cranes are used in automotive plants for tasks such as loading and unloading vehicles from assembly lines, transporting car bodies and components within manufacturing facilities, and handling heavy machinery and equipment.

Functions: Gantry cranes in the automotive industry support production and assembly processes by providing efficient material handling solutions for automotive components, ensuring smooth operations and timely delivery of finished vehicles.

Typical Loads Handling: Automotive industry gantry cranes handle a wide range of loads, including vehicle bodies, chassis, engines, transmissions, and other automotive components used in vehicle manufacturing processes.

Construction Gantry Cranes:

Construction gantry cranes are versatile lifting systems used in construction projects for material handling, equipment installation, and structural assembly. These cranes are available in different configurations to suit various construction environments, including bridge construction, building erection, and infrastructure development.

Design: Construction gantry cranes are versatile and adaptable, designed to meet the specific lifting requirements of construction projects. They may feature adjustable height, span, and lifting capacity to accommodate different construction environments and tasks.

Applications: These cranes are used in various construction projects, including bridge construction, building erection, and infrastructure development, for tasks such as material handling, equipment installation, and structural assembly.

Functions: Construction gantry cranes support construction activities by providing reliable lifting and maneuvering capabilities on job sites, contributing to the efficient completion of construction projects.

Typical Loads Handling: Construction gantry cranes handle a wide range of construction materials and equipment, including steel beams, precast concrete elements, construction machinery, and building materials such as bricks, blocks, and tiles.

Railway Industry Gantry Cranes:

Gantry cranes employed in the railway industry are used for the construction and maintenance of railway tracks, bridges, and infrastructure. These cranes facilitate the handling of rail components, track panels, and heavy machinery required for railway construction and maintenance activities.

Design: Gantry cranes used in the railway industry are designed with heavy-duty construction and precise control for handling rail components, track panels, and heavy machinery. They may feature specialized lifting attachments or fixtures tailored to railway construction and maintenance tasks.

Applications: These cranes are used for the construction and maintenance of railway tracks, bridges, and infrastructure, facilitating the handling of rail components and equipment required for railway construction and maintenance activities.

Functions: Railway industry gantry cranes support railway construction and maintenance operations by providing efficient lifting and positioning capabilities for rail components, ensuring safe and reliable railway infrastructure.

Typical Loads Handling: Railway industry gantry cranes handle a variety of railway components and equipment, including rail tracks, sleepers, switches, ballast, and construction machinery used in railway construction and maintenance projects.

Mining Industry Gantry Cranes:

Gantry cranes used in the mining industry are utilized for the handling of heavy equipment, machinery, and materials in mining operations. These cranes are designed to withstand rugged environments and provide efficient lifting solutions for mining processes such as ore extraction, transportation, and processing.

Design: Gantry cranes used in the mining industry are designed with rugged construction and specialized features to withstand harsh operating conditions and handle heavy loads. They may be equipped with specialized lifting attachments or fixtures tailored to mining operations.

Applications: These cranes are used in mining operations for tasks such as ore extraction, transportation, and processing, as well as the handling of heavy equipment, machinery, and materials.

Functions: Mining industry gantry cranes play a crucial role in mining operations by providing efficient lifting solutions for heavy equipment, machinery, and materials, contributing to the productivity and safety of mining processes.

Typical Loads Handling: Mining industry gantry cranes handle heavy loads commonly found in mining operations, including ore, coal, minerals, overburden, mining equipment, and materials used in mining activities.

Logistics and Warehousing Gantry Cranes:

Gantry cranes used in logistics and warehousing applications are employed for the handling and storage of goods and materials in warehouses, distribution centers, and logistics hubs. These cranes facilitate the efficient movement of pallets, containers, and bulk materials within storage facilities.

Design: Gantry cranes used in logistics and warehousing applications are designed with versatility and flexibility to handle a wide range of goods and materials within storage facilities. They may feature adjustable height, span, and lifting capacity to accommodate different storage environments and tasks.

Applications: These cranes are used in warehouses, distribution centers, and logistics hubs for tasks such as loading and unloading palletized goods, stacking and retrieving containers, and handling bulk materials.

Functions: Logistics and warehousing gantry cranes support material handling and storage operations by providing efficient lifting and movement capabilities for goods and materials, ensuring smooth logistics operations and timely delivery of products.

Typical Loads Handling: Logistics and warehousing gantry cranes handle various types of loads, including palletized goods, containers, bulk materials, and packaged products, depending on the specific requirements of the storage facility.

In summary, industrial gantry cranes or goliath cranes are tailored to meet the specific lifting requirements and operational demands of different industrial applications. They are designed with features and capabilities optimized for handling heavy loads, streamlining material handling processes, and enhancing productivity and efficiency in industrial operations. Each type of gantry crane is uniquely suited to its respective industry, playing a critical role in supporting the safe and efficient movement of goods, materials, and equipment within industrial facilities and job sites.

Export Markets for Gantry Cranes from China

China's gantry crane exports have established a formidable presence in various global markets, catering to diverse industries and construction projects. Let's delve deeper into the key export markets for gantry cranes from China:

United States

The United States stands as one of the largest markets for gantry cranes from China, driven by extensive infrastructure development and industrial projects. Chinese gantry cranes have found applications in sectors such as ports, manufacturing, logistics, and construction, supporting the country's quest for modernization and economic growth. With a focus on quality, cost-effectiveness, and customization, Chinese manufacturers have gained traction in the competitive US market, supplying gantry cranes tailored to meet specific project requirements.

The United States represents one of the largest markets for gantry cranes from China, spurred by significant infrastructure development and industrial projects across the nation. Chinese goliath gantry cranes have garnered widespread applications in various sectors, including ports, manufacturing, logistics, and construction, playing a pivotal role in supporting the country's ongoing modernization efforts and economic expansion.

Driven by a commitment to quality, cost-effectiveness, and customization, Chinese manufacturers have made significant strides in penetrating the competitive US market. These manufacturers have adeptly tailored gantry cranes to meet the specific requirements of diverse projects, thereby solidifying their foothold in the industry.

- Infrastructure Development: The United States has embarked on ambitious infrastructure projects aimed at enhancing transportation networks, modernizing ports, and upgrading logistics facilities. Chinese gantry cranes have been instrumental in supporting these endeavors, providing efficient material handling solutions for the construction and operation of key infrastructure assets.

- Manufacturing Sector: Within the manufacturing sector, gantry cranes are indispensable for handling heavy machinery, raw materials, and finished products in production facilities. Chinese gantry cranes offer reliable performance and cost-effectiveness, making them a preferred choice for manufacturers seeking to optimize their operations and improve productivity.

- Port Operations: Ports play a vital role in facilitating international trade and commerce, requiring robust material handling equipment to efficiently manage cargo operations. Chinese gantry cranes excel in port environments, offering high lifting capacities, precise control, and rapid container handling capabilities, thereby bolstering port efficiency and throughput.

- Logistics and Warehousing: In the realm of logistics and warehousing, gantry cranes are utilized for the efficient storage and retrieval of goods within distribution centers and storage facilities. Chinese gantry cranes contribute to the seamless flow of goods through the supply chain, enhancing logistics operations and reducing turnaround times.

- Construction Projects: The construction industry in the United States relies on gantry cranes for various tasks, including material handling, equipment installation, and structural assembly. Chinese gantry cranes are valued for their versatility, durability, and cost-effectiveness, making them indispensable assets on construction sites nationwide.

In essence, the United States serves as a significant market for Chinese gantry cranes, driven by the nation's robust economic activity and ongoing infrastructure development initiatives. Chinese manufacturers have successfully capitalized on this demand by delivering high-quality, tailored gantry crane solutions that address the diverse needs of industries across the country. As the United States continues to invest in infrastructure and industrial expansion, the demand for Chinese gantry cranes is expected to remain strong, further cementing the mutually beneficial partnership between the two nations in the realm of material handling equipment.

European Union Countries

European Union countries represent another significant market for gantry cranes from China, fueled by infrastructure upgrades, urban development, and industrial expansion. From bustling ports to sprawling construction sites, gantry cranes manufactured in China play a crucial role in facilitating material handling and construction operations across Europe. By adhering to stringent quality standards, offering competitive pricing, and providing reliable after-sales support, Chinese gantry crane suppliers have secured partnerships and contracts in various EU countries, contributing to the continent's economic progress.

European Union (EU) countries stand as pivotal markets for goliath gantry cranes from China, driven by ambitious infrastructure upgrades, urban development projects, and industrial expansion initiatives. Goliath gantry cranes, renowned for their robustness and versatility, are instrumental in facilitating efficient material handling and construction operations across the diverse landscapes of Europe.

- Infrastructure Upgrades: Within the EU, significant investments are directed towards enhancing transportation networks, modernizing ports, and revitalizing urban infrastructure. Goliath gantry cranes, with their substantial lifting capacities and precise control, play a vital role in supporting these infrastructure upgrades by facilitating the efficient movement of materials and equipment at construction sites and logistics hubs. Countries such as Germany, France, and the Netherlands are at the forefront of these infrastructure developments, with large-scale projects requiring advanced material handling solutions.

- Port Operations: Europe boasts a network of bustling ports that serve as vital gateways for international trade and commerce. Goliath gantry cranes, renowned for their reliability and efficiency, are indispensable for loading and unloading cargo from ships, stacking containers in storage yards, and ensuring seamless port operations. Countries with major ports such as the United Kingdom, Belgium, and Spain rely heavily on goliath gantry cranes to handle the increasing volume of maritime trade and containerized cargo.- Netherlands: The Port of Rotterdam in the Netherlands, one of the largest ports in Europe, relies heavily on goliath gantry cranes for its container handling operations. These cranes play a crucial role in facilitating the smooth flow of cargo through the port, contributing to its status as a key logistics hub in the region. Germany: Germany, as Europe's economic powerhouse, is home to several major ports along its coastline, including Hamburg and Bremerhaven. Goliath gantry cranes are extensively used in these ports for container handling and general cargo operations, supporting Germany's thriving maritime trade activities.

- Construction Sector: The construction industry in EU countries is characterized by a diverse range of projects, including residential developments, commercial complexes, and infrastructure ventures. Goliath gantry cranes, prized for their versatility and adaptability, are deployed in various construction applications such as bridge construction, building erection, and infrastructure development. Countries like Italy, Poland, and Sweden witness significant construction activity, driving the demand for goliath gantry cranes to support large-scale building projects and urban expansion initiatives.- France: France, with its ambitious infrastructure projects such as the Grand Paris Express and Lyon-Turin Railway, relies on goliath gantry cranes for construction and material handling tasks. These cranes contribute to the efficient execution of large-scale projects, ensuring timely completion and quality outcomes. - Spain: Spain's construction sector benefits from the use of goliath gantry cranes in projects ranging from high-speed rail networks to urban redevelopment initiatives. These cranes enhance productivity and safety on construction sites, supporting Spain's economic development goals.

- Industrial Expansion: Across EU countries, industrial expansion initiatives drive the demand for goliath gantry cranes in manufacturing facilities, warehouses, and distribution centers. These cranes are essential for handling heavy machinery, raw materials, and finished products, thereby optimizing production processes and ensuring efficient logistics operations. Countries such as Czech Republic, Hungary, and Slovakia are experiencing rapid industrial growth, leading to increased adoption of goliath gantry cranes in their manufacturing and logistics sectors.- Italy: Italy's manufacturing sector, particularly in regions like Lombardy and Emilia-Romagna, relies on goliath gantry cranes for material handling and production processes. These cranes support the automotive, aerospace, and food processing industries, contributing to Italy's industrial competitiveness. - Poland: Poland's rapid industrial growth is fueled by investments in sectors such as automotive manufacturing, electronics, and renewable energy. Goliath gantry cranes play a crucial role in supporting these industries, providing efficient material handling solutions that drive productivity and growth.

By adhering to stringent quality standards, offering competitive pricing, and providing reliable after-sales support, Chinese suppliers of goliath gantry cranes have forged strong partnerships and secured contracts in various EU countries. Their contributions to infrastructure development, urbanization, and industrial expansion are integral to the continent's economic progress and sustainable growth trajectory. As Europe continues to invest in modernization and development projects, the demand for goliath gantry cranes from China is expected to remain robust, further solidifying the mutually beneficial partnership between the two regions.

Middle Eastern Countries

The Middle East, with its ambitious infrastructure projects and rapid urbanization, presents lucrative opportunities for gantry crane exports from China. From towering skyscrapers to sprawling oil refineries, gantry cranes are indispensable in the construction and operation of key facilities in the region. Chinese manufacturers have capitalized on this demand by delivering high-quality gantry cranes tailored to withstand harsh environmental conditions and meet stringent performance requirements. Their ability to offer turnkey solutions, including installation, maintenance, and technical support, has bolstered their presence in Middle Eastern markets, forging long-term partnerships and collaborations.

The Middle East stands as a beacon of opportunity for gantry crane exports from China, driven by ambitious infrastructure projects and rapid urbanization across the region. From towering skyscrapers to sprawling oil refineries and expansive port facilities, gantry cranes play a pivotal role in the construction and operation of key infrastructure assets in the Middle East.

- Infrastructure Projects: The Middle East is renowned for its ambitious infrastructure projects, including the construction of megacities, airports, highways, and transportation networks. Gantry cranes are essential for handling heavy materials, equipment, and prefabricated components at construction sites, contributing to the timely completion of these projects. Countries such as the United Arab Emirates, Saudi Arabia, Qatar, and Kuwait are leading the way with iconic developments such as Dubai's Burj Khalifa, Riyadh's King Abdullah Financial District, Qatar's World Cup stadiums, and Kuwait's Silk City, driving the demand for advanced gantry crane solutions.

- Oil and Gas Industry: The Middle East is home to some of the world's largest oil and gas reserves, with extensive exploration, drilling, and refining operations underway. Gantry cranes are critical for lifting and transporting heavy machinery, pipes, and equipment in oil fields, refineries, and petrochemical plants. Major oil-producing countries such as Saudi Arabia, the United Arab Emirates, Iraq, and Kuwait heavily rely on gantry cranes for their oil and gas operations, fueling the demand for specialized solutions from Chinese manufacturers.

- Port and Maritime Infrastructure: With its strategic location at the crossroads of global trade routes, the Middle East boasts bustling port facilities that serve as vital hubs for maritime commerce. Gantry cranes are indispensable for container handling, bulk cargo operations, and shipbuilding activities at ports and shipyards across the region. Countries like the United Arab Emirates (including Dubai and Abu Dhabi), Saudi Arabia (including Jeddah and Dammam), Oman, and Qatar have invested significantly in expanding and modernizing their port infrastructure, driving the demand for state-of-the-art gantry crane solutions.

- Urban Development: The Middle East is witnessing rapid urbanization, with a surge in construction projects, commercial developments, and residential complexes in cities like Dubai, Riyadh, Abu Dhabi, Doha, and Muscat. Gantry cranes are instrumental in erecting skyscrapers, malls, and infrastructure projects, providing essential lifting and material handling capabilities for construction activities. Chinese manufacturers of gantry cranes have established a strong presence in the Middle Eastern construction sector, delivering reliable solutions that adhere to stringent safety and quality standards.

By offering turnkey solutions encompassing installation, maintenance, and technical support, Chinese gantry crane suppliers have cemented their position in Middle Eastern markets. Their ability to deliver high-quality gantry cranes tailored to withstand harsh environmental conditions, coupled with their commitment to customer service, has resulted in long-term partnerships and collaborations with key stakeholders in the region. As the Middle East continues to invest in infrastructure development and industrial expansion, the demand for gantry cranes from China is expected to remain robust, driving further growth and innovation in the sector.

Southeast Asian Countries

Southeast Asian countries, characterized by burgeoning economies and rapid industrialization, represent a dynamic market for gantry crane exports from China. Infrastructure projects, including ports, airports, and manufacturing facilities, drive the demand for gantry cranes to support material handling and logistics operations. Chinese manufacturers leverage their expertise in customization, agility, and cost-effectiveness to cater to the diverse needs of Southeast Asian markets. By establishing local presence, forging strategic alliances, and understanding regional nuances, they have successfully captured market share and fueled economic development across the region.

Southeast Asian countries, known for their burgeoning economies and rapid industrialization, serve as dynamic markets for gantry crane exports from China. These nations are undergoing significant infrastructure development, including the expansion of ports, airports, and manufacturing facilities, which fuels the demand for gantry cranes to facilitate material handling and logistics operations. Chinese manufacturers, renowned for their expertise in customization, agility, and cost-effectiveness, are well-positioned to cater to the diverse needs of Southeast Asian markets.

- Infrastructure Projects: Across Southeast Asia, governments are investing heavily in infrastructure projects to bolster economic growth and connectivity. Gantry cranes play a vital role in these endeavors, supporting the construction of ports, airports, bridges, and industrial facilities. Chinese gantry crane manufacturers offer a wide range of solutions tailored to the specific requirements of each project, ensuring efficient material handling and construction operations. - Vietnam: Vietnam's rapid industrialization and expanding maritime trade drive the demand for gantry cranes in its ports and logistics hubs. Chinese gantry crane suppliers have capitalized on this demand by providing cost-effective solutions that enhance port efficiency and cargo handling capabilities. - Indonesia: Indonesia's ambitious infrastructure projects, including the development of ports and industrial zones, present opportunities for gantry crane suppliers. Chinese manufacturers offer customizable gantry crane solutions to meet the unique challenges of Indonesia's diverse geography and project requirements.

- Manufacturing Sector: The manufacturing sector in Southeast Asia is experiencing robust growth, driven by favorable investment climates and a skilled workforce. Gantry cranes are essential for material handling and production processes in industries such as automotive manufacturing, electronics, and consumer goods production. Chinese gantry crane manufacturers provide reliable and cost-effective solutions that support the expansion of manufacturing facilities across the region. - Thailand: Thailand's automotive industry, a key contributor to its economy, relies on gantry cranes for handling heavy machinery and components in manufacturing plants. Chinese gantry crane suppliers offer customized solutions that meet the stringent requirements of Thailand's automotive manufacturers, enhancing production efficiency and competitiveness. - Malaysia: Malaysia's electronics manufacturing sector benefits from the use of gantry cranes for handling delicate electronic components and machinery. Chinese manufacturers provide gantry crane solutions equipped with advanced control systems and safety features, ensuring the smooth operation of Malaysia's electronics manufacturing facilities.

- Strategic Alliances and Local Presence: Chinese gantry crane manufacturers understand the importance of establishing local presence and forging strategic alliances to penetrate Southeast Asian markets effectively. By partnering with local distributors, agents, and service providers, they gain valuable insights into regional preferences, regulations, and market dynamics, enabling them to tailor their offerings to suit the needs of Southeast Asian customers. - Singapore: Singapore's status as a global logistics and trade hub presents opportunities for gantry crane suppliers to showcase their expertise and innovation. Chinese manufacturers collaborate with local partners to deliver gantry crane solutions that meet Singapore's stringent safety and operational standards, supporting the city-state's logistics and maritime industries. - Philippines: The Philippines' infrastructure development initiatives, particularly in transportation and logistics, create demand for gantry cranes in ports and industrial zones. Chinese gantry crane suppliers establish local presence through partnerships with Filipino companies, providing reliable and cost-effective solutions that contribute to the country's economic growth and development.

In conclusion, Southeast Asian countries offer lucrative opportunities for gantry crane exports from China, driven by infrastructure development, industrialization, and manufacturing growth. Chinese manufacturers, leveraging their expertise in customization, agility, and cost-effectiveness, play a significant role in meeting the region's demand for gantry cranes and supporting its economic development aspirations. Through strategic alliances, local presence, and a deep understanding of regional markets, they continue to capture market share and fuel economic growth across Southeast Asia.

Latin American Countries

Latin American countries, with their vast natural resources and burgeoning construction projects, offer fertile ground for gantry crane exports from China. From mining operations to port facilities and urban infrastructure, gantry cranes play a pivotal role in driving progress and productivity in the region. Chinese manufacturers have positioned themselves as reliable partners, offering technologically advanced gantry cranes tailored to the unique requirements of Latin American markets. Through collaboration with local stakeholders, investment in service infrastructure, and commitment to quality and reliability, they have carved a niche in Latin America's construction landscape, contributing to sustainable development and economic growth.

Latin American countries, characterized by their vast natural resources and burgeoning construction projects, present fertile ground for gantry crane exports from China. These nations rely on gantry cranes across a spectrum of industries, from mining operations to port facilities and urban infrastructure projects, to drive progress and enhance productivity. Chinese manufacturers have emerged as reliable partners in this dynamic market, offering technologically advanced gantry cranes tailored to the unique requirements of Latin American industries.

- Mining Operations: Latin America is renowned for its rich mineral reserves, and mining operations form a cornerstone of the region's economy. Gantry cranes are essential for handling heavy equipment, extracting ores, and transporting materials within mining sites. Chinese manufacturers supply robust gantry cranes equipped with specialized features to withstand the rugged conditions of mining operations, contributing to the efficiency and productivity of the industry. - Chile: As one of the world's leading copper producers, Chile relies heavily on gantry cranes for material handling in its mining operations. Chinese gantry crane suppliers provide durable and high-capacity cranes tailored to the specific requirements of Chile's mining industry, supporting the country's position as a global mining powerhouse. - Brazil: Brazil's mining sector, encompassing iron ore, bauxite, and gold mining, requires robust material handling solutions to support its operations. Chinese gantry crane manufacturers offer customizable solutions that enhance the efficiency and safety of material handling processes in Brazil's mines, contributing to the country's economic development.

- Port Facilities: Latin American ports serve as vital hubs for international trade and commerce, requiring efficient material handling equipment to facilitate cargo operations. Gantry cranes play a crucial role in loading and unloading ships, stacking containers, and managing cargo flows in port terminals. Chinese manufacturers supply gantry cranes equipped with advanced automation and control systems to optimize port operations and enhance throughput. - Mexico: Mexico's strategic location as a gateway between North and South America positions its ports as key nodes in global supply chains. Chinese gantry crane suppliers offer cutting-edge solutions that improve the efficiency and capacity of Mexico's port facilities, supporting the country's trade and economic growth objectives. - Argentina: Argentina's ports play a significant role in exporting agricultural commodities such as soybeans, corn, and wheat. Gantry cranes are instrumental in handling bulk cargo at these ports, ensuring timely shipments and efficient logistics operations. Chinese gantry crane manufacturers provide reliable solutions that meet the demanding requirements of Argentina's port infrastructure, contributing to the country's export competitiveness.

- Urban Infrastructure Projects: Latin American countries are undergoing rapid urbanization, leading to a surge in construction projects aimed at enhancing transportation networks, utilities, and public amenities. Gantry cranes are indispensable for lifting heavy materials, erecting structures, and supporting construction activities in urban areas. Chinese manufacturers supply gantry cranes tailored to the specific needs of Latin American construction projects, contributing to the development of sustainable infrastructure. - Colombia: Colombia's infrastructure development initiatives, including road expansion and urban redevelopment projects, rely on gantry cranes for efficient material handling and construction operations. Chinese gantry crane suppliers offer cost-effective solutions that support Colombia's infrastructure goals and contribute to the country's economic progress. - Peru: Peru's construction sector, driven by investments in transportation infrastructure and housing projects, requires versatile gantry cranes to meet its diverse needs. Chinese manufacturers provide customizable gantry crane solutions that enhance the productivity and safety of construction sites in Peru, supporting the country's development objectives.

In conclusion, Latin American countries offer vast opportunities for gantry crane exports from China, driven by the region's resource-rich economy and ambitious construction projects. Chinese manufacturers, through their focus on quality, customization, and customer satisfaction, have established themselves as key players in Latin America's construction landscape. By collaborating with local stakeholders, investing in service infrastructure, and delivering reliable gantry crane solutions, they contribute to sustainable development and economic growth across the region. China's gantry crane exports exemplify its commitment to driving progress and prosperity in global markets, reinforcing its position as a leading supplier of material handling equipment worldwide.

Reasons for the Global Demand for Gantry Cranes from China

Gantry cranes manufactured in China have captured significant market share worldwide, owing to several compelling factors that drive global demand. Let's explore these reasons in detail:

Cost-Effectiveness and Competitive Pricing

One of the primary reasons for the global demand for gantry cranes from China is their cost-effectiveness and competitive pricing. Chinese manufacturers leverage economies of scale, efficient production processes, and lower labor costs to offer gantry cranes at competitive price points compared to counterparts from other regions. This affordability makes Chinese gantry cranes an attractive option for construction companies, port operators, manufacturing facilities, and other industries seeking cost-effective material handling solutions without compromising on quality.

- Economies of Scale: Chinese gantry crane manufacturers benefit from economies of scale due to the sheer size and scale of their operations. By producing gantry cranes in large quantities, they can spread fixed costs across a greater number of units, resulting in lower production costs per crane. This efficiency allows Chinese manufacturers to offer gantry cranes at highly competitive prices without compromising on quality.

- Efficient Production Processes: Chinese manufacturers have invested heavily in streamlining their production processes to maximize efficiency and minimize waste. Through the implementation of advanced manufacturing techniques, automation, and lean principles, they can produce gantry cranes with precision and consistency while minimizing production costs. This efficiency translates into cost savings that are passed on to customers in the form of competitive pricing.

- Lower Labor Costs: China's abundant labor force and comparatively lower labor costs compared to Western countries contribute significantly to the competitive pricing of gantry cranes. Chinese manufacturers can leverage this advantage to offer gantry cranes at more affordable price points without compromising on the skill and expertise of their workforce. This allows them to remain competitive in the global market and attract customers seeking cost-effective material handling solutions.

- Attractiveness to Various Industries: The cost-effectiveness of Chinese gantry cranes makes them an attractive option for a wide range of industries, including construction, ports, manufacturing, and logistics. Companies across these sectors can benefit from the affordability of Chinese gantry cranes without sacrificing performance or reliability. This versatility has helped Chinese manufacturers capture a significant share of the global gantry crane market and establish themselves as leaders in the industry.

In summary, the cost-effectiveness and competitive pricing of gantry cranes from China are key drivers of their global demand. Chinese manufacturers' ability to leverage economies of scale, efficient production processes, and lower labor costs allows them to offer high-quality gantry cranes at attractive price points. This affordability makes Chinese gantry cranes a preferred choice for industries worldwide seeking reliable material handling solutions that deliver exceptional value for money.

Quality and Reliability of Gantry Cranes Manufactured in China

Despite their competitive pricing, gantry cranes manufactured in China are renowned for their quality and reliability. Chinese manufacturers adhere to stringent quality control standards and invest in state-of-the-art manufacturing facilities to ensure that their gantry cranes meet international standards of performance and durability. Rigorous testing procedures, adherence to industry regulations, and continuous improvement initiatives contribute to the reputation of Chinese gantry cranes for delivering reliable and high-quality solutions for various applications.

Gantry cranes manufactured in China have garnered widespread acclaim for their exceptional quality and reliability, despite their competitive pricing. Chinese manufacturers prioritize quality assurance at every stage of the production process, ensuring that their gantry cranes meet and exceed international standards of performance and durability.

- Stringent Quality Control Standards: Chinese gantry crane manufacturers adhere to rigorous quality control standards to maintain the highest levels of product quality. From sourcing raw materials to final assembly, every aspect of the manufacturing process is closely monitored and inspected to ensure compliance with stringent quality specifications. By implementing robust quality management systems, Chinese manufacturers instill confidence in the reliability of their gantry cranes among customers worldwide.

- State-of-the-Art Manufacturing Facilities: Chinese manufacturers invest heavily in state-of-the-art manufacturing facilities equipped with advanced machinery, technologies, and infrastructure. These modern facilities enable them to produce gantry cranes with precision and efficiency while maintaining consistent quality standards. By leveraging automation, robotics, and digitalization, Chinese manufacturers optimize production processes and minimize defects, resulting in gantry cranes of unparalleled quality and reliability.

- Rigorous Testing Procedures: Prior to shipment, each gantry crane undergoes comprehensive testing procedures to validate its performance, safety, and reliability. From load testing to functional testing, every aspect of the gantry crane's operation is meticulously evaluated to ensure optimal functionality and adherence to design specifications. Chinese manufacturers conduct these tests in accordance with international standards and regulations, providing customers with the assurance of a reliable and high-quality product.

- Adherence to Industry Regulations: Chinese gantry crane manufacturers prioritize compliance with industry regulations and standards to uphold the integrity and safety of their products. They stay abreast of evolving regulatory requirements and ensure that their gantry cranes meet or exceed all applicable standards for design, construction, and operation. By adhering to these regulations, Chinese manufacturers demonstrate their commitment to delivering gantry cranes that prioritize safety, performance, and reliability.

- Continuous Improvement Initiatives: Chinese manufacturers are committed to continuous improvement and innovation to enhance the quality and reliability of their gantry cranes. They invest in research and development initiatives to explore new technologies, materials, and design concepts that can further optimize gantry crane performance and durability. By embracing innovation and embracing feedback from customers and industry experts, Chinese manufacturers drive continuous advancements in gantry crane quality and reliability.

In conclusion, gantry cranes manufactured in China are synonymous with exceptional quality and reliability, underpinned by stringent quality control standards, state-of-the-art manufacturing facilities, rigorous testing procedures, adherence to industry regulations, and continuous improvement initiatives. Chinese manufacturers' unwavering commitment to delivering reliable and high-quality gantry cranes has earned them the trust and confidence of customers worldwide, solidifying their reputation as leaders in the global gantry crane industry.

Advanced Technology and Innovation in Manufacturing Processes

Chinese gantry crane manufacturers are at the forefront of technological innovation, continually investing in research and development to enhance their products' performance and functionality. Advanced automation, precision engineering, and innovative design techniques are employed in the manufacturing processes of gantry cranes, resulting in products that offer superior efficiency, precision, and safety. From advanced control systems to cutting-edge materials and components, Chinese gantry cranes incorporate the latest technological advancements to meet the evolving needs of the global market.

Chinese gantry crane manufacturers are leading the charge in technological innovation, consistently investing in research and development to push the boundaries of performance and functionality in their products. By integrating advanced automation, precision engineering, and innovative design techniques into their manufacturing processes, they produce gantry cranes that stand out for their superior efficiency, precision, and safety.

- Advanced Automation: Chinese gantry crane manufacturers leverage advanced automation technologies to streamline production processes and improve manufacturing efficiency. Automated assembly lines, robotic welding systems, and computer-controlled machining centers ensure consistent quality and precise construction of gantry crane components. By minimizing manual intervention and optimizing workflow, automation enhances productivity while maintaining high standards of craftsmanship.

- Precision Engineering: Precision engineering techniques play a crucial role in the manufacturing of gantry cranes, ensuring tight tolerances, accurate alignments, and smooth operation. Chinese manufacturers utilize state-of-the-art machining equipment, CNC (Computer Numerical Control) machining centers, and 3D modeling software to design and fabricate gantry crane components with exceptional precision. This meticulous attention to detail results in gantry cranes that perform reliably and consistently under demanding operating conditions.

- Innovative Design Techniques: Innovative design plays a pivotal role in enhancing the performance and functionality of gantry cranes. Chinese manufacturers employ cutting-edge design software and simulation tools to optimize the structural integrity, load-bearing capacity, and operational efficiency of gantry crane designs. By exploring novel design concepts and engineering solutions, they create gantry cranes that are tailored to meet the evolving needs of the global market.

- Advanced Control Systems: Gantry cranes from China feature advanced control systems that enhance their safety, reliability, and ease of operation. Programmable logic controllers (PLCs), variable frequency drives (VFDs), and remote monitoring capabilities enable precise control over crane movements, speeds, and load handling operations. Integrated safety features, such as collision avoidance systems and overload protection, ensure compliance with stringent safety standards and enhance operator confidence.

- Cutting-Edge Materials and Components: Chinese gantry crane manufacturers utilize cutting-edge materials and components to enhance the performance and longevity of their products. High-strength steel alloys, corrosion-resistant coatings, and durable polymeric materials are employed to construct gantry crane structures that withstand harsh environmental conditions and heavy-duty operations. Precision-engineered components, such as bearings, gears, and wire ropes, are selected for their reliability, longevity, and performance under load.

In summary, Chinese gantry crane manufacturers are at the forefront of technological innovation, leveraging advanced automation, precision engineering, innovative design techniques, advanced control systems, and cutting-edge materials to produce gantry cranes of unparalleled quality and performance. By embracing innovation and investing in research and development, they continue to raise the bar for gantry crane technology, meeting the demands of the global market and driving progress in the material handling industry.

Diverse Range of Gantry Crane Products Meeting Varied Industry Needs

Another key factor driving the global demand for gantry cranes from China is the diverse range of products available to meet varied industry needs. Chinese manufacturers offer gantry cranes in a wide range of configurations, capacities, and specifications, catering to diverse applications across industries such as construction, manufacturing, logistics, mining, and ports. Whether it's heavy-duty gantry cranes for large-scale industrial projects or compact gantry cranes for smaller operations, Chinese manufacturers provide solutions tailored to meet specific customer requirements, enhancing their appeal in the global marketplace.

The global demand for gantry cranes from China is further propelled by the extensive range of products tailored to meet diverse industry needs. Chinese manufacturers offer gantry cranes in a plethora of configurations, capacities, and specifications, catering to a wide spectrum of applications across industries such as construction, manufacturing, logistics, mining, and ports. This versatility ensures that Chinese gantry cranes are well-suited to address the unique requirements of different sectors, bolstering their appeal in the global marketplace.

- Customization Options: Chinese gantry crane manufacturers excel in providing customization options that allow customers to tailor gantry cranes to their specific operational requirements. Whether it's adjusting lifting capacities, span lengths, or hoisting speeds, customers have the flexibility to customize gantry cranes to match their exact needs. This versatility ensures that Chinese gantry cranes can be seamlessly integrated into a wide range of industrial environments, optimizing efficiency and productivity.

- Wide Range of Capacities: Chinese manufacturers offer gantry cranes with a diverse range of lifting capacities, spanning from light-duty cranes for small-scale operations to heavy-duty cranes capable of handling massive loads. This broad spectrum of capacities ensures that customers can find gantry cranes suitable for their unique lifting requirements, regardless of the scale or complexity of their operations. Whether it's lifting containers at a port terminal or hoisting heavy machinery in a manufacturing facility, Chinese gantry cranes deliver the power and performance needed to get the job done.

- Versatile Configurations: Chinese gantry cranes are available in various configurations to accommodate different spatial constraints and operational needs. From single-girder and double-girder designs to semi-gantry and full gantry configurations, customers can choose the most suitable setup for their specific applications. This versatility enables Chinese gantry cranes to adapt to diverse environments, whether it's navigating tight spaces in a warehouse or spanning expansive outdoor yards in a construction site.

- Specialized Features and Accessories: Chinese manufacturers offer a wide array of specialized features and accessories to enhance the functionality and performance of gantry cranes. From advanced control systems and precision positioning technology to anti-sway devices and environmental protection features, customers can equip gantry cranes with a range of add-ons to optimize their operation. This customization ensures that Chinese gantry cranes can meet the unique demands of various industries, providing tailored solutions that drive efficiency and productivity.

- Comprehensive After-Sales Support: In addition to offering a diverse range of gantry crane products, Chinese manufacturers provide comprehensive after-sales support services to ensure customer satisfaction and long-term reliability. This includes installation assistance, operator training programs, preventive maintenance services, and prompt technical support. By standing behind their products with reliable service and support, Chinese manufacturers instill confidence in the performance and durability of their gantry cranes, fostering lasting relationships with customers worldwide.

In summary, the diverse range of gantry crane products offered by Chinese manufacturers, coupled with their commitment to customization, versatility, and after-sales support, positions them as preferred suppliers in the global marketplace. By addressing the unique needs of different industries and applications, Chinese gantry cranes continue to play a vital role in driving efficiency, productivity, and innovation across a wide range of industrial sectors.

Competitive Advantages of Gantry Crane Exports from China

Gantry crane exports from China possess distinct competitive advantages that set them apart in the global market. Here are the key factors contributing to their competitiveness:

Strong Manufacturing Infrastructure and Expertise

China boasts a robust manufacturing infrastructure and extensive expertise in gantry crane production. State-of-the-art facilities equipped with advanced machinery and skilled workforce enable Chinese manufacturers to produce gantry cranes with exceptional precision and efficiency. The scale of production, coupled with years of experience in the industry, allows China to meet the growing global demand for gantry cranes promptly and effectively, giving them a competitive edge over competitors.

China's formidable manufacturing infrastructure and unparalleled expertise in gantry crane production are foundational to its dominance in the global market. Equipped with state-of-the-art facilities and bolstered by a skilled workforce, Chinese manufacturers excel in delivering gantry cranes with unmatched precision, efficiency, and reliability. This manufacturing prowess, combined with extensive experience in the industry, positions China as a frontrunner in meeting the burgeoning global demand for gantry cranes.

- State-of-the-Art Facilities: Chinese gantry crane manufacturers operate within cutting-edge facilities outfitted with the latest machinery, technologies, and production processes. These state-of-the-art facilities enable streamlined manufacturing operations, ensuring the consistent quality and performance of gantry cranes. Automated assembly lines, CNC machining centers, and robotic welding systems enhance efficiency while maintaining stringent quality standards, allowing Chinese manufacturers to meet the diverse needs of global customers.

- Skilled Workforce: China boasts a highly skilled and specialized workforce trained in the intricacies of gantry crane production. From engineers and technicians to craftsmen and operators, Chinese manufacturers employ individuals with extensive experience and expertise in their respective fields. This skilled workforce is instrumental in ensuring the precision engineering, meticulous assembly, and rigorous testing of gantry cranes, guaranteeing their reliability and longevity in demanding industrial environments.

- Scale of Production: The sheer scale of gantry crane production in China is unparalleled, with manufacturers capable of fulfilling large orders promptly and efficiently. Leveraging economies of scale, Chinese manufacturers can produce gantry cranes in high volumes without compromising on quality or performance. This scalability enables them to meet the growing global demand for gantry cranes across a diverse range of industries, cementing their position as leading suppliers in the market.

- Years of Experience: Chinese manufacturers benefit from decades of experience in gantry crane production, having honed their craft through years of innovation, refinement, and adaptation to evolving market trends. This wealth of experience equips them with invaluable insights into customer needs, industry requirements, and technological advancements, enabling them to continually improve their products and processes. By leveraging this accumulated knowledge, Chinese manufacturers stay ahead of the curve and maintain a competitive edge in the global gantry crane market.

In summary, China's strong manufacturing infrastructure, combined with extensive expertise in gantry crane production, positions the country as a powerhouse in the global market. With state-of-the-art facilities, a skilled workforce, scalable production capabilities, and decades of experience, Chinese manufacturers consistently deliver gantry cranes of unparalleled quality, reliability, and performance. This manufacturing prowess underpins China's leadership in meeting the growing demand for gantry cranes worldwide, driving innovation and progress across industries.

Adherence to International Quality Standards

Chinese gantry crane exports are synonymous with quality and reliability, thanks to stringent adherence to international quality standards. Manufacturers prioritize quality control at every stage of production, from sourcing raw materials to final assembly and testing. Rigorous quality assurance measures ensure that gantry cranes meet or exceed industry standards for performance, safety, and durability. By maintaining consistently high-quality standards, Chinese exporters instill confidence in customers worldwide, enhancing their competitive position in the global market.

Chinese gantry crane exports have earned a reputation for unparalleled quality and reliability, a testament to the manufacturers' unwavering commitment to adhering to stringent international quality standards. At every step of the production process, from the sourcing of raw materials to the final testing and inspection, manufacturers prioritize quality control to ensure that gantry cranes meet or exceed the rigorous requirements set by global industry standards. This steadfast dedication to maintaining consistently high-quality standards not only enhances the reliability and performance of gantry cranes but also instills confidence in customers worldwide, bolstering the competitive edge of Chinese exporters in the global market.

- Comprehensive Quality Control Procedures: Chinese gantry crane manufacturers implement comprehensive quality control procedures to monitor and regulate every aspect of the manufacturing process. Stringent quality checks are conducted at various stages, including material inspection, component fabrication, welding, assembly, and final testing. This meticulous attention to detail ensures that each gantry crane meets the prescribed quality standards and specifications before it is dispatched to customers.

- Certification and Compliance: Chinese manufacturers adhere to a myriad of international quality standards and certifications to validate the quality and safety of their gantry cranes. These may include ISO (International Organization for Standardization) certifications, such as ISO 9001 for quality management systems and ISO 14001 for environmental management systems, as well as CE (Conformité Européenne) certification for compliance with European Union safety standards. By obtaining these certifications, manufacturers demonstrate their commitment to upholding the highest standards of quality, safety, and environmental responsibility.

- Continuous Improvement Initiatives: Chinese gantry crane manufacturers are dedicated to continuous improvement initiatives aimed at enhancing product quality and reliability. Feedback from customers, internal audits, and performance evaluations drive ongoing refinements to manufacturing processes and product designs. By embracing a culture of continuous improvement, manufacturers strive to identify and address areas for enhancement, ensuring that gantry cranes consistently meet or exceed customer expectations.

- Thorough Testing and Inspection: Prior to shipment, every gantry crane undergoes thorough testing and inspection to validate its performance, functionality, and safety. Tests may include load testing, dynamic testing, functional testing, and operational checks, conducted in accordance with established protocols and standards. Any deviations or anomalies are promptly identified and rectified to ensure that each gantry crane meets the stringent quality requirements before it is delivered to the customer.

- Customer Satisfaction Focus: Chinese manufacturers prioritize customer satisfaction as a key pillar of their quality assurance efforts. By actively engaging with customers, addressing their concerns, and soliciting feedback, manufacturers strive to continuously improve their products and services. Responsive customer support, prompt resolution of issues, and effective communication contribute to building trust and loyalty among customers, further reinforcing the reputation of Chinese gantry crane exports for reliability and quality.

In summary, Chinese gantry crane manufacturers uphold the highest standards of quality and reliability through stringent adherence to international quality standards, comprehensive quality control procedures, certification and compliance initiatives, continuous improvement efforts, thorough testing and inspection protocols, and a relentless focus on customer satisfaction. This unwavering commitment to quality not only ensures the superior performance and durability of gantry cranes but also enhances the competitive position of Chinese exporters in the global market, driving sustained growth and success in the industry.

Customization Options to Meet Specific Customer Requirements

Flexibility and customization are hallmarks of gantry crane exports from China. Manufacturers offer a wide range of customization options to tailor gantry cranes to specific customer requirements and project needs. Whether it's adjusting lifting capacities, span lengths, or control systems, Chinese exporters collaborate closely with customers to deliver gantry cranes that align perfectly with their operational needs. This ability to offer bespoke solutions enhances customer satisfaction and gives Chinese gantry crane exports a competitive advantage in meeting diverse industry demands.