Behind the Scenes: Inside Overhead Crane Factories in China

Uncover the secret of overhead crane manufacturer & supplier in China. Take a look at the workshops of Chinese overhead crane factories. Get your crane!

Category: China

Your Trusted Overhead Electric Crane Manufacturer & Supplier

Behind the Scenes: Inside Overhead Crane Factories in China

Overhead crane in China for Sale 1 Ton to 100 Ton , Custom Design for Your Needs, Cost-effective Price

Overhead crane in China for sale 1 ton to 100 ton,good price for your selection.Uncover the secret of overhead crane manufacturer & supplier in China. Take a look at the workshops of Chinese overhead crane factories. Get your crane!

When we think of global manufacturing powerhouses, China undoubtedly tops the list. Its vast industrial landscape is a symphony of innovation, precision, and sheer scale. Among the multitude of industries thriving within this colossal manufacturing landscape, one often overlooked yet critical sector stands tall—overhead crane factories. These factories play a vital role in supplying the world with the lifting solutions needed to build, transport, and operate in industries spanning from construction to logistics.

In this post, we'll unveil the inner workings of these Chinese overhead crane factories, offering you an exclusive glimpse into the epicenter of crane manufacturing. These factories, often hidden from public view, are at the heart of the global supply chain, producing the machines that bear the weight of industries worldwide.

There's a natural curiosity among buyers and industry enthusiasts worldwide to unravel the mysteries concealed within crane factories. What makes these factories tick? How do they craft these colossal machines with such precision? What drives the innovation that continually pushes the boundaries of crane technology?

Our quest isn't just a matter of curiosity; it's a necessity. Transparency in manufacturing processes is not only beneficial but essential for buyers seeking reliable, high-quality overhead cranes. By taking this behind-the-scenes journey, we aim to demystify the manufacturing process, shed light on the innovation that powers the industry, and provide you with the insights needed to make informed decisions when it comes to choosing the right overhead crane manufacturer.

The Inner Workings of Overhead Crane Factories

Manufacturing Processes and Assembly Lines

As we step onto the factory floor of a Chinese overhead crane manufacturing facility, we are greeted by a symphony of precision and coordination. The manufacturing process of these colossal machines is a meticulously choreographed dance of engineering excellence.

Exploring the Step-by-Step Processes: From the initial fabrication of steel components to the assembly of intricate electrical systems, every stage is carefully planned and executed. Skilled workers, often with years of experience, bring each component to life with unparalleled craftsmanship. Witnessing these steps provides a profound appreciation for the complexity and dedication that goes into creating each crane.

Showcasing Precision and Skill: It's on the factory floor that we truly grasp the skill of the workforce. These professionals possess an innate understanding of crane dynamics and mechanics. They meticulously weld, align, and assemble each part, ensuring that the final product meets the highest standards of quality and safety.

Material Selection and Quality Control

The strength and durability of an overhead crane begin with the selection of materials. Inside these factories, materials are chosen with meticulous care, and quality control is an unwavering commitment.

Delving into Material Choices: Steel, in various forms, is the backbone of overhead crane construction. The selection of high-quality steel is non-negotiable. Components undergo rigorous testing to ensure they meet the necessary tensile strength and load-bearing capacities. This attention to material quality guarantees the longevity and reliability of the cranes.

Highlighting Rigorous Quality Control: Quality control is not just a step in the process; it's a pervasive ethos. Inspections occur at multiple checkpoints throughout the assembly process. This includes non-destructive testing, dimensional checks, and thorough examinations of welds and joints. Only when a crane passes these stringent assessments does it earn the right to bear the label of reliability.

Qualtiy seetl materials for all types of steel crane production: Steel overhead crane, Steel gantry crane & Steel jib crane

R&D and Innovation Centers

Driving innovation is a hallmark of Chinese overhead crane manufacturing. Behind the scenes, research and development centers hum with creative energy.

Revealing the Innovation Centers: Within these facilities, engineers and designers continually push the boundaries of crane technology. They experiment with new materials, cutting-edge control systems, and advanced safety features. These innovations not only improve crane performance but also enhance safety, efficiency, and sustainability.

Continuous Innovation: Innovation isn't a one-time endeavor; it's a perpetual journey. Chinese manufacturers invest heavily in R&D, ensuring that their cranes remain at the forefront of technological advancement. This commitment to innovation contributes not only to the competitiveness of the Chinese crane industry but also to the global crane landscape.

As we venture deeper into the world of overhead crane factories, we gain a deeper appreciation for the craftsmanship, precision, and commitment to excellence that characterize these manufacturing hubs. In the next section, we'll explore the cutting-edge technology and innovative features that make Chinese overhead cranes stand out on the global stage.

Cutting-Edge Technology and Innovation

Advanced Machinery and Equipment

Visiting Chinese overhead crane factories takes us to the heart of technological advancement. Here, modern machinery and equipment stand as testaments to innovation in manufacturing.

Introducing State-of-the-Art Machinery: The floors of these factories are a playground for cutting-edge machinery. CNC (Computer Numerical Control) machines, laser cutting systems, and robotic welders are just a glimpse of the technology employed. These machines ensure precision in every cut, weld, and bend, raising the bar for crane manufacturing standards.

Role of Automation: Automation has emerged as a driving force in crane manufacturing. Automated systems not only enhance precision but also significantly boost production efficiency. From material handling to quality control, automation plays a pivotal role in ensuring that cranes are constructed to exacting specifications.

Innovations in Crane Design

Innovation in overhead crane design is not just a goal; it's an ongoing commitment. Chinese manufacturers continually reimagine crane design to meet the evolving needs of industries worldwide.

Showcasing Innovative Design Features: Walk alongside these cranes, and you'll discover innovative design features that set them apart. Enhanced safety features, ergonomic controls, and adaptable configurations are just the tip of the iceberg. These design innovations are aimed at improving operator safety, efficiency, and overall crane performance.

Translating Innovation into Performance: Innovation isn't just about aesthetics; it's about tangible benefits. These design innovations translate into cranes that operate seamlessly in a wide range of industries. From shipyards to warehouses, these cranes prove their worth daily, lifting tons of weight with precision and ease.

Manufacturing Capability and Scale

The magnitude of overhead crane manufacturing in China is awe-inspiring. To truly appreciate the scale of production, one must step into these factories and witness firsthand the capacity to meet global demand.

Explaining the Scale: Chinese overhead crane factories operate on a colossal scale. They produce thousands of cranes annually, ranging from small jib cranes to massive double girder cranes. The scale of production is a testament to China's commitment to providing lifting solutions to industries across the globe.

Meeting Global Demand: The demand for overhead cranes knows no borders. From North America to Southeast Asia, industries rely on these cranes for their daily operations. Chinese manufacturers understand this global need and have positioned themselves as dependable suppliers, ensuring that cranes are readily available to meet the demands of diverse industries.

Our exploration of Chinese overhead crane factories reveals a world where technology, innovation, and scale converge to create reliable and cutting-edge lifting solutions. In the next section, we'll delve into the customization and tailoring of crane solutions to meet diverse customer needs, emphasizing the collaborative nature of this industry.

Customization and Tailoring Crane Solutions

Meeting Diverse Customer Needs

Chinese overhead crane factories are versatile hubs of innovation and adaptability. One of their most remarkable qualities is their ability to cater to a wide spectrum of customer needs.

Exploring Flexibility: Step into these factories, and you'll witness the incredible flexibility they offer in customizing crane solutions. Each customer is unique, with specific requirements and operational challenges. Chinese manufacturers understand this diversity and rise to the occasion, ensuring that each crane is tailored to meet the exact demands of the industry it serves.

Tailoring to Specific Industries and Applications: Overhead cranes are not one-size-fits-all solutions. They vary in size, capacity, and features based on the industry they serve. Whether it's a heavy-duty crane for a steel mill or a precise crane for a high-tech manufacturing facility, Chinese factories have the expertise to design and manufacture cranes that excel in their intended applications.

Collaborative Design and Client Input

The success of a customized overhead crane often hinges on collaboration. These factories understand the importance of involving clients in the design process.

Emphasizing Collaboration: Collaboration between manufacturers and clients is more than a buzzword; it's a fundamental aspect of crane design. Manufacturers actively seek input from clients, taking the time to understand their unique challenges and operational requirements. This collaborative approach ensures that the end product is not just a crane but a tailored solution.

Examples of Successful Collaborations: The power of collaboration shines in the many successful customized crane projects that have been realized. From specialized cranes for the aerospace industry to explosion-proof cranes for hazardous environments, these factories have a rich history of turning client visions into reality. These examples serve as a testament to the industry's adaptability and dedication to meeting client needs.

Our journey inside overhead crane factories in China highlights the artistry of customization and the importance of client collaboration. In the following section, we'll delve into the quality assurance and safety measures that underpin every crane's construction, ensuring they meet stringent international standards.

Navigating the Overhead Crane Landscape: Types of Overhead Crane Factories in China

When it comes to overhead cranes, the manufacturing landscape in China is as diverse as the cranes themselves. For buyers seeking to invest in specific types of overhead cranes, understanding the specialization of manufacturers and regional strengths is paramount. In this segment, we embark on a journey to explore the types of overhead crane factories in China.

Specialized Crane Manufacturers

One of the defining characteristics of China's overhead crane manufacturing sector is specialization. Numerous factories have chosen to focus their expertise on crafting specific types of overhead cranes. This specialization enables them to delve deep into the intricacies of their chosen crane category, resulting in finely tuned solutions for particular industries and applications.

Exploring Specialization: Imagine a factory that excels in manufacturing single girder cranes for light-duty applications, ensuring that every component is optimized for efficiency and precision. Alternatively, picture another facility that specializes in producing heavy-duty gantry cranes, built to withstand the most rigorous industrial demands. These specialized factories are akin to artisans honing their craft to perfection.

Highlighting Expertise and Unique Offerings: The advantage of collaborating with specialized crane manufacturers lies in their profound knowledge and unique features. For instance, if your operations demand explosion-proof cranes for hazardous environments, connecting with a factory specializing in this niche ensures that you receive a crane that not only meets but exceeds the highest safety and performance standards. The expertise of these manufacturers is your assurance of a crane tailored precisely to your specific application.

Locations and Regional Specializations

China's vast expanse hosts a diverse tapestry of overhead crane manufacturing regions, each known for its unique strengths and specializations. Understanding these regional dynamics can be your compass in finding the right source for your specific crane requirements.

Discussing Geographical Distribution: Chinese crane factories are not clustered in a single area but are distributed across the country. This decentralization means that the location of the factory you choose can significantly impact your procurement process. For instance, coastal regions are renowned for producing maritime cranes that are indispensable for shipyards and port operations. In contrast, inland areas often focus on industrial and construction cranes.

Highlighting Regional Specializations: Coastal regions, such as Shanghai and Qingdao, excel in manufacturing maritime cranes tailored for shipbuilding and port logistics. These cranes are designed to withstand the rigors of marine environments. Meanwhile, regions like Henan and Jiangsu, located inland, are known for their prowess in producing industrial and construction cranes. Recognizing these regional strengths allows you to connect with factories that are specialists in the specific type of crane you require, optimizing your procurement experience.

A short list of the overhead crane production zones in China along with their respective regions:

Henan Province

Notable City: Zhengzhou

Specialization: Various types of overhead cranes, including single and double girder cranes.

Jiangsu Province

Notable Cities: Suzhou, Changzhou, Wuxi

Specialization: Diverse crane production, proximity to major industrial centers.

Shandong Province

Notable City: Qingdao

Specialization: Gantry cranes and other heavy machinery.

Zhejiang Province

Notable City: Ningbo

Specialization: Various types of cranes, including single and double girder overhead cranes.

Shanghai

Specialization: A major international trade and manufacturing center, Shanghai is home to several crane manufacturers.

These regions are known for their concentration of overhead crane manufacturing facilities and their specific areas of specialization. Depending on your requirements, you can explore manufacturers in these zones to find the right overhead crane for your needs.

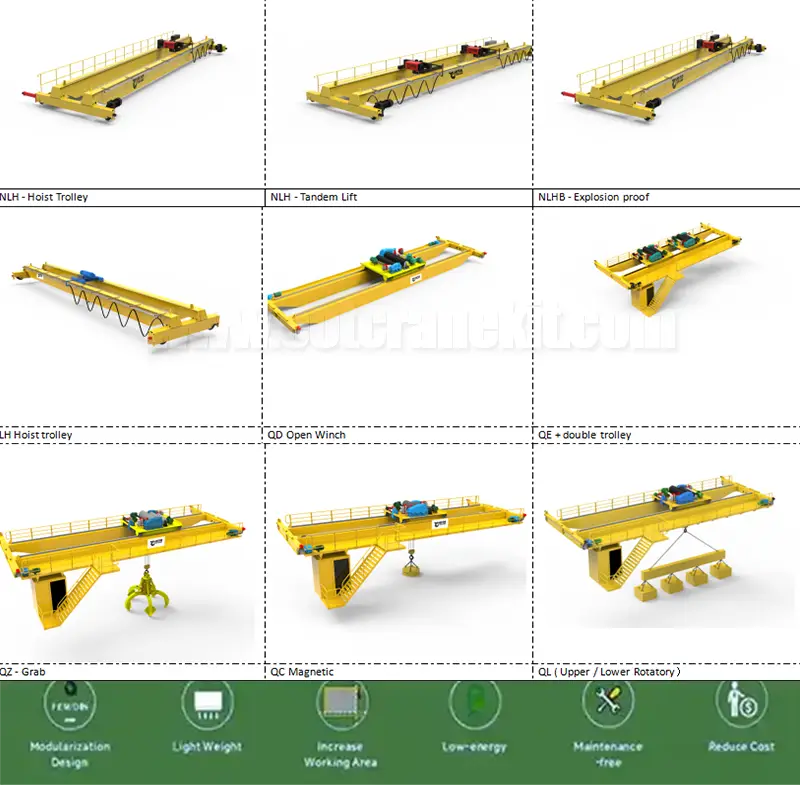

Types of Overhead Cranes Produced in Factory

The Chinese overhead crane manufacturing landscape is characterized by its remarkable diversity. Factories across the country produce an extensive range of overhead crane types, catering to the multifaceted needs of various industries.

Providing an Overview: From single girder cranes renowned for their efficiency in light-duty applications to double girder cranes designed for heavy industrial lifting, the Chinese overhead crane manufacturing scene offers a comprehensive selection. Bridge cranes, gantry cranes, jib cranes, electric hoists, and more are part of this diverse repertoire. This breadth ensures that buyers can find the precise crane solution they need, tailored to their industry, application, and budget.

Showcasing Versatility: The versatility of Chinese crane factories is a distinct advantage. Whether you require a compact jib crane to optimize workshop space or a robust double girder crane to handle heavy loads with precision, you can find a suitable solution in China. The diverse range of cranes produced means that there's a crane for virtually every conceivable challenge.

As you navigate the landscape of overhead crane factories in China, keep in mind the value of specialization, regional expertise, and the diversity of crane types produced. Whether you're in search of a specialized crane for a niche application or require a versatile solution for a broad industry, the Chinese overhead crane manufacturing panorama is primed to meet your needs.

Exploring a World of Possibilities: Types of Overhead Cranes in China

In the field of heavy industry and manufacturing, there exists a critical piece of equipment that plays a pivotal role in material handling and production processes – the overhead crane. These mighty machines, suspended from above, effortlessly lift and transport heavy loads, making them indispensable in a multitude of industries.

From steel mills and shipyards to construction sites and warehouses, overhead cranes are the unsung heroes that keep operations running smoothly. They contribute to increased efficiency, enhanced safety, and the ability to handle massive materials that would be impossible for human labor alone.

As the demand for overhead cranes continues to rise, so does the diversity of crane types and configurations. Each type of crane is designed with specific applications and industries in mind, tailored to meet unique needs and challenges. It's imperative for businesses and operators to grasp the distinctions between these crane types to ensure they select the right one for their requirements.

The variety of overhead cranes available can be overwhelming, but the benefits of choosing the right crane are significant. Efficiency gains, safety improvements, and cost savings are all achievable when the correct crane type is matched with the task at hand.

Single Girder Overhead Cranes

Single girder overhead cranes, often referred to as single beam cranes, are a type of overhead crane characterized by a single horizontal beam, or girder, that spans the width of the crane runway. This girder is supported by end trucks on either side.

5 ton single girder overhead crane, top running crane design

10 ton single girder overhead crane, top running crane design

Basic Characteristics:

Simplicity: Single girder cranes are known for their straightforward design, consisting of a single bridge beam.

Lower Headroom: They require less vertical space compared to double girder cranes, making them suitable for facilities with height restrictions.

Light to Medium Duty: Ideal for light to medium-duty lifting and material handling tasks.

Cost-Effective: Generally more budget-friendly in terms of both initial purchase and maintenance costs.

Applications and Industries Where Single Girder Cranes Excel

Single girder overhead cranes find their niche in a range of industries and applications, including:

Warehousing: Efficiently move and stack goods in warehouses and distribution centers.

Workshops: Support assembly lines and facilitate the movement of materials in manufacturing processes.

Maintenance Garages: Lift and transport vehicle components for servicing and repairs.

Foundries: Handle molten metal and heavy casting molds.

Small Machine Shops: Assist with positioning and transferring materials during machining operations.

Retail and Wholesale Distribution: Aid in inventory management and order fulfillment.

Advantages and Limitations

Advantages:

Cost-Efficiency: Single girder cranes are often more affordable both in terms of initial investment and maintenance costs.

Space Savings: Their compact design requires less headroom, making them suitable for facilities with height constraints.

Ease of Installation: They are relatively easy to install, resulting in shorter downtime during setup.

Limitations:

Lower Capacity: Compared to double girder cranes, they have lower lifting capacities and may not be suitable for heavy-duty applications.

Span Limitations: Single girder cranes may have limitations on their span width.

Less Stability: They may exhibit more sway during operation compared to double girder cranes.

Notable Manufacturers and Regions in China for Single Girder Cranes

When exploring single girder overhead cranes in China, you'll find numerous reputable manufacturers scattered across the country. Some regions known for producing single girder cranes include:

Henan Province: Zhengzhou, located in Henan Province, is a prominent hub for overhead crane manufacturing, including single girder cranes.

Jiangsu Province: Cities like Suzhou and Changzhou in Jiangsu are known for their manufacturing prowess, producing a variety of crane types, including single girders.

Shanghai: Being a major international trade and manufacturing center, Shanghai is home to several crane manufacturers, some specializing in single girder configurations.

As we continue our journey through the world of overhead cranes, the next stop will be to explore the realm of double girder overhead cranes and their applications.

Double Girder Overhead Cranes

Double girder overhead cranes, also known as twin girder cranes, are a class of overhead cranes distinguished by two horizontal girders running parallel to each other. These girders are supported by end trucks on both sides, providing enhanced stability and lifting capacity.

10 ton double girder overhead crane, top running crane design

25 ton double girder overhead crane top running crane design for steel coil handling

Primary Features:

Heavy-Duty Capacity: Double girder cranes are designed to handle heavy and oversized loads, making them suitable for high-capacity applications.

Wide Span: They offer a broader span width compared to single girder cranes, making them ideal for larger work areas.

Enhanced Stability: The presence of two girders provides greater stability, reduced sway, and improved control during lifting operations.

Height Under Hook: They offer more headroom under the crane, allowing for the movement of tall or bulky loads.

Industrial Applications and Sectors Suitable for Double Girder Cranes

Double girder overhead cranes excel in various industrial applications and sectors, including:

Steel Mills: Handling heavy steel coils, billets, and slabs.

Manufacturing: Supporting production lines and material transport in heavy manufacturing industries.

Shipping Yards: Loading and unloading cargo containers from ships.

Construction Sites: Lifting and positioning materials for construction projects.

Power Plants: Managing the movement of equipment and machinery within power generation facilities.

Aerospace: Precise handling of aircraft components during assembly.

Automotive: Transporting and positioning vehicle parts in large-scale automotive manufacturing.

Key Benefits and Potential Drawbacks

Key Benefits:

High Lifting Capacity: Double girder cranes are designed for heavy-duty lifting, capable of handling significant loads.

Durability: They are built to withstand rigorous industrial environments and provide long-lasting performance.

Wide Span: Suitable for larger work areas, making them versatile for various applications.

Enhanced Control: The dual girder design offers improved stability and precise load control.

Potential Drawbacks:

Higher Cost: Double girder cranes are generally more expensive to purchase and maintain compared to single girder cranes.

Complex Installation: Their installation may be more intricate and time-consuming.

Space Requirements: Require ample vertical clearance due to their height, limiting their use in facilities with low ceilings.

Prominent Chinese Manufacturers and Regions Specializing in Double Girder Cranes

In China, several manufacturers specialize in the production of double girder overhead cranes. Notable regions for manufacturing and sourcing double girder cranes include:

Henan Province: Zhengzhou, located in Henan Province, is known for its diverse range of crane manufacturers, including those specializing in double girder configurations.

Jiangsu Province: Jiangsu, particularly cities like Suzhou and Changzhou, is a hub for crane production and innovation, including double girder cranes.

Shandong Province: Qingdao, situated in Shandong, has manufacturers specializing in gantry cranes and double girder overhead cranes.

Zhejiang Province: Ningbo, in Zhejiang Province, is a significant manufacturing hub for various crane types, including double girder cranes.

Shanghai: Being a major international trade and manufacturing center, Shanghai is home to several crane manufacturers, some of whom focus on double girder crane production.

Double girder overhead cranes, with their robust capabilities and wide span, are crucial workhorses in industries that demand heavyweight lifting and precise control. As we continue our exploration, our next stop will introduce us to bridge cranes and their diverse range of applications.

Gantry Cranes

Gantry Cranes Definition: Gantry cranes, also known as portal cranes or goliath cranes, are a type of overhead crane supported by legs or movable supports that run along the floor or tracks. These cranes are highly adaptable and designed for both indoor and outdoor use.

25 ton double girder gantry crane for stone block handling outdoor use

10 ton single girder gantry crane

30 ton rtg gantry crane for construction site, tunnel contruction

Rail mounted gantry crane 41 ton for sale, custom for automotive industrial for container handling

Configurations:

Single Girder Gantry Cranes: These feature a single bridge beam and are suitable for light to medium-duty lifting tasks.

Double Girder Gantry Cranes: With two bridge beams, these cranes offer increased lifting capacity and are ideal for heavy-duty applications.

Rubber Tired Gantry Cranes (RTG): Equipped with rubber tires, RTG cranes are mobile and commonly used in container handling at ports and terminals.

Rail Mounted Gantry Cranes (RMG): RMG cranes are designed for container stacking at ports and are mounted on rails for precise movement.

Usage Across Industries and Specific Applications

Gantry cranes find applications across various industries and specific tasks, including:

Shipping and Ports: Handling and stacking cargo containers in ports and container yards.

Construction: Lifting and positioning construction materials and equipment at building sites.

Warehousing: Managing and organizing heavy goods and machinery within large warehouses.

Manufacturing: Assisting in production processes by moving heavy components and machinery.

Agriculture: Handling and transporting agricultural machinery and bulk materials on farms.

Steel Mills: Moving and stacking heavy steel coils and products.

Advantages and Potential Limitations

Advantages:

Versatility: Gantry cranes can be used both indoors and outdoors and can handle various load sizes and types.

Mobility: Rubber tired gantry cranes are mobile, offering flexibility in container handling.

High Lifting Capacity: Double girder gantry cranes have impressive lifting capacities suitable for heavy industries.

Precise Control: Gantry cranes provide accurate load positioning and control.

Potential Limitations:

Space Requirements: Gantry cranes require ample floor space, especially when handling large loads.

Initial Investment: The cost of gantry cranes, especially for heavy-duty applications, can be substantial.

Complex Installation: Installing gantry cranes, particularly rail-mounted models, can be intricate and time-consuming.

Noteworthy Gantry Crane Manufacturers in China

China is home to several prominent manufacturers specializing in the production of gantry cranes. Notable regions and manufacturers include:

Shandong Province: Qingdao, in Shandong, is renowned for producing gantry cranes for various applications.

Henan Province: Manufacturers in Henan, such as those in Zhengzhou, offer a range of gantry crane configurations.

Jiangsu Province: Jiangsu, with its manufacturing expertise, houses companies known for their gantry crane production.

Zhejiang Province: Ningbo, located in Zhejiang, is a significant manufacturing hub for various crane types, including gantry cranes.

Shanghai: As a major industrial and manufacturing center, Shanghai hosts several crane manufacturers, some of which specialize in gantry crane manufacturing.

Gantry cranes, with their adaptability and versatility, are pivotal in various industries and applications. Our journey continues as we explore another essential type of overhead crane, jib cranes, and their unique attributes.

Jib Cranes

Jib cranes are a type of overhead crane characterized by a vertical mast or pillar that supports a horizontal boom. The boom, which can rotate around the mast, includes a hoist or lifting mechanism for handling loads. Jib cranes are versatile and designed for localized lifting and material handling.

Freestanding jib crane, with 360 rotating cranes

Floor mounted jib crane

wall travelling jib cranes

wall mounted jib cranes

Primary Uses:

Material Transfer: Jib cranes are used for transferring materials from one location to another within a limited radius.

Workstation Assistance: They assist workers in positioning heavy components, tools, or equipment.

Loading and Unloading: Jib cranes are employed in loading and unloading tasks in various industries.

Machine Tool Applications: In machining shops, jib cranes help with positioning workpieces or tooling.

Assembly and Production: Supporting assembly processes by lifting and moving components.

Maintenance and Repair: Jib cranes are valuable for lifting and servicing machinery.

Niche Applications and Sectors That Benefit from Jib Cranes

Jib cranes are particularly beneficial in niche applications and sectors, including:

Foundries: Handling molten metal and pouring it into molds.

Marine and Shipbuilding: Assisting with ship construction and maintenance.

Automotive Repair: Lifting vehicle engines and components for maintenance and repair.

Agriculture: Supporting tasks like lifting heavy farm equipment and machinery.

Construction: Aiding in material handling on construction sites.

Waste Management: Efficiently handling waste and recyclable materials.

Key Attributes and Constraints

Key Attributes:

Compact Design: Jib cranes are compact and occupy minimal floor space, making them suitable for congested areas.

Precise Positioning: They offer precise load positioning due to their rotational capability.

Ease of Use: Jib cranes are user-friendly and require minimal operator training.

Cost-Effective: They are often more cost-effective than larger overhead crane systems.

Constraints:

Limited Range: Jib cranes have a limited radius of operation compared to other types of cranes.

Load Capacity: They are suitable for relatively lighter loads and are not designed for heavy-duty lifting.

Space Requirements: The area around the jib crane's base must remain clear for safe operation.

Chinese Jib Crane Manufacturers and Their Specializations

China is home to several manufacturers specializing in the production of jib cranes. Notable Chinese jib crane manufacturers and their specializations include:

Shandong Province: Qingdao in Shandong is known for producing a variety of jib crane configurations, including wall-mounted and floor-mounted options.

Henan Province: Manufacturers in Henan, such as those in Zhengzhou, offer a range of jib cranes suitable for diverse applications.

Jiangsu Province: Jiangsu, with its manufacturing expertise, houses companies known for their jib crane production, particularly those designed for workshops and small-scale operations.

Zhejiang Province: Ningbo, located in Zhejiang, is a significant manufacturing hub for various crane types, including jib cranes designed for specific applications.

Shanghai: As a major industrial and manufacturing center, Shanghai hosts several crane manufacturers, some of which specialize in jib crane manufacturing.

Jib cranes, with their versatility and compact design, serve niche applications across various industries. As we continue our journey through the world of overhead cranes, our next stop will introduce us to electric hoists and their role in material handling.

Electric Hoists

Electric hoists are a crucial component of various lifting and material handling systems. These devices, powered by electricity, are designed to vertically raise and lower loads with precision and control. Electric hoists find extensive use in industries and applications where efficient and safe material handling is paramount.

Significance: Electric hoists are significant for several reasons:

They enhance workplace safety by providing precise control over load movement.

They increase operational efficiency, reducing manual labor and downtime.

They find applications in a wide range of industries, making them versatile and adaptable.

Explosion proof overhead crane hoist 10 ton

35 ton hosit trolley for double girder crane

Versatile Applications and Industries Where Electric Hoists Are Vital

Electric hoists play a vital role in numerous industries and versatile applications, including:

Construction: Lifting and positioning heavy building materials and equipment.

Manufacturing: Assisting in assembly processes and transporting materials within manufacturing plants.

Warehousing and Logistics: Efficiently moving and organizing inventory in warehouses and distribution centers.

Mining: Handling and transporting materials and equipment in mining operations.

Automotive: Lifting and positioning vehicle components during manufacturing and repair.

Aerospace: Precisely handling aircraft components during assembly and maintenance.

Features, Options, and Considerations

Electric hoists come with a variety of features, options, and considerations:

Load Capacity: Hoists are available in different load capacities to suit specific lifting requirements.

Lift Height: Consider the required lift height when selecting an electric hoist.

Speed Control: Some hoists offer variable speed control for precise load handling.

Power Source: Electric hoists can be powered by various voltages, so ensure compatibility with your facility's power supply.

Mounting: Hoists can be mounted on overhead beams, trolleys, or other structures, so choose the mounting option that suits your needs.

Safety Features: Look for safety features such as overload protection, emergency stop buttons, and limit switches.

Renowned Chinese Manufacturers of Electric Hoists

China stands as a hub for renowned manufacturers specializing in the production of electric hoists, with notable expertise and specialization found across various regions. From Henan and Jiangsu to Shandong, Zhejiang, and Shanghai, these manufacturers offer a diverse range of electric hoists tailored to meet the unique needs of different industries and applications. Their contributions are instrumental in supporting material handling and lifting operations across diverse industrial sectors, underscoring their significance in the realm of crane technology and industrial operations.

- Henan Province: Zhengzhou: Zhengzhou, located in Henan Province, is renowned for producing a diverse range of electric hoists suitable for various applications. The manufacturers in this region offer electric hoists designed to meet the diverse material handling requirements of industrial sectors, contributing to operational efficiency and precision in lifting operations.

- Jiangsu Province: Jiangsu Province houses companies with specialized expertise in electric hoist manufacturing, offering a range of options tailored to different industries. These manufacturers play a pivotal role in delivering electric hoists that meet stringent industry standards and operational requirements, catering to diverse material handling needs.

- Shandong Province: Qingdao: Qingdao in Shandong Province is known for its production of heavy-duty electric hoists suitable for various industrial applications. The manufacturers in this region specialize in delivering robust and reliable electric hoists designed to handle heavy loads and support industrial lifting operations with precision and efficiency.

- Zhejiang Province: Ningbo: Ningbo, located in Zhejiang Province, serves as a significant manufacturing hub for electric hoists designed for different load capacities. The manufacturers in this region offer a diverse portfolio of electric hoists, catering to the specific load handling needs of diverse industrial applications, ensuring operational precision and efficiency.

- Shanghai: As a major industrial and manufacturing center, Shanghai hosts several crane manufacturers, some of whom specialize in electric hoist production. The manufacturers in this region play a pivotal role in delivering electric hoists that meet the diverse material handling requirements of industries, contributing to operational efficiency and precision in lifting operations.

In conclusion, the renowned Chinese manufacturers of electric hoists across regions play a pivotal role in delivering tailored solutions that meet the diverse material handling needs of industries. Their expertise and specialization in electric hoist production contribute to operational efficiency, precision, and safety in lifting operations across a range of industrial applications, underscoring their significance in the realm of crane technology and industrial operations.

Specialized Crane Configurations

While standard overhead crane types cover a broad spectrum of lifting needs, some industries and applications demand specialized crane configurations tailored to unique requirements. These specialized cranes are engineered to handle specific tasks with precision and efficiency, making them indispensable in niche sectors.

Niche Industries and Use Cases for Specialized Cranes

Specialized crane configurations play a critical role in a diverse range of niche industries and use cases, each tailored to meet specific operational requirements and industry standards. From the nuclear industry to entertainment and automated warehousing, specialized cranes are engineered to address unique challenges and ensure safety, precision, and efficiency in their respective applications.

- Nuclear Industry: In the nuclear industry, specialized cranes are designed to handle radioactive materials with the utmost safety and precision. These cranes adhere to rigorous safety standards and are equipped with features to minimize the risk of contamination and ensure secure material handling within sensitive nuclear environments.

- Pharmaceutical Manufacturing: Cleanroom cranes tailored for pharmaceutical manufacturing facilities are engineered to meet stringent hygiene and contamination control standards. These specialized cranes play a crucial role in maintaining the integrity of pharmaceutical production processes by ensuring a sterile and controlled environment for material handling.

- Food and Beverage: In the food and beverage industry, specialized cranes with stainless steel components are essential for sanitary material handling in food processing. These cranes are designed to meet strict hygiene requirements and prevent contamination, making them indispensable for ensuring food safety and quality in production facilities.

- Chemical and Hazardous Materials: For handling hazardous materials, explosion-proof cranes are engineered to operate in hazardous environments, ensuring safety and compliance with stringent safety regulations. These specialized cranes are equipped with features to mitigate the risk of ignition and provide secure material handling in chemical and hazardous material processing facilities.

- Entertainment and Events: Specialized cranes adapted for hoisting stage equipment and props play a vital role in the entertainment industry. These cranes are designed to facilitate the precise and efficient movement of stage equipment, enabling seamless production setups and ensuring the safety of performers and crew.

- Automated Warehousing: In the realm of automated warehousing, specialized cranes are integrated into automated storage and retrieval systems to facilitate efficient material handling. These cranes play a pivotal role in optimizing warehouse operations, enabling the swift and precise movement of goods within automated storage environments.

From the stringent safety requirements of the nuclear industry to the precise material handling needs of pharmaceutical manufacturing and the entertainment industry's demand for efficient stage equipment hoisting, specialized cranes are indispensable assets tailored to meet the unique demands of niche industries and use cases. Their role in ensuring safety, precision, and operational efficiency underscores their significance in diverse industrial applications.

Customization Options and Manufacturers Catering to Specialized Needs

Manufacturers catering to specialized crane needs offer customization options to meet unique requirements. Some notable regions in China where such manufacturers are found include:

In China, manufacturers specializing in customized crane solutions play a pivotal role in meeting the unique and diverse requirements of niche industries. These manufacturers offer tailored customization options to address the specific demands of various sectors, ensuring that specialized cranes are engineered to meet stringent industry standards and operational needs. Notable regions in China, including Henan, Jiangsu, Shandong, Zhejiang, and Shanghai, are home to manufacturers capable of delivering customized crane solutions for specialized applications across a range of industries.

- Henan Province: Zhengzhou: Zhengzhou, located in Henan Province, is home to manufacturers with the expertise to customize cranes for various industries, catering to specialized applications. These manufacturers offer tailored solutions to meet the unique material handling requirements of diverse industrial sectors, ensuring precision, safety, and operational efficiency.

- Jiangsu Province: Jiangsu Province houses companies with specialized expertise in tailoring cranes to niche industry demands, particularly in pharmaceutical and cleanroom environments. Manufacturers in this region offer customized crane solutions designed to meet stringent hygiene and contamination control standards, addressing the specific needs of pharmaceutical and cleanroom manufacturing facilities.

- Shandong Province: Qingdao: Qingdao in Shandong Province is renowned for producing specialized cranes, including those designed for hazardous material handling. Manufacturers in this region offer customized crane configurations engineered to operate in hazardous environments, ensuring safety and compliance with stringent safety regulations in chemical and hazardous material processing facilities.

- Zhejiang Province: Ningbo: Ningbo, located in Zhejiang Province, serves as a significant manufacturing hub where custom crane configurations are available to meet unique industry needs. Manufacturers in this region offer tailored crane solutions designed to address the specific material handling requirements of diverse industrial sectors, ensuring precision and operational efficiency.

- Shanghai: As a major industrial and manufacturing center, Shanghai hosts several crane manufacturers, some of whom specialize in producing customized crane solutions for specialized industry needs. These manufacturers offer tailored customization options to address the unique demands of various sectors, ensuring that specialized cranes are engineered to meet stringent industry standards and operational needs.

In conclusion, the presence of manufacturers specializing in customized crane solutions across regions in China underscores the country's commitment to meeting the diverse and unique material handling requirements of niche industries. These manufacturers play a crucial role in delivering tailored crane solutions that ensure precision, safety, and operational efficiency in specialized applications across a range of industries, contributing to the advancement and optimization of industrial operations.

Specialized crane configurations exemplify the adaptability and innovation within the overhead crane industry. As our exploration continues, we will discover the regions in China known for their expertise in crane manufacturing, focusing on Henan, Jiangsu, Shandong, Zhejiang, and Shanghai.

Advancements in Crane Design and Technology

Innovation: Overhead crane technology has seen significant advancements in recent years, driven by the need for increased efficiency, safety, and automation in material handling processes. These innovations have reshaped the landscape of overhead cranes, making them more versatile and adaptable to a wide range of industries.

Benefits of Modern Features and Automation

The integration of modern features and automation in overhead cranes delivers a host of benefits, enhancing safety, efficiency, precision control, data analytics, and remote monitoring. These advancements play a pivotal role in optimizing operations, mitigating risks, and improving productivity in industrial settings.

- Enhanced Safety: Advanced safety systems, including collision avoidance and load monitoring, significantly reduce the risk of accidents, fostering a secure operational environment and safeguarding personnel and assets.

- Increased Efficiency: Automation streamlines operations, leading to improved productivity and a reduction in human error. The seamless integration of automated processes enhances workflow efficiency and overall operational output.

- Precision Control: Modern controls and variable speed options enable precise load positioning and movement, contributing to enhanced operational accuracy and refined material handling processes.

- Data Analytics: Crane data collection and analysis play a crucial role in maintenance planning and optimization, providing valuable insights for proactive maintenance and operational efficiency.

- Remote Monitoring: Remote access capabilities allow for real-time monitoring and diagnostics, facilitating proactive maintenance and enhancing operational efficiency through remote access and monitoring.

In conclusion, the incorporation of modern features and automation in overhead cranes yields a spectrum of benefits, ranging from enhanced safety and increased efficiency to precision control, data analytics, and remote monitoring. These advancements underscore the pivotal role of modern technology in optimizing industrial operations and ensuring a secure and efficient working environment.

How Chinese Manufacturers Are Contributing to Crane Advancements

Chinese crane manufacturers are at the forefront of driving advancements in crane technology, contributing to the development of innovative solutions that enhance performance, customization, global collaboration, automation, and compliance. Through their commitment to research and development, customization, global collaboration, adoption of automation, and adherence to international standards, Chinese manufacturers are shaping the landscape of crane technology and solidifying their position as key contributors to industry advancements.

- Research and Development: Chinese manufacturers are investing significantly in research and development to pioneer new technologies and features that elevate crane performance, efficiency, and safety. This dedication to innovation drives the evolution of crane technology and sets new standards for operational excellence.

- Customizationt: By offering customization options, Chinese manufacturers cater to specific industry and application needs, tailoring crane solutions to address unique operational requirements and industry standards. This commitment to customization underscores their adaptability and responsiveness to diverse industry demands.

- Global Collaborationt: Chinese manufacturers actively engage in partnerships with international companies, facilitating the exchange of knowledge and technologies. This collaborative approach fosters a dynamic environment for innovation, enabling the integration of diverse perspectives and expertise into crane development.

- Adoption of Automationt: The integration of automation and smart technologies into crane design represents a significant focus for Chinese manufacturers, driving the evolution of advanced, efficient, and precise material handling solutions. This emphasis on automation underscores their commitment to enhancing operational efficiency and precision control.

- Compliancet: Chinese manufacturers prioritize the adherence to international safety and quality standards, ensuring that their cranes meet and exceed regulatory requirements. This dedication to compliance underscores their commitment to delivering safe, reliable, and high-quality crane solutions for global markets.

In conclusion, Chinese manufacturers are actively driving advancements in crane technology through their commitment to research and development, customization, global collaboration, adoption of automation, and compliance with international standards. Their contributions are instrumental in shaping the future of crane technology, fostering innovation, and delivering cutting-edge solutions that meet the evolving needs of diverse industries worldwide.

China's crane industry has become a global leader, not only in manufacturing but also in innovation and technology adoption. As we continue our exploration, we will delve into the regions within China known for their prominence in overhead crane manufacturing.

Quality Assurance and Safety

In the world of overhead cranes, quality and safety are paramount. In this segment, we'll explore how esteemed Chinese manufacturers uphold rigorous quality assurance and safety protocols.

Meeting International Standards

Prioritizing Global Standards: Quality and safety are universal concerns, transcending borders. Esteemed Chinese crane manufacturers understand this and place significant emphasis on aligning with international safety and quality standards. Whether it's ISO 9001 for robust quality management or ISO 14001 for environmentally responsible practices, certifications signify an unwavering commitment to excellence.

Certifications and Compliance: Buyers can have confidence in the overhead cranes from reputable Chinese manufacturers, knowing that they are meticulously designed and manufactured in accordance with globally recognized standards. Moreover, some cranes carry specialized certifications, such as ATEX for explosion-proof equipment or CE marking for conformity to European Union regulations. These certifications serve as tangible evidence of a crane's strict compliance with specific safety and performance prerequisites, offering assurance to discerning buyers.

Rigorous Testing and Inspection

Understanding the Testing and Inspection Regimen: Safety is not a mere promise; it's a tangible outcome of thorough testing and inspection. Before an overhead crane departs the factory, it undergoes comprehensive testing to verify its compliance with safety and performance specifications. This entails a battery of assessments, encompassing functional tests, load tests, and often, simulated operational tests that replicate real-world scenarios.

Prioritizing Safety and Performance: Chinese crane manufacturers are unwavering in their commitment to ensuring the safety and performance of their products. Through meticulous testing and inspection, they leave no stone unturned in identifying potential issues. This meticulous approach ensures that the crane operates with unwavering reliability and safety. By scrutinizing every facet of the crane's functionality, manufacturers minimize the risk of defects and malfunctions, thus upholding the highest safety standards.

When you invest in an overhead crane from a reputable Chinese manufacturer, you are investing in a product that not only meets but surpasses international safety and quality benchmarks. Their dedication to stringent testing, adherence to certifications, and unwavering pursuit of excellence mean that these cranes aren't just equipment; they are trusted allies in your operations, steadfastly championing both safety and efficiency.

Conclusion

Our captivating journey through the inner sanctums of Chinese overhead crane factories draws to a close, leaving us with a treasure trove of insights into precision engineering, innovation, and an unwavering commitment to quality and safety. Let's take a moment to reflect on these remarkable discoveries and celebrate the artistry that propels the crane manufacturing industry in China.

Peering Behind the Scenes

- Summarizing Our Unique Insights: Our expedition has unraveled the well-guarded secrets of Chinese overhead crane factories, providing us with an exclusive peek into the meticulous craftsmanship that defines this industry. Along the way, we've encountered a dedication to excellence that knows no bounds, a strict adherence to international standards, and an unyielding passion for innovation.

- Reflecting on Craftsmanship and Innovation: The crane manufacturing sector in China stands as a shining example of the fusion of skill and innovation. Each crane is a masterpiece of precision engineering, a testament to an unwavering commitment to safety. Our exploration has illuminated the pivotal role these cranes play in industries and global infrastructure.

Appreciating the Craftsmanship

- Acknowledging the Masters: Behind every overhead crane, there exists an assembly of skilled artisans who invest their expertise and passion to craft these feats of engineering. Their tireless dedication to quality and safety transforms these cranes from mere tools into dependable partners in the world of industry.

- A Deeper Appreciation for Manufacturing: Our expedition encourages us to recognize the pivotal role of manufacturing in shaping industries and infrastructure. It serves as a poignant reminder that meticulous craftsmanship, innovation, and a relentless pursuit of excellence lie at the heart of ensuring that cranes power our world with reliability and precision.

As we bring the curtain down on this riveting journey, the exploration of Chinese overhead crane factories not only enriches our understanding but also adds a layer of fascination to the world of precision engineering. As you contemplate your investment in overhead cranes, may this odyssey inform your choices and deepen your reverence for the artistry that fuels this essential industry.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch